2900

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

calculation of the raft, punching and shearing capacities

calculation of the raft. The wind and earthquake actions need to

be considered in the process of design calculation of the pile

foundation for high rise building. The following load cases

should be considered in the design. (1) Gravity load (dead load

and live load); (2) Combination of gravity load and wind load;

(3) Combination of gravity load and frequently earthquake load;

(4) Combination of gravity load, wind load and frequently

earthquake load; (5) Combination of gravity load and

fortification intensity earthquake load.

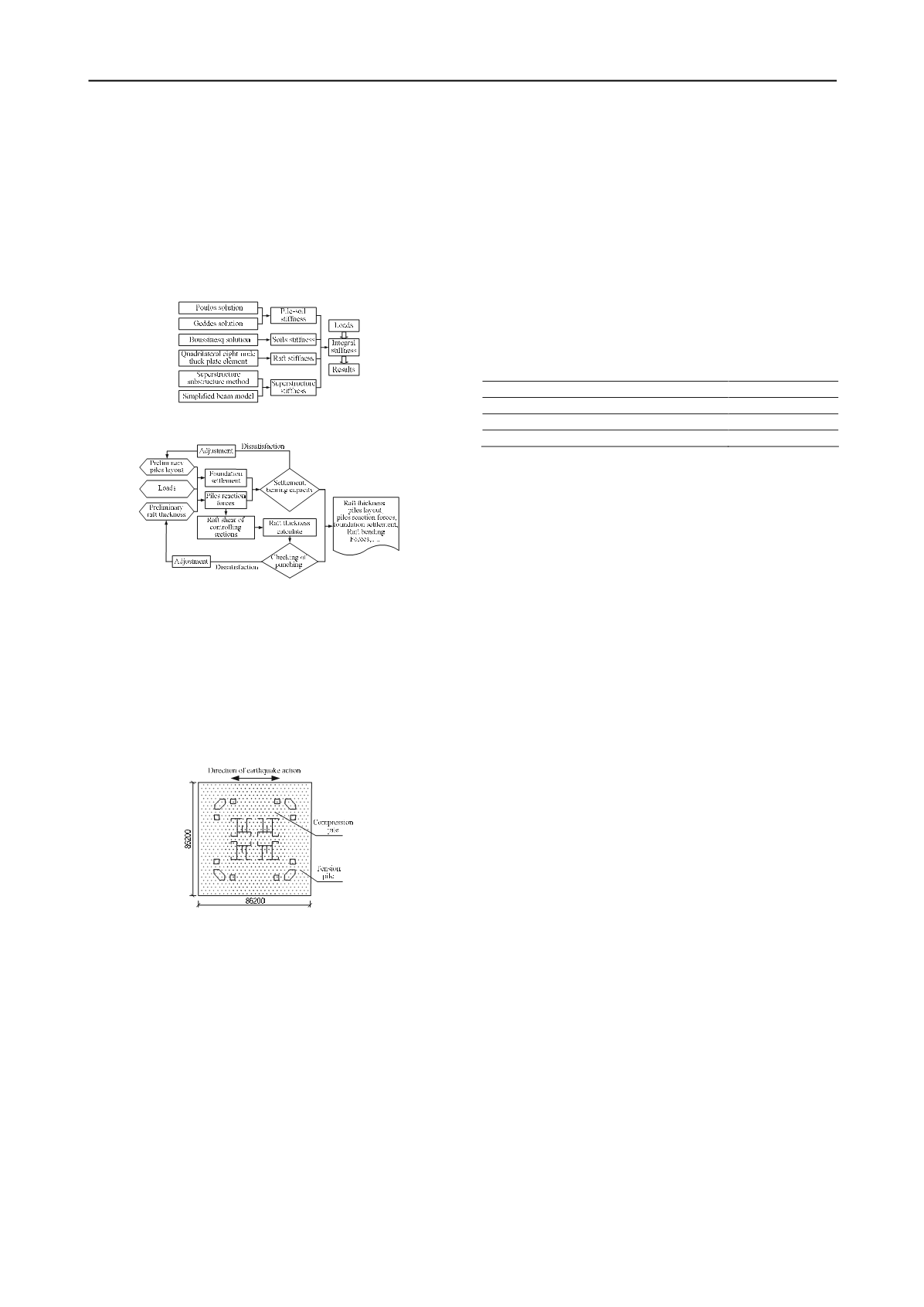

Figure 4 Theoretical framework and procedures of a practical method

for analysis and calculation of pile foundation

Figure 5 A general design calculation process of pile foundation

The lateral forces imposed by wind load and earthquake

action may be very high for super high-rise buildings. When the

eccentric vertical forces caused by wind load and earthquake

action were accounted for in the design calculation process of

the pile foundation, the characteristic value of the vertical

bearing capacities of the piles can be increased about 20% and

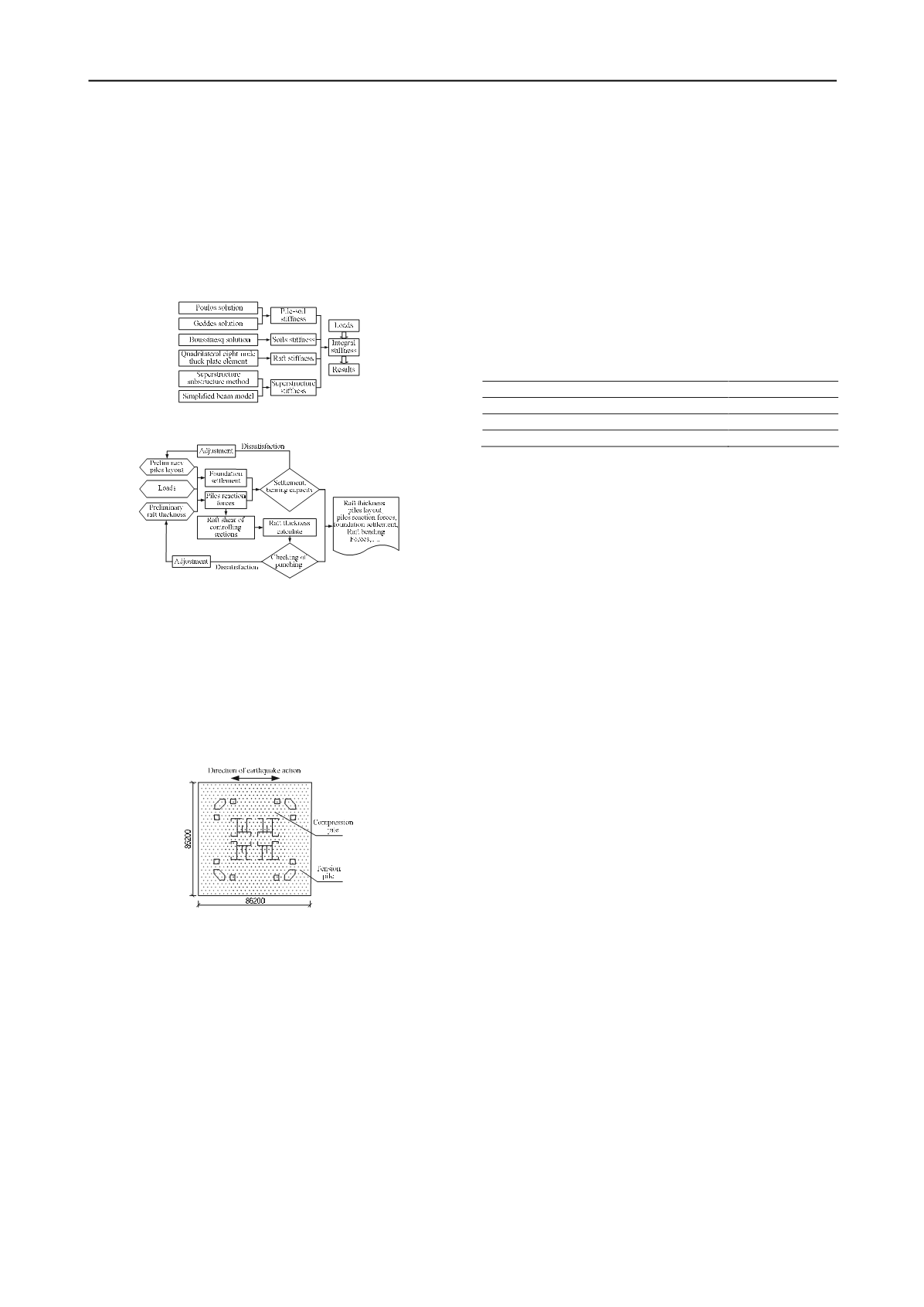

50%, respectively. Moreover, if tension and compression zones

generate in the foundation caused by the action of earthquake,

for example as shown in Figure 6, the tension and compression

bearing capacities of the piles in those zones should be checked.

Figure 6 Distribution of tension and compression zones in the pile

foundation of the Tianjin 117 Tower under the earthquake action

7 KEY CONSTRUCTION TECHNIQUES AND PILE

QUALITY INSPECTION

Suitable drilling machine, techniques and some other auxiliary

measures are key factors for successful construction of super

long bored piles. Slewing drilling machine can be used in soft

soils. But in the hard soils or soft rock layers, the construction

efficiency of rotary drilling rig is higher than that of Slewing

drilling machine. For example, in the Wuhan Tower project,

which site soil stratigraphy consists of some dense slit, sand and

moderately to slightly weathered mud rock within the drilling

depth, about 79 hours were saved to construct a single pile

when the rotary drilling rig was used instead of slewing drilling

machine. Different types of rotary drilling rig bit can be selected

for different soils in the borehole depth range. Different drilling

machines can be combined to drill the boreholes in the

complicated project site. For example, in the Wuhan Green

Land Tower project, the rotary drilling rig was adopted for clay,

sand and intense weathered mud rock layers, while the slightly

weathered mud rock and sand rock were drilled by percussion

drilling machine. In the process of the borehole drilling, sand

content in the drilling fluid should be strictly controlled.

Moreover, the density of the drilling fluid should be increased

appropriately to ensure the stability of the super deep borehole

wall. For example, in the Shanghai Center Tower project, the

boreholes need to be drilled through about 60m thick sand

layers. The indexes of the drilling fluid used in this project are

shown in Table 3. If the borehole is very deep or located in

coarse grained soil layers, the technique of pump suction or air-

lift reverse circulation need to be utilized in the drilling

construction process.

Table 3 Drilling fluid indexes of the Shanghai Center Tower project

index

Value

Density (g/cm

3

)

1.1~1.2

Viscosity (s)

16~20

Sand content (%)

<4

Inspection and controlling standards of super-long bored

piles are stricter than those of ordinary piles. Quality of the piles

should be controlled in the process of construction. The

borehole quality, including depth, diameter, verticality and

sediment, need to be comprehensively inspected. The number of

boreholes to be inspected should be not less than 30% of the

total number of boreholes. The pile shaft quality should be

evaluated mainly by sonic logging and core drilling methods.

The number of piles to be inspected should be larger than 10%

of the total number of engineering piles.

8 CONCLUSIONS

According to a great number of engineering practices of super-

long bored pile foundations for super high-rise buildings in

China, the paper systematically describes some key technical

measures of design and construction of the super-long bored

pile foundation together with a briefly summary of the bearing

behaviors of the super-long bored pile. Post grouting technique

is recommended for the super-long bored pile. Deep buried

solid soils are usually selected for the pile tip bearing stratum.

Application of the double steel sleeves, design of the pile top,

construction and measurement requirements are essential issues

that should be considered in the design of the field load test pile.

Design calculation of the pile foundation should consider the

synergism of the superstructure, soils and pile foundation.

Inspection and controlling standards of super-long bored piles

are stricter than those of ordinary piles. Quality of the piles

should be controlled in the process of construction.

9 REFERENCES

Wang, W.D. Zhu, H.H and Li, Y.L. 2011. Urban geotechnical

engineering and new technology. Chinese Journal of Undergrouond

Space and Engineering, 7(s1): 1274-1291 (in Chinese).

Poulos, H.G. 2009. Tall building and deep foundations-Middle East

challenges. Proceeding of the 17th International Conference on Soil

Mechanics and Geotechnical Engineering, Alexandrie, Egypte,

Volume 4: 3173-3205.

Zhang, Y. and Liu, J.B. 2009. Pile Foundation Handbook, China

Building Industry Press, Beijing (in Chinese).

Wang, W.D., Li, Y.H. and Wu, J.B. 2011. Field loading tests on large-

diameter and super-long bored piles of Shanghai Center Tower.

Chinese Journal of Geotechnical Engineering, 33(12): 1817-1826

(in Chinese).

Wang, W.D., Li, Y.H. and Wu, J.B. 2012. Reply to disscussion on

“

Field loading tests on large-diameter and super-long bored piles of

Shanghai Center Tower

”

. Chinese Journal of Geotechnical

Engineering, 34(6): 1167-1168 (in Chinese).