2894

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

different experimental programs were performed to this aim.

Initially, centrifuge model experiments were carried out on

scaled models of helical anchors with different dimensions in

sand, at the “French Institute of Science and Technology for

Transport, Development and Networks” (IFSTTAR) in Nantes,

France, to investigate the variability of the rate of capacity gain

due to the addition of one more helix to a helical anchor.

Considering that the use of helical anchors as tower

foundation has being increased in Brazil, and tropical soils

covers a significant part of the Brazilian territory, the second

experimental program of the present investigation was carried

out at a site of tropical soil, to evaluate the influence of the

helical anchor configuration on the installation torque and on its

uplift capacity.

2 EXPERIMENTS

2.1 Centrifuge testing modeling

A centrifuge model program was performed at the IFSTTAR, in

France, to verify the influence of the diameter and number of

helices on the multi-helix anchor uplift capacity in sand. The

purpose of centrifuge modeling is to reproduce a full-scale

response, with the possibility of comparisons between helical

anchors with different dimensions, as the model anchors were

installed in a uniform sand mass.

Nine small-scale anchor models (Figure 2; Table 1) were

tested in two different samples of dry NE34 Fontainebleau silica

sand (Table 2), with relative densities of 56% (container 1) and

85% (comtainer 2), respectively. The samples were prepared by

the air-pluviation technique in two containers with dimensions

of 1200 mm × 800 mm in plan area and a height of 340 mm.

Figure 2. Photography of the model anchors.

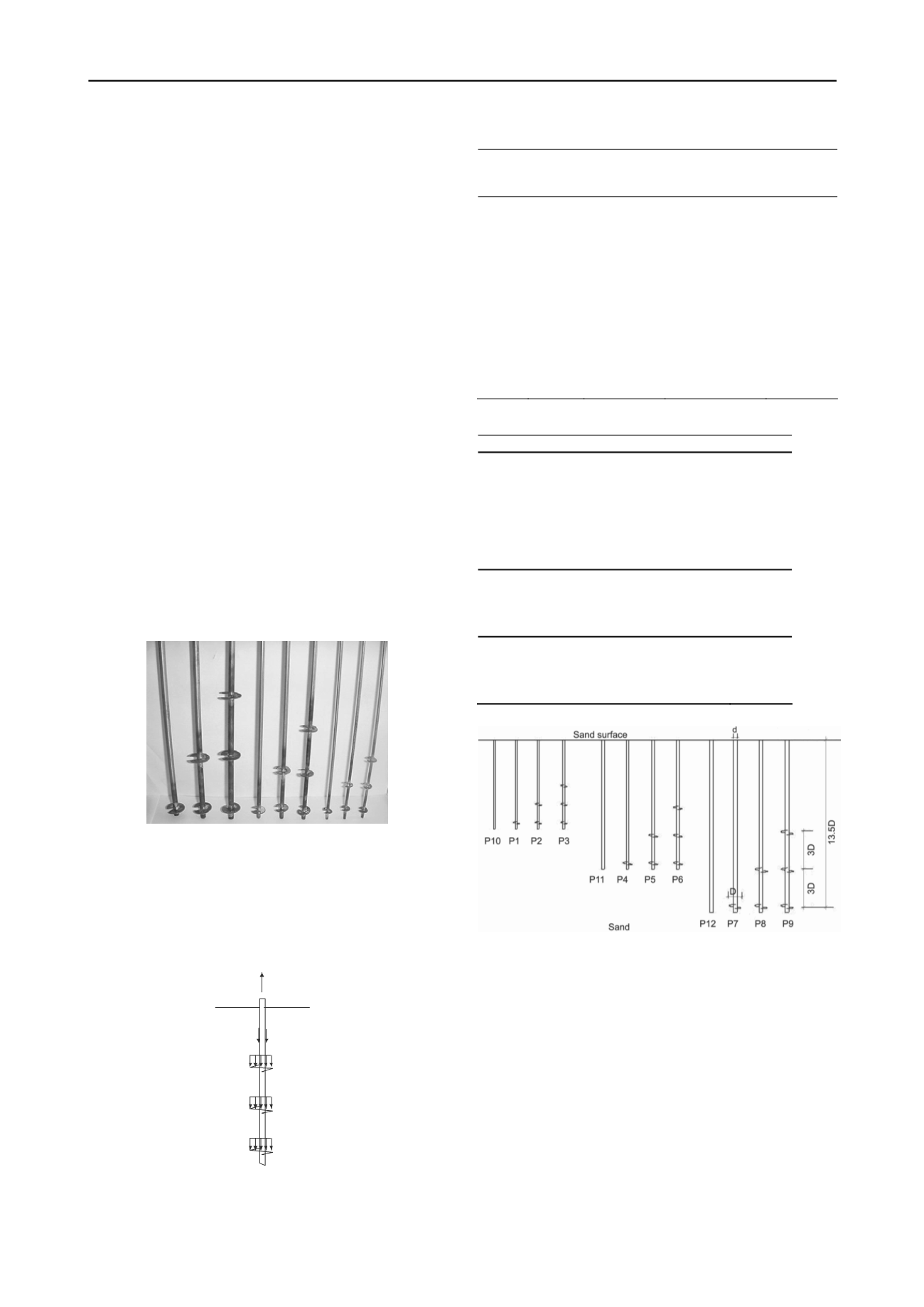

For this investigation, tension load tests were performed on

reduced-scale model piles, without helical plates (P10 to P12),

to separate the shaft resistance, Q

s

, from the total helical anchor

uplift capacity, Q

u

(see Figure 3 and 4). The cylindrical model

anchors (multi-helix with same plate diameter), shown in Figure

2, were fabricated with the spacing between any two helices of

three times the helix diameter.

Q

u

Q

s

Q

h3

Q

h2

Q

h1

sand

Figure 3. Resisting forces to upward movement of a multi-helix anchor

in sand according to the “ individual bearing” failure mechanism.

Table 1. Dimensions of model anchors (M) and prototype anchors (P).

Pile

Nº

of helix

Shaft

diameter

d

M

(d

P

) mm)

Helix

diameter

D

M

(D

P

) (mm)

Prototype

tip depth

(m)

P1

1

3.0(64.3)

10(214)

3.1

P2

2

3.0(64.3)

10(214)

3.1

P3

3

3.0(64.3)

10(214)

3.1

P4

1

4.5(97.7)

15(326)

4.6

P5

2

4.5(97.7)

15(326)

4.6

P6

3

4.5(97.7)

15(326)

4.6

P7

1

6.0(132)

20(440)

6.2

P8

2

6.0(132)

20(440)

6.2

P9

3

6.0(132)

20(440)

6.2

P10

-

3.0(64.3)

10(214)

3.1

P11

-

4.5(97.7)

15(326)

4.6

P12

-

6.0(132)

20(440)

6.2

Table 2. Sand properties.

Property

Value

Unit weight of soil particles (kN/m

3

)

25.90

Maximum dry density (kN/m

3

)

16.68

Minimum dry density (kN/m

3

)

14.13

Maximum void radio

0.834

Minimum void radio

0.550

Maximum porosity

0.455

Minimum porosity

0.355

Container 1

Unit weight (kN/m

3

)

15.46

Density index (%)

56

Friction angle (º )

31

Container 2

Unit weight (kN/m

3

)

16.30

Density index (%)

85

Friction angle (º )

41

Figure 4. Model piles installed in the sand sample.

A total of 18 tensile loading tests were carried out on the

model anchors, nine in the sand container 1, and nine in the

container 2. The model anchors were installed at three different

depths as illustrated in Figure 4. Further details of this

experimental investigation are described in Tsuha et al. (2007).

2.1.1 Results of centrifuge tests

Figure 3 shows examples of load–displacement curves of tensile

tests performed on the model anchors of 214mm helix

(prototype) diameter, installed in the container 2 (denser sand).

The curves of the other loading tests carried out for this

investigation are presented in Tsuha et al. (2012).

From the results of this investigation, the fractions of the

total helix bearing capacity (Q

h

), related to each helical plate of

the double-helix anchors (F

Qhi

= Q

hi

/Q

h

, where Q

hi

is the uplift

helix bearing capacity of helix i), were calculated. The portion

of helix bearing capacity related to the second helix (Qh

2

) of the

double-helix anchors was determined by the difference between