2951

Technical Committee 214 /

Comité technique 214

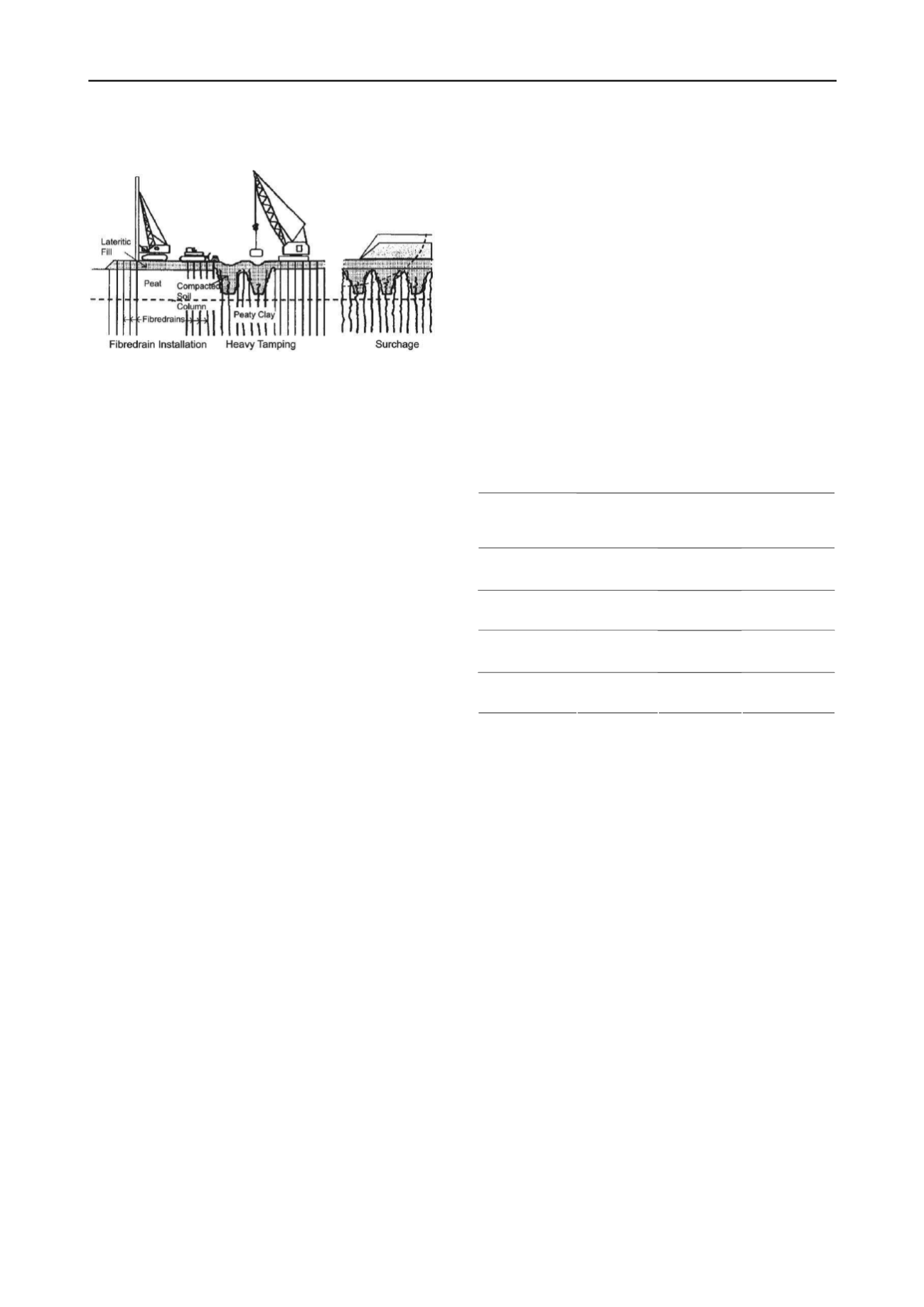

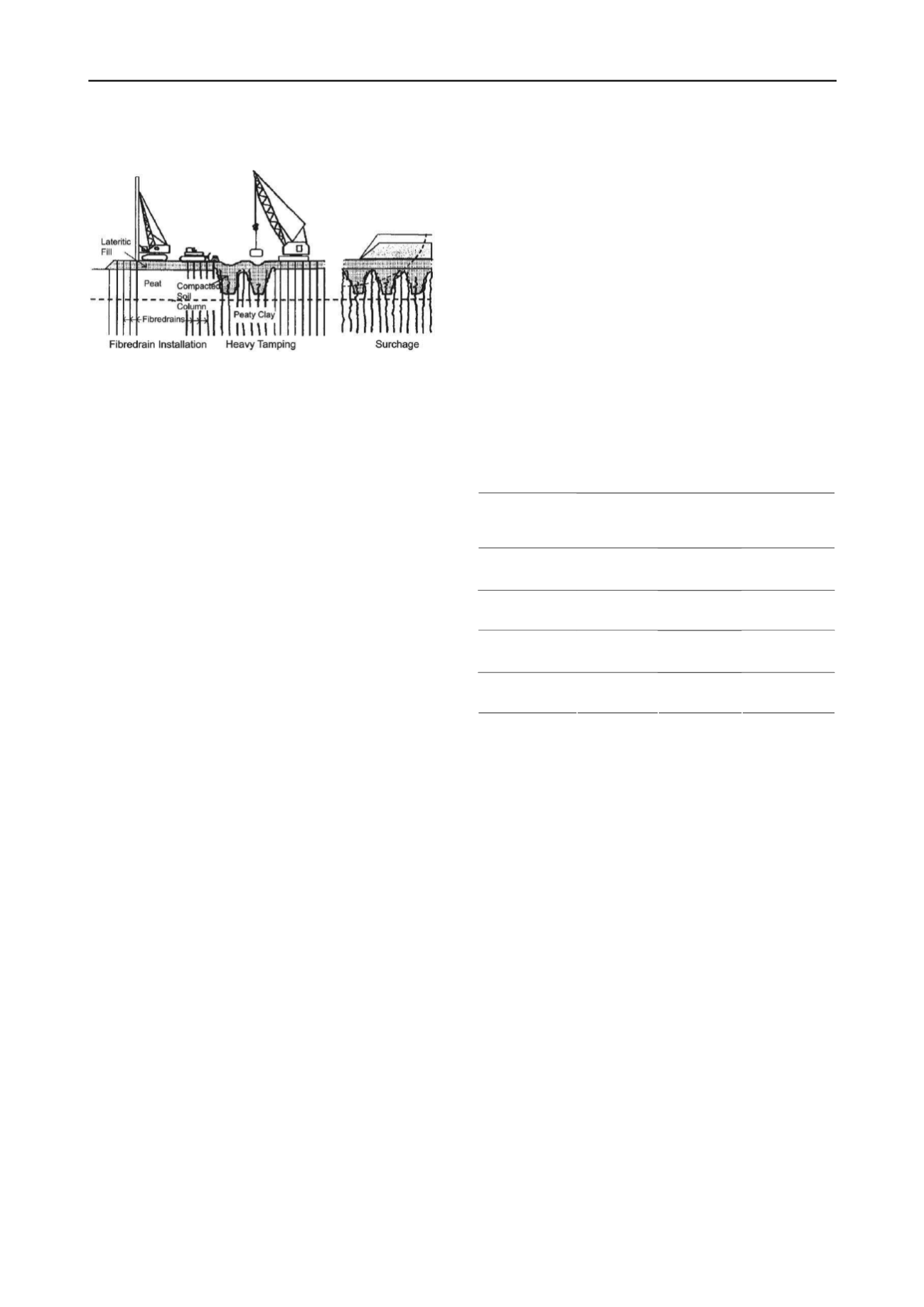

illustrates the major steps in the heavy tamping ground

improvement method adopted in the project.

Figure 2. Major steps in heavy tamping ground improvement

4.2 Vacuum consolidation method

In the application of vacuum consolidation method, about a 1.0

m to 1.5 m thick fill was constructed on the original ground

surface to form a working platform for the band drain

installation machine. Band drains were installed by a machine

up to a designed depth from the original ground surface in a

square pattern with a spacing of 1 m. Thereafter, flexible

horizontal drains (300 mm wide and 4 mm thick) were laid on

top of the fill with a horizontal spacing of 1 m and then

connected to the vertical band drains in order to ensure adequate

horizontal drainage capacity. Subsequently, the tank system was

installed and connected to the designed pipe systems. Small

ditches were excavated perpendicular to the horizontal drains at

20 m intervals and filled with aggregates after placing

perforated pipes. Instrumentation such as settlement plates,

displacement stakes, electrical piezometers and differential

settlement gauges were also installed at the designed depths.

After installation of vertical drains, horizontal drains, perforated

pipes and separator tanks, the surface of the treatment area was

covered by a protection sheet. Thereafter, an air tight sheet was

laid on top and the periphery trench system was constructed to

provide air tightness and the necessary anchorage at the

boundary of the treatment area. Vacuum pressure was then

applied using a vacuum pumping system patented by Maruyama

Industry Co. Ltd, Japan by connecting the suction and water

hoses to the vacuum pump. After confirming that there were no

leaks through the air tight sheet, filling was commenced.

It was expected to apply the surcharge by means of a

vacuum pressure of 70kPa to compensate the primary

consolidation settlements and to minimize the secondary

settlements that can take place in the proposed highway

embankment. However, in many areas the applied vacuum

pressure was less than the designed value and therefore the

above designed surcharge was applied by means of both

vacuum pressure and embankment fills. The designed load was

kept until the expected settlement completed.

5 ASSESSMENT OF THE SOFT GROUND

IMPROVEMENT

The continuous assessment of the improvement of soft ground

was carried out by conducting the field monitoring program. In

addition, the soft ground improvement was assessed by

conducting appropriate field and laboratory testing.

5.1 Field monitoring program

The improvement of the soft ground was monitored through the

measurement of settlement and the excess pore water pressure

during the construction period. Settlement plates were installed

at the top of the soft layer or on top of the pioneer layer and

piezometers were installed at the middle of the soft layer. The

settlement stakes were installed near the toe of the

embankments to check the stability during the construction. In

addition to the above, in the areas improved by vacuum

consolidation, a vacuum pressure monitoring unit was used to

measure the vacuum pressure at the pump and under the air

tight sheet. Also, a water discharge meter was used to measure

the rate and the total discharged water flow due to the vacuum

operation. An automatic data acquisition unit was connected

with the piezometer, vacuum pressure monitoring unit and

water discharge meter to keep continuous records.

The decision to remove the surcharge was made on the basis

of the monitoring data obtained during the surcharge period.

The aim was to eliminate 100% of primary consolidation

settlement and enough secondary settlement such that the

residual settlement was within acceptable performance limits.

The primary consolidation settlement was assessed by

estimating the degree of consolidation and in this project it was

estimated by the method outlined by Asaoka (1978). The degree

of consolidation was also calculated based on the pore water

pressure (PWP) measurements, and laboratory consolidation

testing of peaty samples after the treatment program. The

comparison of the degree of consolidation for each method for

some areas improved by the vacuum consolidation method is

shown in Table 1.

Table 1. Estimation of the degree of consolidation

Degree of Consolidation

Location

Asaoka

Method

Laboratory

Data

PWP

83.10%

Ch. 45.380 –

Ch. 45.430

97.83%

73.87%

79.46%

100.00%

Ch. 47.850 –

Ch. 47.920

97.10%

100.00%

100.00%

80.21%

Ch. 52.950 –

Ch. 53.000

97.57%

90.91%

100.00%

96.70%

Ch. 53.660 –

Ch. 53.730

96.65%

83.62%

68.71%

If the degree of consolidation from the PWP measurement is

assumed to be accurate, Asaoka Method accurately estimates

the degree of consolidation in treatment areas Ch.47.850 to

Ch.47.920 and Ch.52.950 to Ch.53.000 whereas Asaoka method

over predicts the degree of consolidation in treatment areas Ch.

45.380 to Ch. 45.430 and Ch.53.660 to Ch. 53.730. However, in

treatment area Ch.53.660 to Ch.53.730 the degree of

consolidation from the laboratory test results agreed very well

with the same estimated from the Asaoka method. Therefore,

based on this investigation it can be concluded that the degree

of consolidation estimated from the Asaoka method is

reasonably accurate.

In order to assess the secondary settlements, for each

monitoring point, the long-term settlement was predicted by

extrapolating the secondary settlement rate over a period of 3

years. Predictions were made by preparing a plot of

displacement against log (time) for each settlement plate, with

the best-fit line through the data extended to define the likely

settlement after 3 years. The surcharge was removed only after

confirming the residual settlement by considering both the

primary and secondary consolidation settlements as described

above.

5.2 Investigation to confirm the ground improvement

Site investigation was carried out to assess the actual ground

improvement in the areas improved by the vacuum

consolidation method just before the removal of surcharge.

Investigation was carried out in the improved as well the

adjacent unimproved area in order to assess the ground

improvement. Investigation revealed that initial thickness of the

peat layer has been reduced by 50%-60% after ground

improvement. The above reduction agreed reasonably with the