2861

Technical Committee 212 /

Comité technique 212

Table 1. Result of pile test.

Pile parameters

Site

(Pile)

Ø, m

L, m

Head

level, m

Jack

level, m

Max

load, MN

Max

displacement

head/tip, mm

Side resistance determination

method

Pile side

resistance

MN/m

2

3(1)

1,2

28

113

86,1

20

3,1/1,5

D

1,20

3(2)

1,2

28

113

86,1

20

1,8/2,5

D

1,20

4(1)

1,2

28,6

110,4

87,4

26,5

4,1/1,7

D

-

4(2)

1,2

28,0

110,4

84,4

24,5

3,4/1,4

D

-

11(1)

1,2

22,6

104,5

85

20,00

1,8/2,1

D

1,30

11(2)

1,2

22,6

104,5

85

16,50

1,0/1,5

D

1,80

12

1,5

10,5

85,1

81,6

33,30

3,2/7,5

D,F( 4)

2,55 (1,55)*

13А

1,2

27

109

89

33,3

6,1/3

F(6)

2,00

13Б

1,2

29,7

109

83,7

25,13

17/6

F(3)

2,20

14 (1)

1,5

19,2

103,2

88,4

33,33

8/65

D

2,00

14 (2)

1,5

19,2

103,2

92,6

33,33

16/4

D

1,90

15 (1)

1,5

20,4

103,8

93,4

1350

4/150

D

200

15 (2)

1,5

19,4

103,8

86,4

3333

10/10

D

200

16(1)

1,5

24,3

118,5

114

3000

8,3**

F(19)

33

16(2)

1,5

24,3

118,5

114

3200

7,2**

F(19)

36

*2,55(1,55) – values with no brackets were determined from tensometer data analysis , in brackets from fragment test data;** top-down fragments

tests ; D, F – side resistance was determined as per equation 1 and from pile fragment test data ; F(4) – fragment length m.

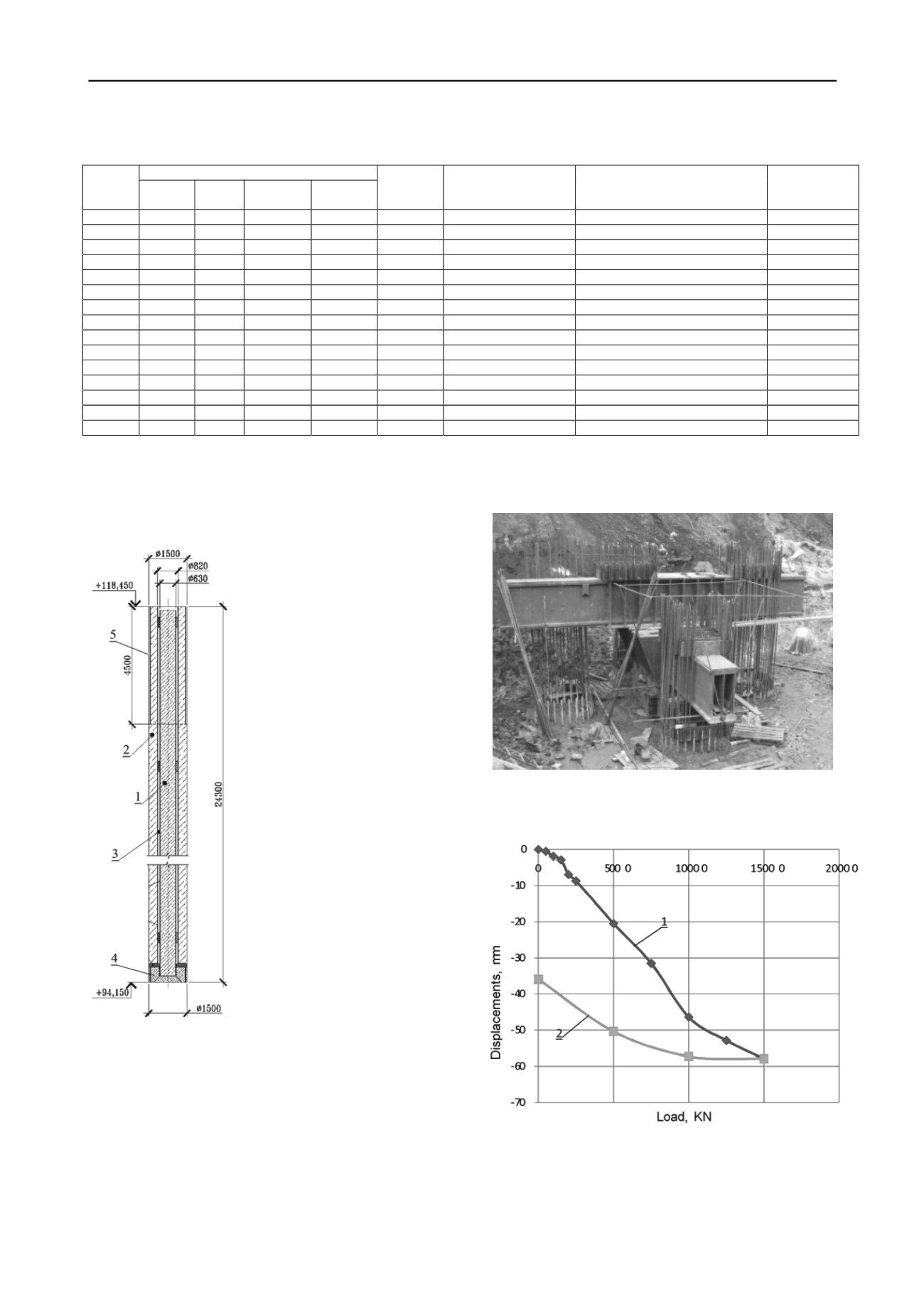

In order to separate side and tip resistances the pile consisted

of two parts: inside part 1 (630 mm external diam.) and outer

part 2 (1500 and 820 mm ring diam.). The hollow space be-

tween the pile segments (3) was filled with elastic material to let

the parts to freely slide against each

other. The interior part (1) was

connected with a stiff plate (4). In

order to isolate the pile exterior top

(2) from the soil mass an external

casing tube was installed on the top

(5). The loaded system included

two steel box cross beams (Figure

7), connected with service piles,

used as anchors.

The tests were started by load

application to the interior part of the

pile (1) and through it to the plate

(4) (pile tip test).

Then the set-up was adjusted to

step wise load application to the

exterior part of the pile (2), and pile

side resistance was determined.

Figure 7. Loading set-up

The initial plate test and elastic

spacers between pile parts prevent

data distortion in the pile exterior

side test.

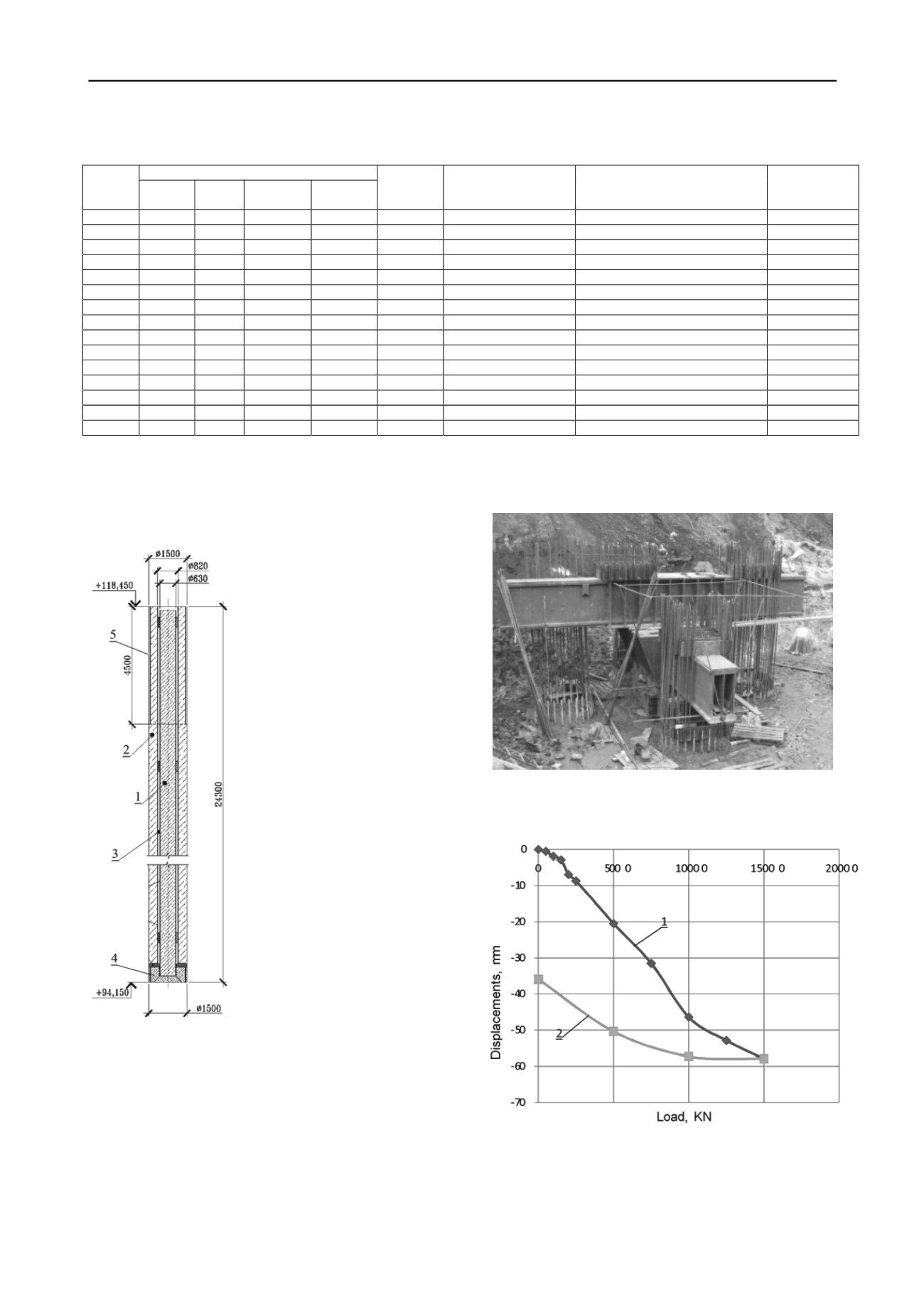

The test results (Figure 8,9)

show that the central part of the

plate displacement largely exceeds

that of the pile-shell.

Figure 6. Loading set-up

The pile tip resistance for equal displacements was one or-

der of magnitude less than that of the side resistance and several

orders of magnitudes less than the analytical value. This fact

shows presence of mud on the borehole bottom, which could not

be removed during drilling operations.

Soil resistance below pile tip at other sites demonstrated its

strong dependence on the quality of the bottom face and on the

quality of special operations (soil grouting), e.g. on site 4 grout-

ing was done to 5 m below the pile tip.

1 – loading, 2 - unloading

This shows the necessity for extra operations to clean and to

compact the bottom, e.g. by grouting the soil under pile tip, by

compacting the bottom, e.g. by ramming broken stone or stiff

concrete into the bottom, etc. (Petrukhin et al, 2011).

Figure. 8. Pile tip test diagram