2871

Technical Committee 212 /

Comité technique 212

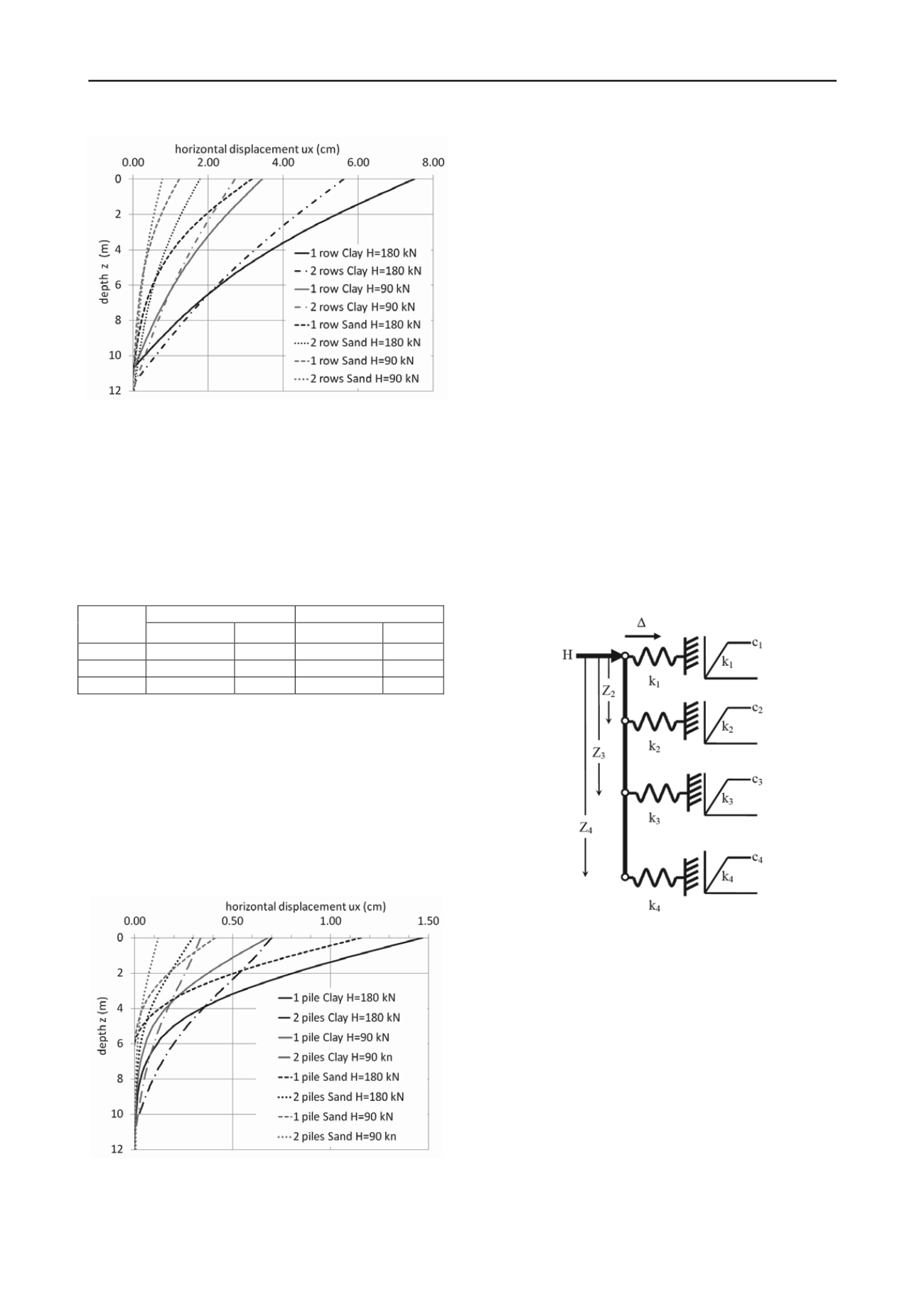

Figure 1. Lateral deflections for 1- and 2-row pile groups

.

Table 2 lists the calculated lateral deflections consistent with the

loads and soils shown in Figure 3. While the elastic/plastic

behavior allowed for nonlinear load-displacement curves,

deflections from these two programs were consistently lower

than Plaxis-2D. There is also reason to believe that the two

subgrade reaction programs may better represent single piles (as

in 3D, discussed later) than as a 2D “pile wall” as represented in

Figure 1.

Table 2. Summary of reaction coefficients and displacements

Axis

Geo 4

Spring

Mode

k (MN/m/m) ux (cm) Ch (MN/m

3

) ux (cm)

Elastic

15-45

0.66

19-56

0.88

Elas/Plas

15-45

1.35

19-56

1.70

Elas/Plas

30-90

1.09

19-56

0.65

4 COMPARING 3-D ANALYSES

3-D methods highlight the same behavior but to different

degrees. Using similar soil properties, one may compare the

benefit of a two-pile system. The 3D model also made use of

interface elements and a thin pile element placed within the

solid element pile in order to determine shear and bending

moments (MIDAS 2009). This time, the benefit is more

pronounced, due to the more efficient process of spreading

reaction loads throughout the soil in three dimensions.

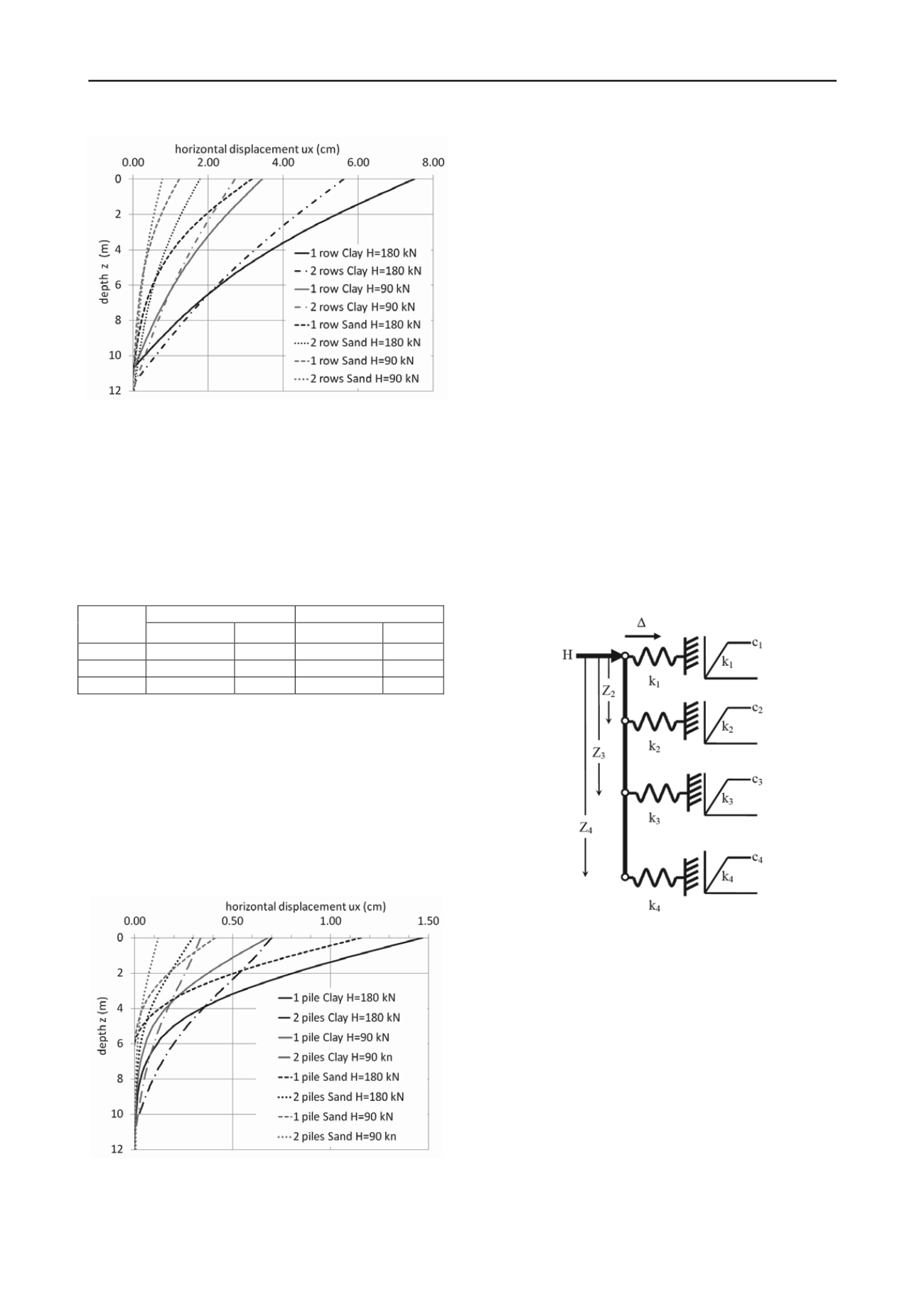

Figure 2. Displacement profiles for 1, 2 piles; Sand, Clay; 90,180 kN.

Displacement magnitude is much less for all combinations of

load and soil. Surface displacements are smaller than those in

Figure 3 by a factor of about 5-8x. This time the number of piles

resisting movement is more influential in reducing displacement

than the soil modulus. This is evidenced by the fact that the

displacement profiles are grouped by number of piles and load

magnitude (1 pile Sand H=180 is most near to 1 pile Clay

H=180, etc.) The single piles also show a very pronounced

slope at the surface which will again translate to rigid body

rotation of the bridge pylons.

5 COMBINING ANALYSES

Presently the research group is adapting an optimization method

to translate pile head displacement and rotations computed from

2D and 3D finite element analyses to a small number of elasto-

plastic subgrade springs for use in structural or geotechnical

design software (such as GEO and AXIS). The method assumes

the pile has identical structural properties as the original (more

sophisticated) analysis software. Four to six lateral springs are

placed on the pile at various depths. One spring is always placed

at the surface, another at the pile tip. The remaining springs will

be placed in optimal positions to produce similar responses at

the top of the pile.

The procedure seeks to optimize three quantities for each

spring: elastic constant, k; plastic limit, c; and depth were the

spring is attached to the pile, z. The pile structural element is

modeled as a series of beam elements with nodes located at the

pile tip, point of application of the middle springs, and the pile

top. For a four spring model, the pile will consist of four nodes

and three elements (Figure 5).

.

Figure 3. Four element pile with elasto-plastic springs.

The optimization process varies the eight spring parameters

and two depths (the other two are the fixed length of the pile

and zero) to minimize the least squares error between the

deflection, Δ, computed above and the displacement generated

from the finite element model for the same load, H. When the

sum of least-squares error is minimized, the problem is solved.

This is the same process one uses for fitting trend lines to data.

The program is written in Visual Basic for Applications (VBA)

and runs within an Excel spreadsheet. Computing deflections

for the various loads is done with a small, nonlinear matrix

structural analysis program that is called as an Excel function

and returns the computed deflection value to the spreadsheet.

The optimization makes use of the Solver add-in found in

Excel. The parameters that are varied in the solver are those

discussed above, the target value to minimize is the sum of the

squared errors. Sample output for the optimization process is

shown in Figure 6.