2903

Technical Committee 212 /

Comité technique 212

3 CASE STUDY 2

This is a recent case study associated with the Barangaroo South

Stage 1A Development located on the western fringe of the

Sydney CBD, on the eastern shoreline of Darling Harbour.

The site is situated over reclaimed land in an eroded and

infilled paleovalley, with rock ranging in depth from 0m to 30m

as shown in Figure 3. As such, most of the weathered rock has

been removed during the erosional process, and replaced with

overlying Holocene alluvial sand, silt, clay, and manmade fill.

Figure 3. Stratigraphic profile at the site of Case Study 2

The rocks at the site comprise Hawkesbury Sandstone, with

average Point Load Strength Index ranging from 0.05MPa to

1.5MPa between 1m to 3m below rock surface, thereafter

having an average Point Load Strength of about 1.5MPa as

shown in Figure 4. These Point Load Strength index tests

suggested the unconfined compressive strength of the rock to be

on average about 30MPa below 3m depth, but layers having

strengths as high as 60MPa to 80MPa are likely to exist.

Figure 4. Point Load Strength Test Results (Case Study 2)

The sandstone rock at the site was classified in accordance

with Pells et al (1998), and preliminary design parameters for

pile design were assigned as summarized in Table 3. The

project required nearly 1000 piles with diameters ranging from

1m to 2.4m to support 3 towers of up to 34 storeys in height and

a number of low rise buildings over a 4ha site. The design

serviceability pile loads ranged from 7MN to 14MN for 1m

diameter piles, to 72MN to 81MN for the 2.4m diameter piles.

The structural engineer for the project was particularly

concerned about long-term differential settlement effects on the

tower structure, and therefore specified tight pile settlement

criteria. A pile toe settlement limit of 0.3% of the pile diameter

was stipulated at the pile toe. This was an unusual specification

but it was adopted by the structural engineer so that equivalent

structural “springs” could be adopted for the piles in his

structural model of the superstructure, to include modeling of

the piles due to the varying pile lengths on the project.

Table 3. Design Values Adopted for Design (Case Study 2)

Sandstone

Rock Class

Elastic

Modulus*

(GPa)

Poisson’s

Ratio

Ultimate

End

Bearing

Pressure

(MPa)

Ultimate

Shaft

Friction

(MPa)

IV

0.5

0.3

10

0.5

III

1.0

0.3

20

0.8

II or better

2.0

0.2

80

2

*

These represented the initial tangent modulus values.

A non-linear analysis using the following equation was adopted to

describe the secant modulus:

E

sec

= E

t

[1 – R

f

(p/p

f

)]

where:

E

t

= initial tangent elastic modulus (values given in the table)

R

f

= hyperbolic curve-fitting constant (R

fs

= 0.25 adopted for shaft

and R

fb

= 0.7 adopted for base)

p = mobilized pile-soil stress

p

f

= limiting value of pile-soil stress (values of fb and fs given in

table)

Because of concerns that dynamic testing would not be able

to provide sufficient test load and would not capture the

potential creep effect of the rock at high loads, pile load testing

was conducted on two 750mm diameter prototype piles fitted

with Osterberg Cells (O-Cell). Load-settlement prediction, pile

load testing, and back-analyses of the pile load testing results

for the project has been described in Wong and Oliveira (2012).

In brief, the two test piles had rock socket lengths of 7.85m

(SC-01) and 6.38m (SC-02); both founded with the pile toe

socketed more than 3.5m in Class II Sandstone. The O-Cell

was located at the toe of the test piles and the maximum O-Cell

load reached was 22.6MN for SC-01 and 26MN for SC-02.

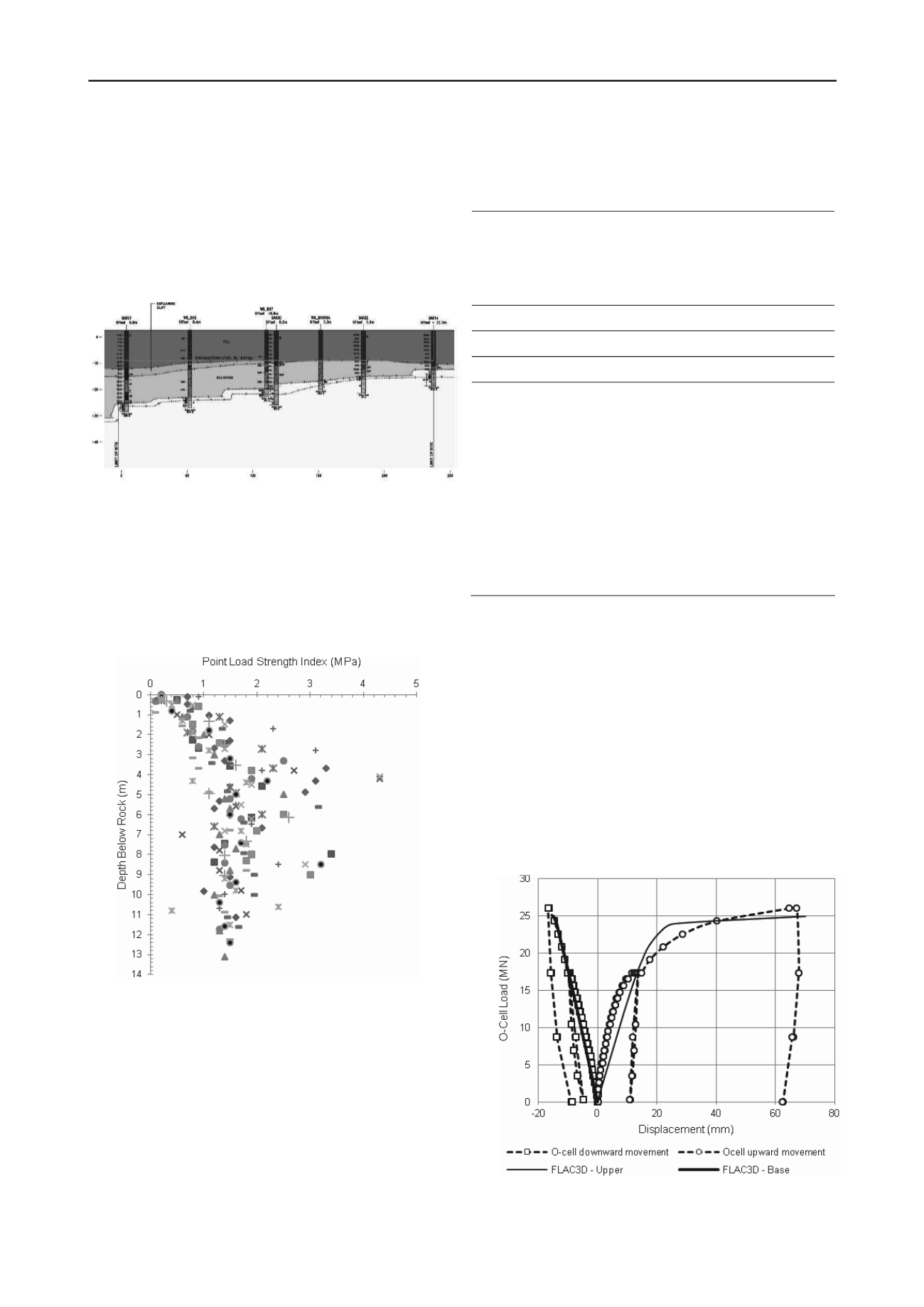

The test results for SC-02, together with results of back-

analyses using the embedded pile element method in the

commercial finite element analysis program FLAC (3D), are

presented in Figure 5.

Figure 5. O-Cell Test and Back-analysis Results (Test Pile SC-02)

The key findings of the O-Cell testing are summarized below: