2938

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

improvement took place (2006), cement prices were

significantly higher because of global demand, and the

estimated cost for the DSM option was estimated to be $150

million (2011 US dollars).

2 PREFABRICATED VERTICAL DRAINS FEASIBILITY

STUDY

Installation of prefabricated vertical drains (PVDs) is a cost-

effective foundation improvement technique at sites where a

surcharge load will be applied (e.g., an MSE berm). In general,

PVDs are installed in soft soils to improve the drainage

characteristics hence accelerating the dissipation of excess pore

pressures generated during stage construction of embankments.

The time it takes for pore pressures to dissipate depends upon

the permeability of the dredge and the spacing between PVDs

and it can be estimated using well known radial flow equations

(e.g., Barron, 1948).

Initially, the use of PVDs to improve the foundation

strength appeared unfeasible due to the massive weight of the

proposed 21-m high MSE berm which was required to gain the

needed airspace. Typically, the maximum height of an MSE

berm on soft soils is dictated by the undrained shear strength of

the underlying soft material. At the CIL site, the maximum

height that could have been built using standard design

techniques would have been on the order of 7.5-m (i.e., about

13.5 m shorter than required to achieve the target airspace of 17

million cubic meters).

Standard design techniques assume that when PVDs are

installed in soft soils: (i) the excess pore pressures generated

between PVDs during loading is uniform; and (ii) only

undrained shear strength is mobilized during loading. The

maximum excess pore pressures (

U

max

) generated after

placement of a soil lift (i.e., 3 m for the CIL project) is

estimated assuming that the soil lift is placed at once and it

generates excess pore pressures (i.e., the pressure of the water

stored within the dredge) approximately equal to the weight of

the soil lift. Although it is recognized that excess pore pressures

at the PVD location is nil and increases with radial distance

from the PVD (Figure 2), it is typically assumed that excess

pore pressures between PVDs are uniform and equal to

U

max

.

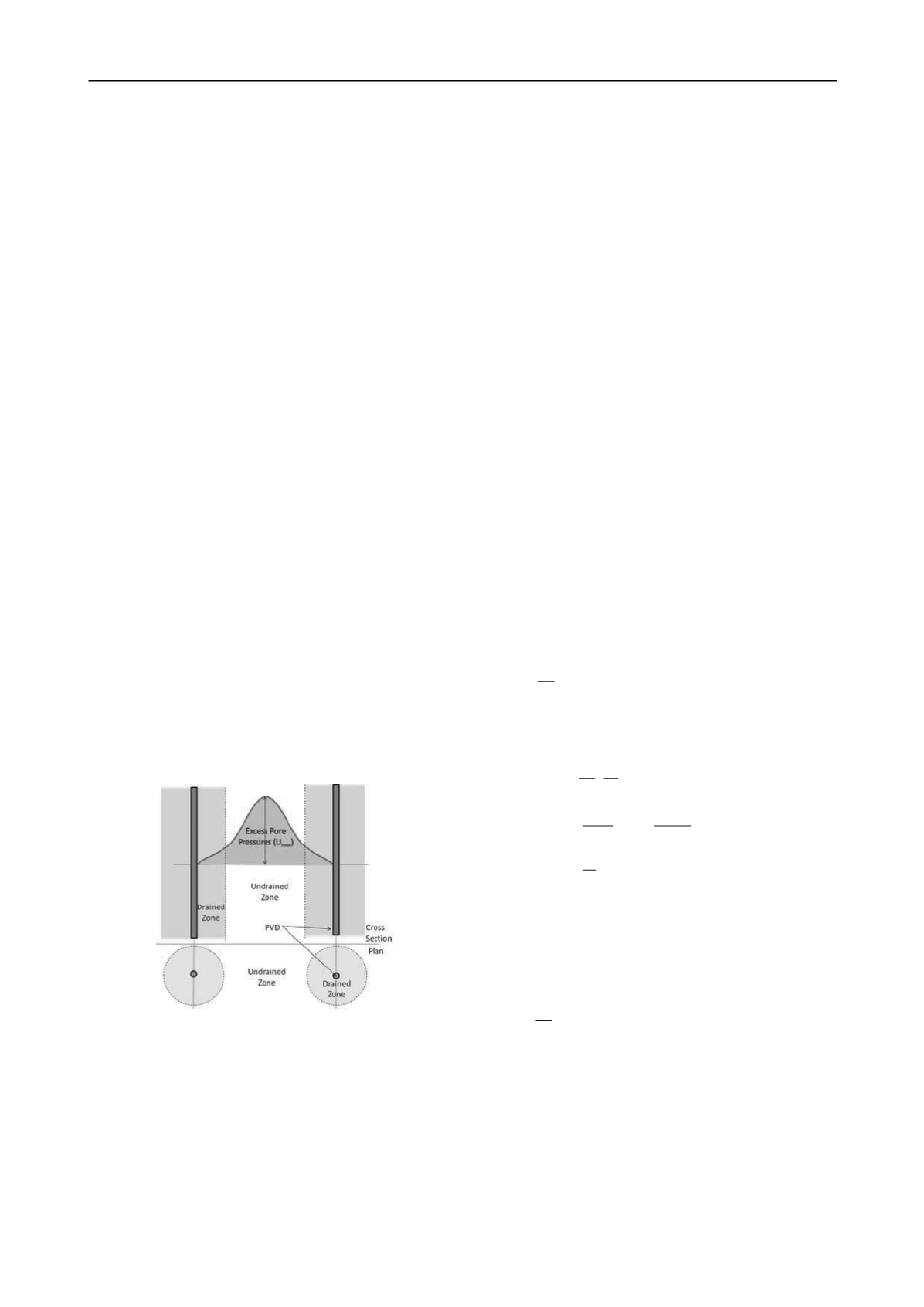

Figure 2. Pore Pressure Model

Because piezometers are located to monitor the maximum

pore pressure, the radial variation is usually neglected.

However, this conservative assumption made for computation

and monitoring expedience not only neglects the fact that the

excess pore pressures is not uniform but also does not take into

consideration how PVDs change the dredge response to loading.

In theory, drained parameters could be used to represent the

shear strength of soft soils with PVDs if the applied loads (i.e.,

construction of the MSE berm) are imposed slowly enough to

allow all excess pore pressures to dissipate as loading takes

place. In practice, this could not be implemented because the

rate of loading would need to be too slow to be feasible.

3 VIRTUAL SAND PILES: HYBRID DRAINED-

UNDRAINED MODEL

The centerpiece of innovation for the design and construction of

this massive MSE berm was the improvement of the weak

dredge/alluvium foundation material using the concept of

‘virtual sand piles’, also described as the Hybrid Drained-

Undrained (HDU) model (Espinoza et al., 2011).

The virtual sand pile concept is illustrated Figure 2. As

shown in this figure, the closer the dredge is to the PVD the

smaller the generated excess pore pressure and the faster that

are dissipated. Hence, depending upon the speed of

construction, it can be assumed that there are two distinct zones

with different shear strength characteristics during loading: a

drained zone, near the PVDs, and an undrained zone further

from the PVDs. This concept constitutes a significant departure

from standard design of soft cohesive soils with PVDs and it is

the central element of the design. The development of the novel

HDU design methodology for PVD design, to analyze the

strength characteristics of the soft foundation soils during

construction made the use of PVDs feasible for the CIL Project.

Subsequently, a more realistic model was developed to

consider that: (i) the soils located closer to PVDs dissipate

excess pore pressures generated during construction to more

quickly than the soils located farther away from PVDs (Figure

2); and (ii) the rate of construction influences the maximum

excess pore pressure that could be generated (i.e., pore pressures

dissipate as the soil lift is placed). To simplify the model

development, the rate of berm placement construction was

assumed constant and equal to

R

c

. For each lift of soil, it was

assumed that excess pore pressures starts to dissipate soon after

it was placed (see Figure 3). Assuming an exponential decay

function, the resulting excess pore pressure equation as a

function of time is:

p

t

c

t t

e R tu

for

1 )(

(1)

where:

t

p

is the time that takes to place the fill and

is a

parameter that is related to Barron’s Equations (1948)

developed for sand drains:

2

2

i

v

n

r

c

F

(2)

2

2

2

2

4

1 3 ) ln(

1

n

n n

n

n F

n

(3)

e

i

r

r n

(4)

and

c

v

is the coefficient of consolidation;

r

i

is the radius of

influence of the PVDs; and

r

e

is the equivalent radius of the

PVD. The maximum pore pressure takes place at

t

=

t

p

. It

follows that after fill placement, it is assumed that excess pore

pressure dissipates according to the same decay function, then:

p

t t

t

c

t t

e e R tu

p

p

for

1 )(

)

(

(5)

4 SELECTING THE DIAMETER OF THE VIRTUAL

SAND PILE

Equations (1) through (5) were used to select the appropriate

PVD spacing along with the corresponding rate of construction

such that the soils near the PVDs would generate significantly

smaller pore pressures that would allow to model the dredge

around the PVD as a virtual sand pile. This meant that these

soils could be considered to have a drained response during

loading. The modified procedure consists of selecting the

magnitude of excess pore pressure that would have negligible

effect on MSE berm stability and then back-calculate the