2971

Technical Committee 214 /

Comité technique 214

each track area is up to 50 t/m². The foundation soil is 10 m

thick soft bluish clay with an average undrained shear strength

of 23 kPa from vane shear test results.

Figure 6. Rehabilitated fabrication yard in use.

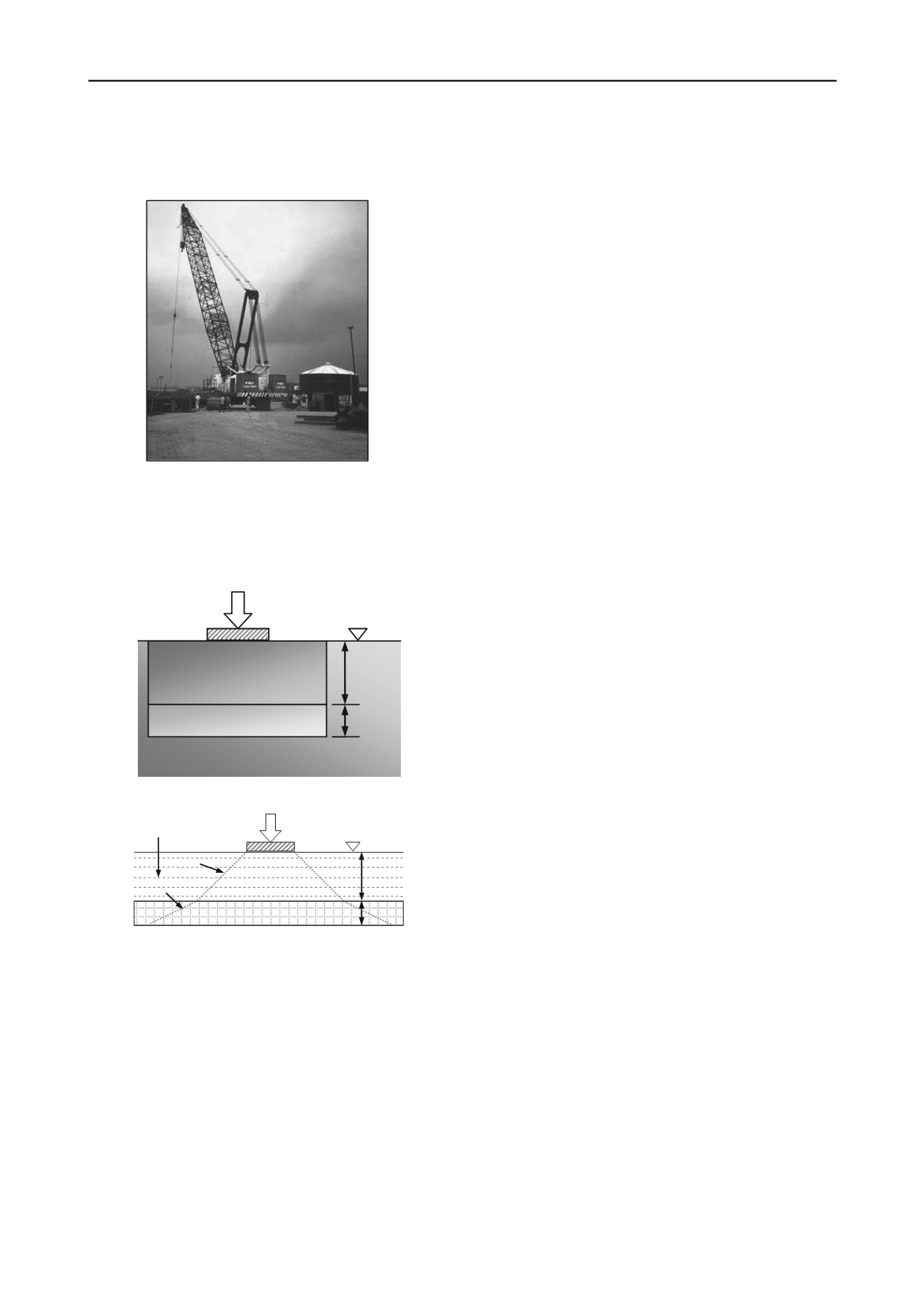

In the calculations, the angle of load spread for the fill

material reinforced with TriAx geogrid within the MSL is taken

to be 1 vertical to 1 horizontal (i.e., 1V:1H) whereby the load

distribution through the geocell mattress was taken as 1 vertical

to 2 horizontal (i.e., 1V:2H) to model the very stiff nature of the

construction (Figure 7).

(a)

(b)

Figure 7. Geocell mattress and MSL platform (after Ong et al., 2011)

Five layers of TriAx geogrids were used to form the 2 m

thick MSL. Stiff uniaxial geogrids were used to form the

interlocking cells of the 1 m thick geocell mattress and a layer

of TriAx geogrid was placed at the base. The aggregate to be

used as backfill material for the MSL and geocell mattress was

specified as well graded granular material with particle size less

than 75 mm. Full scale plate bearing test (PBT) was conducted

to ascertain the performance of the geocell mattress in meeting

the acceptance criterion (i.e., total settlement less than 100 mm

under loading of 50 t/m²). The loading on the steel plate was

increase in six steps: 10 t/m², 20 t/m², 30 t/m², 40 t/m², 50 t/m²

and 60 t/m². Settlement versus applied load and settlement

versus time were plotted. It was found that the specified

settlement requirement was satisfied with total settlement of 41

mm under 60 t/m² load.

4 CONTAINER YARD IN GEBENG, KUANTAN

In this project, a working platform in the form of container yard

was built on soft subgrade with California bearing ratio (CBR)

of 1% to 2%. The container yard was designed to support the

following loadings:

6 m by 2.4 m container with maximum weight of 30 tonnes.

Maximum staking of containers was 2 containers.

Container handler machine with maximum axle load of 105

tonnes. Therefore maximum wheel load of 525 kN

including dynamic factors.

Total number passes of the container handler machine was

designed as 250,000 during service life.

The terms of reference are:

To reduce thickness of unbound granular layer platform.

To mitigate differential settlement.

To provide stable storage area and to increase load spread

using geocell mattress and mechanically stabilised layer

(MSL) with TriAx geogrids.

The analysis conducted indicated that the loadings from the

trafficking movement due to container staker would be more

critical than the static loadings due to the staking of 2

containers. Thus, the requirement for total platform thickness

was assessed based on heavy duty pavement design (Knapton,

2008). By using geocell mattress and MSL, the thickness of

granular fill required to construct the container yard has been

reduced up to 810 mm. This resulted in substantial savings in

terms of construction time and cost.

MECHANICALLY

STABILISED LAYER

(MSL)

GEOCELL MATTRESS

2.0 m

1.0 m

SOFT CLAY

EGL

MAX. CRANE TRACK

LOADING = 50 t/m

For the heavy duty pavement construction of the container

yard, 1 m high geocell mattress was placed on one layer of

TriAx geogrid at subgrade level. The geocell mattress is to

provide a firm and relatively rigid platform with a perfectly

rough interface between the mattress and the soft foundation.

This stiff platform is created by the high tensile strength of

polymer grid material used in the cellular construction to

confine the granular fill which enables an even distribution of

load onto the foundation. On top of the geocell mattress is MSL

of 500 mm to 750 mm compacted well graded granular fill with

3 layers of TriAx geogrids. Granular layers reinforced with

TriAx geogrids perform as composite due to the interlock

phenomenon. The configuration of the geogrid ribs and the

integral junctions provide lateral restraint to the aggregate

particles as they partially penetrate the apertures by a process of

interlock. This interlock effectively stiffens the aggregate and

enables any imposed load to be distributed over a wider area.

The container platform was finished with interlocking paving

blocks. The construction of the container yard is expeditious

starting from placement of TriAx geogrids, forming of geocells,

filling with granular materials according to prescribed grading

envelope, construction of MSL geogrid reinforced layers and

installation of the paving blocks (Figures 8 to 12).

GEOCELL MATTRESS

2.0 m

1.0 m

SOFT CLAY (bearing capacity = 131 kPa)

EGL

MAX. CRANE TRACK

LOADING = 50 t/m

TRIAX GEOGRID

TO FORM MSL

1V:1H

1V:2H

5 DISCUSSION AND CONCLUSION

Comparison is made in the pavement details and settlement

performance of the working platform (Table 1). From Table 1 it

can be seen that all the 3 platforms consist of soft clay layer of

thickness varying from 4.5 m to 10 m. The crane track pressure

exerted on the working platform was up to 500 kPa and axle

load exerted by the reach stacker on the working platform is 105

tonnes. Granular fill of varying thicknesses were used in all

three working platforms. It appears that MSL constructed using

biaxial and TriAx geogrids with granular fill with or without

geocell mattress performed satisfactorily in terms of platform

settlement performances to support the heavily loaded crawler

crane or stacker machine for the fabrication or container yard.