2895

Technical Committee 212 /

Comité technique 212

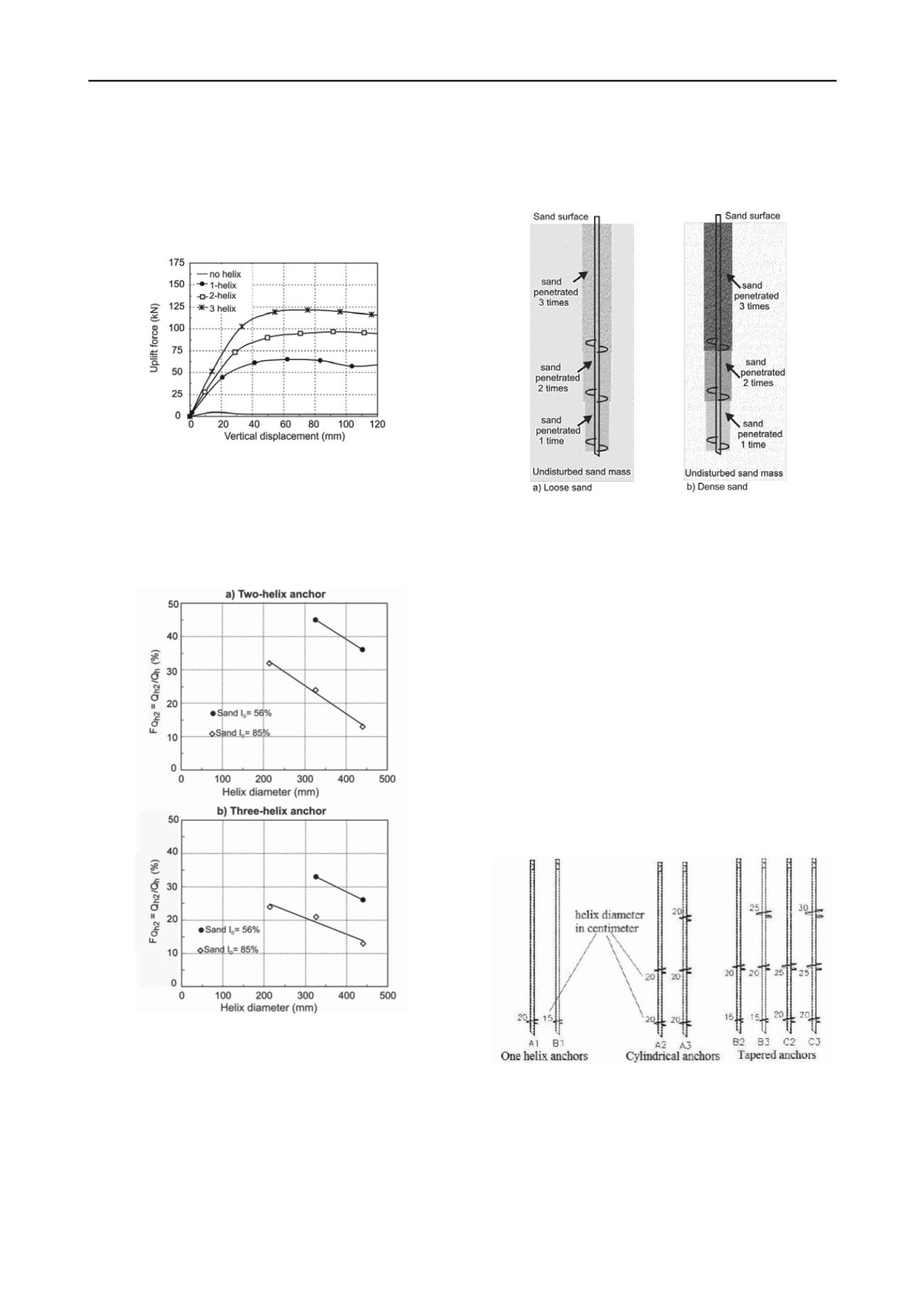

the Q

h

results of double-helix and single-helix anchors with

same helix diameter and tip depth. A similar procedure was

used to calculate the Q

h

fractions of middle and upper helical

plates of triple-helix anchors, and these results are included in

Tsuha et al. (2012). Figure 4 shows the fractions of helix

bearing capacity related to the second helix (F

Qh2

) of the double

and triple-helix anchors tested in this investigation.

Figure 3. Load–displacement curves of tensile tests performed on model

anchors of 214mm helix (prototype) diameter in container 2.

The results of tests performed on the model anchors with

helix diameter of 214 mm in the looser sand are influenced by

some local heterogeneity. For this reason, the contribution of

the second helix of the anchors P2 installed in the container 1,

was not shown in Figure 4.

Figure 4. Relationship between the second helix contribution to total

helix bearing capacity and the helix diameter of a) double helix and b)

triple-helix anchors (Tsuha et al. 2012).

2.1.2 Efficiency of the second helix

Figures 4 shows that the efficiency of the second helix, of

double and triple-helix anchors, depends linearly of the helix

diameter, and also of the initial sand relative density (I

D

).

2.1.3 Effect of sand compactness

The results of Figure 4 illustrate the influence of the relative

density on the efficiency of the second plate of multi-helix

anchors installed in sand. According to Tsuha et al. (2012), for

dense sand, the difference in compactness between the sand

penetrated by a helix one time and the sand penetrated two or

three times is significant. Differently, for the looser tested sand,

after anchor installation, the final relative densities of the sand

above the three helices are similar. This hypothesis is detailed in

Figure 5.

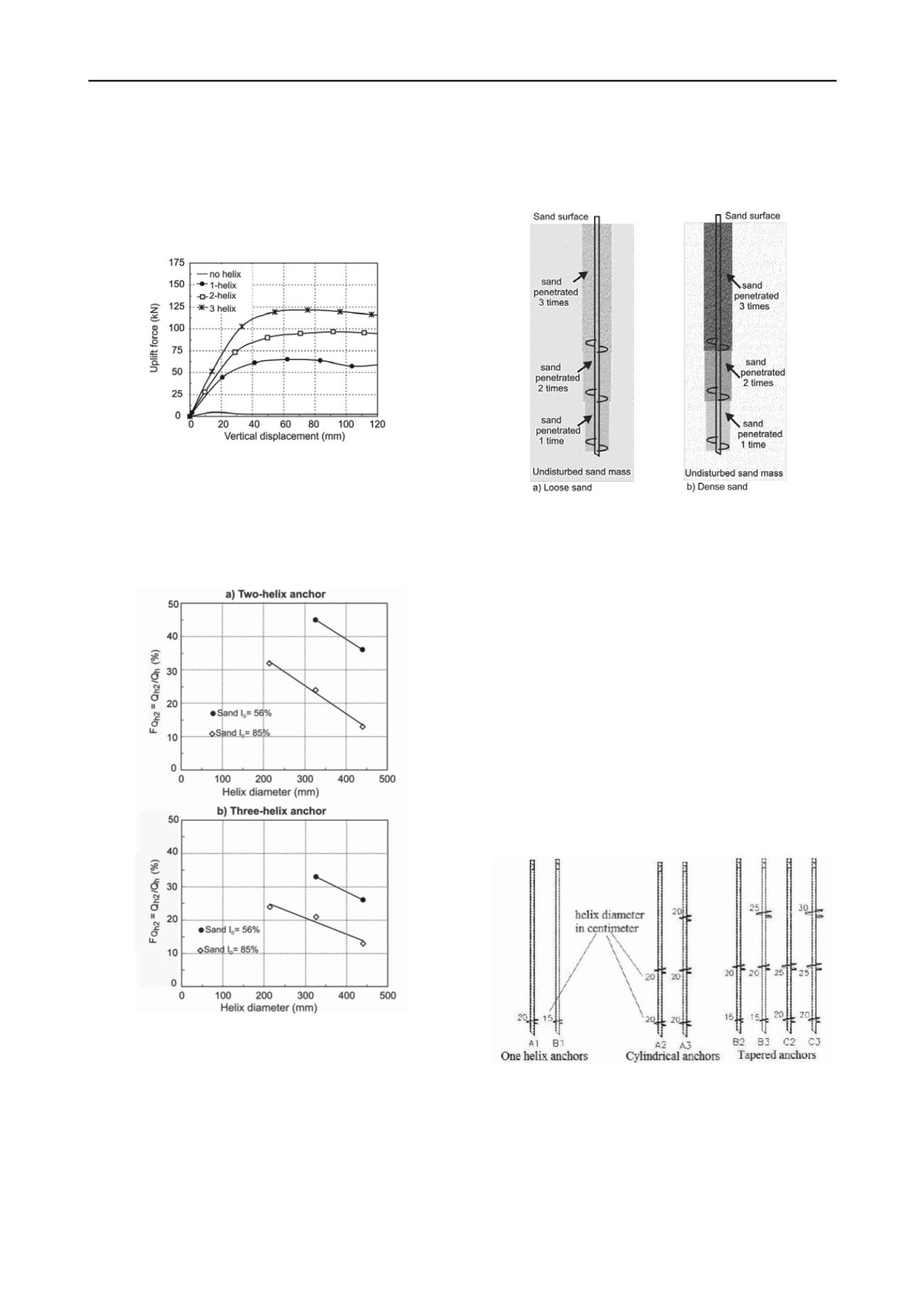

Figure 5. Hypothesis for sand disturbance after installation of a three-

helix anchor: (a) loose sand; (b) dense sand (Tsuha et al. 2012).

2.1.4 Effect of helix diameter

The efficiencies of the second plates of the tested anchors

decrease with the increase in helix diameter, as observed in

Figure 4. This fact indicates that the effect of the helical anchor

installation on the sand mass is more significant for helical

anchors with larger plates. As the region of disturbed sand

around the cylinder circumscribed by the anchors helices after

installation is larger for larger helix diameter (increases with the

helix diameter), the failure surface mobilized during the anchor

loading is more distant from the undisturbed sand.

Consequently, the efficiency of the second helix of cylindrical

helical anchors decreases with the increase in diameter.

2.2 Field testing program

Eight helical anchors (Figure 6), with different configurations

(multi-helix anchors with the same plate diameter and with

increasingly larger diameter helices up the central shaft) were

installed and tested at the CRHEA site of the São Carlos School

of Engineering, São Carlos city, Brazil.

Figure 6. Prototype helical anchors tested at the CRHEA site.

The soil of the CRHEA site is material formed from igneous

rock (basalt) from Serra Geral Formation (Figure 7). The top

layer is a porous colluvial sandy clay with about 8 meters depth.

Below this layer there is a residual soil (from igneous rock)

limited by a thin layer of pebbles. The nature of this tropical soil

is porous and has unstable structure due to the connections

between particles by bonds attributed to soil water suction and

cementing substances.

Figure 7. Soil profile at the CRHEA site.