2760

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2

VISUALIZATION OF GROUND BEHAVIOR UNDER

PLANE STRAIN CONDITION

100mm

250mm

Height of model ground

H

= 270mm

Length of pile

H

1

=200mm

Vertical

load

Load cell

(

Pile head

)

Load cell

(

Pile end

)

Loading plate

Displacement

gauge

Pile

Box shaped cell

Drainage

port

Kaolin clay

Plan view

Side view

Pore pressure

transducer

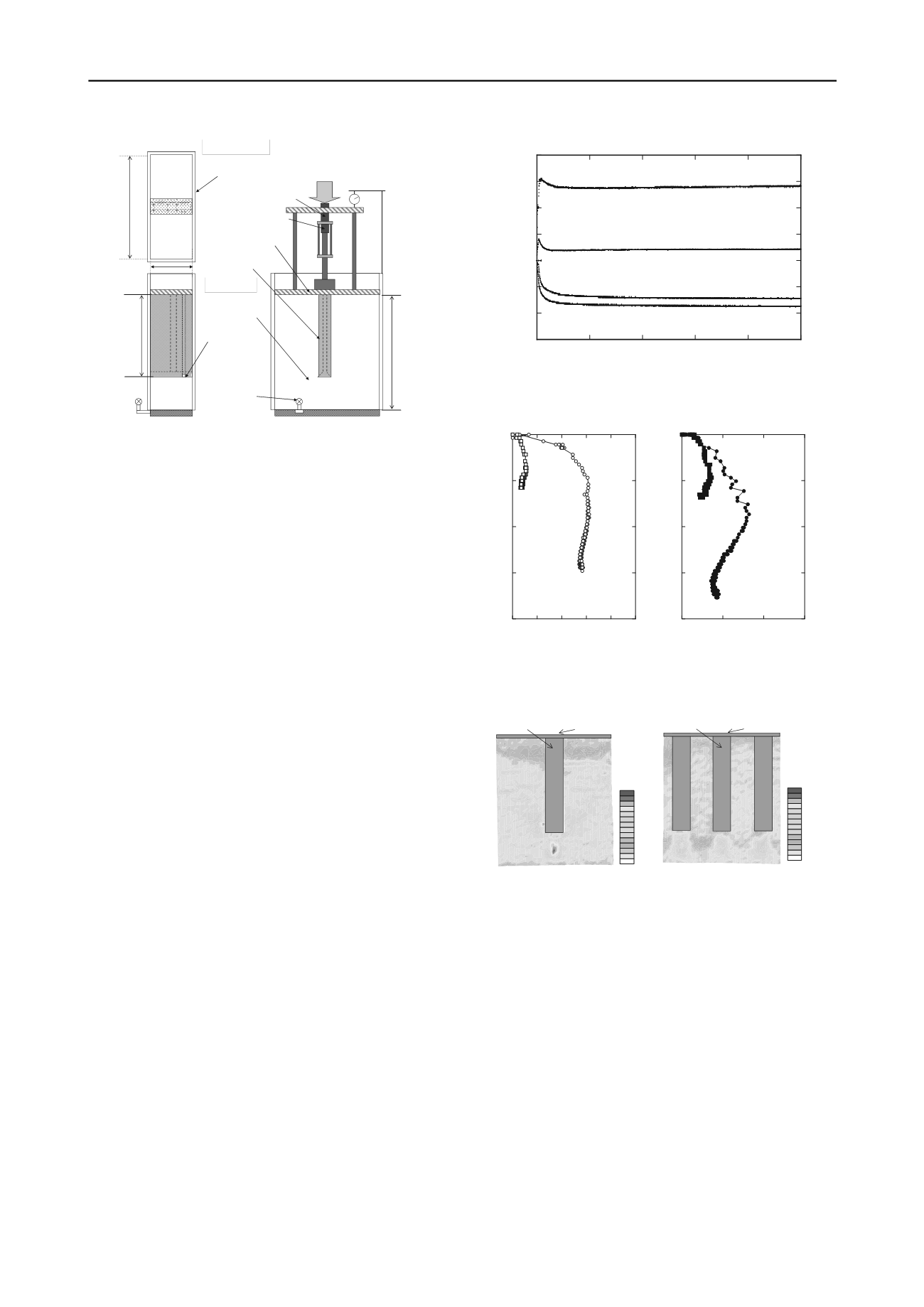

Figure 2. Loading model test under the plane strain condition

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0

100

200

300

400

500

Time

T

(min)

Δ

f

/

Δ

σ

S /D

1 pile

Δf

/

Δσ

(

σ

=20-40 (kPa) )

Δf

/

Δσ

(

σ

=40-80 (kPa) )

S

/

D

(

σ

=20-40 (kPa) )

S

/

D

(

σ

=40-80 (kPa) )

Figure 3. Relationships between skin friction and settlement

2.1

Outline of model test

Figure 2 shows the apparatus used in the model test under the

plane strain condition. The model tests were carried out with

drainage at the upper and lower surfaces. Wall friction was

reduced by a rubber membrane between the specimen and

acrylic plate. The tests for the model ground were conducted

under stress controlled conditions. The vertical load and

consolidation settlement were also measured. This apparatus

can also measure the pile head and end resistance individually at

the center of model pile (Ishikura et al., 2012).

The model ground was prepared by using Kaolin clay and

model pile. Kaolin clay was remolded in a slurry condition with

a water content of about 80%. This slurry was then poured into

the consolidation cell up to a depth of about 350mm. The

specimen was consolidated under a pre-consolidation pressure

of 20kPa using a bellofram cylinder until the end of primary

consolidation. After pre-consolidation, a model ground with a

height

H

of about 270mm was obtained.

0

0.05

0.10

0.15

0.20

0 0.1 0.2 0.3 0.4 0.5

Normalized settlement

S

/

D

Normalized skin friction

Δ

f/

Δ

σ

1pile

Δσ

=20kPa

(

σ

=20-40)

1pile

Δσ

=40kPa

(

σ

=40-80)

3piles

Δσ

=20kPa

(

σ

=20-40)

3piles

Δσ

=40kPa

(

σ

=40-80)

0

0.05

0.10

0.15

0.20

0

0.05

0.10

0.1

Normalized settlement

S

/

D

Normalized skin friction

Δ

f/

Δ

σ

5

Figure4. Relationships between normalized settlement and skin

friction

.

The model piles are composed of aluminum and have 30mm

in width

D

, 100mm in depth and 200mm in length

H

1

. Pore

pressure transducer was placed at the bottom of model pile.

After the model ground was prepared, consolidation pressure

was applied and increased stepwise from σ =20kPa to 40kPa,

40kPa to 80kPa using bellofram cylinder. The loads are applied

to unimproved ground and improved grounds with 1 or 3 piles.

2.2

Test results and discussions

Figure 3 shows the relationships between normalized settlement

S

/

D

, normalized incremental averaged skin friction

Δf

/

Δ

σ and

elapsed time in the consolidation process with 1 pile.

Incremental averaged skin friction

Δf

is the value that divides

the load difference between the pile head and pile end by the

surface area of the model pile. As shown in this figure,

normalized settlement

S

/

D

increased with elapsed time and

converged to the constant value. On the other hand, incremental

averaged skin friction

Δf

initially

increased just applying on the

vertical pressure, however, after reaching the peak incremental

skin friction

Δf

, these began to decrease with elapsed time and

later converged to the constant values.

Figure 4 shows the corresponding relationships between the

normalized settlement

S

/

D

and normalized averaged

incremental skin friction

Δf

/

Δ

σ

under several test conditions. It

is considered that averaged incremental skin friction

Δf

is

mobilized by acting relative displacement between the model

pile and soft clay around the pile end surface during

consolidation. As shown in this figure, normalized skin friction

and normalized settlement curves with 1 pile are different from

that with 3 piles under several consolidation pressures. However,

normalized averaged incremental skin friction

Δf

/

Δ

σ increased

initially with an increase of the normalized settlement and later

converged to the constant value under all the test conditions.

-25

-15

-5

5

15

25

35

45

(%)

Loading plate

Pile

1 pile (σ=0→80kPa)

-25

-15

-5

5

15

25

35

45

(%)

Loading plate

Pile

3 piles (σ=0→80kPa)

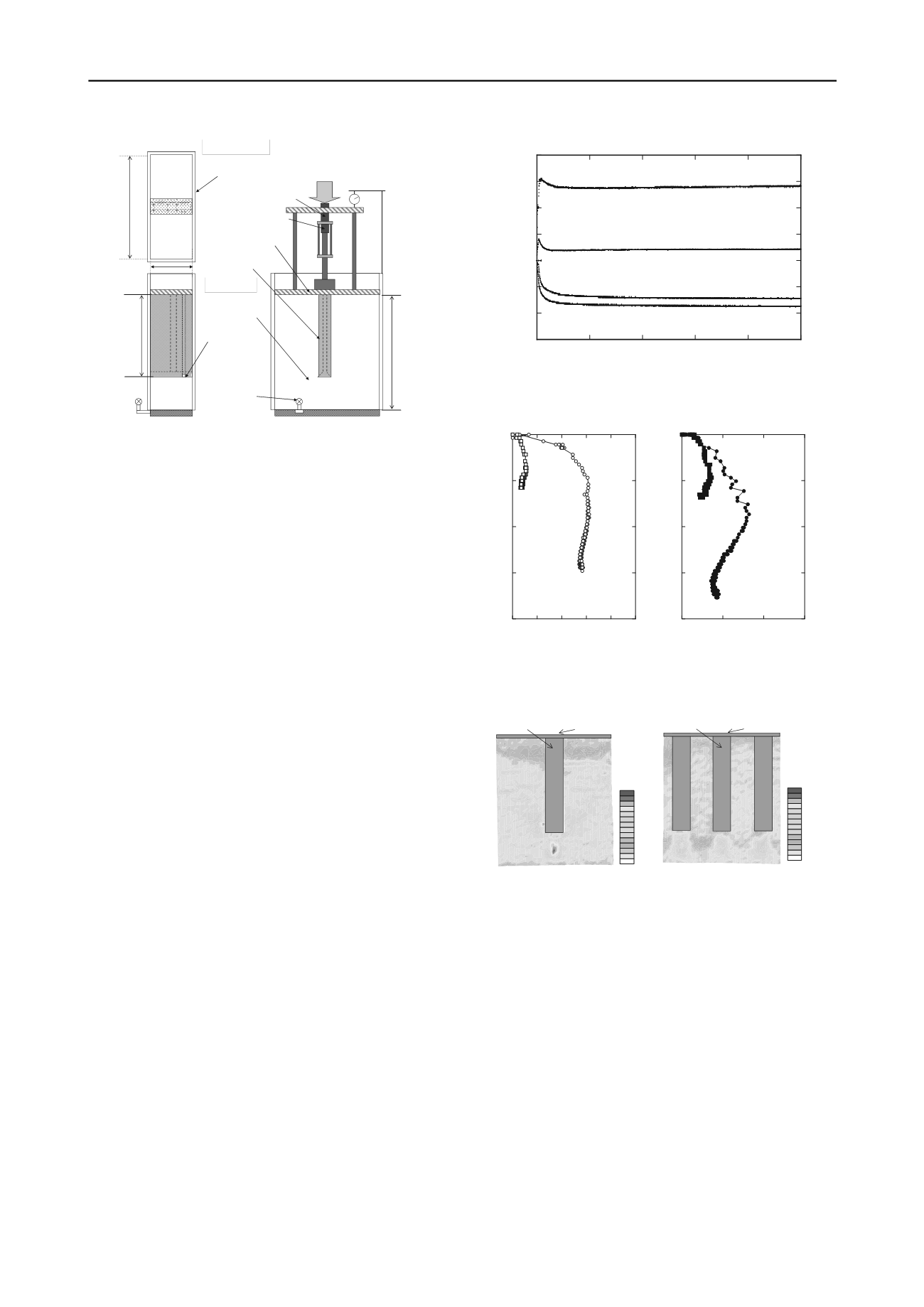

Figure5. Vertical strain distribution after consolidation

Figure 5 shows the vertical strain distributions with 1 pile and

3 piles. These strains can be obtained from the deformation

vectors during loading model tests. Deformation vectors are

obtained by observing the ground behaviors through the rubber

membrane. As shown in this figures, vertical strain of soft clay

just below the pile end increased significantly with 1 pile. It is

considered that the applied load is transferred from the model

pile to the soft clay. It is also observed that vertical strain of soft

clay just below the pile end with 3 piles is smaller than that with

1 pile. On the other hand, soft clay just below the loading plate

has little vertical strain in comparison with that of just below the

pile end in both test conditions.