2887

Technical Committee 212 /

Comité technique 212

•

The literature that was examined confirms the current limit

value for base resistance (API, 2007; Foray et al., 1998).

•

The limit value for shaft friction seems to be on the low

side. Higher shaft resistances have been measured and also

approved in other, foreign, standards (Foray et al., 1998;

Bustamente et al., 2009).

5 GROUP EFFECTS

Group effects include both the effect of the installation and the

consequences of the higher load in the ground as a result of the

loading of the piles. Both effects are taken into account when

calculating the capacity of tensile piles according to the Dutch

standard. The installation effect of soil-displacement piles with

factor f1 and the effect of the load (in the case of tensile piles,

this is a negative effect) with factor f2.

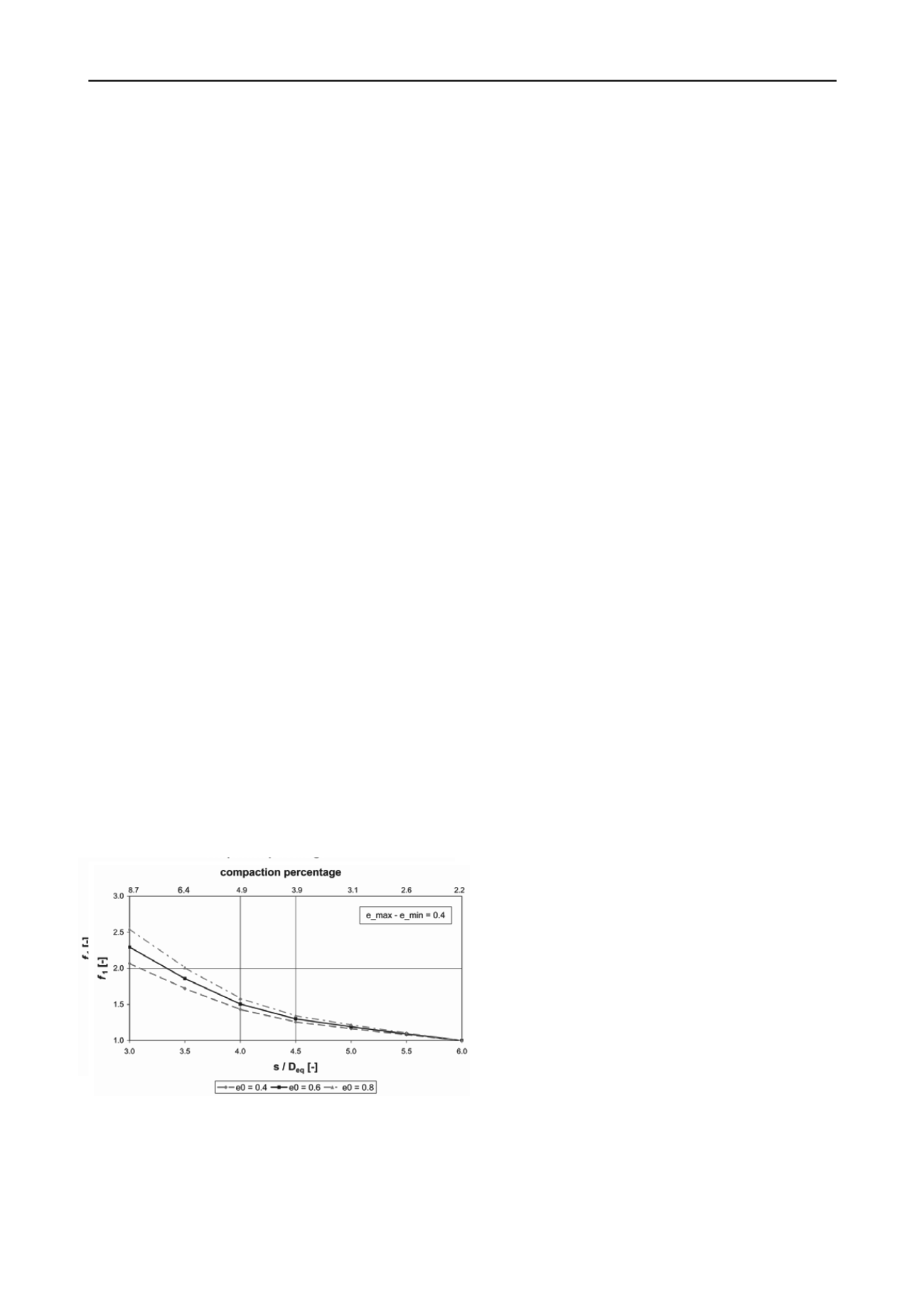

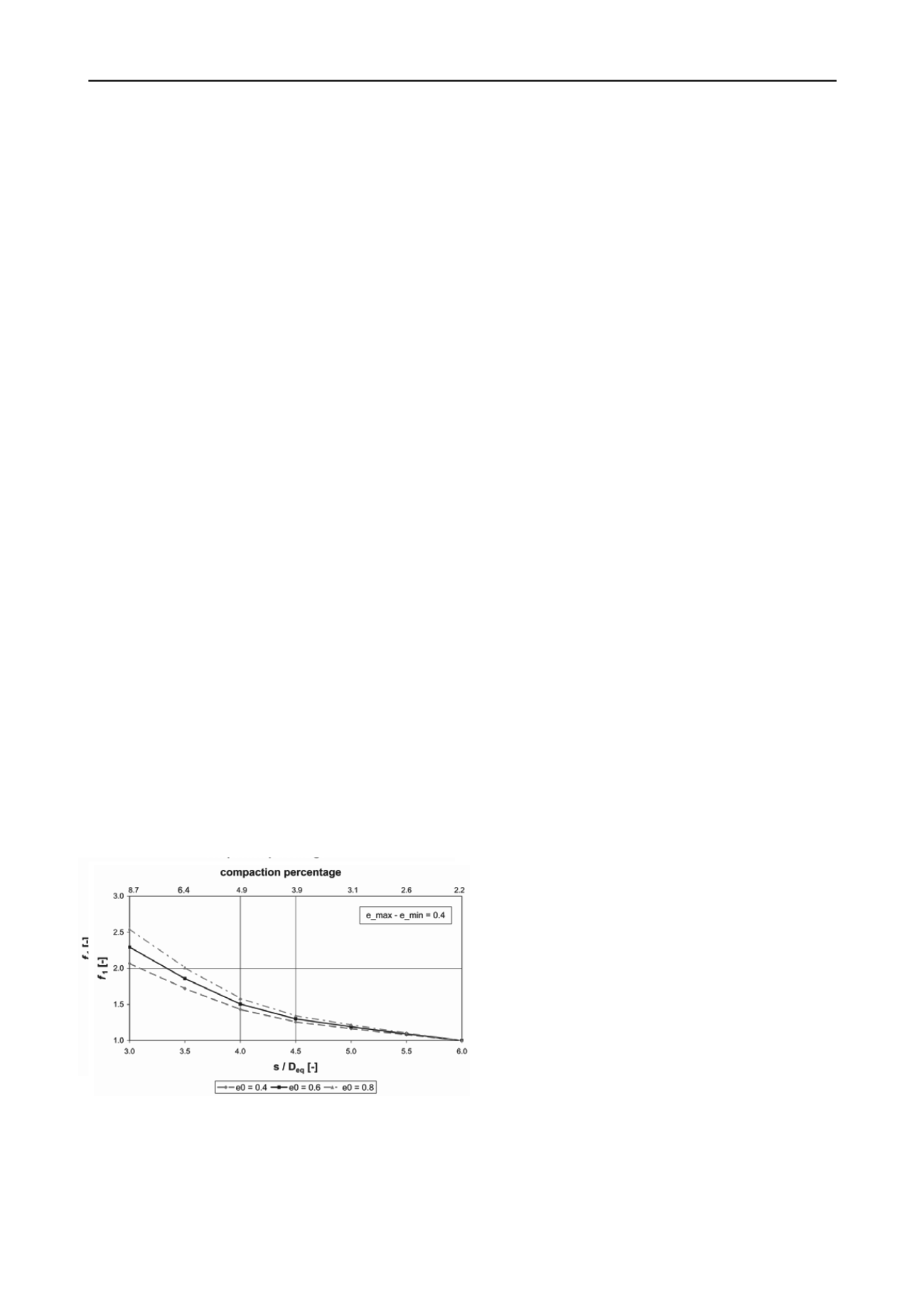

Factor f1 (NEN 9997-1, 2012) is determined by converting

the volume of the piles into compaction combined with an

empirical relationship that, at a constant vertical stress, links

density to cone resistance qc.

Factor f1 is the ratio of increased to initial qc, and it is

included in the Dutch standard calculation method of the shaft

capacity of a tensile pile. In principle, this factor should also be

included when calculating the compressive shaft capacity of

jacked or driven piles. It is under discussion whether

compaction also occurs to this extent below the level of the pile

base and to what depth, and therefore whether this factor can be

included in the calculation of the pile-base capacity. For this

purpose, the depth to which compaction extends must be

determined, as must the effect of the pile-driving sequencing.

Upward pile movement has been noted during the driving of

piles close to piles that have already been installed; the piles in

place move upward. This could have a negative effect on the

pile-base capacity.

The compaction factor f1 determined as described above

may result in a considerable increase in cone resistance and

consequently of shaft capacity.

Figure 4 shows, for a symmetric pile field, factor f1 as a

function of the centre-to-centre distance between the piles. For a

symmetrical pile field with a centre-to-centre distance s of, for

example, 4Deq, f1 is approximately 1.5, with a small variation

due to differences in initial density. The compaction percentage

expressed as pile surface to total surface is 5% here, which is

not an extreme value.

Figure 4. Compaction factor f

1

for a pile in a symmetrical pile field

The densification was checked in several projects by

conducting CPTs before and after the installation of the

displacement piles, (van Tol & Everts, 2003). It emerged that

the value f1, as determined in NEN 9997-1 (2012) is a safe

estimate of the installation effect; the compaction found in

practice is usually higher than the predicted value. This is

advisable in a design guideline, particularly because any over-

estimate of the effect will only be noticed during the execution

of the work, with all the associated consequences.

It should be pointed out that the actual installation effect

with soil-displacement (driven) piles is much more complex

than in an approach complying with NEN 9997-1 (2012).

•

In addition to compaction, there is also an increase of

stresses. If the initial density is already high, the increase

of stresses will actually be dominant with respect to

compaction.

•

Not the full volume of the pile is involved in compaction;

soil is also moved upwards.

•

In the immediate vicinity of the pile shaft, in stead of

compaction there is also dilatant behaviour. However, in

the immediate vicinity of the shaft, there may also be

relaxation, which is known as “friction fatigue” as a result

of the up-and-down movement of the shaft during the pile-

driving.

•

Particularly in dense sands, crushing occurs, and the

increase of stresses is therefore limited.

The conclusion with respect to the group effect is that, in

principle, the compaction factor f1 can also be used for driven

piles loaded in compression.

The following, more specific, topics must therefore be

studied in more detail related to the factor f1:

•

Does f1 also apply to the pile-base capacity and, if so,

down to what depth below the pile base does compaction

occur and what role is played by pile-driving sequencing?

•

Does f1 also apply to small, highly compact, groups of

piles?

•

Is the value of f1 affected by the properties of the sand

such as particle-size distribution, form, strength and the silt

concentration?

6 WIND LOAD AND NEGATIVE SKIN FRICTION

In the current design approach, wind load is transferred to the

load-bearing sand layer. In the western part of the Netherlands,

where the Pleistocene sand is covered by a thick layer of

Holocene clay and peat layers, piles are subjected to negative

skin friction. The loads generated by negative skin friction can

be very considerable, rising to more than 30% of the total pile

load. Wind load is another major, temporary, component of the

total load, particularly in the case of high-rise buildings. In the

case of piles in which negative skin friction is fully developed,

wind load will initially result in the pile being pushed

downwards, decreasing the amount of negative skin friction. A

number of calculations have been conducted for this

phenomenon using an interaction model. Figure 5 shows a

calculated result for the fluctuation of forces in a pile shaft, first

when the pile is subjected only to a permanent load of 1000 kN

and 550 kN negative skin friction. Then there is an additional

temporary wind load of 600 kN. Negative skin friction drops

from 550 to 300kN. In other words, (550-300) / 600 =

approximately 40% of the wind load is transferred to the upper

Holocene layers.

This factor can therefore certainly not be neglected and, in

this case, represents a concealed safety factor in current design

practice.

However, it should be kept in mind that wind load makes a

significant contribution only when the height of the building

exceeds 40 m. The contribution in the total load in that case is

approximately 10% (so much smaller than in the example of

figure 5). This means that the wind load transferred to the upper

layers is therefore only a concealed safety factor in specific

conditions of high buildings.

•

The literature that was examined confirms the current limit

value for base resistance (API, 2007; Foray et al., 1998).

•

The limit value for shaft friction seems to be on the low

side. Higher shaft resistances have been measured and also

approved in other, foreign, standards (Foray et al., 1998;

Bustamente et al., 2009).

5 GROUP EFFECTS

Group effects include both the effect of the installation and the

consequences of the higher load in the ground as a result of the

loading of the piles. Both effects are taken into account when

calculating the capacity of tensile piles according to the Dutch

standard. The installation effect of soil-displacement piles with

factor f1 and the effect of the load (in the case of tensile piles,

this is a negative effect) with factor f2.

Factor f1 (NEN 9997-1, 2012) is determined by converting

the volume of the piles into compaction combined with an

empirical relationship that, at a constant vertical stress, links

density to cone resistance qc.

Factor f1 is the ratio of increased to initial qc, and it is

included in the Dutch standard calculation method of the shaft

capacity of a tensile pile. In principle, this factor should also be

included when calculating the compressive shaft capacity of

jacked or driven piles. It is under discussion whether

compaction also occurs to this extent below the level of the pile

base and to what depth, and therefore whether this factor can be

included in the calculation of the pile-base capacity. For this

purpose, the depth to which compaction extends must be

determined, as must the effect of the pile-driving sequencing.

Upward pile movement has been noted during the driving of

piles close to piles that have already been installed; the piles in

place move upward. This could have a negative effect on the

pile-base capacity.

The compaction factor f1 determined as described above

may result in a considerable increase in cone resistance and

consequently of shaft capacity.

Figure 4 shows, for a symmetric pile field, factor f1 as a

function of the centre-to-centre distance between the piles. For a

symmetrical pile field with a centre-to-centre distance s of, for

example, 4Deq, f1 is approximately 1.5, with a small variation

due to differences in initial density. The compaction percentage

expressed as pile surface to total surface is 5% here, which is

not an extreme value.

Figure 4. Compaction factor f

1

for a pile in a symmetrical pile field

The densification was checked in several projects by

conducting CPTs before and after the installation of the

displacement piles, (van Tol & Everts, 2003). It emerged that

the value f1, as determined in NEN 9997-1 (2012) is a safe

estimate of the installation effect; the compaction found in

practice is usually higher than the predicted value. This is

advisable in a design guideline, particularly because any over-

estimate of the effect will only be noticed during the execution

of the work, with all the associated consequences.

It should be pointed out that the actual installation effect

with soil-displacement (driven) piles is much more complex

than in an approach complying with NEN 9997-1 (2012).

•

In addition to compaction, there is also an increase of

stresses. If the initial density is already high, the increase

of stresses will actually be dominant with respect to

compaction.

•

Not the full volume of the pile is involved in compaction;

soil is also moved upwards.

•

In the immediate vicinity of the pile shaft, in stead of

compaction there is also dilatant behaviour. However, in

the immediate vicinity of the shaft, there may also be

relaxation, which is known as “friction fatigue” as a result

of the up-and-down movement of the shaft during the pile-

driving.

•

Particularly in dense sands, crushing occurs, and the

increase of stresses is therefore limited.

The conclusion with respect to the group effect is that, in

principle, the compaction factor f1 can also be used for driven

piles loaded in co pression.

The following, more specific, topics must therefore be

studied in more detail related to the factor f1:

•

Does f1 also apply to the pile-base capacity and, if so,

down to what depth below the pile base does compaction

occur and what role is played by pile-driving sequencing?

•

Does f1 also apply to small, highly compact, groups of

piles?

•

Is the value of f1 affected by the properties of the sand

such as particle-size distribution, form, strength and the silt

concentration?

6 WIND LOAD AND NEGATIVE SKIN FRICTION

In the current design approach, wind load is transferred to the

load-bearing sand layer. In the western part of the Netherlands,

where the Pleistocene sand is covered by a thick layer of

Holocene clay and peat layers, piles are subjected to negative

skin friction. The loads generated by negative skin friction can

be very considerable, rising to more than 30% of the total pile

load. Wind load is another major, temporary, component of the

total load, particularly in the case of high-rise buildings. In the

case of piles in which negative skin friction is fully developed,

ind load will initially result in the pile being pushed

downwards, decreasing the amount of negative skin friction. A

number of calculations have been conducted for this

phenomenon using an interaction model. Figure 5 shows a

calculated result for the fluctuation of forces in a pile shaft, first

when the pile is subjected only to a permanent load of 1000 kN

and 550 kN negative skin friction. Then there is an additional

temporary wind load of 600 kN. Negative skin friction drops

from 550 to 300kN. In other words, (550-300) / 600 =

approximately 40% of the wind load is transferred to the upper

Holocene layers.

This factor can therefore certainly not be neglected and, in

this case, represents a concealed safety factor in current design

practice.

However, it should be kept in mind that wind load makes a

significant contribution only when the height of the building

exceeds 40 m. The contribution in the total load in that case is

approximately 10% (so much smaller than in the example of

figure 5). This means that the wind load transferred to the upper

layers is therefore only a concealed safety factor in specific

conditions of high buildings.

Bustamente et al., 2009).

5 GROUP EFFECTS

Group effects include both the effect of the installation and the

consequences of the higher load in the ground as a result of the

loading of the piles. Both effects are taken into account when

calculating the capacity of tensile piles according to the Dutch

standard. The installation effect of soil-displacement piles with

factor f1 and the effect of the load (in the case of tensile piles,

this is a negative effect) with factor f2.

Factor f1 (NEN 9997-1, 2012) is determined by converting

the volume of the piles into compaction combined with an

empirical relationship that, at a constant vertical stress, links

density to cone resistance qc.

Factor f1 is the ratio of increased to initial qc, and it is

included in the Dutch standard calculation method of the shaft

capacity of a tensile pile. In principle, this factor should also be

included when calculating the compressive shaft capacity of

jacked or driven piles. It is under discussion whether

compaction also occurs to this extent below the level of the pile

base and to what depth, and therefore whether this factor can be

included in the calculation of the pile-base capacity. For this

purpose, the depth to which compaction extends must be

determined, as must the effect of the pile-driving sequencing.

Upward pile movement has been noted during the driving of

piles close to piles that have already been installed; the piles in

place move upward. This could have a negative effect on the

pile-base capacity.

The compaction factor f1 determined as described above

may result in a considerable increase in cone resistance and

consequently of shaft capacity.

Figure 4 shows, for a symmetric pile field, factor f1 as a

function of the centre-to-centre distance between the piles. For a

symmetrical pile field with a centre-to-centre distance s of, for

example, 4Deq, f1 is approximately 1.5, with a small variation

due to differences in initial density. The compaction percentage

expressed as pile surface to total surface is 5% here, which is

not an extreme value.

Figure 4. Compaction factor f

1

for a pile in a symmetrical pile field

The densification was checked in several projects by

conducting CPTs before and after the installation of the

displacement piles, (van Tol & Everts, 2003). It emerged that

the value f1, as determined in NEN 9997-1 (2012) is a safe

estimate of the installation effect; the compaction found in

practice is usually higher than the predicted value. This is

than in an approach complying with NEN 9997-1 (2012).

•

In addition to compaction, there is also an increase of

stresses. If the initial density is already high, the increase

of s resses will actually be dominant with respect to

compaction.

•

Not the full volume of the pile is involved in compaction;

soil is also moved upwards.

•

In the immediate vicinity of the pile shaft, in stead of

compaction there is also dilatant behaviour. However, in

the immediate vicinity of the shaft, there may also be

relaxation, which is known as “friction fatigue” as a result

of the up-and-down m vement f the shaft during th pile-

driving.

•

Particularly in dense sands, crushing occurs, nd he

increase of stresses is therefore limited.

The conclusion with respect to the group effect is that, in

principle, the compaction factor f1 can also be used for driven

piles loaded in compression.

The following, more specific, topics must therefore be

studied in more detail related to the factor f1:

D es f1 also apply to the pile-ba e capacity and, if so,

d wn to what depth below the pile base does compaction

occur and what role is played by pile-driving equencing?

•

D es f1 also apply to mall, highly compact, groups of

pil s?

•

Is the value of f1 affected by the properties of the s nd

suc as particle-size distribution, form, strength and the silt

concentration?

6 WIND LOAD AND NEGATIVE SKIN FRICTION

In the current desig approach, wind load is transferred to the

load-bearing sand layer. In the western part of th Netherlands,

where the Pleistocene sand is covered by a thick layer of

Holocene clay and peat layers, piles are subjected to negative

skin frictio . The loads g nerated by negative skin friction can

be very c n iderable, rising to mor than 30% of the total pile

load. Wind load is another maj r, em orary, component of the

total load, particularly in the case of high-rise buildings. I the

case of pil in which negative skin friction is fully developed,

wind load will initially result in the pile being pushed

downwards, decreasing the amount of negative skin frictio . A

number of calculations have bee conducted for t is

phenomenon using an interaction model. Figure 5 shows a

calculated result for the fluctuation of forces in a pile shaft, first

when the pile is subjected only to a permanent load of 1000 kN

and 550 kN negative skin friction. Then there is an additional

temporary wind load of 600 kN. Negative skin friction drops

from 550 to 300kN. In other words, (550-300) / 600 =

approximately 40% of the wind load is transferred to the upper

Holocene layers.

This factor can therefore certainly not be neglected and, in

this case, represents a concealed safety factor in current design

practice.

However, it should be kept in mind that wind load makes a

significant contribution only when the height of the building

exceeds 40 m. The contribution in the total load in that case is

approximately 10% (so much smaller than in the example of

figure 5). This means that the wind load transferred to the upper

layers is therefore only a concealed safety factor in specific

conditions of high buildings.