2852

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

minimize friction between the tank wall and sand

particles.

Vertical loads were applied to the model pile by

using a hydraulic jack. The magnitudes of applied loads

were recorded with the help of a pre-calibrated sensitive

proving ring. The lateral load was affected through a 2

mm diameter high-tension steel wire connected to the

pile cap using an eye bolt. The other side of the wire ran

over smooth adjustable pulley with a 70 mm diameter

and supported a load plat form. In order to record the

correct vertical settlement and lateral deflection of the

pile for each load increment applied, four sensitive dial

gauges of the least measurement of 0.01 mm were used,

two for vertical and two for lateral and their average was

taken.

A smooth steel model pile, with diameter of

10mm, and total length 110, 210, 310, and 410 mm were

used in this study. The upper 10 mm of the pile is

screwed part and the other length embedded in sand. The

slenderness ratio (L/D) was chosen to be used in this

research equal to 10, 20, 30, and 40. Five strain gages

were stuck to the surface of the model pile with L/D =

40. The measurement of flexural strains can lead directly

to bending moment curve.

The cap was designed as flexible as possible and

the pile was not deeply seated through it, so that no

restraint of the pile head rotation is available. One edge

of the cap is bent up to allow horizontal dial gauges to be

mounted. At the other side of the cap, a 1.5-cm hook was

welded exactly at the center of this side.

3 SOIL PROPERTIES

The soil used in this study for all of the tests is clean

sand, classified as poorly graded sand according to the

Unified Soil Classification System. The moisture content

(W

c

) was about 2%. The following are the results of the

sieve analysis test; effective grain size D

10

= 0.14 mm

and uniformity coefficient C

u

= 4.357. The sand was

placed to achieve three relative densities. The physical

characteristics of these soils are shown in Table (1).

Table 1. Physical Properties of the Tested Soils.

Soil Condition A B C

Relative density D

r

(%) 25 45 68

Unit weight (kN/ m

3

) 17.5 17.8 18.3

Voids ratio (e) 0.56 0.52 0.48

Porosity (n) 0.36 0.34 0.33

Angle of shearing resistance (Ø) 31

o

34

o

38

o

4 PREPARATION OF EXPERIMENTAL SETUP

Before sand slope preparation, the model pile was then

placed at a specific position. Then, model sand slope

150- mm high with slope angle, θ, of 26.56

o

(2H: 1V)

was prepared in layers of 50 mm thick. The proposed

testing geometry of the slope was first marked on the

walls of the tank for reference. To obtain uniform density

of the soil in the tank, controlled pouring and tamping

techniques using a flat bottom hammer were applied. The

pile was placed and fixed in its correct position before

the formation of sand slope to simulate non displacement

piles.

5 RESULTS AND DISCUSSION

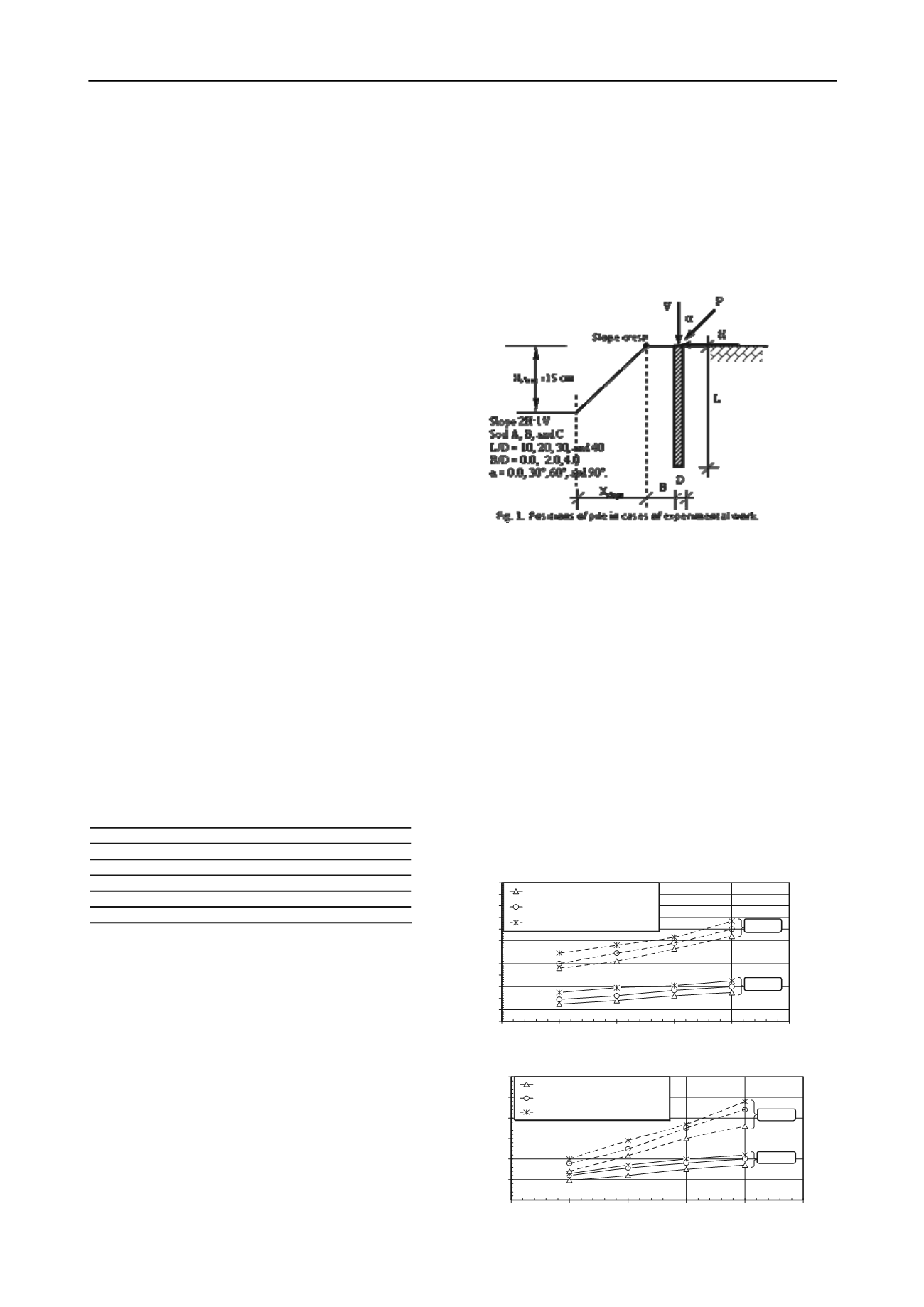

An experimental testing program was designed to study

the effect of inclined load on the behavior of vertical pile

in sand on level ground and adjacent to ground slope.

The geometry of the problem is illustrated in Fig. 1. As

shown in this figure, the height of ground slope (H

slope

)

equal to 15 cm and its horizontal projection (X

slope

) equal

to 30 cm to achieve slope gradient (2H:1V). The location

of the pile relative to the slope crest is the distance (B).

The load-deflection curves were obtained by plotting the

relationship between the vertical and lateral loads and its

axial settlement and lateral deflections, respectively.

According to Terzaghi (1942) and Tomilson (1980), the

ultimate axial (V

u

) and lateral (H

u

) loads are defined as

the loads, which cause a vertical or horizontal deflection

of one tenth of the pile diameter (i.e. 10% of the pile

diameter) to simulate the geotechnical failure in the soil.

5.1

Ultimate capacity of pile in the level ground

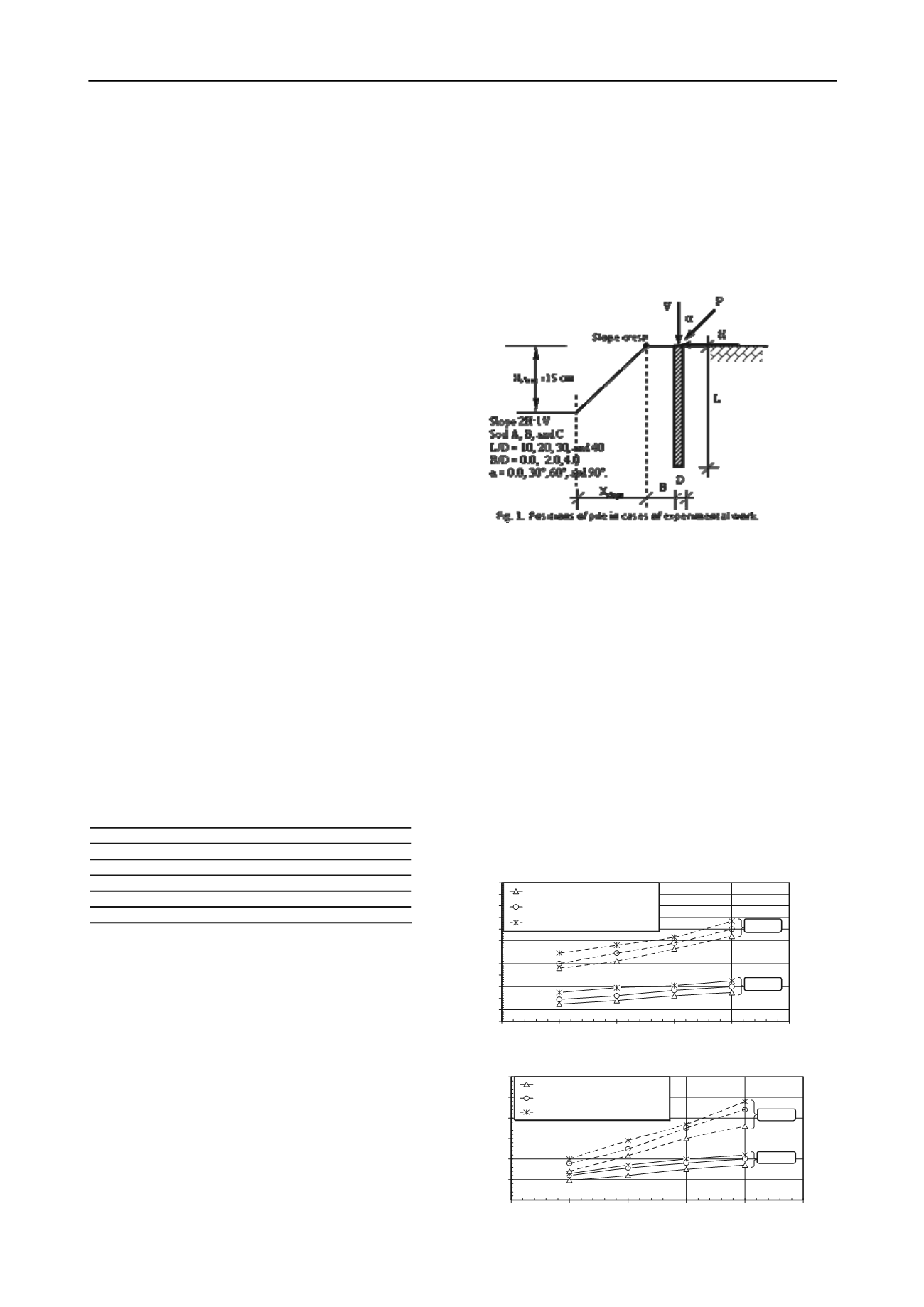

The ultimate axial load and lateral load of the pile

increased during testing program when the slenderness

ratio (L/D) was increased. As shown in Fig. 2, for dense

sand (soil C), a significant increase for ultimate axial

load (V

u

) with increasing slenderness ratio. But for loose

sand (soil A), the effect of slenderness ratio on the

ultimate axial load found to be small. The ultimate axial

load (V

u

) decreased as the inclination of the applied load

with the vertical (α) was increased.

0

10

20

30

40

50

60

70

80

90

100

110

120

0

10

20

30

40

50

L/D

Ultimate axial load Vu (N)

Angle of inclined load = 60 degree

Angle of inclined load = 30 degree

Angle of inclined load = 0.0 degree

Soil (A)

Soil (C)

Fig. 2. Relationship between (L/D) and (V

u

) for soil A and C.

0

10

20

30

40

50

60

0

10

20

30

40

50

L/D

Ultimate lateral load Hu (N)

Angle of inclined load = 90 degree

Angle of inclined load = 60 degree

Angle of inclined load = 30 degree

Soil (A)

Soil (C)

Fig. 3. Relationship between (L/D) and (H

u

) for soil A and C.

minimize friction between the tank wall and sand

particles.

Vertical loads were applied to the model pile by

using a hydr ulic jack. The magnitudes of app ied loads

were recorded with the lp of a pre-calibrated sensitive

proving ing. The lat ral load was affected through a 2

mm diameter igh-t nsion steel wir connected to the

pile c p using an eye b lt. Th other side of the wire ran

over smooth djusta le pull y with a 70 mm d ameter

and upported a load plat form. In order to record the

correct vertical settlement and lateral deflection of the

pil for ach oad incr ment applied, four sensitive dial

gauges of the least m asurement of 0.01 mm wer used,

two for vertical and two for lateral and their av age was

taken.

A smooth steel model pile, with diameter of

10mm, and t tal length 110, 210, 310, and 410 mm were

used in this study. The upper mm of the pil is

crewed part an the other length embedded in sand. The

sl nderness ratio (L/D) was c osen to be u ed in this

r sea ch equal to 10, 20, 30, and 40. Five train gages

w re stuck to he surface of the model pile w th L/D =

40. The measur ment of flexural strains can lead directly

to bending moment curve.

The cap was designed as flexible as possible and

the pile was not de ply seated through it, o that no

r straint of the pil head rotation is available. One edge

of the cap is bent up to all w horizont l dial gaug s to be

mounted. At the other side of the cap, a 1.5-cm hook was

weld exactly a the center of this side.

3 SOIL PROPERTIES

The soil used in this study for all of the tests is clean

sand, clas ified as poorly graded sand according to the

Unified Soil Cl sification System. The m isture c ntent

(W

c

) was about 2%. The following are the results of the

sieve nalysis test; eff ctive grain size D

10

= 0.14 mm

and u iformity co fficient C

u

= 4.357. The sand was

placed to achieve thre relative densities. The physical

charac eristics of t es soi s ar shown in Tabl (1).

Table 1. Physical Properties of the Tested Soils.

Soil Condition A B C

Relative density D

r

(%)

25

45

68

Unit weight (kN/ m

3

)

17.5 17.8 18.3

Voids ratio (e)

0 6 0 52 0.48

Porosity (n) 0.36 0.34 0.33

Angle of shearing resistance (Ø) 1

o

o

38

o

4 PREPARATION OF EXPERIMENTAL SETUP

Before sand slope preparation, the model pile was then

plac d t a specific ositi . Then, mode sand slope

150- mm high w th slope angle, θ of 26.56

o

(2H: 1V)

was prepared in layers of 50 mm thick. The proposed

te ting geometry of the slope was first marked on the

walls of the tank for referenc . To obtain uniform density

of the soil in the tank, controlled pouri g and tamping

tec niques using a flat b ttom hammer were applied. The

pile was placed and fixed in its co rect position before

th formation of sand slope to imulate non d splac ment

piles.

5 RESULTS AND DISCUSSION

An experimental testing program was designed to study

the eff ct of inclined load n the behavior of vertical pile

in sand n level ground and adjacent t ground slope.

The ge metry of the problem is illustrated in Fig. 1. As

shown in his igure, the height of g ound slope (H

slope

)

equal to 15 cm and its horizon al projection (X

slope

) equal

to 30 cm to achieve lope gradient (2H:1V). The location

f the pile relati to th slope crest is the distance (B).

The load-deflection curves were obtained by plotting the

relationship be ween th vertical and lateral loads and its

axial ettlement and lateral deflections, respectively.

According to Terzaghi (1942) and T milson (1980), the

ultimate axial (V

u

) and lateral (H

u

) load are defined as

the loads, which c use vertical or horizontal defl ction

of ne tent of the pile diamete (i.e. 10% of the pile

diam ter) to simulate the geot chnical failure in so .

5.1

Ultimate capacity of pile in the level ground

The ultimate axial load and lateral load of the pile

increased during testing progr m when the slenderness

ratio (L/D) was increased. As sho n i Fig. 2, for d n e

sand (soil C), a significant increase for ultimate axial

load (V

u

) with increasing sle derness ratio. But for loose

s nd (soil A), the effect of slenderness rati on the

ultimate axial load found to be small. The ultimate axial

oad (V

u

) decre sed as the inclination of the applied load

with the vertical (α) was increased.

0

10

20

30

40

50

60

70

80

90

100

110

120

0

10

20

30

40

50

L/D

Ultimate axial load Vu (N)

Angle of inclined load = 60 degree

Angle of inclined load = 30 degree

Angle of inclined load = .0 degree

Soil (A)

Soil (C)

Fig. 2. Relationship between (L/D) and (V

u

) for soil A and C.

0

10

20

30

40

50

60

0

10

20

30

40

50

L/D

Ultimate lateral load Hu (N)

Angle of inclined load = 90 degree

Angle of inclined load = 60 degree

Angle of inclined load = 30 degree

Soil (A)

Soil (C)

Fig. 3. Relationship between (L/D) and (H

u

) for soil A and C.