2896

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

This difference is explained by the fact that during the

tapered anchor installation, the upper helices pass through intact

soil, differently of the upper helices of cylindrical anchor.

However, during the loading of the both anchors, the both

surfaces of soil mobilized above the plates are disturbed by the

installation of the helices.

3 CONCLUSIONS

Two different types of experimental programs were carried on

helical anchors to verify the effect of the helices configuration

on the anchor uplift capacity. Based on the results of these tests,

the most important conclusions are:

The efficiency of the second helix of helical anchors in sand

decrease with the increase of the relative density and the

helix diameter.

2.2.1 Results of field tests

All anchors of this field investigation were installed with the

anchor tip at a depth of 10 meters as illustrated in Figure 7.

After installation, tension load tests were carried out on the

anchors shown in Figure 6. More complete details of this

investigation are available in Santos (2012).

The uplift capacity of a triple-helix anchor with tapered

helices is slightly superior then the one of cylindrical

helices, with same average plate diameter in a tropical soil.

4 ACKNOWLEDGEMENTS

The ultimate capacity (Q

u

) of all tests was taken as the load

producing a relative displacement of 10% of the helix average

diameter. Table 3 presents the results of ultimate capacity (Q

u

)

of the tested anchors, and also the fractions of uplift capacity

related the upper plates. Considering the homogeneity of this

site, the fractions of uplift bearing capacity of the second plate

of the multi-helix anchors (F

Qh2

) were calculated by the

difference between the ultimate capacity of anchors with two

helices and of one helix (same bottom helix diameter). The

fractions of uplift capacity due to the third plate (F

Qh3

) of three-

helix anchors were calculated by using the same procedure.

The authors wish to thank FAPESP (Fundação de Amparo à

Pesquisa do Estado de São Paulo) project n

o

2010/19039-6, and

the

international

Cooperation

USP/Cofecub

project

n

o

2012.1.678.1.9.

5 REFERENCES

Clemence, S.P., Crouch, L.K., and Stephenson, R.W. 1994. Prediction

of uplift capacity for helical anchors in sand. In Proceedings of the

2nd Geotechnical Engineering Conference, Egypt. Vol. I: 332–343.

The comparison between the double-helix anchor A2

(cylindrical) and B2 (tapered) shows that the contribution of the

second helix to the total capacity is better for tapered

configuration. The second helix of the anchor B2 is larger than

the bottom helix, and installed in a less disturbed soil layer

compared to the second helix of the cylindrical anchor A2.

Kulhawy, F.H. 1985. Uplift behaviour of shallow soil anchors — an

overview. In Uplift Behaviour of Anchor Foundations in Soil.

ASCE: 1–25.

Lutenegger, A.J. 2009. Cylindrical Shear or Plate Bearing? – Uplift

Behavior of Multi-Helix Screw Anchors in Clay. Contemporary

Issues in Deep Foundations, ASCE: 456-463.

Table 3. Contribution of the upper plates to the total anchor uplift

capacity.

Lutenneger, A.J. 2011. Behavior of multi-helix screw anchors in sand.

In Proceedings of the 14th Pan-American Conference on Soil

Mechanics and Geotechnical Engineering

, Toronto, Ont. [CD

ROM].

Mitsch, M.P., and Clemence, S.P. 1985. Uplift capacity of helix anchors

in sand. In Uplift Behaviour of Anchor Foundations in Soil, ASCE:

26-47.

Anchor

Helices

diameters

(mm)

Q

u

(kN)

F +

Qh1

Q

s

fraction

(%)

F

Qh2

(%)

F

Qh3

(%)

A1

200

14,5

100.0

A2

200/200

25

58.0

42.0

A3 200/200/200

36

40.3

29.2

30.6

B1

150

13,5

100.0

B2

150/200

31

43.5

56.5

B3 150/200/250

39

34.6

44.9

20.5

C2

200/250

48

30.2

69.8

C3 200/250/300

57

25.4

58.8

15.8

Mooney, J.S., Adamczak, S.J, and Clemence, S.P. 1985. Uplift Capacity

of Helix Anchors in Clay and Silt. Uplift Behaviour of Anchor

Foundations in Soil, ASCE: 48-72.

Sakr, M. 2009. Performance of helical piles in oil sand.

Canadian

Geotechnical Journal

46: 1046–1061.

Santos, T.C. 2012. The effect of helices configuration on the uplift

capacity of helical piles in a tropical soil. Dissertation (master's

degree) – Escola de Engenharia de São Carlos, Universidade de São

Paulo, São Carlos.

However, from the comparison between the third helix

contribution to the total capacity (F

Qh3

) of three-helix anchors

A3, B3, and C3, it could be observed that the efficiency of the

third helix decreases with the third plate diameter, even for the

tapered anchors. A similar trend was observed in the centrifuge

tests presented in this paper. However, further investigation is

needed to confirm this behaviour.

Terzaghi, K. 1943.

Theoretical soil mechanics

. John Wiley & Sons,

New York.

Tsuha, C.H.C., Aoki, N., Rault, G., Thorel, L., and Garnier, J. 2007.

Physical modeling of helical pile anchors.

International Journal of

Physical Modelling in Geotechnics

7(4): 1–12.

Tsuha, C.H.C., Aoki, N., Rault, G., Thorel, L., and Garnier, J. 2012.

Evaluation of the efficiencies of helical anchor plates in sand by

centrifuge model tests.

Canadian Geotechnical Journal

49: 1102–

1114.

2.2.2 Cylindrical and tapered helices

The results of the final installation torque and the uplift capacity

of helical anchors with same average plate diameter (A3 and

B3) were compared. From this comparison it was found that the

gain in uplift capacity for the tapered anchor is about 8%.

However, to install the tapered model, it was necessary to apply

a torque 20% larger than the needed to install the cylindrical

model.

However, from the comparison between the third helix

contribution to the total capacity (F

Qh3

) of three-helix anchors

A3, B3, and C3, it could be observed that the efficiency of the

third helix decreases with the third plate diameter, even for the

tapered anchors. A similar trend was observed in the centrifuge

tests presented in this paper. However, further investigation is

needed to confirm this behaviour.

Tsuha, C.

Physic

Physic

Tsuha, C.

Evalua

centrif

1114.

2.2.2 Cylindrical and tapered helices

The results of the final installation torque and the uplift capacity

of helical anchors with same average plate diameter (A3 and

B3) were compared. From this comparison it was found that the

gain in uplift capacity for the tapered anchor is about 8%.

However, to install the tapered model, it was necessary to apply

a torque 20% larger than the needed to install the cylindrical

model.

This difference is explained by the fact that during the

tapered anchor installation, the upper helices pass through intact

soil, differently of the upper helices of cylindrical anchor.

However, during the loading of the both anchors, the both

surfaces of soil mobilized above the plates are disturbed by the

installation of the helices.

3 CONCLUSIONS

Two different types of experimental programs were carried on

helical anchors to verify the effect of the helices configuration

on the anchor uplift capacity. Based on the results of these tests,

the most important conclusions are:

The efficiency of the second helix of helical anchors in sand

decrease with the increase of the relative density and the

helix diameter.

2.2.1 Results of field tests

All anchors of this field investigation were installed with the

anchor tip at a depth of 10 meters as illustrated in Figure 7.

After installation, tension load tests were carried out on the

anchors shown in Figure 6. More complete details of this

investigation are available in Santos (2012).

The uplift capacity of a triple-helix anchor with tapered

helices is slightly superior then the one of cylindrical

helices, with same average plate diameter in a tropical soil.

4 ACKNOWLEDGEMENTS

The ultimate capacity (Q

u

) of all tests was taken as the load

producing a relative displacement of 10% of the helix average

diameter. Table 3 presents the results of ultimate capacity (Q

u

)

of the tested anchors, and also the fractions of uplift capacity

related the upper plates. Considering the homogeneity of this

site, the fractions of uplift bearing capacity of the second plate

of the multi-helix anchors (F

Qh2

) were calculated by the

difference between the ultimate capacity of anchors with two

helices and of one helix (same bottom helix diameter). The

fractions of uplift capacity due to the third plate (F

Qh3

) of three-

helix anchors were calculated by using the same procedure.

The authors wish to thank FAPESP (Fundação de Amparo à

Pesquisa do Estado de São Paulo) project n

o

2010/19039-6, and

the

international

Cooperation

USP/Cofecub

project

n

o

2012.1.678.1.9.

5 REFERENCES

Clemence, S.P., Crouch, L.K., and Stephenson, R.W. 1994. Prediction

of uplift capacity for helical anchors in sand. In Proceedings of the

2nd Geotechnical Engineering Conference, Egypt. Vol. I: 332–343.

The comparison between the double-helix anchor A2

(cylindrical) and B2 (tapered) shows that the contribution of the

second helix to the total capacity is better for tapered

configuration. The second helix of the anchor B2 is larger than

the bottom helix, and installed in a less disturbed soil layer

compared to the second helix of the cylindrical anchor A2.

Kulhawy, F.H. 1985. Uplift behaviour of shallow soil anchors — an

overview. In Uplift Behaviour of Anchor Foundations in Soil.

ASCE: 1–25.

Lutenegger, A.J. 2009. Cylindrical Shear or Plate Bearing? – Uplift

Behavior of Multi-Helix Screw Anchors in Clay. Contemporary

Issues in Deep Foundations, ASCE: 456-463.

Table 3. Contribution of the upper plates to the total anchor uplift

capacity.

Lutenneger, A.J. 2011. Behavior of multi- elix screw anchors in sand.

In Proceedings of the 14th Pan-American Conference on Soil

Mechanics an Geotechnical Engineering

, Toronto, Ont. [CD

ROM].

Mitsch, M.P., and Clemence, S.P. 1985. Uplift capacity of helix anchors

in sand. In Uplift Behaviour of Anchor Foundations in Soil, ASCE:

26-47.

Anchor

Helices

diameters

(mm)

Q

u

(kN)

F +

Qh1

Q

s

fraction

(%)

F

Qh2

(%)

F

Qh3

(%)

A1

200

14,5

100.0

A2

200/200

25

58.0

42.0

A3 200/200/200

36

40.3

29.2

30.6

B1

150

13,5

100.0

B2

150/200

31

43.5

56.5

B3 150/200/250

39

34.6

44.9

20.5

C2

200/250

48

30.2

69.8

C3 200/250/300

57

25.4

58.8

15.8

Mooney, J.S., Adamczak, S.J, and Clemence, S.P. 1985. Uplift Capacity

of Helix Anchors in Clay and Silt. Uplift Behaviour of Anchor

Foundations in Soil, ASCE: 48-72.

Sakr, M. 2009. Performance of helical piles in oil sand.

Canadian

Geotechnical Journal

46: 1046–1061.

Santos, T.C. 2012. The effect of helices configuration on the uplift

capacity of helical piles in a tropical soil. Dissertation (master's

degree) – Escola de Engenharia de São Carlos, Universidade de São

Paulo, São Carlos.

However, from the comparison between the third helix

contribution to the total capacity (F

Qh3

) of three-helix anchors

A3, B3, and C3, it could be observed that the efficiency of the

third helix decreases with the third plate diameter, even for the

tapered anchors. A similar trend was observed in the centrifuge

tests presented in this paper. However, further investigation is

needed to confirm this behaviour.

Terzag i, K. 1943.

Theoretical soil mechanics

. John Wiley & Sons,

New York.

Tsuha, C.H.C., Aoki, N., Rault, G., Thorel, L., and Garnier, J. 2007.

Physical modeling of helical pile anchors.

International Journal of

Physical Modelling in Geotechnics

7(4): 1–12.

Tsuha, C.H.C., Aoki, N., Rault, G., Thorel, L., and Garnier, J. 2012.

Evaluation of the efficiencies of helical anchor plates in sand by

centrifuge model tests.

Canadian Geotechnical Journal

49: 1102–

1114.

2.2.2 Cylindrical and tapered helices

The results of the final installation torque and the uplift capacity

of helical anchors with same average plate diameter (A3 and

B3) were compared. From this comparison it was found that the

to total

ix and b)

helix, of

the helix

D

).

e relative

ulti-helix

2012), for

the sand

ed two or

increasingly larger diameter helices up the central shaft) were

installed and tested at the CRHEA site of the São Carlos School

of Engineering, São Carlos city, Brazil.

Figure 6. Prototype helical anchors tested at the CRHEA site.

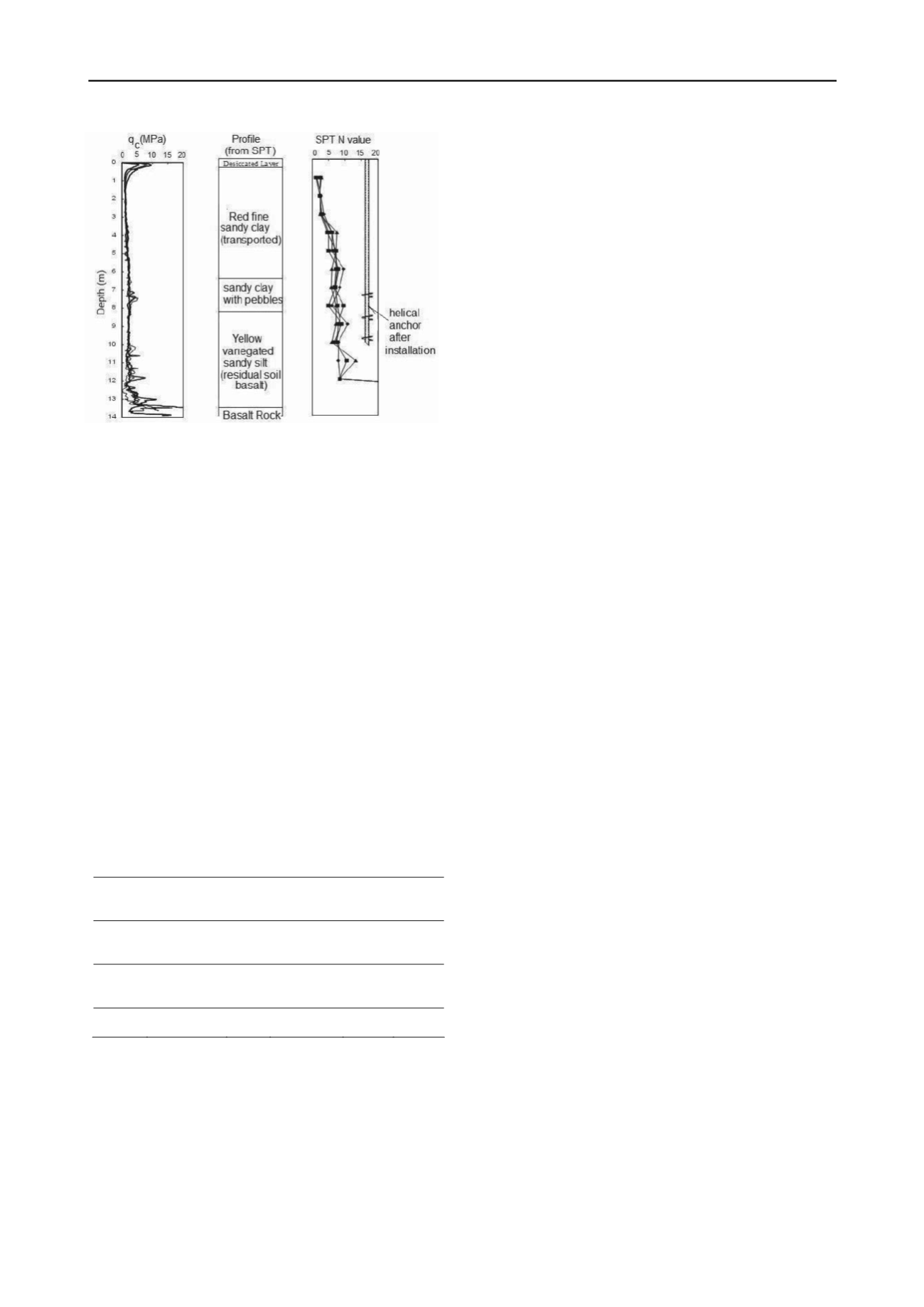

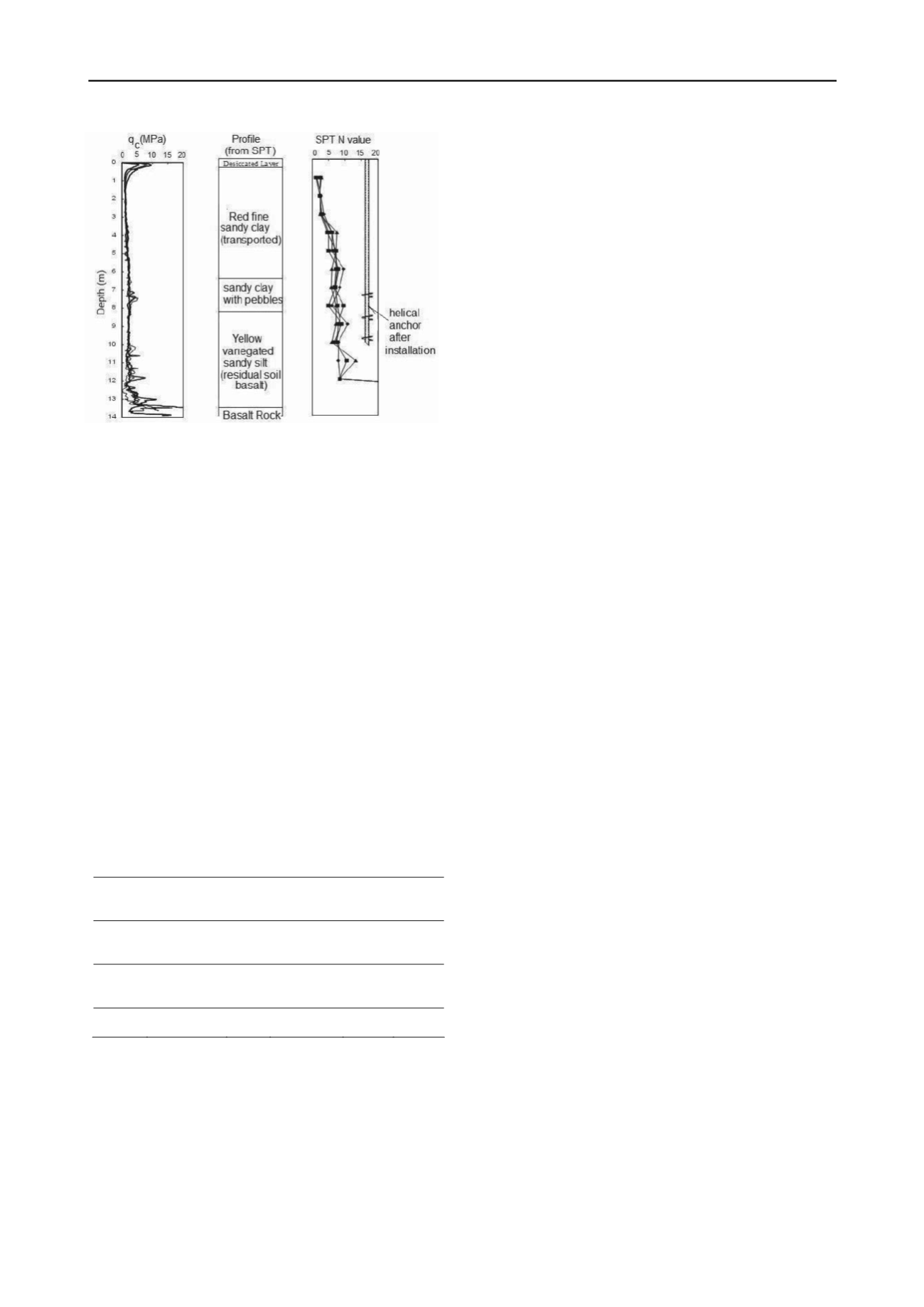

The soil of the CRHEA site is material formed from igneous

rock (basalt) from Serra Geral Formation (Figure 7). The top

layer is a porous colluvial sandy clay with about 8 meters depth.

Below this layer there is a residual soil (from igneous rock)

limited by a thin layer of pebbles. The nature of this tropical soil

is porous and has unstable structure due to the connections

between particles by bonds attributed to soil water suction and

cementing substances.

Figure 7. Soil profile at the CRHEA site.

This difference is explained by the fact that during the

tapered anchor installation, the upper helices pass through intact

soil, differently of the upper helices of cylindrical anchor.

However, during the loading of the both anchors, the both

surfaces of soil mobilized above the plates are disturbed by the

installation of the helices.

3 CONCLUSIONS

Two different types of experimental progr ms were carried on

helical anchors to verify the ffect of the helices configuration

on the anchor uplift capacity. Based on the results of these tests,

the most important conclusions are:

The efficiency of the second helix of helical anchors in sand

decrease with the increase of the relative density and the

helix diameter.

2.2.1 Results of eld ests

All anchors of this field investigation were installed with the

anchor tip at a depth of 10 meters as illustrated in Figure 7.

After installation, tension load tests were carried out on the

anchors shown in Figure 6. More complete details of this

investigation are available in Santos (2012).

The uplift capacity of a triple-helix anchor with tapered

helices is slightly superior then the one of cylindrical

helices, with same average plate diameter in a tropical soil.

4 ACKNOWLEDGEMENTS

The ultimate capacity (Q

u

) of all tests was taken as the load

producing a relative displacement of 10% of the helix average

diameter. Table 3 presents the results of ultimate capacity (Q

u

)

of the tested anchors, and also the fractions of uplift capacity

related the upper plates. Considering the homogeneity of this

site, the fractions of uplift bearing capacity of the second plate

of the multi-helix anchors (F

Qh2

) were calculated by the

difference between the ultimate capacity of anchors with two

helices and of one helix (same bottom helix diameter). The

fractions of uplift capacity due to the third plate (F

Qh3

) of three-

helix anchors were calculated by using the same procedure.

The authors wish to thank FAPESP (Fu dação de Amparo à

Pesquisa do E tado de São Paulo) project n

o

2010/19039-6, and

the

international

Cooperation

USP/Cofecub

project

n

o

2012.1.678.1.9.

5 REFERENCES

Clemence, S.P., Crouch, L.K., and Stephenson, R.W. 1994. Prediction

of uplift capacity for helical anchors in sand. In Proceedings of the

2nd Geotechnical Engineering Conference, Egypt. Vol. I: 332–343.

The comparison between the double-helix anchor A2

(cylindrical) and B2 (tapered) shows that the contribution of the

second helix to the total capacity is better for tapered

configuration. The second helix of the anchor B2 is larger than

the bottom helix, and installed in a less disturbed soil layer

compared to the second helix of the cylindrical anchor A2.

Kulhawy, F.H. 1985. Uplift behaviour of shallow soil anchors — an

overview. In Uplift Behaviour of Anchor Foundations in Soil.

ASCE: 1–25.

Lutenegger, A.J. 2009. Cylindrical Shear or Plate Bearing? – Uplift

Behavior of Multi-Helix Screw Anchors in Clay. Contemporary

Issues in Deep Foundations, ASCE: 456-463.

Table 3. Contribution of the upper plates to the total anchor uplift

capacity.

Lutenneger, A.J. 2011. Behavior of multi-helix screw anchors in sand.

In Proceedings of the 14th Pan-American Conference on Soil

Mechanics and Geotechnical Engineering

, Toronto, Ont. [CD

ROM].

Mitsch, M.P., and Clemence, S.P. 1985. Uplift capacity of helix anchors

in sand. In Uplift Behaviour of Anchor Foundations in Soil, ASCE:

26-47.

Anchor

Helic s

diameters

(mm)

Q

u

(kN)

F +

Qh1

Q

s

fraction

(%)

F

Qh2

(%)

F

Qh3

(%)

A1

200

14,5

100.0

A2

200/200

25

58.0

42.0

A3 200/200/200

36

40.3

29.2

30.6

B1

150

13,5

100.0

B2

150/200

31

43.5

56.5

B3 150/200/250

39

34.6

44.9

20.5

C2

200/250

48

30.2

69.8

C3 200/250/300

57

25.4

58.8

15.8

ooney, J.S., Adamczak, S.J, and Clemence, S.P. 1985. Uplift Capacity

of Helix Anchors in Clay and Silt. Uplift Behaviour of Anchor

Foundations in Soil, ASCE: 48-72.

Sakr, M. 2009. Performance of helical piles in oil sand.

Canadian

Geotechnical Journal

46: 1046–1061.

Santos, T.C. 2012. The effect of helices configuration on the uplift

capacity of helical piles in a tropical soil. Dissertation (master's

degree) – Escola de Engenharia de São Carlos, Universidade de São

Paulo, São Carlos.

However, from the comparison between the third helix

contribution to the total capacity (F

Qh3

) of three-helix anchors

A3, B3, and C3, it could be observed that the efficiency of the

third helix decreases with the third plate diameter, even for the

tapered anchors. A similar trend was observed in the centrifuge

tests presented in this paper. However, further investigation is

needed to confirm this behaviour.

Terzaghi, K. 1943.

Theoretical soil mechanics

. John Wiley & Sons,

New York.

Tsuha, C.H.C., Aoki, N., Rault, G., Thorel, L., and Garnier, J. 2007.

Physical modeling of helical pile anchors.

International Journal of

Physical Modelling in Geotechnics

7(4): 1–12.

Tsuha, C.H.C., Aoki, N., Rault, G., Thorel, L., and Garnier, J. 2012.

Evaluation of the efficiencies of helical anchor plates in sand by

centrifuge model tests.

Canadian Geotechnical Journal

49: 1102–

1114.

2.2.2 Cylindrical and tapered helices

The results of the final installation torque and the uplift capacity

of helical anchors ith same average plate diameter (A3 and

B3) were compared. From this comparison it was found that the

gain in uplift capacity for the tapered anchor is about 8%.

However, to install the tapered model, it was necessary to apply

a torque 20% larger than the needed to install the cylindrical

model.