2757

Technical Committee 212 /

Comité technique 212

Research on the Load-Bearing Behaviour of Bored Piles with Different Enlarged Bases

18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

3

3

TEST SEQUENCE

After complete installation of the appropriate test pile (see

Installation- /Soil parameter Table 1):

4

EVALUATION OF THE RESULTS

For the evaluation of the results and the comparative analysis,

the three tests per pile were averaged. The calculated average values

were used as the representative values for the respective pile models

for all of the following comparisons and computations.

Table 1 shows that all three models had comparable mobilized

skin frictions from 6131.1 to 762.0 N. The skin friction appears to

be a constant value with it’s proportion of the load decreasing

greatly with increasing base enlargement so that a shift in the

resistance occurs from a skin friction/point bearing to a

predominantly point bearing pile. The existing technical

assumption/theory that there is an “arching effect” regarding the

stress distribution with a base enlargement by activating higher skin

friction stresses cannot be substantiated by this test series.

1.Placement /Compaction 1. Layer

2.Placement /Compaction 2. Layer

3.Centering/Plumbing test pile in the container

4.Placement /Compaction 3.-6. Layer,

Table 1. Installation- /Soil parameter

Installation- /Soil parameter

d

Container

[cm]

70

h

layer

(1-6)

[cm]

14.5

M

layer

(1-6)

[g]

15867

D

[g/cm³] 1.71

g

s

[g/cm³] 2.65

I

D

[-]

0.74

Table 2. Results of Test Models 1xD, 2xD, 3xD, Comparison of results

with and without skin friction

Skin friction (R

S

)

Test

Pile

Point bearing (R

b

)

+Skin friction (R

S

)

Point

bearing

Absolute Relative

R

b+s

[N]

R

b

[N]

[N]

[%]

Model

1xD

1645.4

1032.3

613.1

37.2

Model

2xD

4505.2

3743.2

762.0

17.1

Model

3xD

9684.5

9013.1

671.4

6.8

in the test soil (dense sand), the experimental container (steel

cylinder) was centered under the cross beam and hydraulic press.

After installation of the measuring bridge (See Figure 6) a seating

load, F

i

= 250 N, was applied to eliminate any slack in the loading

system and to adjust the strain gauge.

The experimental models 1xD and 2xD were loaded in

increments of 250N, and model 3xD in 500N steps. After each

increment of loading the load was held for 10 minutes. Settlement

readings were made after 0, 1, 2, 3, 5 and 10 minutes. The failure

criterion for the test loadings was taken to be when the pile sank

continuously into the soil under a constant load.

According

to

FRANKE

the

evaluation

of

the

FRANKE/GARBRECHT investigations shows that for bearing

structures with acceptable deformation ranges of 2 to 4 cm and

different loadings, it is possible to equalize settlements by the use of

pile foot base enlargement

(see Table 4).

Table 3. Comparison of the results of model tests 1xD, 2xD, 3xD

Test Pile

1xD

2xD

3xD

Base diameter

[mm]

36

72

108

Contact area

[mm²] 1017.88 4071.5 9160.88

Settlement limit s

gr

[mm]

3.6

7.2

10.8

R(s

gr

)

b+s

from tests

[N]

1645.4

4442.5

9645.9

Proportional increase

related to the 1xD-pile

[%]

-

270.0% 586.2%

R(s

gr

)

b

from tests

[N]

1032.3

3743.2

9013.1

Proportional increase

related to the 1xD-pile [%]

-

362.6% 873.1%

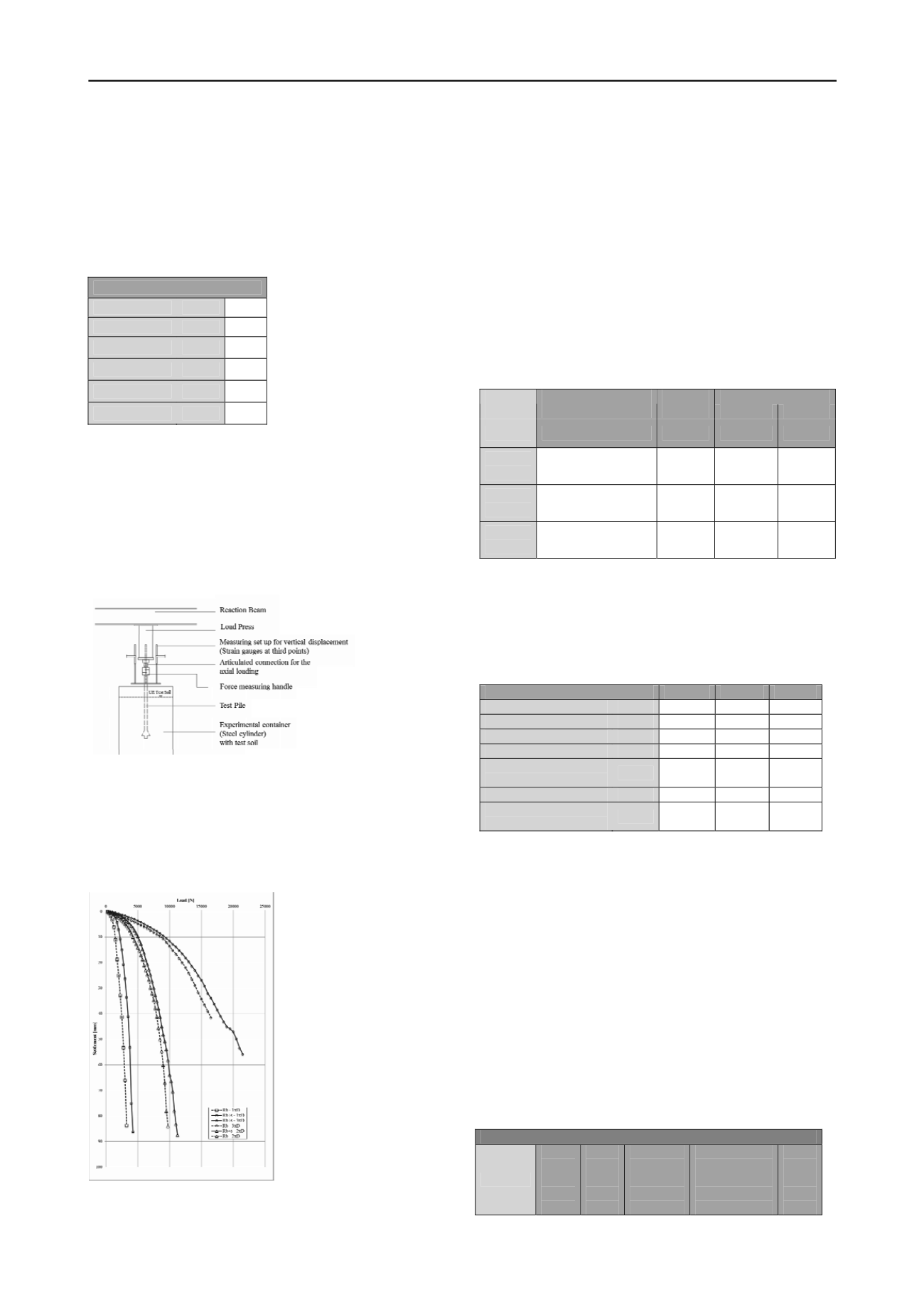

Figure 6. Test Set-Up

3.1

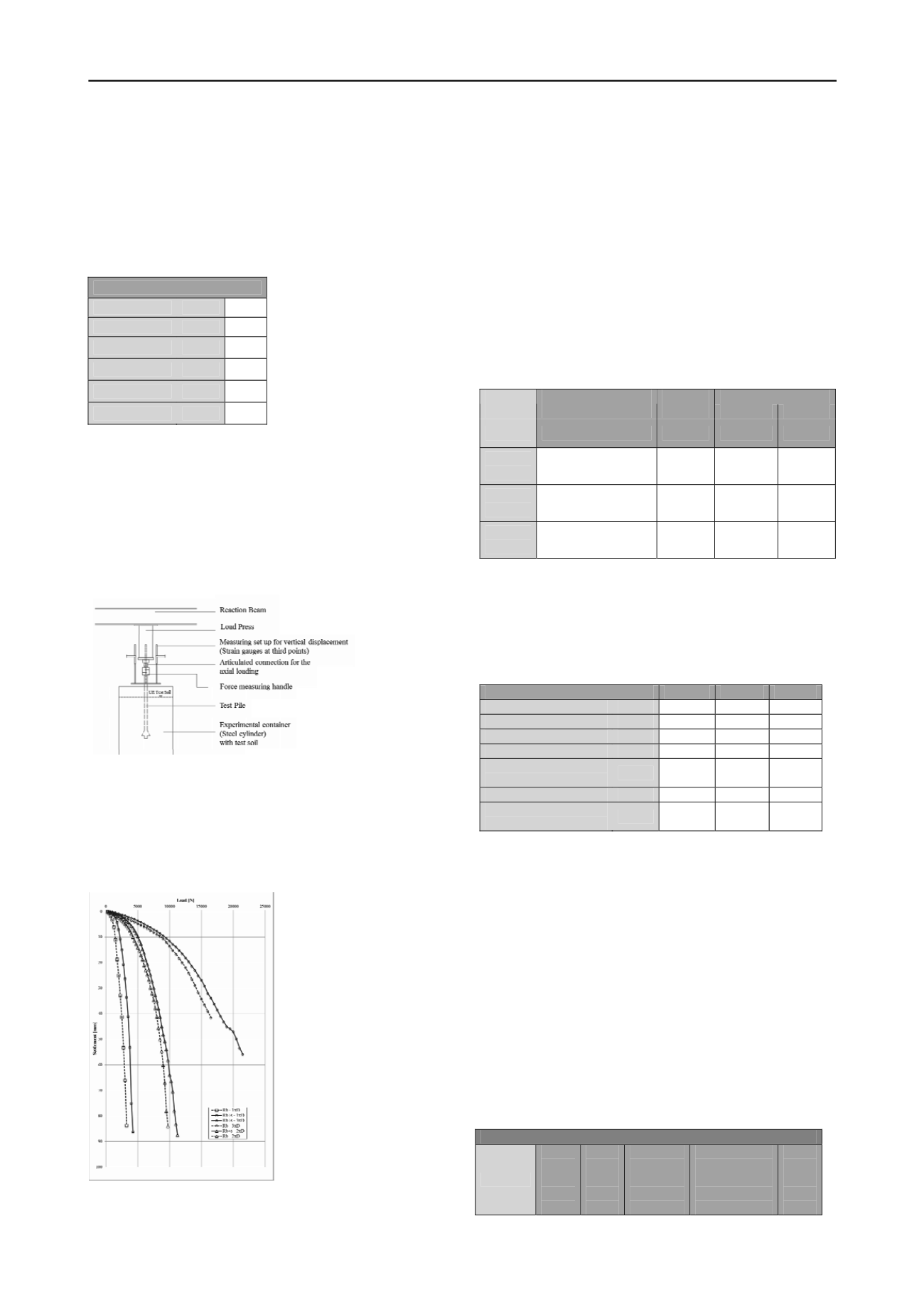

Results of the Load Tests

On the basis the measured values of the applied loads and

associated vertical displacements, a graphic evaluation of the

various test loads was made. The bearing resistance dependant

on the pile settlement is illustrated in the following (see figure

7) by the average resistance-settlement curve (average values of

the R

b+s

and R

b

test loadings).

5

COMPARISON WITH IN SITU TESTS

For the evaluation of the results, there are at present only the

investigations by FRANKE/GARBRECHT in the form of full-scale

tests, which are drilled piles 6 to 14 m long with pile (b) and pile

base diameters (b

f

) from 1100 to 2100 mm hat were manufactured

with and without base enlargements in medium dense sands and

were load tested with deactivated skin friction (using a bentonite

filled ring gap) (see Table 3).

The results of the investigations by Franke/Garbrecht indicate that

the ratio of the breaking stress for the enlarged to the normal pile

amounts to approximately 0.94 to 0.95 (see Table 4 σb(s

gr

)

(1)

to

σb

f

(s

gr

)

(1)

). This with the reducing coefficient for characteristic pile

resistances, α

enlarged

= 0.75, verifies the manufacturer’s partial safety

factor, γ > 1.25 (see Eq. 1 resp. Eq. 2 / Table 4),

R

bf

(s

gr

) / (R

bf

(s

gr

) · 0,75) > 1,25

(Eq. 1)

σb

f

(s

gr

)

(1)

/ (σb

f

(s

gr

)

(1)

· 0,75) > 1,25

(Eq. 2)

the acceptable safety representative of the researched pile foot base

enlargement.

Table 4. Comparison of the results of Franke/Garbrecht with own Tests

Figure 7. Load Test Resistance-Settlement Curves, R

b+s

and R

b

(average

values in each case from 3 test load trials)

FRANKE/GARBRECHT

Pile

b

resp.b

f

Ratio

b

f

resp.

b

[-]

Pile foot

base area

[m²]

σb(s

gr

)

(1)

resp.

σb

f

(s

gr

)

(1)

[N/mm2]

σb(s

gr

)

(1)

to

σb

f

(s

gr

)

(1)