2890

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

technique to ensure the soundness of solidified improved

columns, especially in relation to the dynamic behavior of piles.

Against this background, a large-scale model experiment

was conducted for the purpose of establishing a new design

verification method for composite ground pile foundations. The

experiment focused on the manifestation of horizontal subgrade

reaction (i.e., the feasibility of the elastic subgrade reaction

design method for piles) in particular when the strength and

depth of solidified improved columns were changed.

3 LARGE-SCALE MODEL EXPERIMENT

3.1

Experiment overview

The large-scale model experiment involved static horizontal

cyclic loading tests on piles in composite ground with solidified

improved columns using a laminar shear box (1,200 mm in

width (loading direction) × 800 mm in depth × 1,000 mm in

height) and a 15-tiered shear frame) (Japanese Geotechnical

Society 2010). Photo 1 shows the experimental setup.

The test ground had an upper layer with solidified improved

columns and a lower layer of natural soil to simulate a

composite ground pile foundation. The natural soil was the

sandy type with an

N

value of 10, and was formed with a

compaction water content of w = 5%. The required strength of

the composite ground with solidified improved columns was

achieved using bentonite as the base material and adding early-

strength cement (Public Works Research Center 2004). The test

piles were the point-bearing steel pipe type simulating the actual

scale (pile diameter

D

= 101.6 mm, thickness

t

= 4.2 mm, length

L

= 1,110 mm).

引き側

(

+

)

押し側

(

-

)

In the static horizontal loading experiment, peak-to-peak

alternate loads were applied repeatedly with displacement

controlled. Each loading step was performed three times with

the maximum horizontal displacement of piles at the road

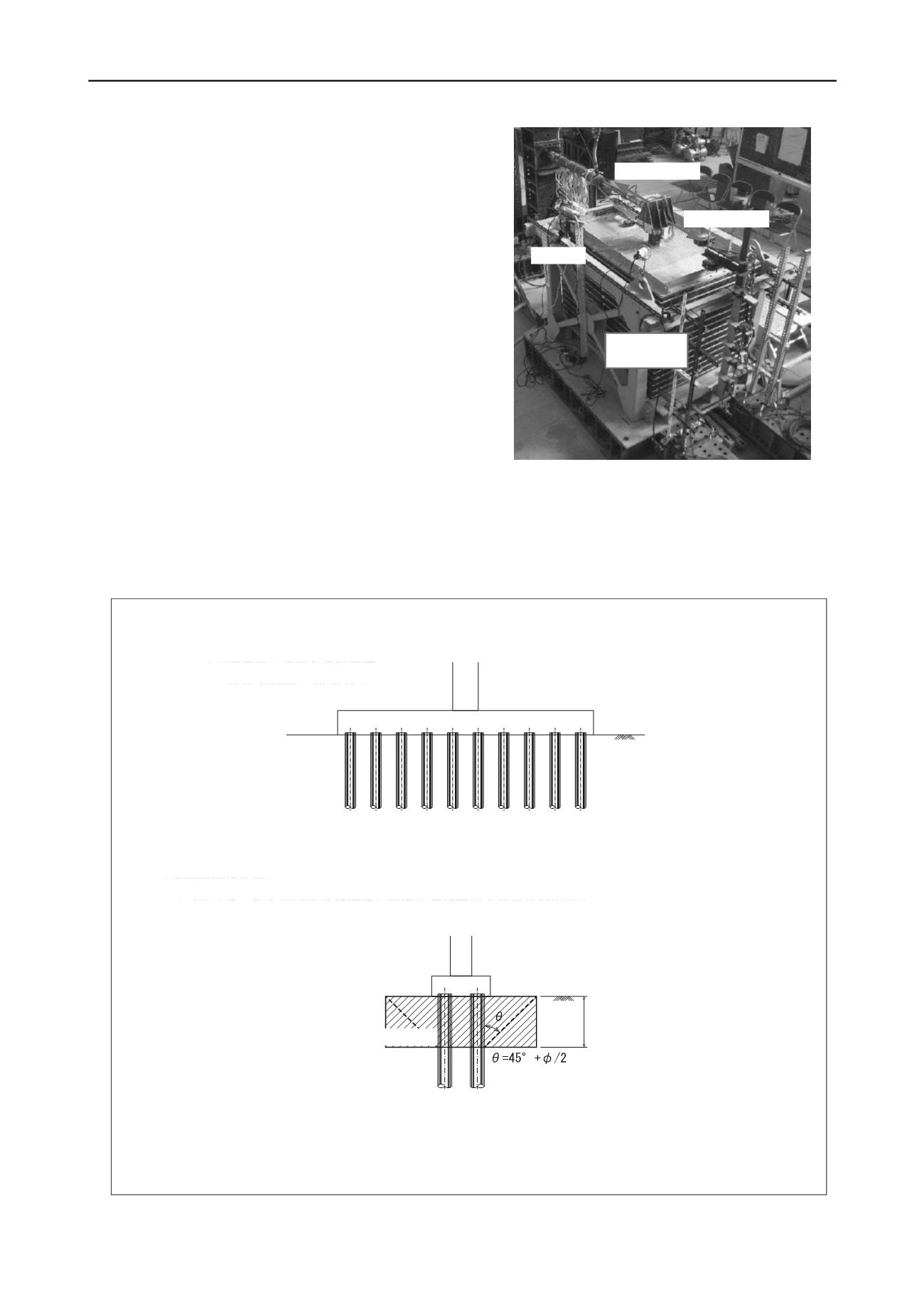

Figure 1. Comparison of the conventional design method for pile foundations in soft ground and composite ground pile foundations

[Conventional design method]

Pile design method for soft ground: Horizontal resistance is insufficient and the foundation is large; the design

method is not feasible.

(Site example) Cast-in-place pile foundation

Pile diameter 1,000 mm / 10 or more rows

Design-related problems: (1) group pile design method, (2) bearing capacity of piles depending on arrangement, (3) bending rigidity of

footing

Problems with other methods: (1) lightweight embankment method: seismic performance; (2) inclined pile foundation: axial force,

bending stress

[Composite ground pile foundation]

Concept: reduction of foundation size and improvement of seismic performance based on the use of piles in

combination with ground improvement

(Site example) Cast-in-place pile foundation

Pile diameter 1,200 mm / 2 or more rows

Solidified improved column

1/

β

or more

Key points of design: (1) composite ground design method, (2) range of 1/

β

or more,

θ

= 45° +

/2), (3) strength:

q

u

= 200 to 500 kN/m

2

Key points of the actual design method:

(1) Normal conditions: elastic subgrade reaction method (sliding/horizontal subgrade reaction verification)

試験杭

せん断土槽

Photo 1. Setup of the large-scale model experiment

Pulling side (+)

Pushing side (-)

Test pile

LAMINAR

SHEAR BOX

(2) During Level-1 earthquake motion: seismic coefficient method (permissible horizontal displacement/cross-sectional force of piles at

the boundary)

(3) During Level-2 earthquake motion: verification of horizontal load bearing capacity during earthquakes (permissible response

ductility), dynamic nonlinear analysis