2904

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

End Bearing Resistance

Maximum mobilised resistance = 59MPa (ultimate end

bearing pressure not reached)

Little or no creep at an end bearing pressure of 38MPa

(this pressure was held for 30 minutes)

Shaft Resistance

Creep started at an average shaft resistance (over 5.5m

length) of 1.06MPa and was significant at 1.3MPa

The shaft response became “plastic” at a movement of

about 30mm, with a corresponding average shaft

resistance of 1.74MPa

The O-Cell test results confirmed the ultimate design values

adopted for design, and as in Case Study 1, demonstrated that

significantly higher serviceability end bearing pressure could be

considered in the design of rock socketed piles in Sydney rock.

If the presumptive end bearing pressure given in Table 2 for

Class I and II Sandstone was adopted, the serviceability end

bearing resistance would have been limited to 12MPa. The O-

Cell test clearly demonstrated that significantly higher

serviceability end bearing could be adopted, provided the base

of the rock socket is adequately cleaned. The pile construction

aspect of this case study to ensure adequate rock socket

roughness and base cleanliness is described in Sethi et al

(2012). However, it should also be stressed that under

serviceability loading, a large proportion of the applied load

may be carried by the pile shaft depending on the length to

diameter ratio of the rock socket. Therefore, the use of

excessively high serviceability end bearing pressure may not be

warranted. A detailed assessment of the rock-socket load-

deformation response is necessary for each specific case.

In the above case study, the non-linear load-deformation

behavior observed from the O-Cell test is of particular interest.

Using the back-analyzed test results, and by close inspection of

the load-deformation behavior of both the shaft and base, it was

possible to deduce the operating secant modulus of the rock

socket material at various mobilized base and shaft resistance as

shown in Figures 6 and 7.

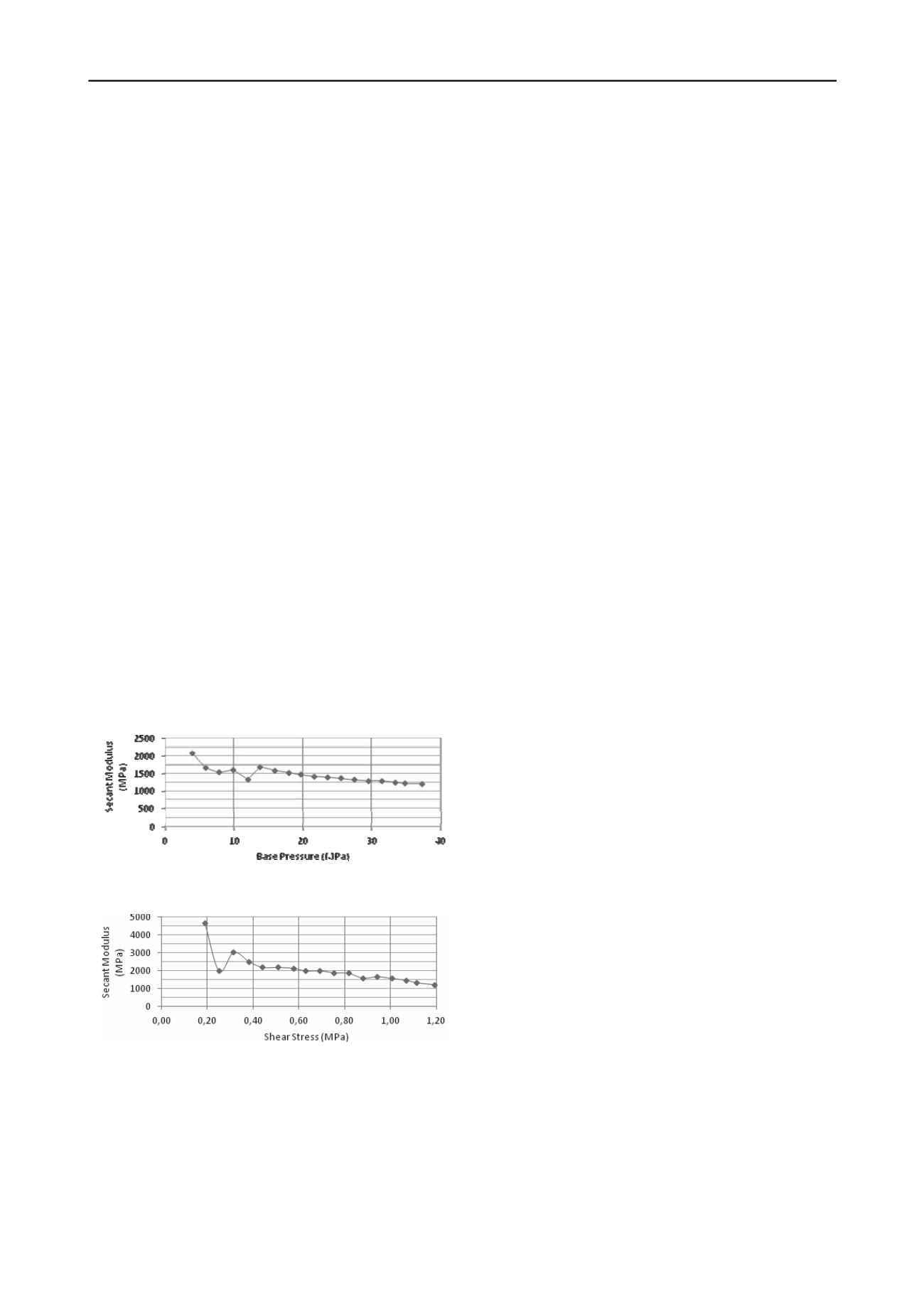

Figure 6. Deduced Secant Modulus of Rock below Pile Base

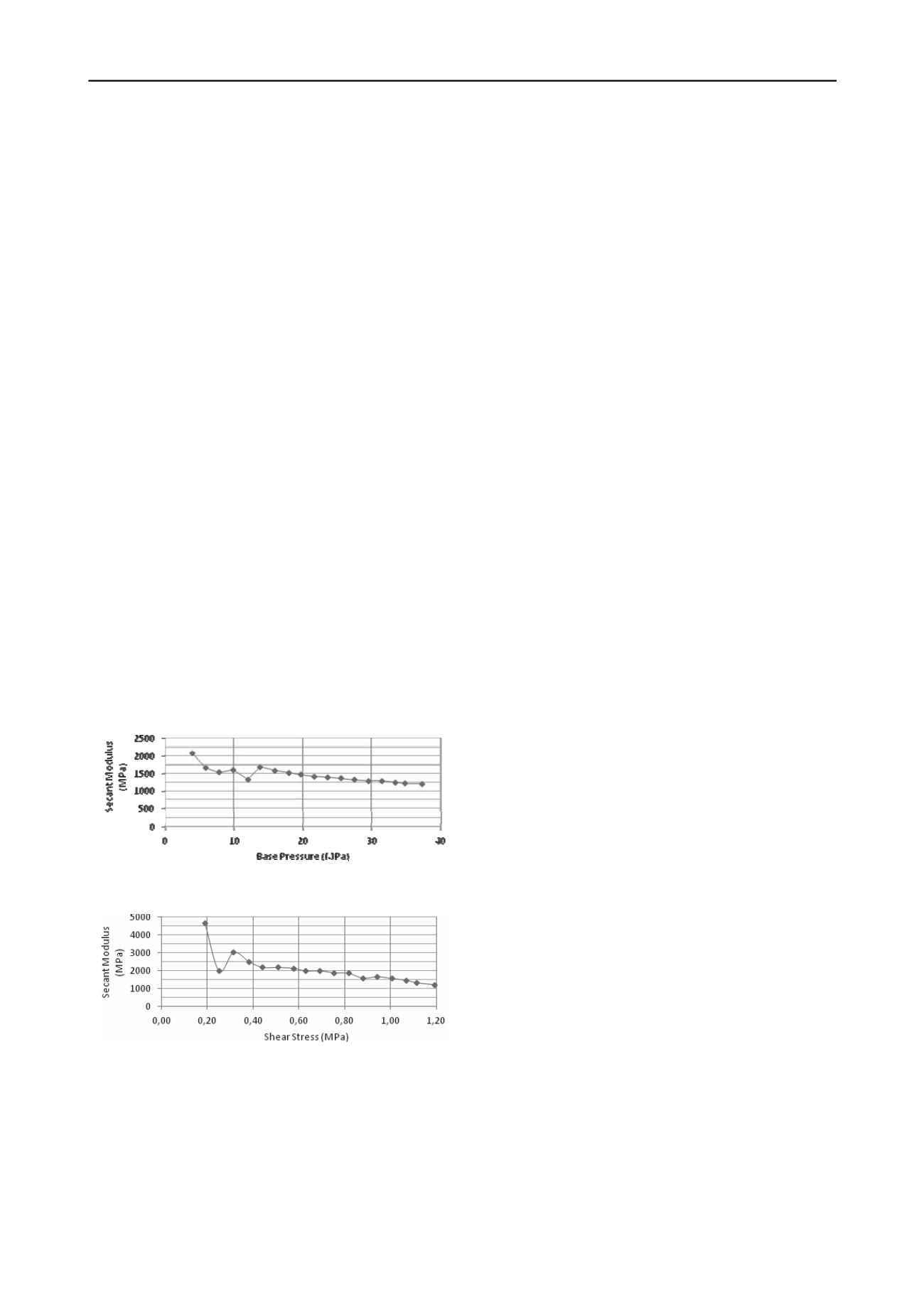

Figure 7. Deduced Secant Modulus of Rock around Pile Shaft

It can be seen from Figure 6 that there was a rapid drop in

the inferred secant modulus of the rock below the pile base

when a base pressure of 5MPa was reached, and remained at

approximately 1.6GPa to 1.7GPa until a base pressure of

14MPa was reached. Above this pressure, the inferred secant

modulus continued to drop steadily and reached a value of

1.3GPa at a base pressure of 30MPa. The initial drop in secant

modulus at a base pressure of 5MPa to 14MPa could be

attributed to compression of disturbed material or residual

debris at the base of the socket, and the gradual drop of secant

modulus beyond a base pressure of 14MPa is considered to be

representative of the actual rock mass behavior.

From Figure 7, it can be seen that the inferred secant

modulus of the rock socket material was initially very high

(over 5GPa), then dropped rapidly to 2.5GPa at an average shaft

resistance of 0.4MPa, then continued to drop steadily to 1.2GPa

at a mobilized shaft resistance of 1.2MPa. Comparing these

results with the non-linear function to describe the secant

modulus adopted for design as shown in Table 3, it may be

concluded that different initial rock modulus should be applied

to describe the base and shaft response. However, for simplicity

of design, and considering the operating stresses at the

serviceability loads for the piles on this project, it was

concluded that an initial tangent modulus value of 2GPa would

still be appropriate for the Class II Sandstone if the hyperbolic

pile base and shaft factors, R

fb

and R

fs

(see Table 3), were

modified to 0.55 and 0.8 respectively. These values correspond

to secant modulus values of approximately:

Pile Base Response – 1.7GPa and 1.2GPa for the rock

below the pile base, for end bearing pressures of

14MPa and 30MPa respectively, and

Pile Shaft Response – 1.8GPa and 1.2GPa for the rock

around the pile shaft for shaft resistance of 0.4MPa

and 1.2MPa respectively.

However, these changes would only make very small changes

(≤ 3mm) to settlement prediction values at serviceability

loading. Therefore, the original design parameters were

adopted without changes for subsequent designs.

Supported by the O-Cell pile load testing, significant

reduction in pile lengths and cost savings were achieved for this

project as a result of the load-deformation analyses and

performance based design carried out.

4 CONCLUSIONS

Other than very weak to weak rock, socketed pile design is

generally governed by serviceability requirements rather than

ultimate capacity. In such circumstances, economy pile designs

can be achieved if accurate predictions of load-deformation

behavior of the piles are made, rather than adopting recipe style

presumptive values. Pile load testing should be carried out for

such performance based design method.

Two case studies of rock socketed pile design and pile load

testing have been presented in this paper, both of which clearly

illustrated the advantages of this performance based design

approach, with significant cost savings in foundation works.

The use of the O-Cell testing method in Case Study 2

demonstrated the non-linear nature of high strength rock

commonly encountered in the Sydney area of Australia.

5 REFERENCES

Pells P.J.N., Douglas D.J., Rodway, B., Thorne, C.P. and McMahon,

B.R. (1978) Design Loading for Foundations on Shale and

Sandstone in the Sydney Region,

Australian Geomechnics.

Jnl. Vol.

8, 31-39.

Pells P.J.N., Mostyn G., and Walker, B.F. (1998) Foundations on

Sandstone and Shale in the Sydney Region,

Australian

Geomechnics

. Jnl. No. 33 Part 3, 17-29.

Poulos, H.G. (1979) Settlement of Single Piles in Non-homogenous

Soil, Jnl. Geot. Eng. Div., ASCE, Vol. 105, No. GT5, 627-641.

Wong, P.K. and Oliveira, D. (2012) Class A Prediction versus

Performance of O-Cell Pile Load Tests in Sydney Sandstone,

Australian Geomechanics

Jnl,. Vol 47, No. 3, 89-96.

Sethi, P.L., Geng, I. and Wong, P.K. (2012) Construction of Rock

Socketed Piles in Sydney Sandstone to Meet Performance

Requirements,

Australian Geomechan.

Jnl., Vol 47, No. 3, 97-102.

End Bearing Resistance

Maximum mobilised resistance = 59MPa (ultimate end

bearing pressure not reached)

Little or no creep at an end bearing pressure of 38MPa

(this pressure was held for 30 minutes)

Shaft Resistance

Creep started at an average shaft resistance (over 5.5m

length) of 1.06MPa and was significant at 1.3MPa

The shaft response became “plastic” at a movement of

about 30mm, with a corresponding average shaft

resistance of 1.74MPa

The O-Cell test results confirmed the ultim te design values

adopted for design, and as in Case Study 1, demonstrated that

significantly higher serviceability end bearing pressure could be

considered in the design of rock socketed piles in Sydney rock.

If the presumptive end bearing pressure given in Table 2 for

Class I and II Sandstone was adopted, the serviceability end

bearing resistance would have been limited to 12MPa. The O-

Cell test clearly demonstrated that significantly higher

serviceability end bearing could be adopted, provided the base

of the rock socket is adequately cleaned. The pile construction

aspect of this case study to ensure adequate rock socket

roughness and base cleanliness is described in Sethi et al

(2012). However, it should also be stressed that under

serviceability loading, a large proportion of the applied load

may be carried by the pile shaft depending on the length to

diameter ratio of the rock socket. Therefore, the use of

excessively high serviceability end bearing pressure may not be

warranted. A detailed assessment of the rock-socket load-

deformation response is necessary for each specific case.

In the above case study, the non-linear load-deformation

behavior observed from the O-Cell test is of particular interest.

Using the back-analyzed test results, and by close inspection of

the load-deformation behavior of both the shaft and base, it was

possible to deduce the operating secant modulus of the rock

socket material at various mobilized base and shaft resistance as

shown in Figures 6 and 7.

Figure 6. Deduced Secant Modulus of Rock below Pile Base

Figure 7. Deduced Secant Modulus of Rock around Pile Shaft

It can be seen from Figure 6 that there was a rapid drop in

the inferred secant modulus of the rock below the pile base

when a base pressure of 5MPa was reached, and remained at

approximately 1.6GPa to 1.7GPa until a base pressure of

14MPa was reached. Above this pressure, the inferred secant

modulus continued to drop steadily and reached a value of

1.3GPa at a base pressure of 30MPa. The initial drop in secant

modulus at a base pressure of 5MPa to 14MPa could be

attributed to compression of disturbed material or residual

debris at the base of the socket, and the gradual drop of secant

modulus beyond a base pressure of 14MPa is considered to be

representative of the actual rock mass behavior.

From Figure 7, it can be seen that the inferred secant

modulus of the rock socket material was initially very high

(over 5GPa), then dropped rapidly to 2.5GPa at an average shaft

resistance of 0.4MPa, then continued to drop steadily to 1.2GPa

at a mobilized shaft resistance of 1.2MPa. Comparing these

results with the non-linear function to describe the secant

modulus adopted for design as shown in Table 3, it may be

concluded that different initial rock modulus should be applied

to describe the base and shaft response. However, for simplicity

of design, and considering the operating stresses at the

serviceability loads for the piles on this project, it was

concluded that an initial tangent modulus value of 2GPa would

still be appropriate for the Class II Sandstone if the hyperbolic

pile base and shaft factors, R

fb

and R

fs

(see Table 3), were

modified to 0.55 and 0.8 respectively. These values correspond

to secant modulus values of approximately:

Pile Base Response – 1.7GPa and 1.2GPa for the rock

below the pile base, for end bearing pressures of

14MPa and 30MPa respectively, and

Pile Shaft Response – 1.8GPa and 1.2GPa for the rock

around the pile shaft for shaft resistance of 0.4MPa

and 1.2MPa respectively.

However, these changes would only make very small changes

(≤ 3mm) to settlement pr diction values at serviceability

loading. Therefore, the original design parameters were

adopted without changes for subsequent designs.

Supported by the O-Cell pile load testing, significant

reduction in pile lengths and cost savings were achieved for this

project as a result of the load-deformation analyses and

performance based design carried out.

4 CONCLUSIONS

Other than very weak to weak rock, socketed pile design is

generally governed by serviceability requirements rather than

ultimate capacity. In such circumstances, economy pile designs

can be achieved if accurate predictions of load-deformation

behavior of the piles are made, rather than adopting recipe style

presumptive values. Pile load testing should be carried out for

such performance based design method.

Two case studies of rock socketed pile design and pile load

testing have been presented in this paper, both of which clearly

illustrated the advantages of this performance based design

approach, with significant cost savings in foundation works.

The use of the O-Cell testing method in Case Study 2

demonstrated the non-linear nature of high strength rock

commonly encountered in the Sydney area of Australia.

5 REFERENCES

Pells P.J.N., Douglas D.J., Rodway, B., Thorne, C.P. and McMahon,

B.R. (1978) Design Loading for Foundations on Shale and

Sandstone in the Sydney Region,

Australian Geomechnics.

Jnl. Vol.

8, 31-39.

Pells P.J.N., Mostyn G., and Walker, B.F. (1998) Foundations on

Sandstone and Shale in the Sydney Region,

Australian

Geomechnics

. Jnl. No. 33 Part 3, 17-29.

Poulos, H.G. (1979) Settlement of Single Piles in Non-homogenous

Soil, Jnl. Geot. Eng. Div., ASCE, Vol. 105, No. GT5, 627-641.

Wong, P.K. and Oliveira, D. (2012) Class A Prediction versus

Performance of O-Cell Pile Load Tests in Sydney Sandstone,

Australian Geomechanics

Jnl,. ol 47, No. 3, 89-96.

Sethi, P.L., Geng, I. and Wong, P.K. (2012) Construction of Rock

Socketed Piles in Sydney Sandstone to Meet Performance

Requirements,

Australian Geomechan.

Jnl., Vol 47, No. 3, 97-102.

End Bearing R istance

Maximum mobi i ed resi tance = 59MPa (ultimate end

be rin pressure not re ched)

Little or no creep at an end bearing pressure of 38MPa

(this pressure was held for 30 minutes)

Shaft Resistance

Creep started at an average shaft resistance (over 5.5m

length) of 1.06MPa and was significant at 1.3MPa

The shaft respo se became “plastic” at a movement of

about 30mm, with a corr sponding average shaft

resi tance of 1.74MPa

The O-Cell test results confirmed the ultimate de ign values

adopted for design, an as in Case Stu y 1, dem nstrated that

sig ificantly high r serviceability end bearing pressure could be

considered in the design of rock sock ted piles in Sydney rock.

If the presumptive end bearing pressure given in Table 2 for

Class I and II Sandston w s a opte , the serviceability end

bearing resistance would have b en limited to 12MPa. The O-

Cell test clearly demonstrated that significantly higher

serviceability end bearing could be adopted, provided the base

of the r ck socket is adequately cleaned. The pile construction

aspect of this case study to ensure adequate rock socket

roughness and base cl anliness i described in Sethi et al

(2012). However, it should also e stressed that under

serviceability loading, a large proportion of the applied load

may be carried by the pile shaft depending on the length to

diameter r tio of the r ck socket. Therefore, the use of

excessively high serviceability end bearing pressure may not be

warrant d. A detailed assessment of the rock-socket load-

deformation response is necessary for each specific case.

In the above case study, the non-linear load-deformation

behavior observed from the O-Cell test is of particular interest.

Using the back-analyzed test results, and by close inspection of

the load-deformation behavior of both the shaft and base, it was

possible to deduce the operating secant modulus of the rock

socket material at various mobilized base and shaft resistance as

shown in Figures 6 and 7.

Figure 6. Deduced Secant Modulus of Rock below Pile Base

Figure 7. Deduced Secant Modulus of Rock around Pile Shaft

It can e seen from Figure 6 that there was a rapid drop in

the inferred secant modulus of the rock below the pile base

when a base pressure of 5MPa was reached, and remained at

approximately 1.6GPa to 1.7GPa until a base pressure of

14MPa was reached. Above this pressure, the inferred secant

modulus continued to drop steadily and reached a value of

modulus beyond a base pressure of 14MPa is considered to be

representative of the actual rock mass behavior.

From Figure 7, it can be seen that the inferred secant

modulus of the rock socket material was initially very high

(over 5GP ), the dropped rapidly to 2.5GPa at an average shaft

resistance of 0.4MPa, then continued to drop steadil to 1.2GPa

at a mobilized shaft resistance of 1.2MPa. Comparing th se

results with the non-linear function to describe the secant

modulus adopted for design as shown in Table 3, it may be

conclud d that different initial rock modulus sh uld be applied

to describe the base and haft esponse. However, for simplicity

of design, and considering the operating stresses at the

serviceability loads for the piles on this project, it was

concluded that an initial tangent modulus value of 2GPa would

still be appropriate for the Class II Sandston if the hyperbolic

pile base and shaft fac ors, R

fb

a d R

fs

( ee Table 3), were

modified to 0.55 and 0.8 respect ve y. These v lues correspond

to secant modulus values of approximately:

Pile Base Response – 1.7GPa and 1.2GPa for the rock

below the pile base, for end bearing pressures of

14MPa and 30MPa respectively, and

Pile Shaft Response – 1.8GPa and 1.2GPa for the rock

around the pile shaft for shaft resistance of 0.4MPa

and 1.2MPa respectively.

However, these changes would only make v ry small cha ge

(≤ 3mm) to settlement prediction values at se vic ability

loading. Therefore, t e original design paramet rs were

adopt d without changes for subs quent designs.

Supp rted by the O-C ll pile load test n , significant

reduction in pile lengths and cost savings were achieve for this

project as a r sult of the load-deformation analyses and

performanc based design carried out.

4 CONCLUSIONS

Other than very weak to weak rock, socketed pile esign is

generally governed by serviceability requirements rathe than

ultimate capacity. In such circumstances, economy pile esigns

can be achieved if accurate predictions of load-deformation

behavior of the piles are made, rather than adopting recipe style

presumptive values. Pile load testing should be carried out for

such performance based desig method.

Two cas studies of rock s cketed pile d sign a d pile load

testing have been presented in this paper, both of which clearly

illu trated the advantages of this performance based design

approach, with significant cost savings in foundation works.

The use of the O-Cell testing method in Case Study 2

demonstrated the non-linear nature of high strength rock

commonly encountered in the Sydney area of Australia.

5 REFERENCES

Pells P.J.N., D uglas D.J., Rodway, B., Thor e, C.P. and McMahon,

B.R. (1978) Design Loading for Foundations on Shale and

Sandstone in the Sydney Region,

Australian Geomech ics.

Jnl. Vol.

8, 31-39.

Pells P.J.N., Mostyn G., and Walker, B F. (1998) Foundations on

Sandstone and Shale in the Sydney Region,

Australian

Geomechnics

. Jnl. No. 33 Part 3, 17-29.

Poulos, H.G. (1979) Settlement of Single Piles in Non-homogenous

Soil, Jnl. Geot. Eng. Div., ASCE, Vol. 105, No. GT5, 627-641.

Wong, P.K. and Oliveira, D. (2012) Class A Prediction versus

Performance of O-Cell Pile Load Tests in Sydney Sandstone,

Australian Geomechanics

Jnl,. Vol 47, No. 3, 89-96.

Sethi, P.L., Geng, I. and Wong, P.K. (2012) Construction of Rock

End Bearing Resistance

Maximum mobilised resistance = 59MPa (ultimate end

bearing pressure not reached)

Little r no creep at an end bearing pressure of 38MPa

(this pressure was held for 30 minutes)

Sh ft Resistance

Creep started at an average shaft resistance (over 5.5m

length) of 1.06MPa and was significant at 1.3MPa

The shaft response became “plastic” at a movement of

about 30mm, wi h a corr sp di g ver ge shaft

resistance of 1.74MPa

The O-Cell test r sul s confirmed the ultimate esign values

adopted for design, and as in Ca e S udy 1, demonstrat d that

significantly higher serviceability end bearing pressur ould be

consider d in the desi n of ock socket d piles in Sydney rock.

If the presumptive end bearing pressur g ven in Tab 2 for

Class I and II Sandstone was a opted, the s rviceability nd

b aring resistance would have b en limited to 12MPa. The O-

Cell test clearly demon trated that signifi antly higher

serviceability end bearing could be adopte , prov ded the base

of the rock socket is dequately cl a ed. The pile construction

aspect f this case study to ensur adequate rock sock t

roughness and base cleanliness is described in Sethi et al

(2012). However, it should als be stressed th t under

serviceability loading, a large proportion of the applied load

may be c rried by the pile shaft epending on the length to

diameter ratio of the rock socket. Therefore, the use of

excessively high serviceability end bearing pressure may not be

warranted. A etailed assessment of the rock-socket load-

deformation response is necessary for each specific case.

In the above case study, the non-linear load-deformation

behavior observed from the O-Cell test is of particular interest.

Using the back-analyzed test results, and by close inspection of

the load-deformation behavior of both the shaft and base, it was

possible to deduce the operating secant modulus of the rock

socket material at various mobilized base and shaft resistance as

shown in Figures 6 and 7.

Figure 6. Deduced Secant Modulus of Rock below Pile Base

Figure 7. Deduced Secant Mod lus of Rock around Pile Shaft

m dulus eyond base pr ssure of 14MPa is considered to be

repres ntative of the actual rock mass behavior.

From F gure 7, it can be seen that t e inferred secant

m dulus of the rock socket material was initially very high

(over 5GPa), th n dropped rapidly to 2.5GP at an average shaft

resistance of 0.4MPa, then continued to drop t dily to 1.2GPa

at mobilized shaft resistanc of 1.2MPa. Comparing these

results with the no -linear function o describe the secant

modulus adopted for design as shown in Table 3 it may be

concluded that diff rent initial rock modulus should b applied

to des ribe the base and shaft response. However, for simplicity

of design, and considering the operating stresses at the

serviceability loads for the piles on this project, it was

concluded that an initial tangent modulus value of 2GPa would

still be appropriate for the Class II Sandstone if the hyperbolic

pile base and shaft factors, R

fb

and R

fs

(see Table 3), were

modified to 0.55 and 0.8 respectively. These values correspond

to secant modulus values of approximately:

Pile Base Response – 1.7GPa and 1.2GPa for the rock

below the pile base, for end bear ng pressures of

14MPa and 30MPa respectively, and

Pile Shaft Response – 1.8GPa and 1.2GPa for the rock

around the pile shaft for shaft resistance of 0.4MPa

and 1.2MPa respectively.

However, these changes would only make very small change

(≤ 3mm) to settlement pr diction values at serviceability

loading. Therefore, the o igi al design parameters were

ad pted without changes for subsequent designs.

Supported by the O-Cell pile load testing, significant

reduction in pile lengths and cost savings were achieved for this

project as a result of the load-deformation analyses and

performance based design carried out.

4 CONCLUSIONS

Othe than very weak to weak rock, socketed pile design is

generally governed by serviceability requirements rather than

ulti ate capacity. In such circumstances, economy pile designs

can be achi ved if accura e pre ictions of load-deformation

behavior of the piles are made, rather than adopting recipe style

presumptive values. Pile load testing should be carried out for

such performance based design method.

Tw case studie of rock socketed pile design a pile load

testing have b en prese ted in this paper, both of which clearly

illustrated the adv ntages of this performance based design

approach, with significant cost savings in foundation works.

The use of the O-Cell testing method in Case Study 2

demonstrated the non-linear nature of high strength rock

commonly encountered in the Sydney area of Australia.

5 REFERENCES

Pells P.J.N., Douglas D.J., Rodway, B., Thorne, C.P. and McMahon,

B.R. (1978) Design Loading for Foundations on Shale and

End Bearing Resistance

Maximum mobilised resistance = 59MPa (ultimate end

bearing pressur not reached)

Little or no creep at an end bearing pressure of 38MPa

(this pressure was h ld for 30 minutes)

Shaft Resistance

Creep started at an average shaft resistance (over 5.5m

length) of 1.06MPa and was significant at 1.3MPa

The shaft response became “plastic” at a movement of

about 30mm, with a corresponding averag shaft

resistance of 1.74MPa

The O-Cell test results confirmed the ultimate design values

adopted for design, and as in Case Study 1, demonstrated that

significantly higher service bility end bearing pressure could be

considered in the design of rock socketed piles in Sydney rock.

If the presum tive nd bearing pr sure given in Table 2 for

Class I and II Sandstone was a opted, the serviceability end

bearing resistance would have been limited to 12MPa. The O-

Cell test clearly demonstrated that significantly higher

serviceability end bearing could be adopted, provided t e base

of the rock socket is adequately cleaned. The pile construction

aspect of this case study to ensure adequate rock socket

roughness and base cleanliness is described in Sethi et al

(2012). However, it should also be stressed that under

serviceability loading, a large proportion of the applied load

may be carried by the pile shaft depe ding on the length to

diameter ratio of the rock socket. Therefore, the use of

excessively high serviceability end bearing pressure may not be

warranted. A detailed assessment of the rock-socket load-

deformation response is necessary for each specific case.

In the above case study, the non-linear load-deformation

behavior observed from the O-Cell test is of particular interest.

Using the back-analyzed test results, and by close inspection of

the load-deformation behavior of both the shaft and base, it was

possible to deduce the operating secant modulus of the rock

socket material at various mobilized base and shaft resistance as

shown in Figures 6 and 7.

Figure 6. Deduced Secant Modulus of Rock below Pile Base

Figure 7. Deduced Secant Modulus of Rock around Pile Shaft

It can be seen fro Figure 6 that there was a rapid drop in

the inferred secant odulus of the rock below the pile base

when a base pressure of 5MPa was reached, and remained at

approximately 1.6GPa to 1.7GPa until a base pressure of

14MPa was reached. Above this pressure, the inferred secant

modulus continue to drop steadily and reached a value of

1.3GPa at a base pressure of 30MPa. The initial drop in secant

modulus at a base pressure of 5MPa to 14MPa could be

attrib ted to compression of disturbed material or residual

debris at the base of the socket, and the gradual drop of secant

modulus beyond a base pressure of 14MPa is considered to be

representative of the actual rock mass behavior.

From Figure 7, it can be seen that the inferred secant

modulus of the rock socket material was initially very high

( ver 5GPa), then dropped rapidly to 2.5GPa at an average shaft

resistance of 0.4MPa, then continued to drop steadily to 1.2GPa

at a mobilized shaft resistance of 1.2MPa. Comparing these

results with the non-linear function to describe the secant

modulus adopted for design as shown in Table 3, it may be

concluded that different initial rock modulus should be applied

to describe the base and shaft response. However, for sim licity

of design, and considering the operating stresses at the

serviceability loads for the piles on this project, it was

concluded that an initial tangent modulus value of 2GPa would

still be appropriate for the Class II Sandstone if the hyperbolic

pile base and shaft factors, R

fb

and R

fs

(see Table 3), were

modified to 0.55 and 0.8 respectively. These values correspond

t secant modulus values of approximately:

Pile Base Response – 1.7GPa and 1.2GPa for the rock

below the ile base, for end bearing pressures of

14MPa and 30MPa respectively, and

Pile Shaft Response – 1.8GPa and 1.2GPa for the rock

around the pile shaft for shaft resistance of 0.4MPa

and 1.2MPa respectively.

However, these c anges would only make very small changes

(≤ 3mm) to settlement prediction values at serviceability

loading. Therefore, the original design parameters were

adopted without changes for subsequent designs.

Supported by the O-C ll pile load testing, signi icant

reduction in pile lengths and cost savings were achieved for this

project as a result of the load-deformation analyses and

performance based design carried out.

4 CONCLUSIONS

Other than very weak to weak rock, socketed pile design is

generally governed by serviceability requirements rather than

ultimate capacity. In such circumstances, economy pile designs

can be achieved if accurate predictions f load-deformation

behavior of the piles are made, rather than adopting recipe style

presumpt ve values. Pile load testing should be car ied out for

such performa ce based design met od.

Two c se studies of rock socketed pile design and pile load

testing have been presented in this pa er, both of which clearly

illustrated the advantages of this erformance based design

approach, with significant cost savings in foundation works.

The use of the O-Cell testing method in Case Study 2

demonstrated the non-linear nature f high strength rock

commonly encountered in the Sydney area of Australia.

5 REFERENCES

Pells P.J.N., Douglas D.J., Rodway, B., Thorne, C.P. and McMahon,

B.R. (1978) Design Loading for Foundations on Shale and

Sandstone in the Sydney Region,

Australian Geomechnics.

Jnl. Vol.

8, 31-39.

Pells P.J.N., Mostyn G., and Walker, B.F. (1998) Foundations on

Sandstone and Shal in the Sydney Region,

Australian

Geomechnics

. Jnl. N . 33 Part 3, 17-29.

Poulos, H.G. (1979) Settlement of Si gle Piles in Non-homogenous

Soil, Jnl. G ot. Eng. Div., ASCE, Vol. 105, No. GT5, 627-641.

Wong, P.K. and Oliveira, D. (2012) Class A Prediction versus

Performance of O-Cell Pile Load Tests in Sydney Sandstone,

Australian Geomechanics

Jnl,. Vol 47, No. 3, 89-96.

Sethi, P.L., Geng, I. and Wong, P.K. (2012) Construction of Rock

Socketed Piles in Sydney Sandstone to Meet Performance

Requirements,

Australian Geomechan.

Jnl., Vol 47, No. 3, 97-102.