2898

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

because of the large length and slenderness ratio of the super-

long bored pile, the stiffness of pile-soil system is relative small.

This directly influences the bearing characteristics of the super-

long bored pile. According to the analysis of filed load tests

results (Zhang and Liu, 2009), the basic bearing behaviors of

super-long bored piles can be summarized as follows:

1. The pile load versus settlement curve (

Q

~

s

curve) has no

significant change in slope if sediment under the pile tip is

cleaned up or the pile tip is post grouted.

2. Under the ultimate bearing load, the pile top settlement is

mainly caused by pile shaft compression, especially the

compression of the upper half pile shaft. Moreover, the pile

shaft presents large plastic compression deformation under

very high load.

3. The mobilization of the pile shaft friction is asynchronous. In

other words, the pile shaft friction in the shallow soil layers

is mobilized before that in the deep layers. In the shallow

soil layers, due to the large relative displacement between

the pile shaft and the around soils, the pile shaft friction

usually reaches ultimate value, and is prone to softening. The

mobilization of the pile shaft friction in the deep soil layers

and the pile tip resistance is hysteretic due to the small

relative displacement between the pile shaft and the around

soils. The pile tip resistance is difficult to be mobilized

adequately due to the small pile tip deformation. The pile

shaft friction resistance occupied a fairly large proportion of

the pile ultimate bearing capacity. Therefore, super-long

bored pile can usually be identified as friction pile.

4. The mobilization of the pile shaft friction is correlated with

support condition at the pile tip. Not only the pile tip bearing

capacity is low but also the pile shaft friction resistance can

be cut down severely, when the bearing stratum is soft or the

sediment is thick under the pile tip. However, both the pile

tip resistance and pile shaft friction can be increased

significantly after the support condition is improved by post

grouting at pile tip.

3 SELECTION OF PILE TYPE AND PILE TIP BEARING

STRATUM

Considering post grouting or not, super-long bored pile can be

divided into normal pile, tip post grouted pile and tip and shaft

post grouted pile. It is difficult to guarantee the bearing

performance of the normal bored pile usually due to the

problems of pile shaft mud cake and pile tip sediment. The

sediment problem can be effectively solved by pile tip grouting

technique, which can help to improve the bearing behaviors of

the pile tip and pile shaft, and accordingly, the bearing capacity

of the pile can be greatly increased. Therefore, the pile tip

grouting technique is recommended for super-long bored pile.

When the pile tip is embedded very deeply, or soils around the

pile shaft are soft or settlement control of the pile is very strict,

pile shaft grouting can be implemented, which can further

improve bearing behaviors of the pile shaft and increase the pile

shaft friction. Post grouting technique was adopted for all the

projects listed in Table 1.

Although super-long bored pile is usually identified as

friction pile, the pile tip bearing condition has a great influence

on the mobilization of the pile shaft friction and the bearing

capacity and deformation characteristics of the pile. Therefore,

the deep and solid soil layers, such as rock, gravel layer and

sand layer, are often selected as bearing stratums for super-long

bored pile tip bearing stratums. As bearing behaviors of the soil

at the pile tip and the pile bearing capacity are improved by post

grouting, the shallower solid soil layer can be possibly selected

as bearing stratum. The depth of pile tip extended into the

bearing layer can also be decreased for this reason. Thus post

grouting technique has expanded the range of selection of pile

tip bearing stratum. This technique is benefit to shorten the

length of the pile, save engineering quantity, and achieve

optimization design of pile foundations.

4 FIELD LOAD TEST PILE DESIGN

Static filed load test is a basic and reliable method to obtain the

bearing behaviors of the super-long bored pile. It is also a

necessary link of inspection and optimization design of the pile

foundation. As a design principle of the test pile, test data and

technical parameters should be got as many as possible for

design and construction of pile foundation. Besides the general

contents, double steel sleeves, pile head, construction and

measurement requirements should be especially concerned

during the test pile design process.

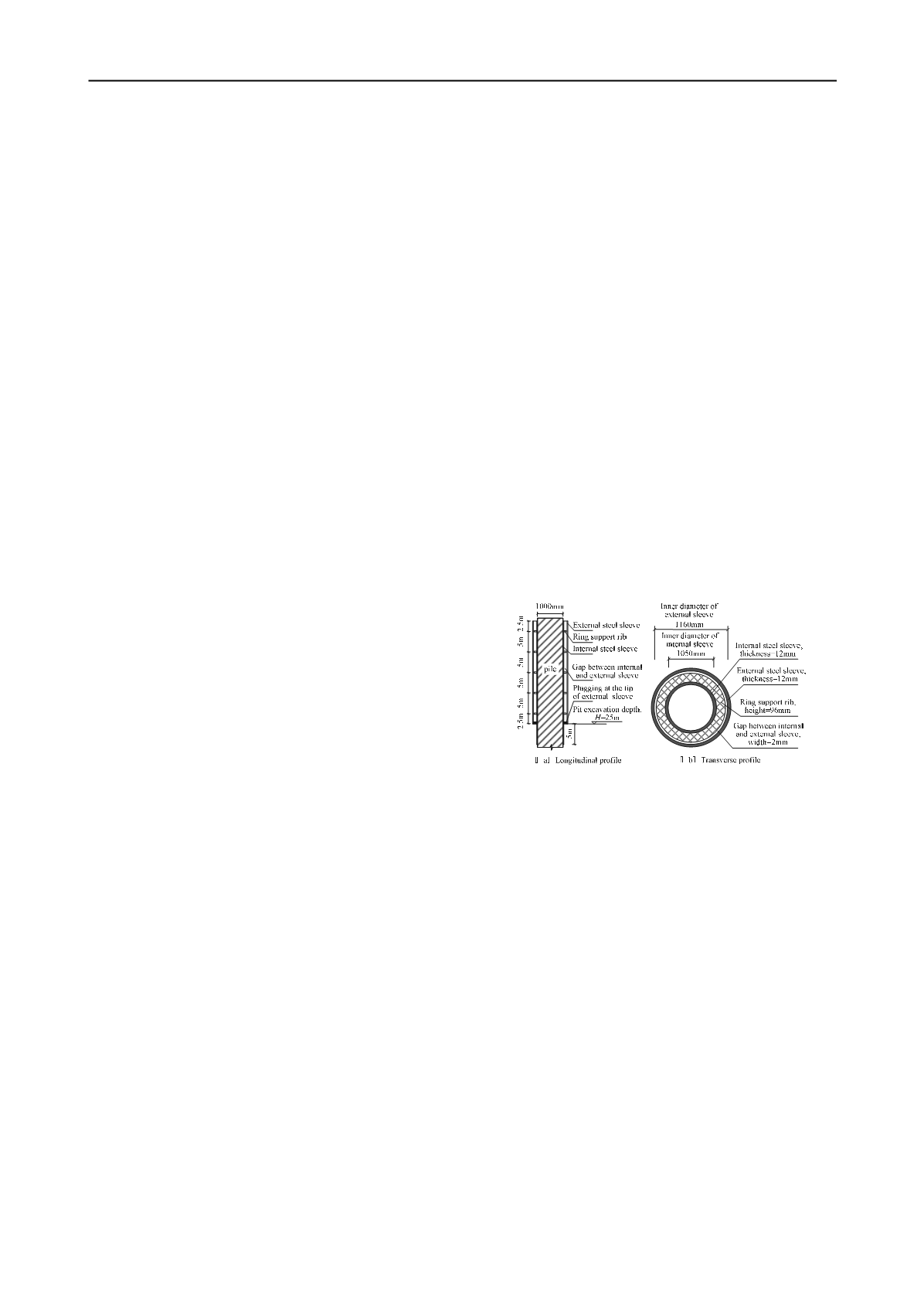

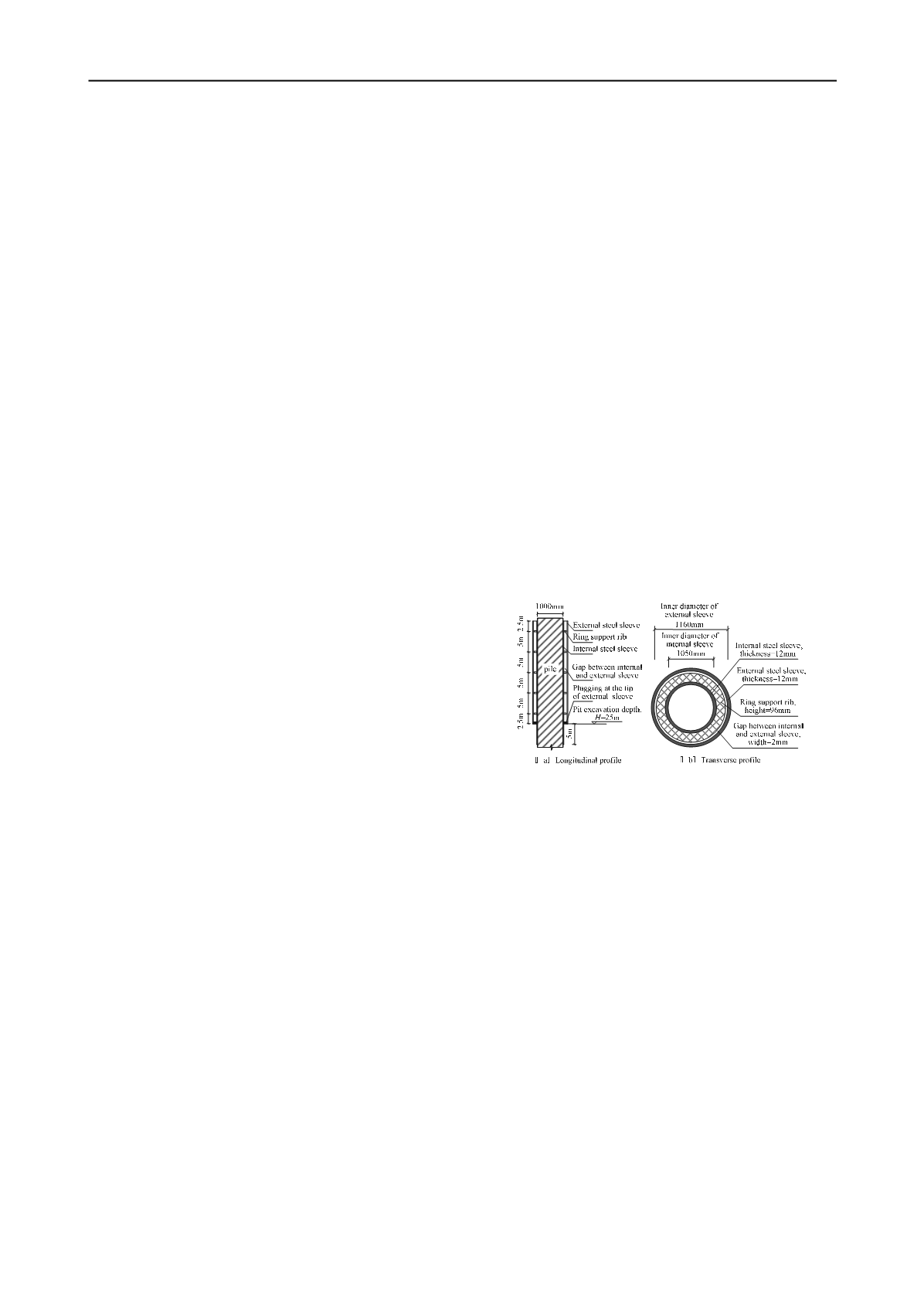

4.1 DOUBLE STEEL SLEEVES DESIGN

The base rafts of the super high-rise buildings are often deeply

buried. Therefore, it is necessary to concern how to reasonably

deduct the pile shaft friction in the excavation segment when

the load test is carried out at the ground surface. The pile test

with double steel sleeves isolating pile-soil contact in the pit

excavation segment can reasonably reflect the bearing behaviors

of pile (Wang et al, 2011). Double steel sleeves have been

applied in the pile load tests of several super high-rise building

projects, such as the Shanghai Center Tower, The Tianjin 117

Tower, The Wuhan Green land Tower, et al. The design

diagrams of double steel sleeves for the test piles of the

Shanghai Center Tower project are shown in Figure 1.

Figure 1 Design diagrams of double steel sleeves for the test piles of the

Shanghai Center Tower project

4.2 PILE HEAD DESIGN

Super-long bored test piles often bear very large loads. For

example, the load applied to the field test pile of Wuhan Green

Land Tower reached 45000kN. Therefore, the test pile head

need to be special designed. According to loading condition and

test requirements, the pile head should be formed to provide a

plane surface which is normal to the axis of the test pile and

large enough to accommodate the loading and measuring

equipments. The pile head should be adequately reinforced or

protected to prevent damage caused by the concentrated loads

applied from the loading equipment. The pile head should be

concentric with the pile. The strength of the joint between the

pile head and the pile should be equivalent to that of the pile. If

the double steel sleeves are adopted for the test pile, measures

should be made to ensure that the head and the external sleeve

would not connect together during the construction process.

Figure 2 shows the design schematic diagrams of the test pile

head for the Shanghai Center Tower project. The anchor pile-

cross beam reaction devices were used in this field test. The

maximum load was 30000kN, which was applied using 8

hydraulic jacks. The capacity of each jack was 5000kN.