2899

Technical Committee 212 /

Comité technique 212

300

300

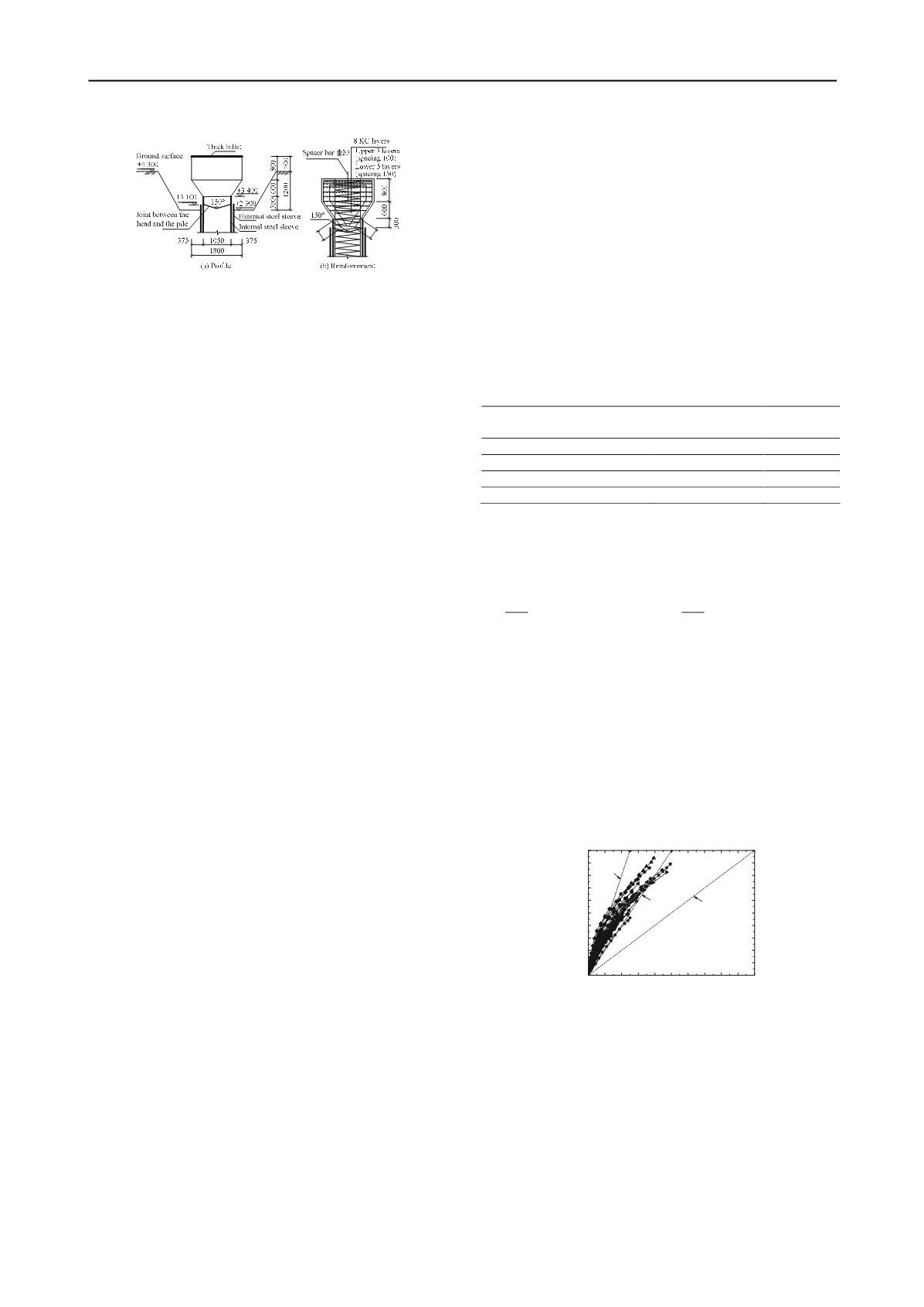

Figure 2 Design schematic diagrams of the test pile head for the

Shanghai Center Tower project

4.3 CONSTRUCTION AND MEASUREMENT

REQUIREMENTS

Practical construction conditions should be simulated in the

construction process of the test piles. Artificial drilling fluid and

desanding device should be used when the borehole is drilled

through the deep sand layers. Vertical deviation of the borehole

should be not more than 1/250. Thickness of the sediment at the

borehole tip should be less than 50mm after the secondary tip

cleaning. If post grouting technique is adopted for the test pile,

the grouting construction parameters should be determined. The

construction machineries, techniques and parameters are also

need to be determined to form a guideline for pile construction.

Measurement items of super-long bored pile load test are

illustrated as follows: (1) Drilling fluid density, viscosity, sand

content and other technical indexes in different depth of the

borehole. These parameters should be continuously monitored

for not less than 36 hours in the construction process. (2)

Concrete quality of the test pile, including pile shaft integrity

and concrete strength. (3) Sediment and grouting effect under

the test pile tip. (4) Ultimate bearing capacity of the test pile. (5)

Pile shaft axial force and pile shaft friction. (6) Pile shaft

deformations, including deformations of pile top, pile tip,

section at the rock surface, and other pile shaft sections under

each load level.

5 SINGLE PILE DESIGN

5.1 PILE ULTIMATE BEARING CAPACITY

The ultimate bearing capacity of super-long bored pile is

determined by filed load test. If the load versus settlement curve

of the test pile shows a slowly change in slope, the load

corresponding to the pile head settlement of 40mm~60mm or

5% of the pile diameter can be used as the ultimate bearing

capacity of the pile. For pile foundation under a condition of

deep excavation, some factors, such as the soils gravity and pile

shaft friction in pit excavation segment and unloading rebound

of the soil at the bottom of the pit, should be concerned to

determine the ultimate bearing capacity of engineering pile

(Wang et al, 2012).

Due to the problems of pile shaft mud and pile tip sediment,

measured values of the ultimate bearing capacities of the normal

super-long bored piles are often lower than the values estimated

by empirical methods. Test results of 10 field test piles from 5

different sites in Shanghai district were collected by the authors.

It illustrates that the ratios of the measured values of the

ultimate bearing capacities of the piles to the values estimated

by empirical method range from 0.5 to 0.97. The average ratio

is 0.69. The pile bearing capacity can be greatly improved by

post grouting technique. Measured data of 28 post grouted piles

from 9 Shanghai project sites indicate that the average ratio of

the measured values of the piles ultimate bearing capacities to

the values estimated by empirical method is 1.32. Therefore, the

post grouting technique should be adopted for super-long bored

piles in deep soft soils.

5.2 PILE SHAFT STRENGTH AND COMPRESSION

Due to the application of the post grouting technique, the

bearing capacities of the foundation soils around the super-long

pile are improved greatly. Therefore, the strength of pile shaft

should match well with the bearing capacities of the foundation

soils in the design of a single pile. The application of high-

strength concrete is helpful to achieve this object. As shown in

Table 2, in order to make the piles shaft strength meet the piles

bearing capacities requirements, Grade C45 and even Grade

C50 concrete were adopted for the foundation piles of several

super high-rise buildings in China. Meanwhile, concrete

strength can be enhanced by the effect of stirrup constraint.

Thus, the spacing of spiral stirrups at the pile top within a scope

of about 3

D

~5

D

(

D

is the pile diameter) should be appropriate

reduced to increase the bearing capacity of pile shaft.

Table 2 Pile shaft strength of several projects in China

Project name

Concrete

strength grade

UCS

(MPa)

Shanghai Center Tower

C50

40.0

Shanghai magnolia square

C45

44.3

Tianjin 117 Tower

C50

59.3

Wuhan Center Tower

C50

54.6

Note:

UCS

is the average unconfined compressive strength of the

concrete drilled from the shaft.

Pile shaft compression is a part of the pile top settlement

deformation. It is often estimated by the following empirical

formula:

0

0

s

e

0

0

p

p

1

L

z

Q L

S

Q d q z dz dz

AE

AE

(1

)

Where

Q

0

is the load applied at pile top;

L

is the pile length;

A

is

the pile section area;

E

p

is the elastic modulus of the pile shaft;

e

is the pile shaft compression coefficient. For friction pile,

e

=1/2~2/3.

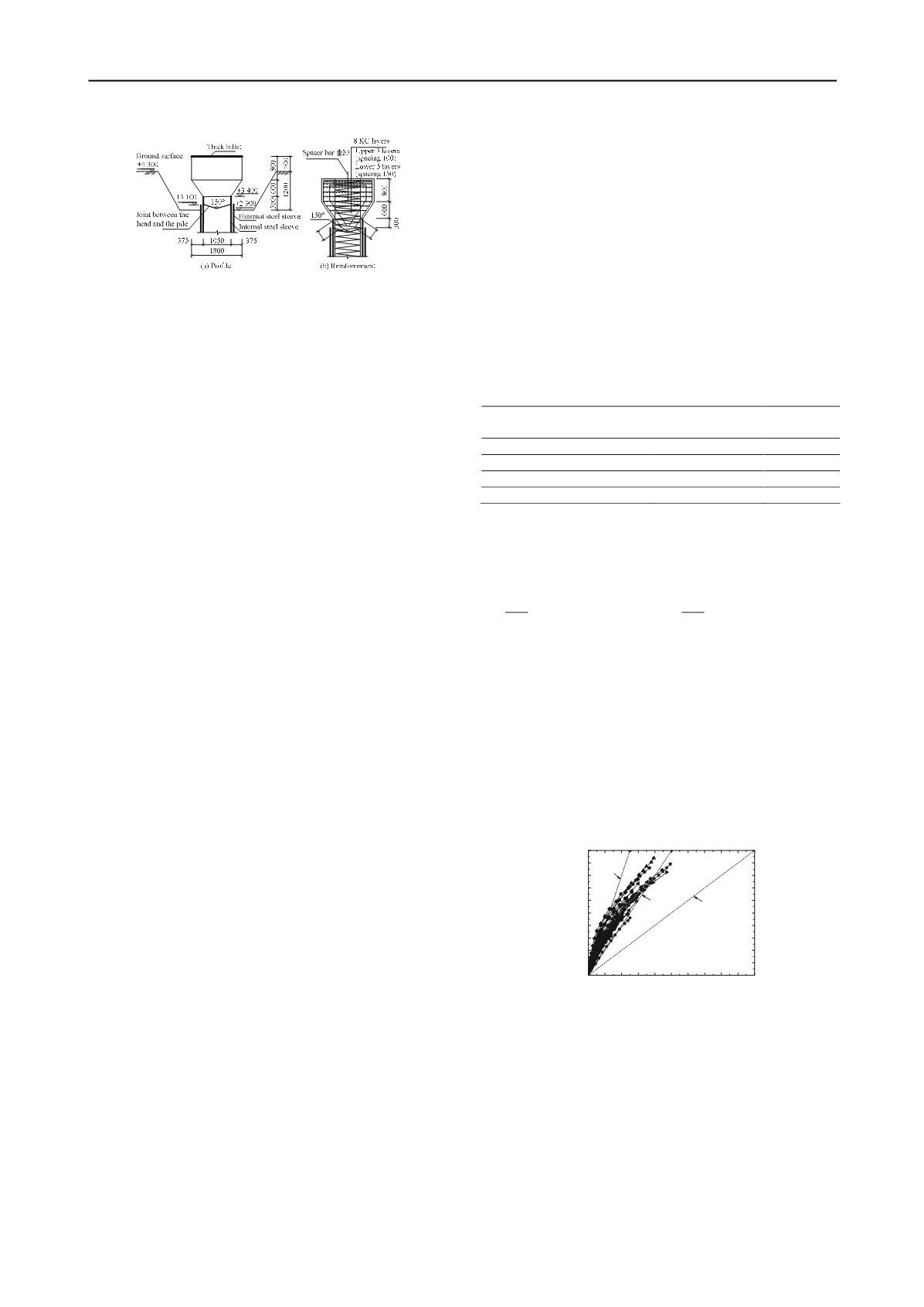

According to measured data of nearly 40 super-long bored

test piles from 15 sites, diagram of the relationship between the

measured values of the pile shaft compression and the

calculated value of

Q

0

L

/

AE

p

was drawn, as shown in Figure 3.

As can be seen from the graph, under the working loads, the pile

shaft compression coefficients are less than 1/2. Therefore, the

value of

e

for calculating super-long bored pile shaft

compression by formula (1) should be not larger than 1/2.

0 10 20 30 40 50 60 70 80 90 100

0

10

20

30

40

50

60

70

80

90

100

e

=1/4

e

=1/2

Q

0

L

/

E

p

A

(mm)

Measured value of pile shaft compression (mm)

e

=1.0

Figure 3 Diagram of the relationship between the measured values of

the pile shaft compression and calculated values of

Q

0

L

/

AE

p

6 PILE FOUNDATION DESIGN

The synergism of the superstructure, foundation soils and pile

foundations should be considered in the design calculation of

pile foundations for super high-rise buildings. According to this,

a practical method for analysis and calculation of the pile

foundation is given in this paper. The theoretical framework and

procedures of this method are illustrated in Figure 4. The

general calculation process is shown in Figure 5.

Design calculation of the pile foundation consists of four

parts, including foundation settlement calculation, bearing

capacity calculation of the grouped piles, bending stress