2886

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

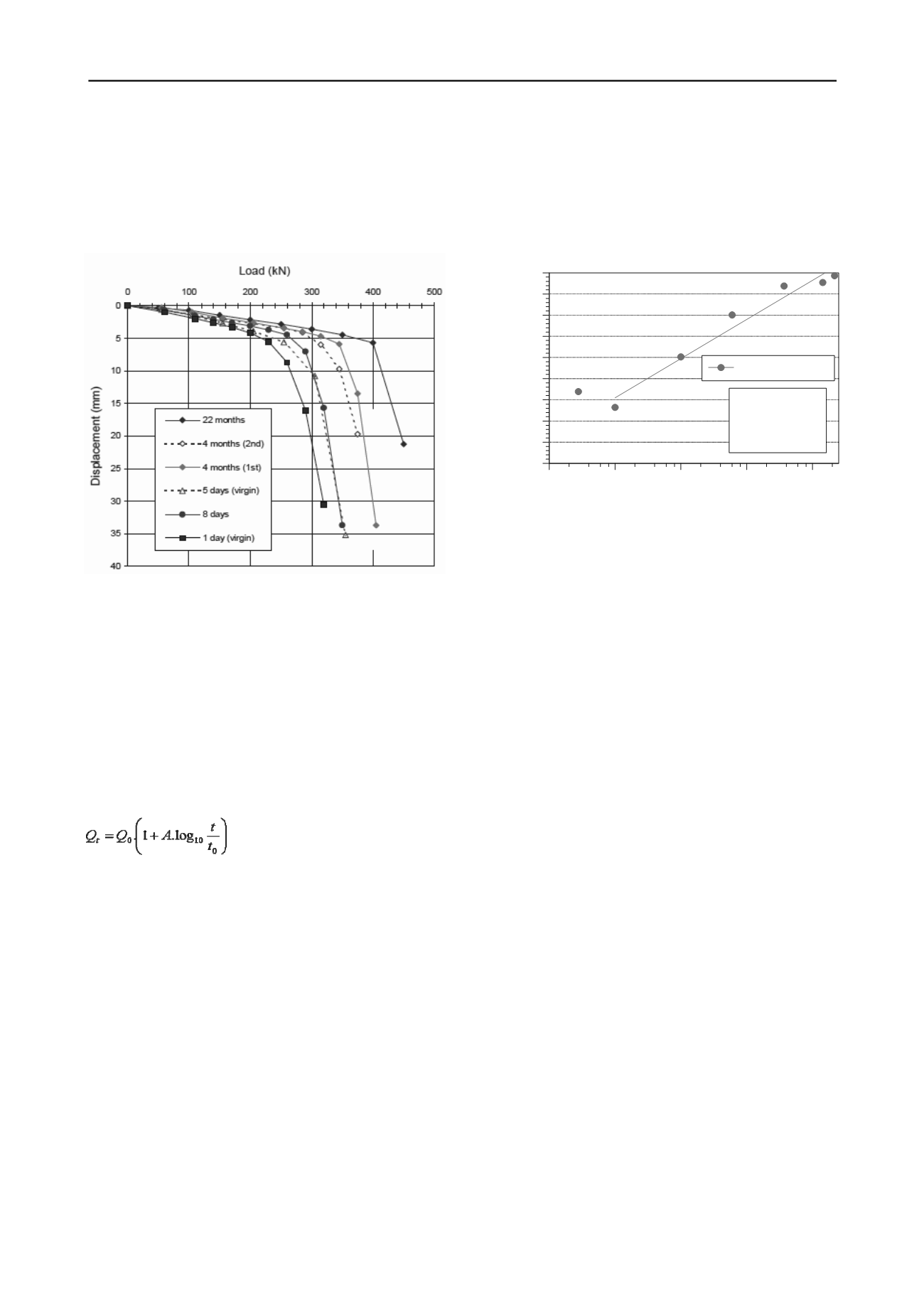

the shaft. Static load tests were conducted 1, 5, 8, 141 and 667

days after the installation of the pile. Figure 2 shows the load-

displacement curves for the load tests. This shows that the total

capacity of the pile increases substantially over time. The

increase in the pile-base capacity is at maximum approximately

10%. The increase in capacity is therefore mainly caused by an

increase in the shaft capacity.

Figure 2. Head displacement, static tests, Axelsson (2000)

This is confirmed by the horizontal effective stress on the

pile shaft. A distinction is made between the horizontal stress on

the pile in loaded and unloaded conditions. The difference

between the contact pressure in loaded and unloaded conditions

is caused by dilatant behaviour. The increase over time of the

horizontal stress during loading is primarily a result of

increasing dilatant behaviour, which indicates a change in

particle structure where the pile and the soil meet (Axelsson,

2000).

The increase in capacity over time is expressed by a range of

authors as an increase with the logarithm of time in line with the

equation below (Skov and Denver, 1988):

(1)

Where:

Q

t

is the pile capacity at time t

Q is the pile capacity at t

0

0

A is a factor – dependent of the type of soil

t

0

is the time for Q

0

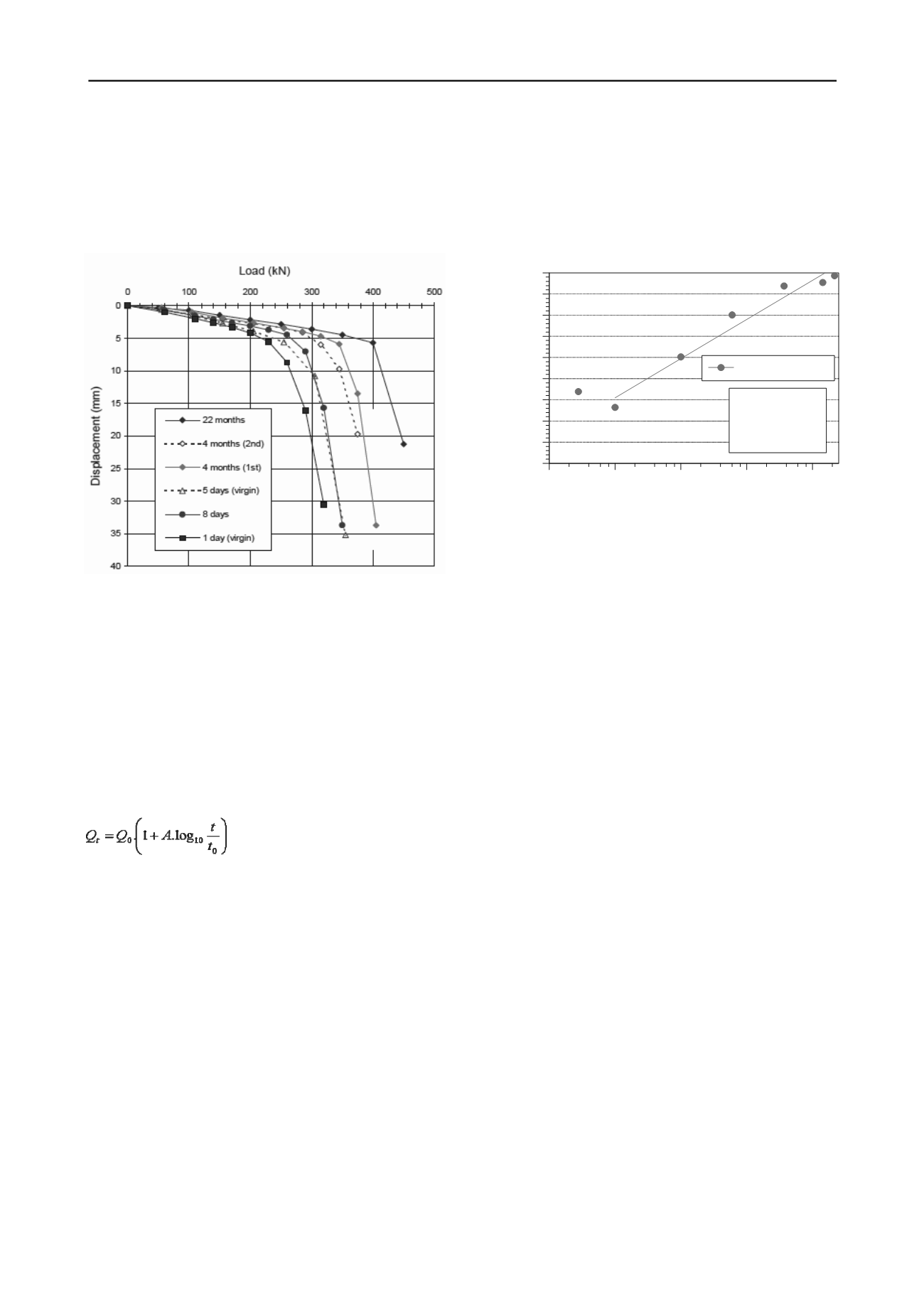

The values for A used in the literature for clay and sand

respectively are 0.6 and 0.2. This means that capacity increases

by 60% per decade in clay and by 20% in sand. The lower limit

generally used for piles in sand is 15%. However, Axelsson's

study stated a much higher value of A=37.5% for a driven

concrete pile in silty sand, see Figure 3.

The literature relating to set-up, the usual term for the

phenomenon of increasing capacity over time, shows that the

following factors are important in determining the set-up level

(Axelsson, 2000; Sobolewsky; 1995, Chow & Jardine, 1997;

Joshi et al., 1995; Baxter & Mitchell, 2004):

•

Relative density and stiffness of the soil: set-up increases

with density

•

Particle-size distribution: set-up in silty sand is higher than

in coarser sand

•

Particle strength: set-up is higher in strong sands

•

Particle structure and form: angular particles result in

higher set-up

•

Soil humidity: very high set-up is observed in unsaturated

sand

•

Stress level: at high stress levels, dilatant behaviour is a

more significant factor

•

Installation process determines the stress conditions after

installation and therefore set-up

•

Diameter of pile: higher set-up with smaller diameter

0

200

400

600

800

1,000

1,200

1,400

1,600

1,800

Capacity (kN)

10

-2

10

-1

10

0

10

1

10

2

time (days)

Axelsson B, 2002

Q = 989 kN

0

A = 0.374

t = 1 day

0

Figure 3. Measurements from Axelsson, 2000, fitted with equation (1)

Before the positive effect of time can be included in the

regulations, the most important of these factors will have to be

investigated. Another important question is the extent to which

the increase in capacity persists after varying loads have been

imposed. A study by Jardine et al. (2006) demonstrated that the

repeated testing of piles in sand resulted in lower capacity

measurements than tests on piles that have not been subjected to

loads in the past. Tensile capacity in repeat testing approximates

the trend line of Chow at al. (1997) which corresponds,

according to their findings, with A is approximately 27.5%.

Subsequent research will, then, have to take this into

account, as well as the effects of varying loads.

3 RESIDUAL STRESSES

In loading tests with driven piles, the strain gauges used to

measure the forces in the pile are normally reset to 0 after the

installation of the pile or installed as a string of gauges

cemented into a tube in the pile, also after installation. That

means that any residual stresses present in the pile base (after

pile-driving) are not included in the measurement of the base

capacity in pile load tests. This could explain why the pile-base

capacity in the load tests was low (and lower than the value

resulting from the design rule). However, any increase in the

base capacity resulting from this consideration will be at the

expense of the shaft capacity.

Xu et al. (2008) showed that the residual stress at the pile

base is negligible in the case of piles when penetration is less

than 20D; substantial residual stresses occur only when the

driven depth exceeds 30D in the load-bearing layer. This

phenomenon does not therefore explain the low pile-base

resistance as shown in Figure 1, where the penetration depth of

all the piles is less than 25D.

4 LIMITING – LIMIT VALUES

Another explanation for the lack of problems with the capacity

of driven piles in practice could therefore be that the limit

values prescribed in the Dutch standard (15 MPa for pile-base

resistance and 150 kPa for shaft resistance) are too conservative.

On the basis of a comparison between foreign standards and

research looking at measured pile-base stresses in sand layers

with very high cone resistances, it can be concluded that: