2959

Technical Committee 214 /

Comité technique 214

However, the perimeter of the circular pile is 1.338 m, which is

smaller than that of the XCC pile of 1.759 m. Thus, with the

same cross section area, the pile-soil interface contact area of

the XCC pile is 31.5 % more than that of the circular pile.

4.2 Analysis of Test Results and Discussions

100

80

60

40

20

0

0

20 40 60 80 100 120 140

(a)

XCC pile

Circular pile

Pile head compressive load,

Q

(kN)

Displacement of pile head,

s

(mm)

-100

-80

-60

-40

-20

0

-20 -30 -40 -50 -60 -70 -80 -90

(b)

XCC pile

Circular pile

Pile head uplift load,

Q

(kN)

Displacement of pile head,

s

(mm)

50

40

30

20

10

0

0

10

20

30

40

50

60

(c)

XCC pile

Circular pile

Pile head lateral load,

H

0

(kN)

Lateral displacement of pile head,

y

0

(mm)

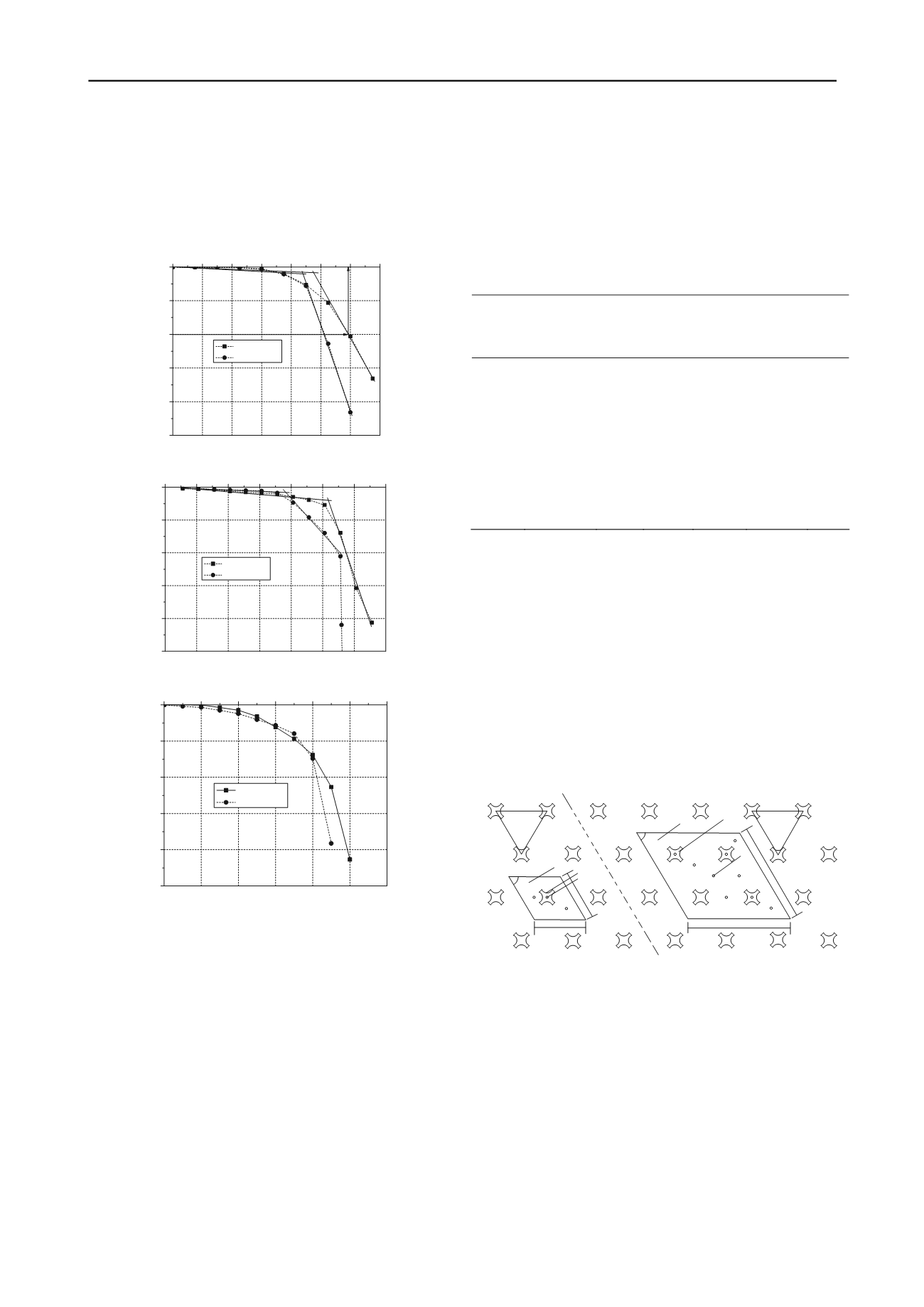

Figure 2. The curves of load versus displacement: (a) compressive load-

displacement; (b) uplift load-displacement; (c) lateral load-displacement.

Fig. 2(a) shows load-displacement curves of the XCC pile and

the circular section pile at the pile head. The ultimate

compressive load-carrying capacity of the circular pile and XCC

pile is equal to 90 kN, and 111 kN, respectively. The ultimate

compressive capacity was improved nearly 24.0 % by changing

the pile cross section from common circular section to X-

section when the same amount of concrete volume was used.

Fig. 2(b) shows the load-displacement curves under uplift load

for the two different pile sections. The uplift capacity of XCC

pile and circular pile was found to be -70.6 kN and -56.1 kN,

respectively. The ultimate uplift capacity was improved nearly

25.8 % by changing the pile cross section from a circular

section to an X-section for the same amount of concrete volume

used. The test result of the lateral load versus lateral deflection

at pile head is plotted in Fig. 2(c) for two different pile sections.

The lateral

H

0

-

y

0

curve of XCC pile is similar with that of

circular pile. For the same lateral capacity, the amount of

concrete volume used in a XCC pile is about 6.9 % less than in

a circular pile.

5 FIELD TEST CASE STUDY

5.1 Summary of Field Test Conditions

The test site locates at north bridge of Nanjing city, where the

landform is Yangtze River floodplain. By geological

exploration, and laboratory soil test, the physical and

mechanical parameters and distribution of soil layers are shown

in Table 3.

Table 3. The soil layers and soil parameters in field test site

Soil

symbol

Name

Depth

h

(m)

Water

content

w

(%)

Unit

weight

γ

(kN/m

3

)

Modulus

E

s

(MPa)

Void

ratio

e

�

Filled

back soil

0.20

�

2

Mucky

silty clay

1.30

38.60

17.60

3.50

1.11

�

2A

Silty sand

1.00

25.30

19.20

10.77

0.70

�

2

Mucky

silty clay

1.50

38.60

17.60

3.50

1.11

�

2B

Silty sand

1.80

26.10

19.30

8.00

0.71

�

2

Mucky

silty clay

2.30

38.60

17.60

3.50

1.11

�

3

Fine sand

9.40

26.30

18.90

11.83

0.76

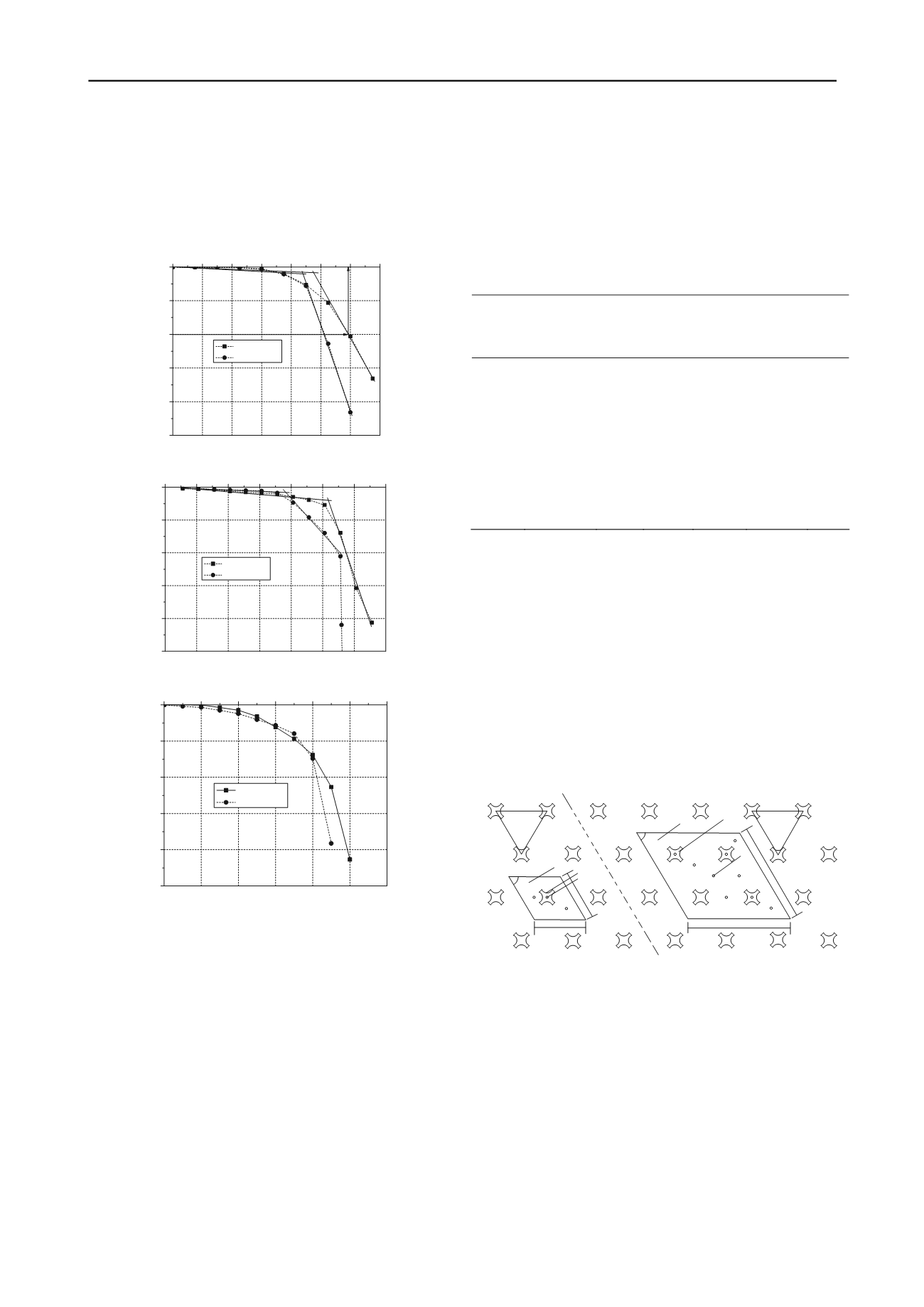

The pile layout in Fig. 3 shows that the piles distribute as

equilateral triangles, and the distances between two adjacent

piles for single pile test and 2×2 pile groups test equal 1.85 m,

and 1.80 m, respectively. In static loading tests of 2×2 pile

group composite foundation, the loading plates are rhombic

with side length of 3.6 m, which covers four piles. A layer of

gravel cushion with the thickness of 30 cm is paved between

pile top and loading plate. During the load tests, the total load

applied to the loading plate was measured by a load cell placed

on the loading plate, the axial force of pile shaft along pile

depth was measured by reinforcement stress meters, the soil

pressures and pile head pressures were measured by earth

pressure cells, and settlement of the pile head was recorded by

two LVDTs installed symmetrically at the loading plate. Data

from the load cells and LVDTs during the load test were

captured by a data acquisition system.

1850

1850

1800

1800

60

o

60

o

Unit: mm

3600

1850

1850

3600

1

2

3

1

3

2

1: XCC pile

2: Loading plate

3: Soil pressure cell

Figure 3. The instrument arrangements of XCC pile composite

foundation.

5.2 Analysis of Test Results and Discussions

Fig. 4 shows the changes of axial forces result in the variations

of side friction. When the load is relatively large, the side

friction from the depth of -1 m to -2 m is negative, which is the

typical characteristic of composite foundation. The load applied

on loading plate causes the non-uniform settlement between the

soil and piles. When the load is not very large, the differential

settlement is in apparent, so the negative friction is extremely

small. As the increase of the load step, the load shared by the

piles also increases, and then the pile top tends to penetrate into

the cushion, at the same time the soil subsidence occurs under