2954

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

associated with such problems, including future maintenance

costs. This paper outlines the problem of designing and

constructing the expansion of the second branch of the Namhae

Expressway and suggests solutions to the problems involved.

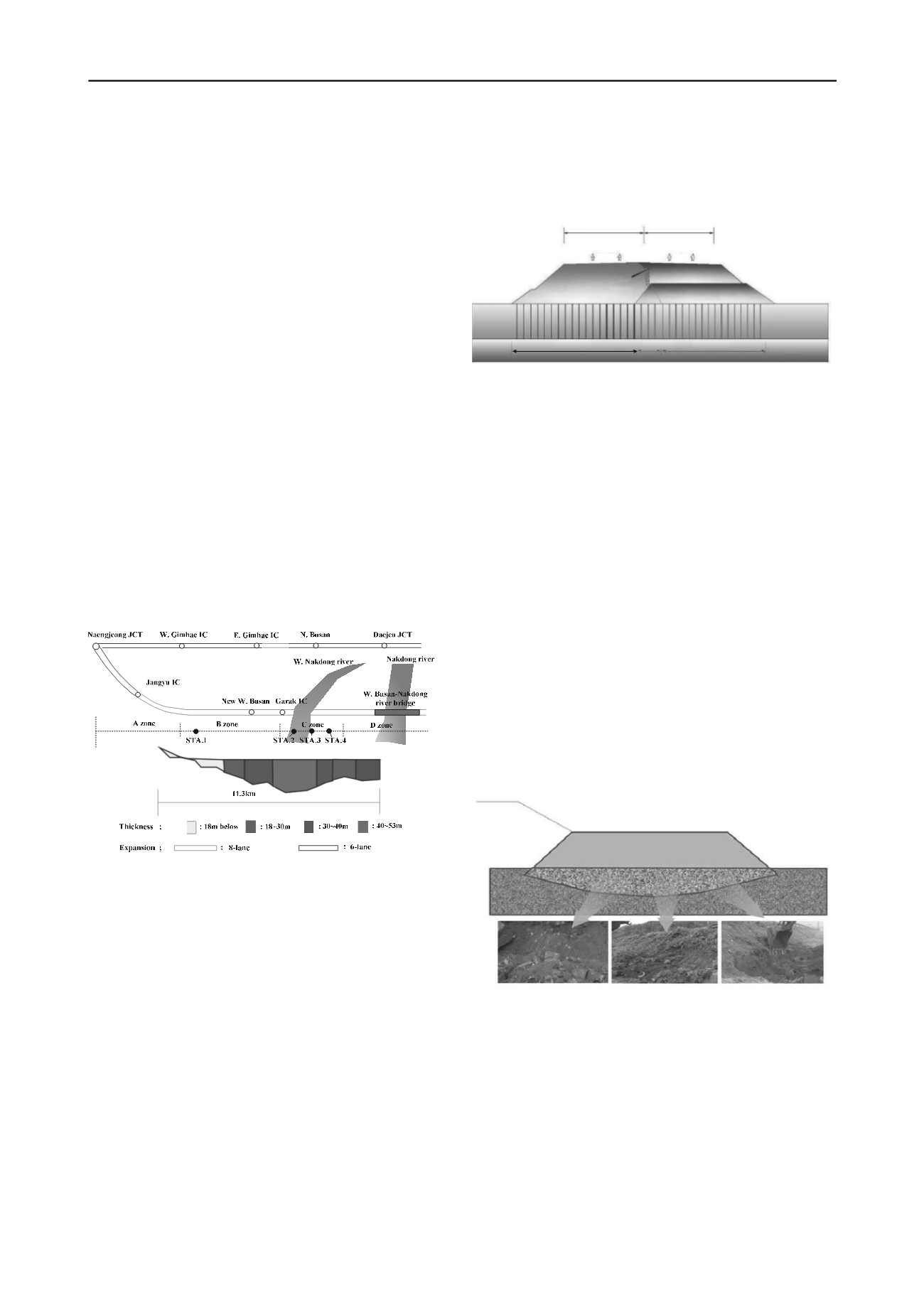

2 STRIBUTION OF SOFT SOIL ON THE PROJECT SITE

Construction of the expansion of the second branch of the

Namhae Expressway is in progress. The project has been

divided into four construction zones (A, B, C and D). The

distribution of soft soil in each zone is as follows (Korea

Expressway Corporation, 2008d; 2008e; 2008f).

In zone A, which has a total length 6.40 km, soft soil is

present at thicknesses in the range of 0.0~15.4 m in a segment

890 m in length, from station 5+110 to station6+000. According

to the results of the boring investigation, the soft soil consists of

clayey silt and silty clay. Zone B has a total length of 5.50 km

and is located across the Joman River (5+140 to 5+500). The

soft soil is present at thicknesses in the range of 2.0~50.8m

throughout zone B, except between stations 0K+000 and

1K+000. Zone C is located across the W. Nakdong River

(6K+160) and Pyeonggang Creek (8K+080 to 8K+230) and has

a total length of 3.56 km. This section also has soft soil present

at thicknesses in the range of 2.0~53 m. In the area of the W.

Nakdong River, sandy soil is present to a depth of 10~12 m due

to sedimentation from the river, and soft clay soil is present

below the sandy soil. In zone D, soft sandy soil is present at

thicknesses of 2.9~11.4 m, and soft clay soil is present at

thicknesses of 8.0~25.2 m. The soft clay soil consists of clayey

silt or silty clay.

Figure 1. Route map of expansion construction for the second branch of

the Namhae expressway and distribution of soft soil along the route.

3 THE ORGINAL DESIGN

Most of the new construction zones were planned to be

expanded bordering the existing road in the direction of

Naengjeong, except for a portion of the zones in which the

horizontal alignment was to be adjusted. An accelerated

consolidation method was applied to satisfy the requirement of

10 cm of allowable residual settlement. PBDs were selected as

the vertical drain type to be used in the consolidation

acceleration. For horizontal drainage, fiber drains were to be

used in parts of zones C and D where sandy soil is present in the

upper layer. In the remainder of the zones, a crushed stone mat

was to be used for drainage.

For the existing road, prefabricated vertical drains (PVD)

were installed along 1.2 km of the roadway, equivalent to 6% of

the total length 19.6 km when it was constructed in May of

1978 (Korea Expressway Corporation, 1982). Long-term and

continuous consolidated settlement occurred in the remainder of

the zones because an embankment was built during the

operation of the road after constructing MAT using sand and

gravel and crushed stone. Thus, the construction method below

was designed for and applied to the existing road because it was

thought to be an economical method of ensuring the long-term

stability of the roadway, allowing residual settlement by

removing the existing soil, installing vertical drains for

consolidation acceleration and preloading with counterweight

fill.

1st stage expansion section 2nd stage expansion section

Naengjeong bound

Busan bound

Temporary structure

Existing road

1 : 1.5

1 : 1.8

P.B.D. installation

P.B.D. installation after drilling

P.B.D. installation after removing the existing road

Figure 2. Overview of original design of road expansion.

4 EXAMINATION OF PROBLEMS WITH THE

ORIGINAL DESIGN

4.1

Low constructability and increased costs

According to the original design, an improvement method

should be applied to the soft soil after removing the soil under

the sting road. When constructing the existing road, only a part

of the sections improved with paper drains, and the remainder

of the sections banked using sand, gravel, and crushed stone on

the lower part without vertical drains being installed. The sand,

gravel and crushed stone rested on the lower part of the natural

soil during construction and use of the road. Thus, these objects

pose obstacles to the installation of vertical drains under this

expansion construction.

Therefore, it is expected that the constructability would be

very poor because of the difficulty of removing the settled

crushed stone and transport the soils removed from the existing

roadbed. It is also expected that the costs would be increased by

the need to transport and dispose of the waste asphalt concrete

resulting from removal of the existing road. Examination of the

cores reveals that the thickness of the asphalt concrete at an

abutment is 1~1.5 m, due to repeated overlays of the pavement

necessitated by settling of the soil over a long period of time.

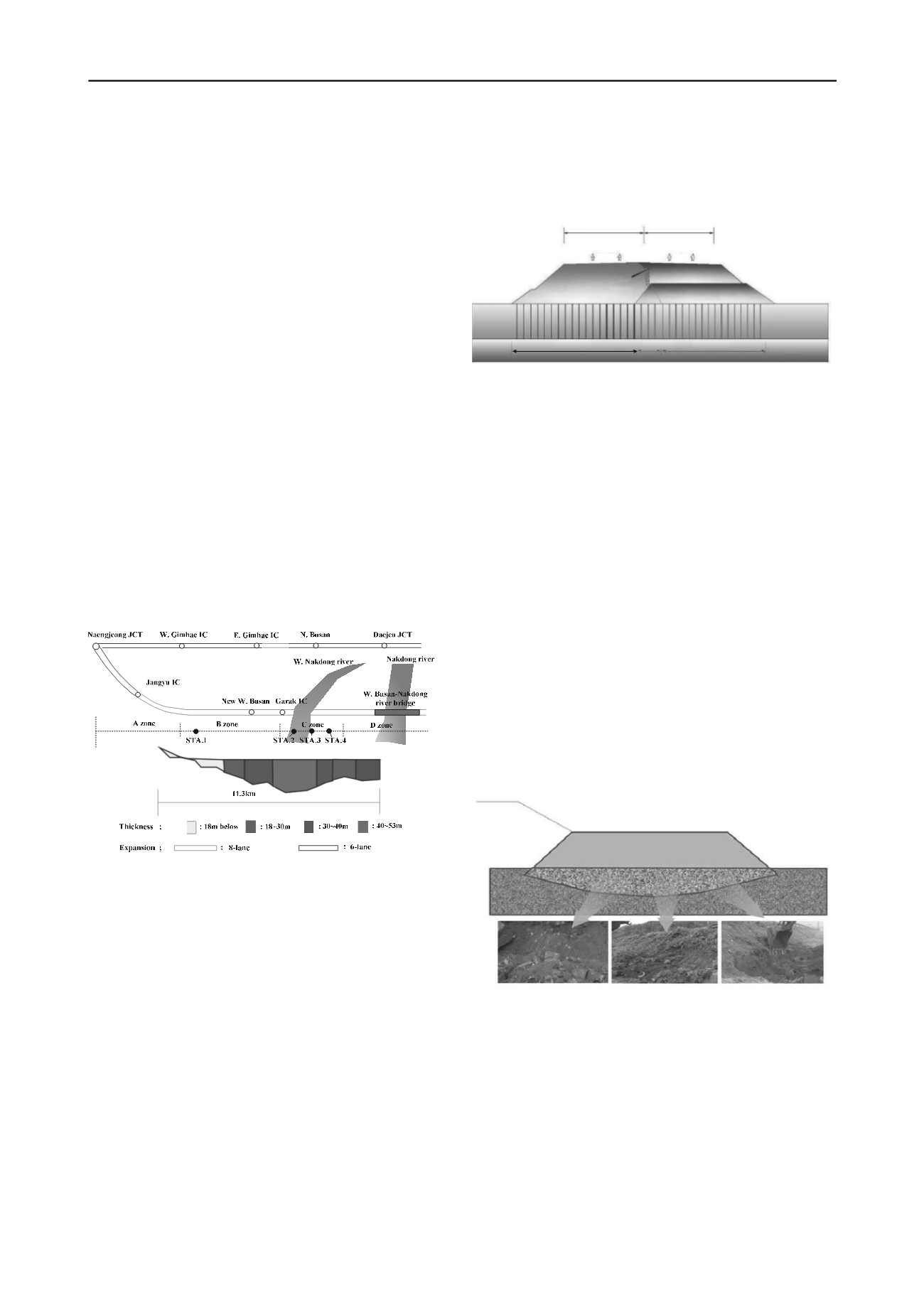

Expansion

section

The existing

road

Settled soils

Original

ground

Figure 3. Results of field survey of the existing road.

4.2

Problems of PBD construction on the existing Road

Typical PBD construction is not expected to be possible

because of resistance from the crushed stone and other coarse

materials in the existing roadbed. Thus, special drilling and

excavation are necessary, but these activities will delay

construction and increase costs. If the existing roadbed soil is

completely removed, the stability of the soil may be

disrupted by PBD construction. If a drilling PBD method is

applied on the slope of the existing road, it is expected that

construction will be delayed due to the additional time required

for construction processes such as drilling and filling the drilled

hall.