2865

Technical Committee 212 /

Comité technique 212

group and to safeguard against excessive or differential overall

displacements.

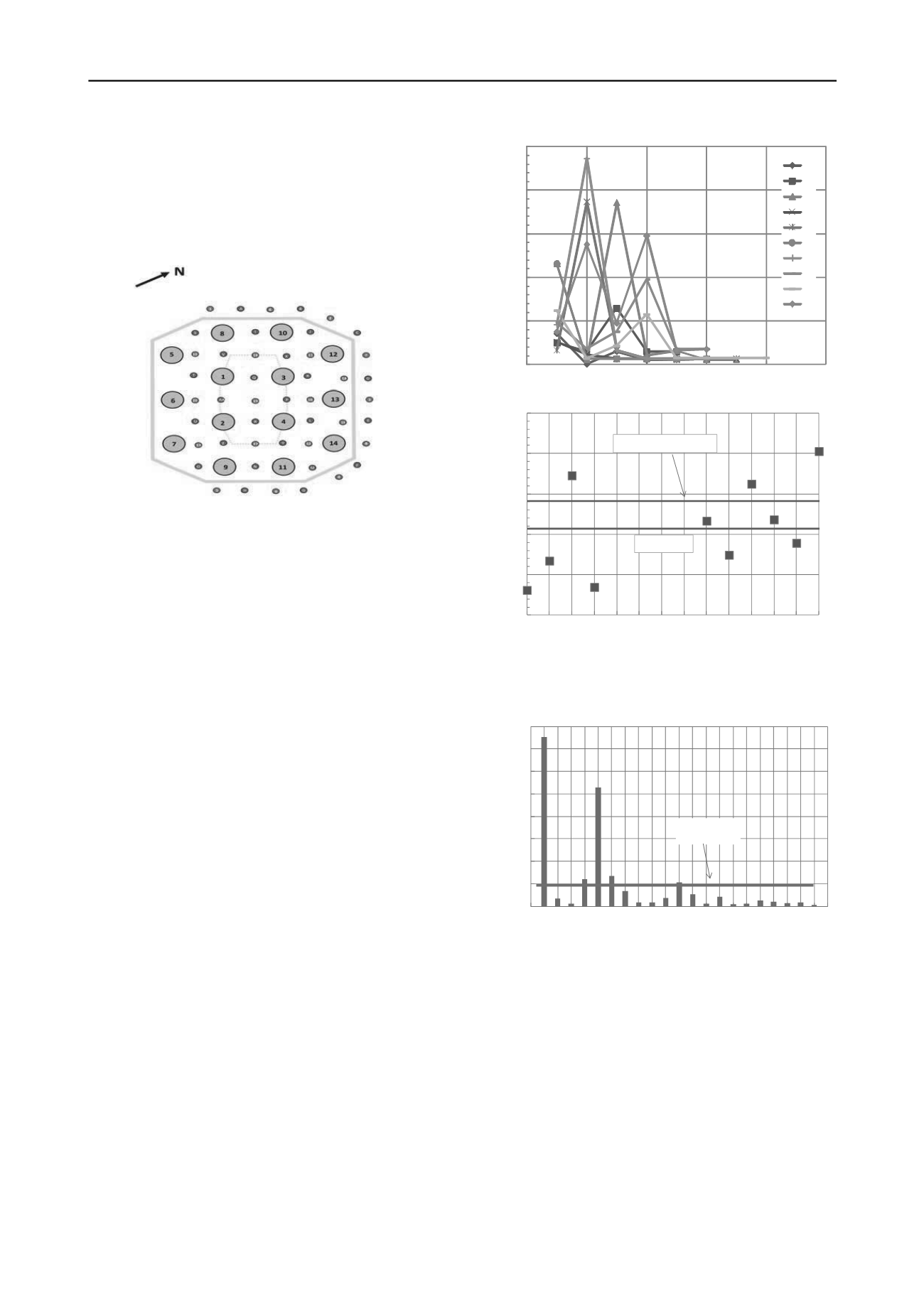

The grouting scheme devised consisted of primary and sec-

ondary grouting holes in staggered sequence as shown sche-

matically in Figure 5. To maximize the effect the sequence of

grouting is staggered.

Figure 5. Schematic grouting scheme with primary grout holes in Ara-

bic numbers and secondary grout holes in letters (pile numbers of the 14

Ø2 m piles shown for reference; piles 5, 6, 7 and 8 were drilled into the

competent limestone prior to the remediation scheme).

The holes for pressure grouting (40 m deep) were drilled "de-

structively" from the ground surface using a Ø141 mm drill in

the Marl (with casing) and a Ø105 to 115 mm drill to the full

depth (without casing). The grout take was carefully measured

using the same type of grout as before, but now with a settling

<5% after 2 hours. The uncased part passing through the cavity

feature was pressure grouted using packers with 12 bar pressure.

The cased part was gravity grouted as the casing was with-

drawn.

4 MONITORING OF REMEDIATION MEASURES

Based on the surface texture of the holes drilled for the piles

(very uneven surface) the actual consumption would be ex-

pected to be higher than the theoretical consumption based on

the bore and grout hole diameters. The consumption of concrete

when casting the Ø2000 mm piles was:

Piles P4/5 to P4/8 (46 to 50 m length): 113% ± 3.7%

Remaining 10 piles (22 to 28 m length): 108% ± 1.8%

i.e. roughly 10% excess consumption.

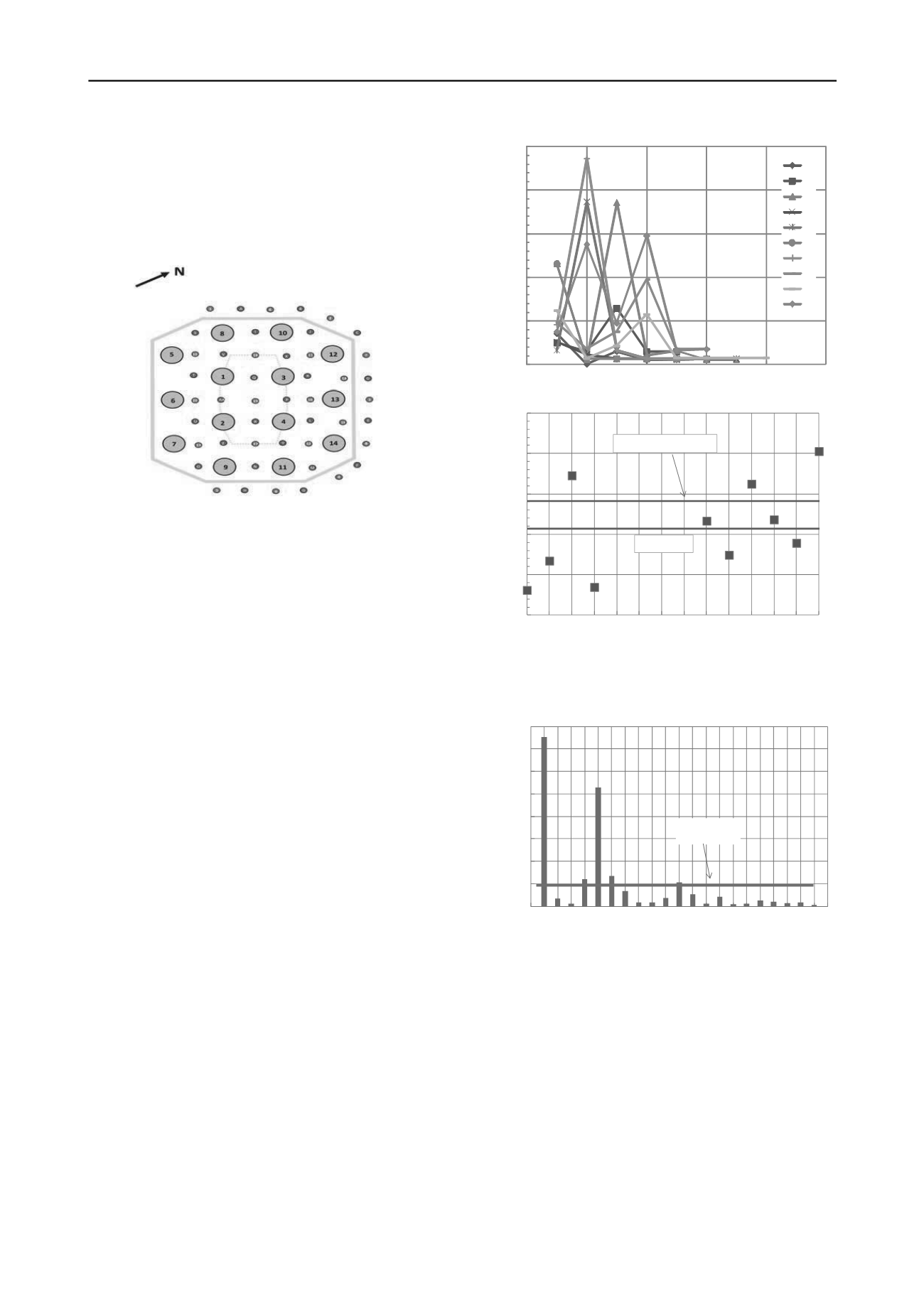

As the Ø178 mm holes were re-drilled it seems likely that

actual nominal consumption would be 115% of the theoretical

consumption. Using this as baseline the excess grout take from

the five reinforcement-holes below each of the ten Ø2000 mm

piles are shown in Figure 6. In some cases re-grouting of the

holes took place and hence a sequence number in excess of five

occurs for some of the piles.

Although there is considerable scatter the excess grout take

decreases by and large as a function of the sequence as would

be expected as any cavity feature will be more readily filled

during the initial grouting. Piles 3, 9, 11, 12 and 14 show grout

take above average which is interpreted as a more persistent

cavity feature at these locations.

0

5

10

15

20

25

0

2

4

6

8

Excess grout take per m

icropile (m

3

)

Sequence of micropile grouting per pile

10

1

2

3

4

9

10

11

12

13

14

0

10

20

30

40

50

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Excess grout take in micropiles (m

3

)

Pile Number

average

95% upper limit

Figure 6. Excess grout take in "micropile" holes; (a) as function of se-

quence (2-6 weeks from grouting of fist to last pile); (b) accumulated

values per pile location

0

2

4

6

8

10

12

14

16

P11

P16

P19

P18

P1

P2

P6

P7

P8

P9

P4

P5

P3

P12

P13

P17

P10

P20

P9 bis

P15

P14

Excess grout take (m

3

)

Primary grout hole

average

Figure 7. Excess grout take versus sequence for primary grout holes

The actual sequence of the subsequent pressure grouting in pri-

mary (Figure 7) and secondary (Figure 8) deviated slightly from

the sequence in Figure 5 but followed the principal intent. The

theoretical grout take was based on the nominal drilling diame-

ters but with reference to the considerations for the piles and

pre-drilling holes this may entail some 15% underestimation of

take.

As seen in Figure 7 and Figure 8 the excess grout take was

very limited in the majority of holes.