2891

Technical Committee 212 /

Comité technique 212

surface

y

(1) 0.5 mm, (2) 1.0 mm, (3) 2.5 mm and (4) 5.0 mm,

which was set at the time of design to simulate normal and

earthquake conditions.

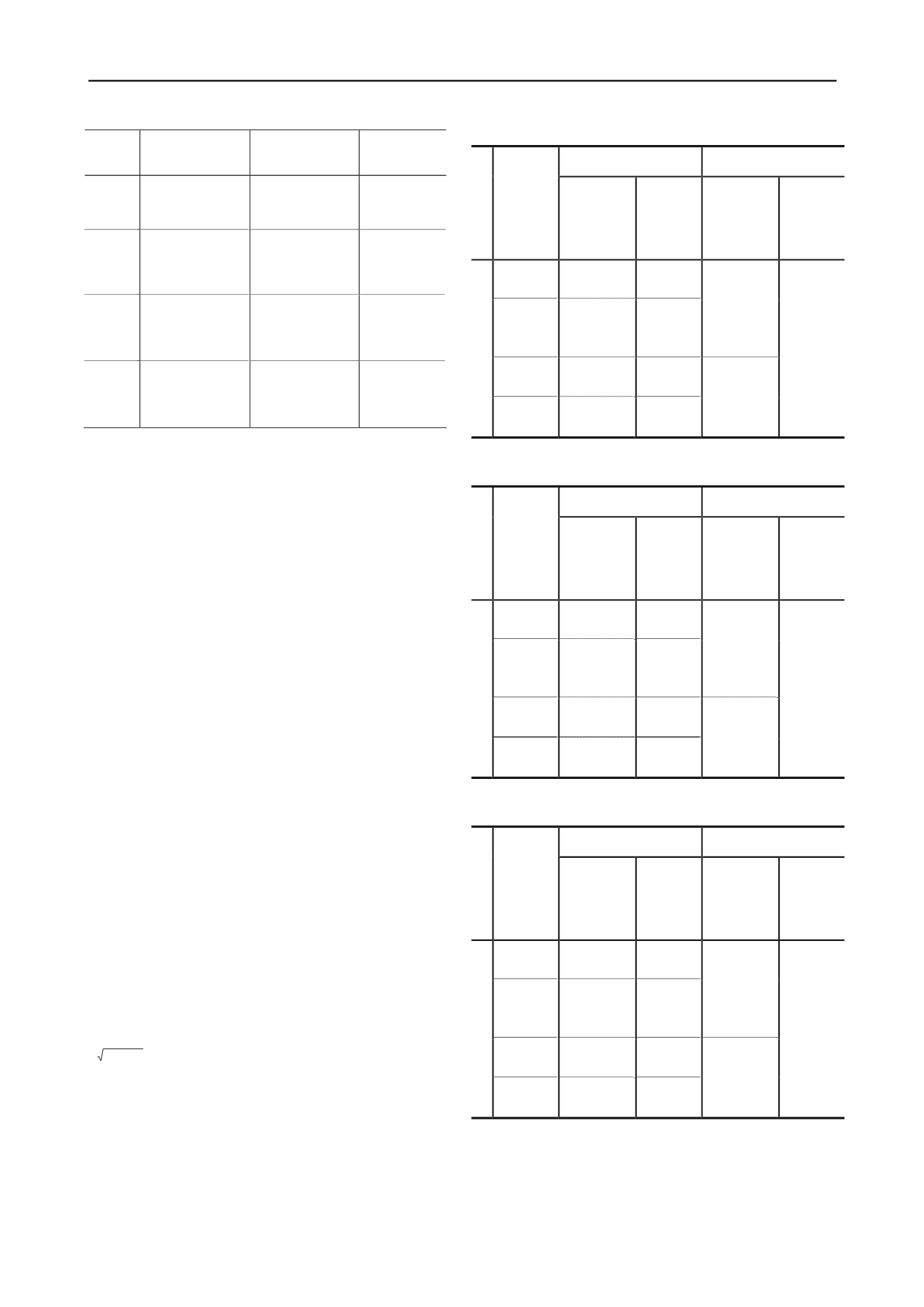

Table 1. Experiment cases

Experiment

case

Ground condition

Unconfined compressive

strength

q

u

(kN/m

2

)

The large-scale part of the model experiment was conducted

for the four cases listed in Table 1. Case 1 involved natural

ground with no improvement and an N value of 10 for the entire

layer. Case 2 involved two-layered ground where the

unconfined compressive strength of the solidified improved

columns in the upper layer qu was close to the standard value of

q

u

= 200 kN/m

2

(223 kN/m

2

in actual strength) and the

improvement depth was 1/

β

= 50 cm in accordance with the

basic design method for composite ground pile foundations.

Case 3 involved two-layered ground where the improvement

depth of solidified improved columns in the upper layer was 1/

β

= 50 cm and the unconfined compressive strength

q

u

was

around 1,000 kN/m

2

(1,440 kN/m

2

in actual strength), which

was about five times as large as that of Case 2 (ratio in actual

strength: 1,440 kN/m

2

/ 223 kN/m

2

≈ 6.5 times). Case 4

involved two-layered ground where the unconfined compressive

strength of solidified improved columns in the upper layer was

similar to that of Case 2 (205 kN/m

2

in actual strength) and the

improvement depth was half (1/2

β

= 25 cm).

3.2

Results of horizontal subgrade reaction experiment

Tables 2 to 4 summarize the experimental results regarding the

horizontal subgrade reaction in Cases 2 to 4 as obtained from

the large-scale model experiment. The actual modulus of

subgrade reaction

k

in the horizontal direction in the table was

found via back-calculation from the basic equation of the elastic

subgrade reaction method for finite piles (Eq. (1)) based on the

H-y relationship at each displacement as found from the static

horizontal cyclic loading experiment (Japan Road Association

2002).

y

= (

C

1

+

C

2

) / (2

EIβ

3

)

(1)

Here,

C

1

and

C

2

are the integral constants of the pile head

fixation condition,

β

is the characteristic value of piles (m

-1

)

β

=

4

,

D

is the pile diameter (m) and

EI

is the pile bending

rigidity (kN/m

2

). The measured horizontal subgrade reaction

P

H

was set as the product of the modulus of subgrade reaction in

the horizontal direction

k

and the displacement of piles at the

ground surface (maximum displacement).

4/) (

EI

kD

The design modulus of subgrade reaction in the horizontal

direction

k’

was calculated as the modulus of deformation

E

for

the solidified improved columns. The design horizontal

subgrade reaction

P

HU

was assumed to be the upper-limit value

of the horizontal subgrade reaction, which is the passive earth

pressure strength of composite ground with solidified improved

columns as calculated using Eq. (2) (Japan Road Association

2002).

p u S

HU

aqa P

(2)

Here,

α

S

is the correction factor for composite ground in

which solidified improved columns are used, and was set as 1.5

as in the calculation for cohesive soil ground in consideration of

related physical properties.

The experiment results were examined as described here.

First, the modulus of the subgrade reaction in the horizontal

Remarks

CASE-1

Entire layer: natural

ground 1.00 m

-

No improved

ground (natural

ground)

CASE-2

Upper layer: solidified

improved columns 0.50

m (= 1/β); lower layer:

natural ground 0.50 m

200

(actual strength: 223)

Standard

strength

CASE-3

Upper layer: solidified

improved columns 0.50

m (= 1/β); lower layer:

natural ground 0.50 m

1000

(actual strength: 1,440)

Varied

improvement

strength

CASE-4

Upper layer: solidified

improved columns 0.25

m (= 1/2β); lower layer:

natural ground 0.75 m

200

(actual strength: 205)

Varied

improvement

depth

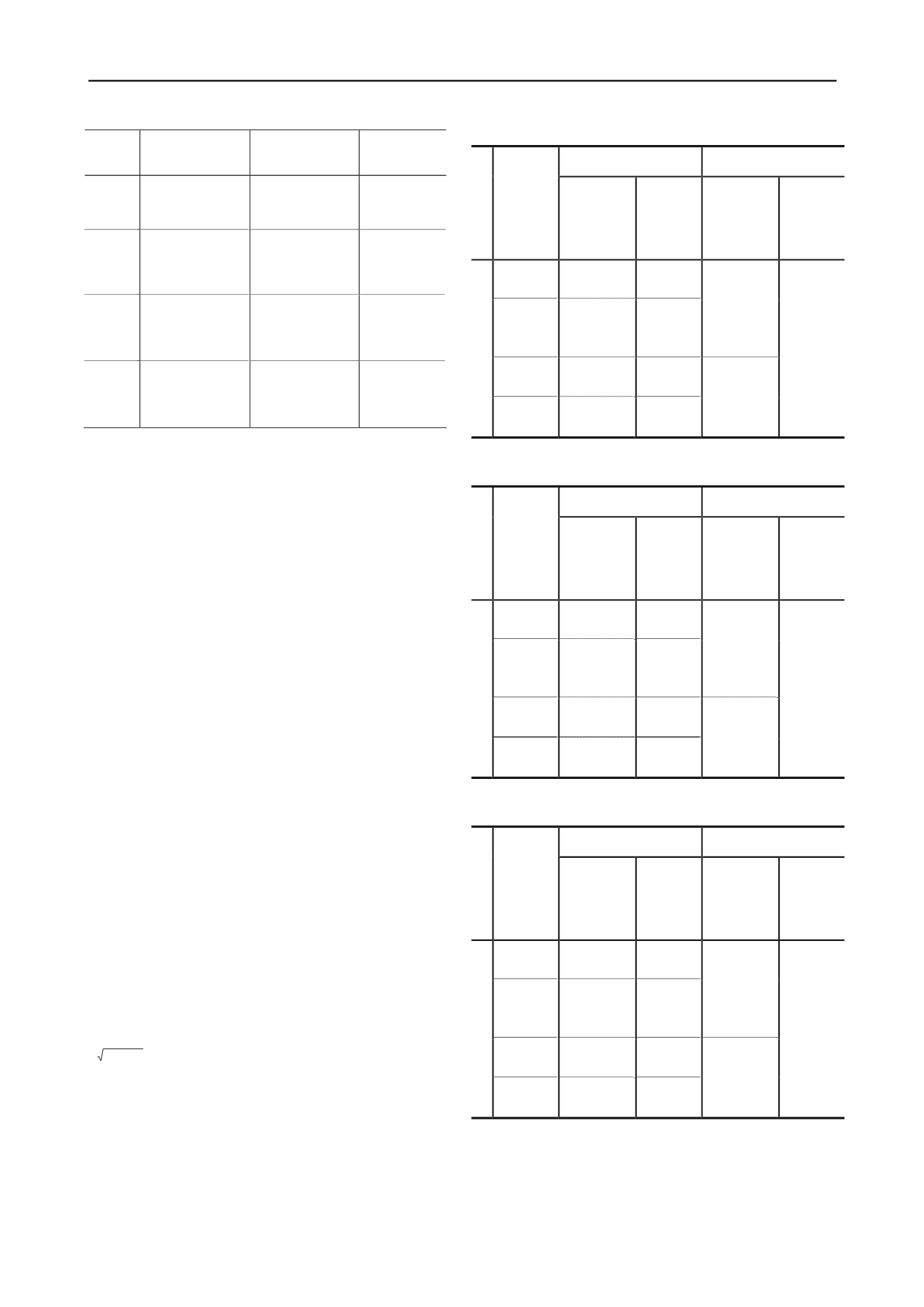

Table 2. Modulus of subgrade reaction in the horizontal direction

k

and

horizontal subgrade reaction

P

H

in Case 2

Experiment value

Design value

Experiment case

Pile displacement at

the ground surface

(ratio to pile diameter)

Modulus of

subgrade reaction

in the horizontal

direction

k

(kN/m

3

)

Horizontal

subgrade

reaction

P

H

(kN/m

2

)

Modulus of

subgrade reaction

in the horizontal

direction

Horizontal

subgrade

reaction

k’

(kN/m

3

)

P

HU

(kN/m

2

)

0.5 [0.5%]

383,466

191.7

1.0 [1.0%]

233,577

233.6

Composite

ground with

solidified

improved

columns

395,642

2.5 [2.5%]

121,290

303.2

CASE-2

5.0 [5.0%]

73,880

369.4

Natural

ground with an

N

value of

around 10

Upper-limit

value for

solidified

improved

columns

110,165

334.5

Table 3. Modulus of subgrade reaction in the horizontal direction

k

and

horizontal subgrade reaction

P

H

in Case 3

Experiment value

Design value

Experiment case

Pile displacement at

the ground surface

(ratio to pile diameter)

Modulus of

subgrade reaction

in the horizontal

direction

k

(kN/m

3

)

Horizontal

subgrade

reaction

P

H

(kN/m

2

)

Modulus of

subgrade reaction

in the horizontal

direction

Horizontal

subgrade

reaction

k’

(kN/m

3

)

P

HU

(kN/m

2

)

0.5 [0.5%] 2,150,363

1,075.2

1.0 [1.0%] 1,056,491

1,056.5

Composite

ground with

solidified

improved

columns

3,098,529

2.5 [2.5%]

412,912

1,032.3

CASE-3

5.0 [5.0%]

202,867

1,014.3

Natural

ground with an

N

value of

around 10

Upper-limit

value for

solidified

improved

columns

110,165

2,160.0

Table 4. Modulus of subgrade reaction in the horizontal direction

k

and

horizontal subgrade reaction

P

H

in Case 4

Experiment value

Design value

Experiment case

Pile displacement at

the ground surface

(ratio to pile diameter)

Modulus of

subgrade reaction

in the horizontal

direction

k

(kN/m

3

)

Horizontal

subgrade

reaction

P

H

(kN/m

2

)

Modulus of

subgrade reaction

in the horizontal

direction

Horizontal

subgrade

reaction

k’

(kN/m

3

)

P

HU

(kN/m

2

)

0.5 [0.5%]

295,440

147.7

1.0 [1.0%]

188,945

188.9

Composite

ground with

solidified

improved

columns

240,555

2.5 [2.5%]

104,641

261.6

CASE-3

5.0 [5.0%]

66,922

334.6

Natural

ground with an

N

value of

around 10

Upper-limit

value for

solidified

improved

columns

307.5

110,165