2943

Technical Committee 214 /

Comité technique 214

The mud was initially sieved through a 2.36 mm sieve to

eliminate all the broken shells and debris and then mixed with

sea water at a water content of 270 % in a slurry form. Sea

water obtained from Townsville (in Queensland) was used to

mix the slurry (Salt concentration 370 N/m

3

). The dredged mud

slurry was placed in a cylindrical tube of 100 mm diameter and

800 mm height and allowed to undergo sedimentation. When

the dredged mud column accomplished most of its self weight

consolidation settlement, it was sequentially loaded with small

weights in the range of 500 to 3000 g. The soil column was

allowed to consolidate under each vertical stress increment for

two days before the next weight was added. Pore water

dissipation was allowed through the porous caps placed at the

top and bottom of the dredged mud column. The soil column

was loaded up to a maximum vertical stress of 21 kPa over a

duration of 8 weeks. The final thickness of the column at the

completion of consolidation was around 300 mm.

From the final sediment, specimens were extruded for the

oedometer tests. Six oedometer specimens of 76 mm diameter,

20 mm height, were extruded at three different depth levels as

shown in Fig. 2. Three specimens were subjected to standard

vertical consolidation tests (denoted by ‘V’) and three were

tested to radial consolidation tests (denoted by ‘R’). The

procedure for the radial consolidation tests is explained below

briefly.

Figure 2: Specimen locations for oedometer tests

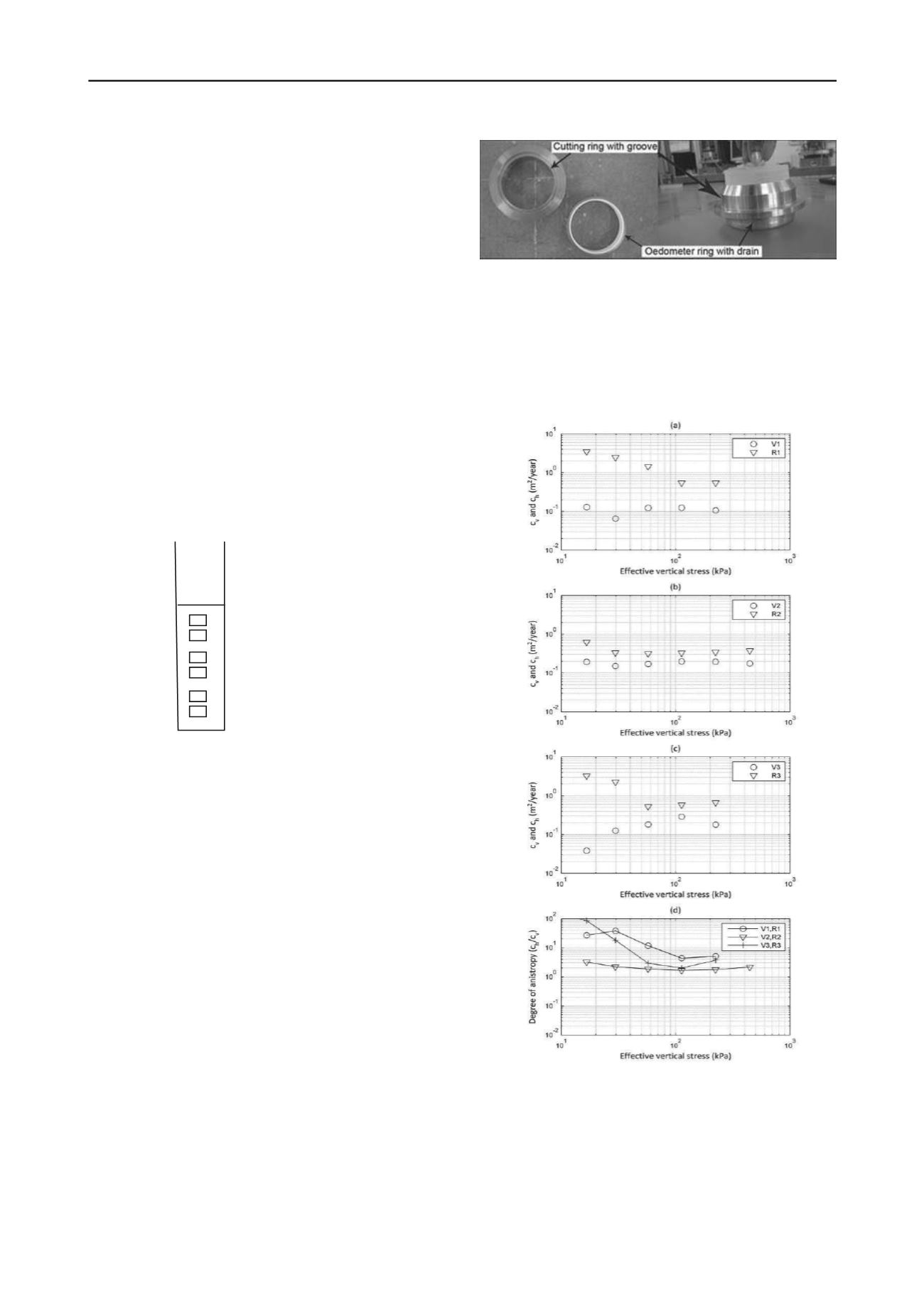

Specimens R1, R2 and R3 were tested for radial

consolidation with an outer peripheral drain. The material used

for outer peripheral drain was 1.58 mm in thickness. The strip

drain was aligned along the inner periphery of the oedometer

ring. A special cutting ring of diameter of 72.84 mm was used

to cut specimens. The cutting ring had a circular flange at its

bottom. A groove was carved along the inner periphery of the

flange, which had a thickness equal to the thickness of the

bottom edge of oedometer ring plus peripheral drain. The

oedometer ring was placed tightly in the groove, to make it

align properly with the cutting ring (Fig. 3). The specimen in

the cutting ring was then carefully transferred to the oedometer

ring using a top cap, without causing any disturbance. The

porous bottom and top caps used for standard vertical

consolidation tests were replaced with two impermeable caps,

for radial consolidation tests.

All the specimens were loaded in the oedometer apparatus

approximately between a vertical stress range of 9 kPa to 440

kPa (9 kPa, 17 kPa, 30 kPa, 59 kPa, 118 kPa and 220 kPa and

440 kPa). A load increment ratio of around 1.0 was adopted

throughout the loading stage. From the settlement – time data of

the specimens under each load increment, the vertical and radial

coefficients of consolidation

c

v

and

c

h

were estimated. Taylor’s

square root of time method was used for estimating

c

v

.

c

h

was

obtained from the curve fitting procedure given in McKinlay

(1961) for radial consolidation with a peripheral drain.

Figure 3: Specimen preparation for radial consolidation test

3.1 Results and discussion

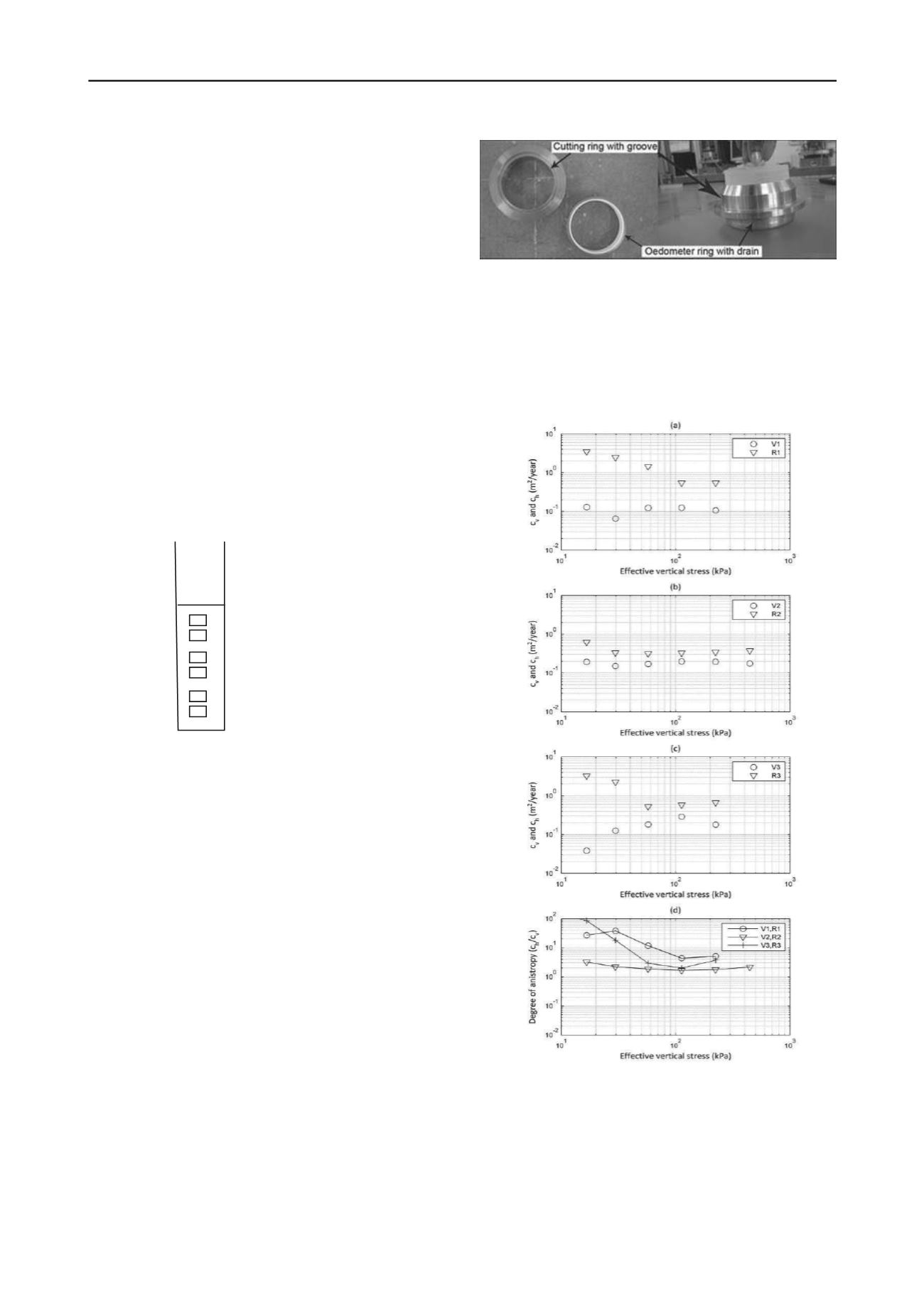

Figs. 4(a), (b) and (c) show the comparison of

c

v

and

c

h

for pairs

V1-R1, V2-R2 and V3-R3 respectively at different effective

vertical stresses

’

v

. The degree of anisotropy, given by (

c

h

/c

v

) is

plotted against

’

v

in Fig. 4(d) for the three pairs of specimens.

R3

Notations

V3

R2

‘V’‐ Vertical consolidation

V2

‘R’‐ Radial consolidation

R1

V1

Figure 4: Comparison of

c

v

and

c

h

for specimens (a) V1, R1 (b) V2,

R2 (c) V3, R3 (d) Degree of anisotropy

As clearly observed, the horizontal coefficient of

consolidation is higher than that in the vertical direction at all

three depths. The ratio

c

h

/c

v

generally decreases with the

increase in

’

v

. At low

’

v

(

’

v

< 20 kPa), the ratio

c

h

/c

v

varies

from 2 to as much as 100. The average degree of anisotropy in

permeability (

k

h

/k

v

) for the various stress levels is given in

Table 1. The ratio

k

h

/k

v

lies between 1 to 4. The horizontal