2939

Technical Committee 214 /

Comité technique 214

distance from the PVD that corresponds to this value. As a

result, the dredge/alluvium materials enhanced with PVDs could

be viewed (and analyzed) as a soft soil layer enhanced with

virtual sand piles. In other words, the soil columns around the

PVDs (hereafter, virtual sand piles) develop a drained shear

strength during loading, whereas the soil outside the virtual

sand piles develops an undrained shear strength response during

loading.

u

e

= R

c

t

*

t

*

t

u

d

u

e

e

–

(

t

-

t

*)

d

u

e

d

t

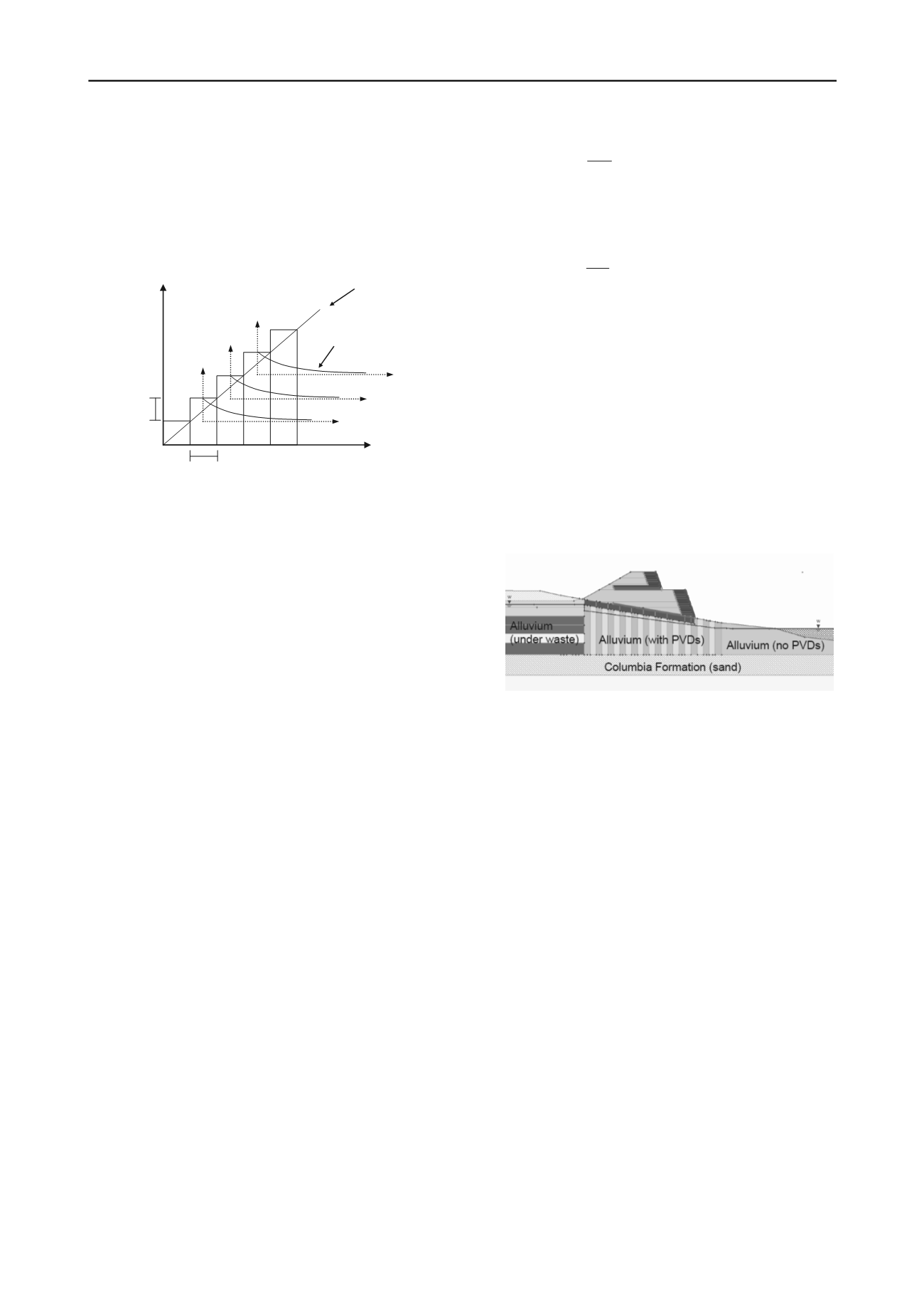

Figure 3. Pore Pressure Model

For the rate of construction (approximately 1 m of fill

placed per week) and site-specific soils at this site (

c

v

= 0.0022

cm

2

/s), approximately 1.8 million meters of prefabricated

vertical drains (PVDs) were installed at a 1.5-m spacing to

allow 90% dissipation of the excess pore-water pressures that

were generated during construction of the overlying MSE berm

within approximately 90 days. The berm was specified to be

constructed 3-m high at a time at a rate of 1 m per week every 3

months (90 days). For a fill unit weight of 19.7 kN, the initial

maximum pore pressure was 60 kPa (i.e., 6.1 m of water). For

these conditions, it was estimated that if the average pore

pressure generated within a certain distance from the PVD was

about 15% of the maximum estimated excess pore pressure, the

material could be considered drained. Based on this, it was

estimated that the dredge/alluvium located within a 46-cm

radius of the PVDs would be drained during each stage of MSE

berm construction.

5 STABILITY ANALYSIS

The main purpose of the proposed methodology was to allow

design engineers to use typical tools for analysis and design

(i.e., limit equilibrium based methods). The HDU methodology

expedited the stability analysis during the design stage as it was

readily implemented using conventional limit equilibrium

methods taking into consideration the soil strengths in the

drained and undrained zones. In that way, hundred of different

cross-sections were evaluated to optimize the design (i.e.,

minimize the MSE berm volume while still providing the same

airspace for the same factor of safety). Accordingly, for slope

stability analysis using limit equilibrium methods, the

dredge/alluvium near the PVDs was considered to be drained

with effective stress parameters given by

´ = 34º (obtained

from triaxial tests), whereas the area further away from the

PVDs was considered undrained with undrained parameters

normalized with effective overburden given by

S

u

/

´ = 0.29

(parameters obtained from an extensive cone penetration tests

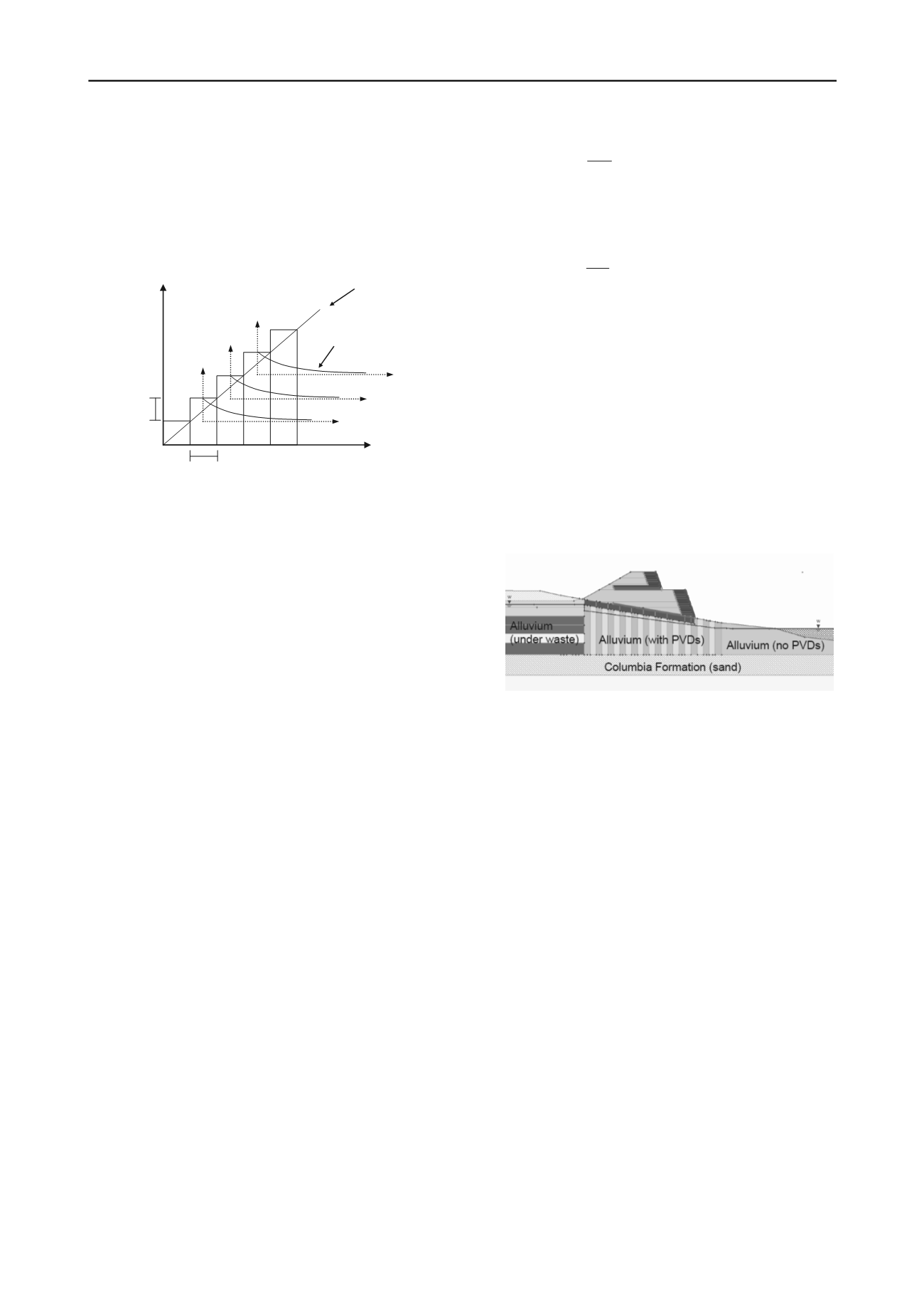

and field vane shear tests). Figure 4 shows the soil stratigraphy

during construction used inlimit equilibrium analysis. As

shown in this figure, the soft dredge under the MSE berm is

modeled as vertical strips of interchanging parameters (drained

and undrained) to represent the HDU model. As shown in the

model, the width of the soil columns does not need to represent

the actual width of the virtual sand column (i.e., 0.92 m in

diameter); only the ratio between drained to undrained areas

needs to be taken into account. This can be simply estimated

as:

100

2

2

pvd

s

r

D

r

A

(6)

where:

D

pvd

is the distance between PVDs and

r

s

is the radius of

the virtual sand (1.5 m and 0.46 m for this project, respectively).

Hence, the percentage of drained area respect to the total area

for this project is:

%38 100

5.1

92.0

2

r

A

Hence, when modeling using limit equilibrium methods, as

long as the vertical strips represent approximately 38% of total

area with PVDs, the actual width of the vertical strips is

immaterial. However, the number of vertical strips should be

selected in a wayit does not have an influence on the failure

mechanism. For instance, two vertical strips would not be

appropriate. Another powerful application of the HDU model is

that PVDs outside the loaded area also have a positive effect on

stability as 38% dredge can be modeled using drained

parameters, hence increasing the overall shear strength along

the potential failure surface. As shown in Figure 4, the zone

with PVDs extended beyond the toe of the MSE berm to

increase the factor of safety against sliding during construction.

Typical design procedures would only account for the shear

strength increase due to the overburden pressure located above

the PVDs, hence PVDs outside the MSE berm footprint would

not be installed as it would not be considered in the analysis.

Figure 4. Limit Equilibrium Model of Enhanced Dredge with PVDs

In addition, to improve the stability of the MSE berm during

construction, over 200.000 m

2

of high strength geotextile was

installed at the base of the berm. The strength specified (1.170

kN/m) was one of the strongest materials ever manufactured by

Tencate at the time of construction. The proposed solution for

foundation improvement was significantly cheaper than DSM.

The total cost of installing the PVDs including the high-strength

geotextile was approximately $11 million, thus resulting in

significant savings from the initial design. Although more

engineering was required for design and construction, the total

cost was significantly less than the DSM alternative.

6 CONSTRUCTION MONITORING AND MODELING

In order to prevent unacceptably high pore pressures from

developing, construction was conducted in stages and each

stage of berm construction was limited to a 3-m thick lift

followed by a 3-month pore pressure dissipation period,

estimated initially. To monitor the performance of the

foundation during the stages of construction, data was collected

from a total of 85 geotechnical monitoring instruments along 17

lines spaced approximately 150 meters apart along the length of

the MSE berm including 51 piezometers to measure pore

pressures generated within the dredge/alluvium during loading

at three different depths, 17 settlement sensors to measure the

compressibility (i.e., vertical displacement) of the

dredge/alluvium during berm construction, and 17 slope

inclinometers at the toe of the berm to obtain a profile of

horizontal displacement with depth during loading.

Although the use of limit equilibrium analysis expedites the

analysis during design when dozens of cross sections are

analyzed during the design stage, during construction, the

recorded displacements (horizontal and vertical) could not be

used in conjunction with limit equilibrium methods. Moreover,