2878

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

reached the first dense sand layer at about 28.5 m. deep. The

second very dense sand where the pile tip of the building is

seated is found at about 46 m. deep below ground surface. Table

1 presents the soil condition and the engineering properties.

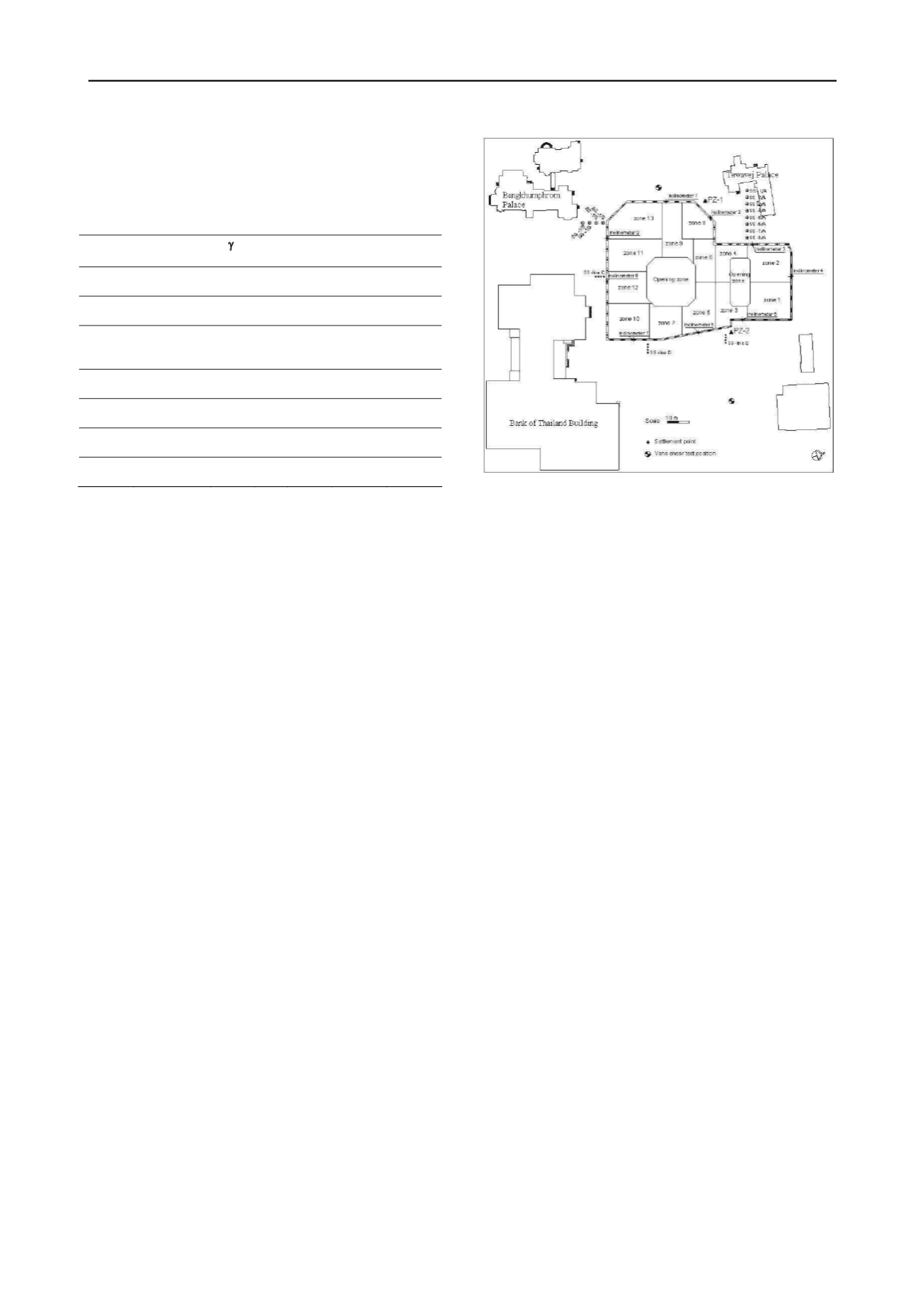

Table 1. Soil conditions and engineering properties.

Depth

(m.)

Soil

Description

t

Su N Eu

E’

0 -

12.5

Soft Clay

16.0

15

-

8750

-

12.5 -

15.0

Medium

Stiff Clay

16.5

40 -

18000

-

15.0 -

20.0

Stiff to

Very Stiff

Silty Clay

19.0

-

12 85000

-

20.0 -

28.5

Hard Clay

20.0

-

35

300000

-

28.5 –

39.0

Dense Silty

Sand

20.0

-

40

80000

39.0 –

46.0

Hard Silty

Clay

20.0

-

45

-

-

46.0 –

65.0

Very Dense

Silty Sand

20.0

-

>50

-

-

Note:

t = Total Unit Weight (kN/m

3

)

Su = Undrained Shear Strength (kN/m

2

)

N

= SPT N-Value (Blows/ft)

Eu, E’ = Undrained and Drained Young’s Modulus (kN/m

2

)

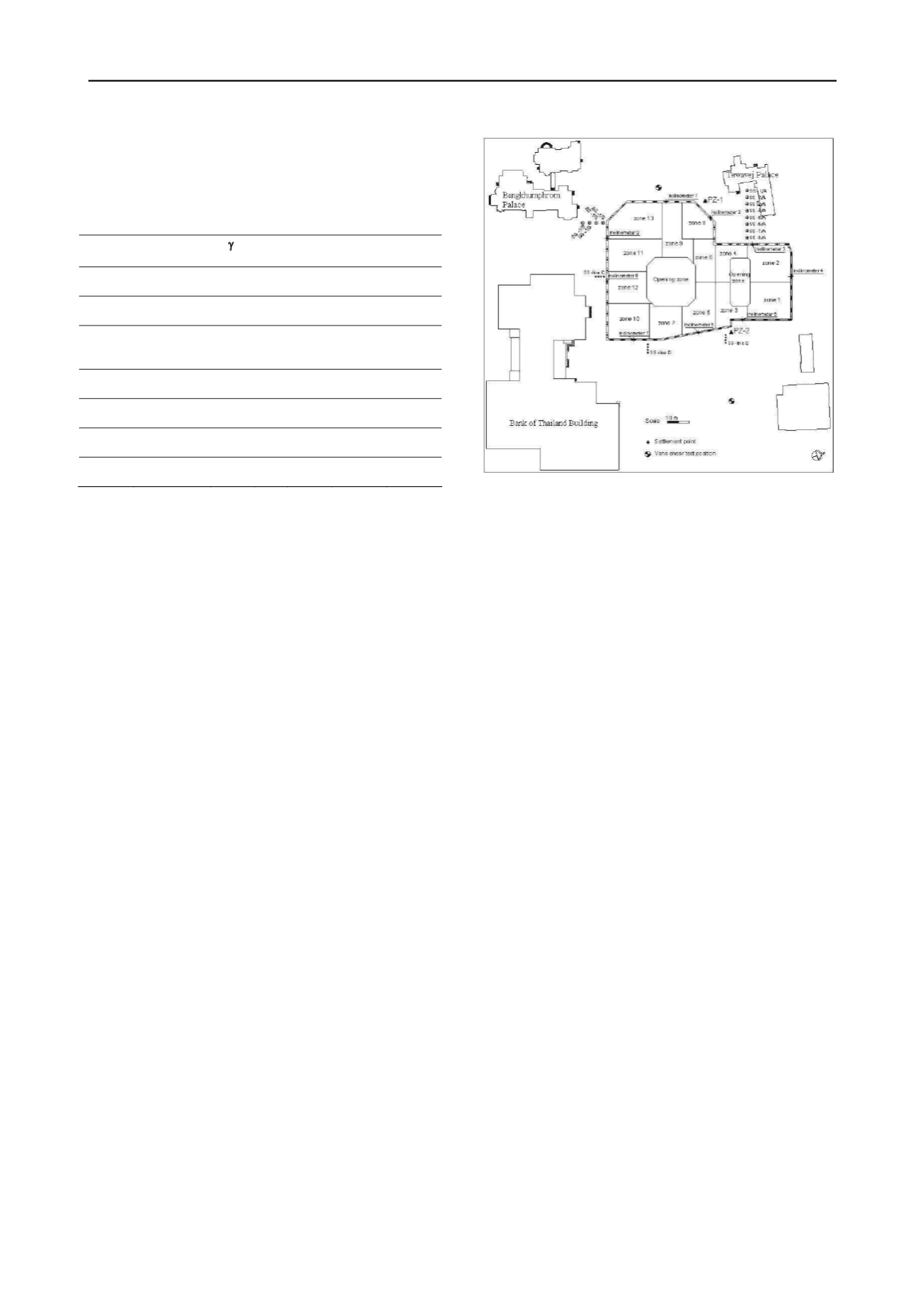

3 PROJECT DESCRIPTION

The basement design and construction of the new head office of

bank of Thailand aims to solve the problem of car park from

both staff as well as visitors. The surface area of excavation is

approximately 10790 m

2

with 5 m. and 10 m. away from

Tewavej Palace and Bangkhumphrom Palace accordingly as

shown in Fig 2. The Tewavej Palace and Bangkhunphrom

Palace are the historical palace constructed by brick and bearing

wall seated on shallow foundation. In order to minimize the

influence on these two palaces, the basement of BOT was

designed to be constructed by top-down construction method

which has been used only in Bangkok city restricted area such

as the subway station of MRT project.

The diaphragm wall (D-Wall) of 1.0 m. thick and 20 m. deep

was designed as the temporary wall for 15.8 m. deep excavation

and used as permanent wall at the final stage. Five basement

floors consist of F

1

,P

1

,P

2

,P

3

and P

4

floor at -1.20 m., -4.70 m.,

-7.70 m., -10.70 m., and -13.70 m. deep respectively as

illustrated in Fig 3.

The top-down construction method was started by casting

the first basement F

1

at -1.20 m. then moving to third basement

floor (P

2

) at -7.70 m. and constructing the fifth basement floor

and mat foundation at -13.70 m. deep as shown in Fig 3.

Loading of the permanent basement floor during construction

was transferred through the stanchion at the centerline of the

column which was installed into the bored pile during

construction of the bored pile.

Figure 2. The BOT project plan view.

4 INSTRUMENTATION

The head office of BOT was constructed in the large area of

more than 10790 m

2

; therefore, the excavation area for top-

down construction was divided into 13 zones as presented in

Fig 2. Two large opening zones were provided for excavation

work. The excavation at the deeper basement required to

excavate step by step from far corner to the opening zone where

the excavated soil was moved out of the project area. For safety

reason and to monitor basement wall behavior, the full scheme

of instrumentation was installed at the palaces on the ground

surface and in the diaphragm wall as shown in Fig 2 and Table

2.

5 ANALYSIS AND DESIGN OF DIAPHRAGM WALL

The analysis and design of the diaphragm wall was carried out

by means of the FEM. The construction sequence was simulated

in the FEM analysis. The sequence of basement construction

consists of 8 steps as follows:

1.Excavating to -1.75 m. deep and casting lean concrete.

2.Casting the first permanent basement floor at -1.20 m.

(thickness 0.45 m.)

3.Excavating to the third basement floor at -8.10 m. deep and

casting lean concrete.

4.Casting the third permanent basement floor at -7.70 m.

(thickness 0.30 m.)

5.Excavating to the fifth basement floor (base slab) at -15.60 m.

deep and casting lean concrete.

6.Casting the fifth basement floor (base slab) at -13.70 m.

(thickness 1.30 m.)

7.Casting the permanent fourth basement floor at -10.70 m.

(thickness 0.30 m.)

8.Casting the permanent second basement floor at -4.70 m.

(thickness 0.30 m.)

The detail of construction sequence is presented in Fig. 4.

The analysis and design of the diaphragm wall for 15.6 m.

deep excavation were carried out by FEM. As the basement

constructed in soft clay layer, the undrained concept based on

bi-linear Mohr-Coulomb failure theory was used for FEM

analysis. The Young’s modulus (Eu) was used in terms of an

undrained shear strength (Su) of Eu/Su = 500 and 1000 for soft

clay and stiff clay respectively (Teparaksa, 1999b). The value of

Young’s modulus is also presented in Table 1.

The Young’s modulus or shear modulus (G) of clay depends

on the shear strain of the system as proposed by Mair (1993) as