2848

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

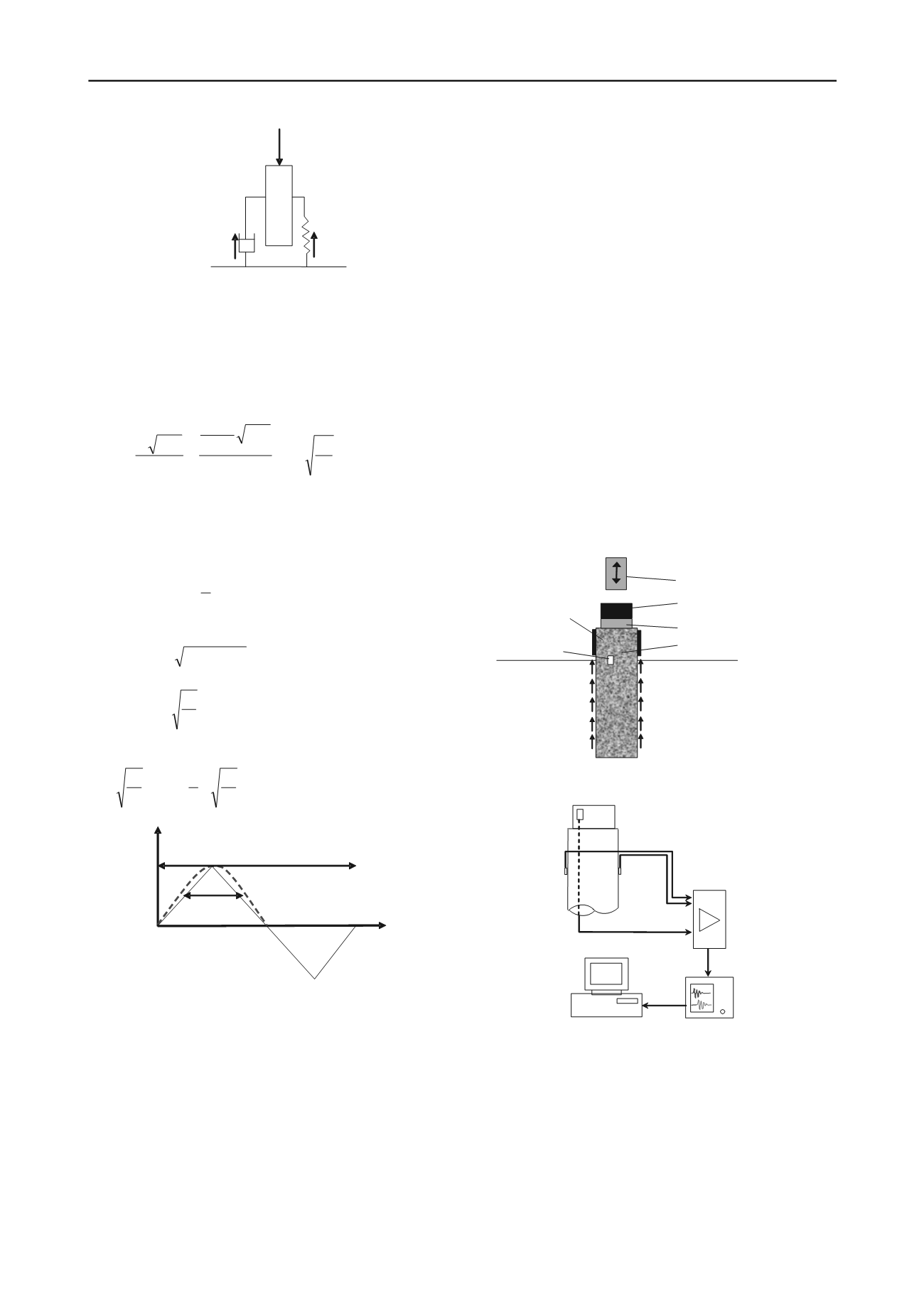

Figure 2: Model for the soil pile interaction in the peudoestatic model.

To increase the application time of loading, a high strength

resilient material is required to be placed on the head of the pile

in the area of impact. Assuming that the load is obtained by a

falling mass of approximately 10% of the ultimate capacity of

the pile (Fu) and also considering the charging triangular

diagram of Figure 3, then:

g

h

F

gh

g

F

F

gh m t

u

u

u

21.0

2 1.0

2

50

(3)

Where

h

is the falling height of the mass

m

. This cinematic

equilibrium equation is an approximation since restitution

forces has been overridden.

The maximum forces that can be exerted on the pile tip

(F

max

) due to the falling mass on a cushion material of elastic

constant

k

e

can be calculated as:

max

max

2

1

z F hgm

(4)

Where z

max

is the maximum deformation of the cushion

material z

max

= F

max

/k

e

. Then, replacing in equation (4),

e

khgm F

2

max

(5)

Being the natural frequency of the mass-cushion system:

e

k

m T

2

(6)

Since t

50

is half of the natural frequency and assuming a

triangular shape of the wave (see Figure 3):

e

e

k

m

t

k

m

3

2

50

(7)

Figure 3: Simplified model of the stress pulse.

Equations (5) to (7) allows to evaluate the magnitude of

the mass and the falling height to obtain a maximum force F

max

according to the elastic constant

k

e

of the cushion material.

From Figure 2, the equilibrium equation can be derived

as:

(8)

aMM F F F

p

s

k c d

)

(

Where

M

s

and

M

p

are the mass of the pile and the soil

respectively and

a

is the acceleration of the movement.

Equation (8) can be rewritten in terms the resistant forces as a

function of the dynamic parameter

F

c

= c v

, and

F

k

= k u

, being

u

and

v

the displacement and velocity of displacement

respectively:

(9)

aMM uk vc F

p

s

d

)

(

Dynamic Force

Equation (9) allows determine dynamic influence on the

measured force at the point of where the velocity becomes zero

and thereafter correcting the measured force by the dynamic

effect.

Fd

Mp

2 TESTING PROCEDURE.

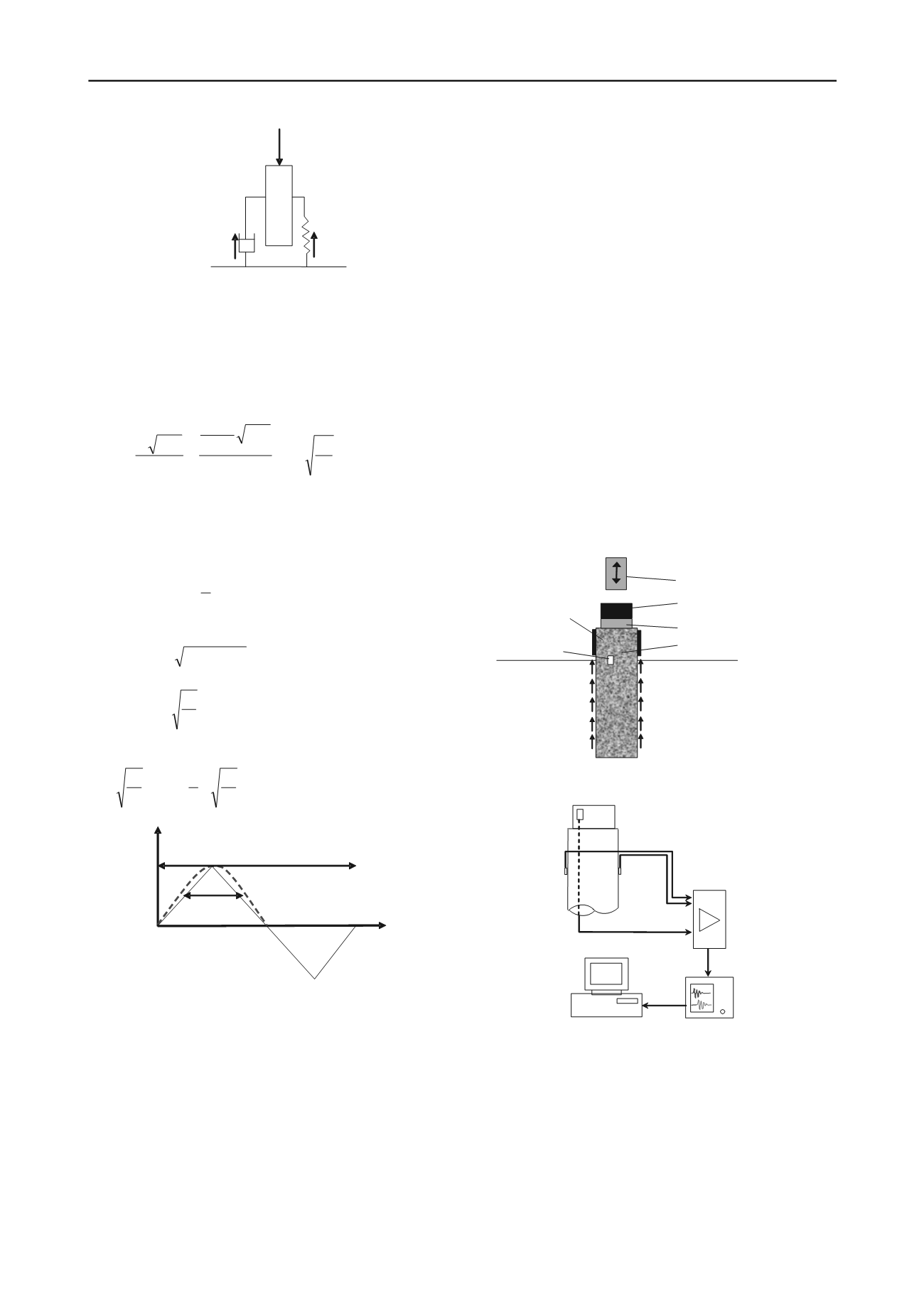

Figure 4 and 5 sketch the testing setup and electronic devices

used for the pseudoestatic load test. This loading design

generates a time-controlled load which will depend on the

magnitude and height of the falling mass, and geometry and

elastic properties of the elastomeric cushion included between

the mass and head of the pile. The force pulse is captured by a

load cell placed below the cushion. The displacement of the pile

is obtained from the double integration of the signals captured

by two accelerometer placed on the shaft and below one

diameter from top of the pile. The weight of the mass to be used

ranges between 5% and 10% of the servicebility capacity of the

pile. The test requires the continuous increment of the height of

drop of the mass. The output of the conditioners is then

digitized by the dynamic analyzer and conveniently stored for

subsequent laboratory analysis. In addition to the equipment

shown, a proximeter is placed to capture displacements and

permanent settlement of the pile. The maximum testing load is

obtained when a permanent displacement is generated or until

the 50% of the service load is reached.

Figure 4. Testing setup for the pseudoestatic load test.

Figure 5. Testing electronic devices used for the pseudoestatic load test.

The impact mass can be made at the site usually employing a

concrete slab or a steel casing filled with concrete depending on

its size. For the purpose of centering the load, steel bars are used

as guides for obvious safety reasons and ensuring the impact of

the mass be centered avoiding the generation of moments. For

the purpose of preventing the damage of the pile by the

application of impact on the mass, the shaft is increased (1.5 to

2 times the diameter) by means of a steel case of the same

diameter of the shaft. In all cases, the accelerometers must be

positioned below this extension or in a window made on it. The

Spring

+

Force

Ms

Damping

Force

F

c

F

k

c

k

Amplitude (KN)

T

t

50

Time

Falling Weight

Cushion

Pile

Steel

Load Cell

Case

Accelerometer

Load cell

Signal Conditioner

Signal Recorder

Signals from

Signals from load cell

Pile

Signal Processor