2940

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

the monitoring data do not indicate the stability condition of the

MSE berm directly.

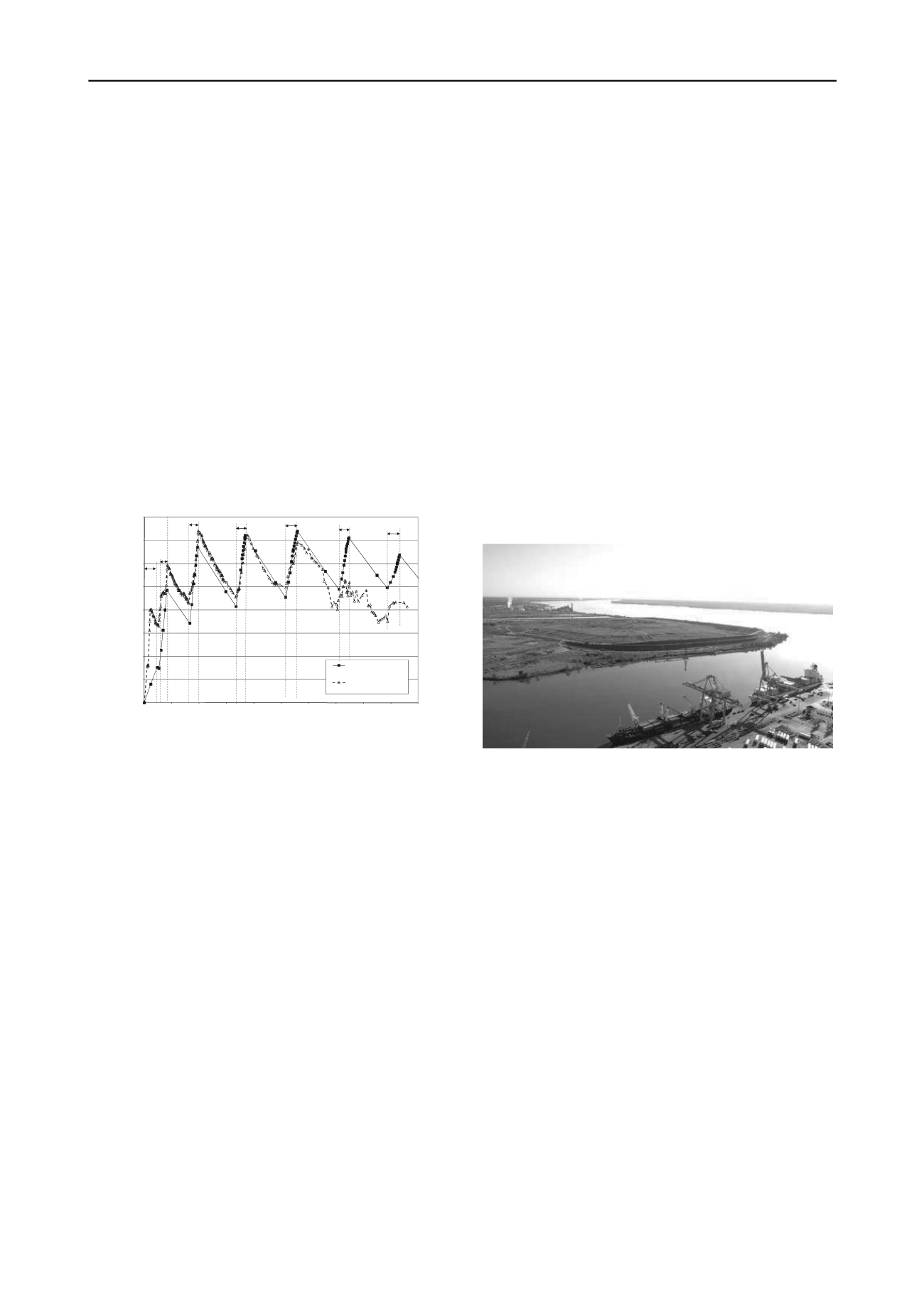

Several finite element models (FEM) were developed for

evaluating the stability of the MSE berm during construction

using PLAXIS® software. The soil consolidation parameters

obtained from laboratory and pilot tests were used as an initial

model calibration. These parameters were adjusted during the

initial 3-m lift placement and then used to predict pore

pressures, lateral and vertical displacements during construction

for subsequent lifts. The calibrated FEM models were used to

closely monitor the construction of the MSE berm. After

construction of each stage, the predicted horizontal and vertical

displacements and excess pore water pressure were compared to

the measured values at selected cross sections to verify

whetherthe MSE berm was performing as expected. In

addition, using ashear strength reduction method, factors of

safety (FS) at each stage of construction was estimated by the

FEM model. The procedure consisted of reducing the soil shear

strength parameters by a factor in an iterative procedure until

large displacements of the FEM model were observed. The

ultimate factor achieved represented the factor of safety against

instability using PLAXIS.Figure 5 shows an example of the

comparison between the measured and predicted pore pressures.

0.00

5.00

10.00

15.00

20.00

25.00

30.00

35.00

40.00

0

100

200

300

400

500

600

700

800

900

1000

ExcessPoreWater Pressure (ft)

Time (days)

FEMPrediction

CorrectedMornitoring

Data

Comp.

Berm

1stLift

2ndLift

3rdLift

4thLift

FS=2.21

FS=2.23

FS=2.05

FS=1.55

FS=1.80

FS=1.45

FS=1.51

FS=1.39

FS=1.30

5thLift

FS=1.63

FS=1.33

FS=1.41

6thLift

(5baskets)

FS=1.87

Figure 5. Example of monitoring results vs. predicted ones

The calculated FS at each stage of the construction are also

shown in Figure 5.Although the construction schedule was

initially established based upon estimated rates of pore pressure

dissipation using the simplified drainage model described

above, the schedule was constantly adjusted during construction

based on the interpretation of the stability condition.

The MSE berm has undergone significant deformation.A

settlement of approximately 4m was initially estimated.The

recorded maximum vertical and horizontal displacements were

approximately 4.2 m and 1.7 m, respectively.

7 BERM CONSTRUCTION

Construction of embankments designed using the HDU model

requires close interaction between the designer, the contractor,

and the owner, to allow timely geotechnical review and

interpretation of monitoring data and communication of

findings. During the initial stage of the project, it was found that

the rate of pore pressure dissipation varied by sections of the

MSE berm due to the localized subsurface geotechnical

conditions. Because of the difference in consolidation rates, the

contractor was required to alter its original construction

sequence for the berm, moving back and forth between the

different sections.By providing clarity to all parties on when

subsequent berm lifts were likely to be feasible in any particular

location, flexibility in construction task management and

minimized disruption to the overall construction schedule could

be achieved. With daily review of geotechnical data and

frequent review of finite-element modeling output prepared for

numerous berm cross sections, the designer was able to identify

areas of construction on a “just-in-time” basis for the contractor

to continue uninterrupted work. Eventually, the original plan of

building a 3m-thick lifts over 600m to 900m length of the berm

every 90 days evolved into construction of lifts in thicknesses as

thin as 1m and/or berm lengths as short as 300m, which were

patched together as review of geotechnical data would allow.

The contractor’s ability to reorganize its efforts to construct the

various sections of the berm based on week-to-week feedback

from the designer became a critical piece of the success of the

project. In this way, by August 2010, 36 months after starting,

MSE berm construction was completed. A detailed description

of the berm construction is presented by Espinoza et al (2008)

and (2011).

8 CONCLUSIONS

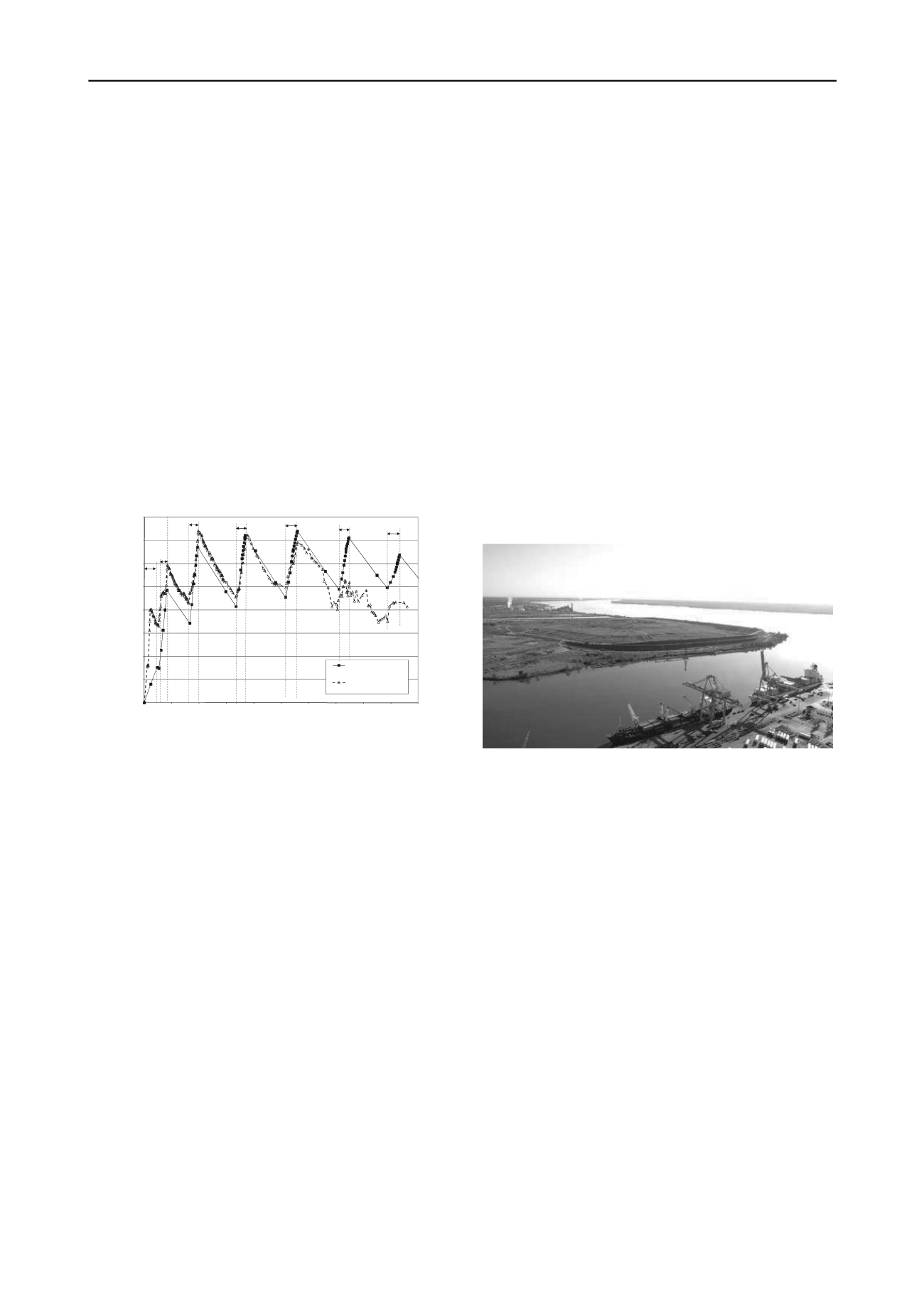

The completion of this 1.8 million cubic meters MSE berm (see

picture below) represents a significant engineering achievement

considering the size of the embankment, the deep layer of very

soft soils over which the berm was constructed, and the amount

of settlements during construction. The successful design and

construction of a 2,400m long, 21m high MSE berm over

extremely soft dredge using innovative design and construction

techniques opens opportunities not only for extending the

capacity of existing disposal facilities over dredge disposal sites

but also for very cost effectively raising levees and dykes at

critical locations prone to flooding.

Figure 6. View of Completed MSE berm

The use of PVDs at this site, which was shown to be

feasible using the HDU methodology, resulted in savings of

over $150 million when compared to conventional ground

improvement techniques such as DSM.

9 REFERENCES

Espinoza R.D., Lazarte, C.A., Germain, A.M., and Houlihan M.F. 2008.

Design Considerations for Expansion of an Existing Landfill Over

Extremely Compressible Soils.

Geo-Strata

, March-April 2008, pp.

38-43.

Espinoza R.D., Houlihan M.F. and Ramsey, T.B.Design of High Soil

Berms over Soft Soils.

Geo-Strata

, March-April 2011, pp. 52-54.

Barron, R.A. (1948). Consolidation of Fined-Grained Soils by Drain

Wells. ASCE Trans, paper 2346, V. 113, 718-724.