2750

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The unified pile design approach is the combination of capacity,

drag load, settlement, and downdrag. The main tenet of method

includes the sustained working load, the shaft resistance

distribution, and the soil settlement distribution; they interact

with the neutral plane location, the downdrag, and the pile toe

load-movement response.

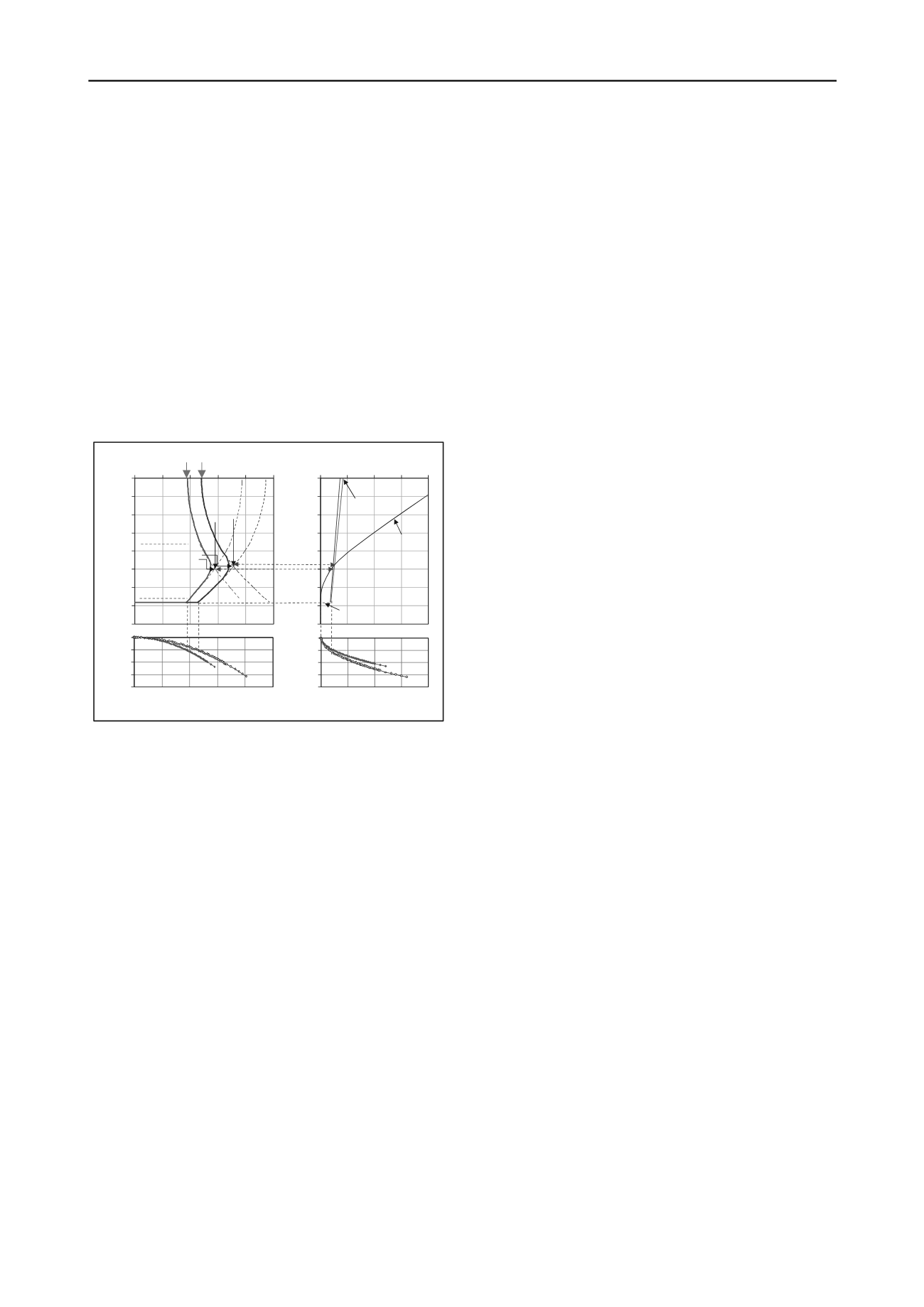

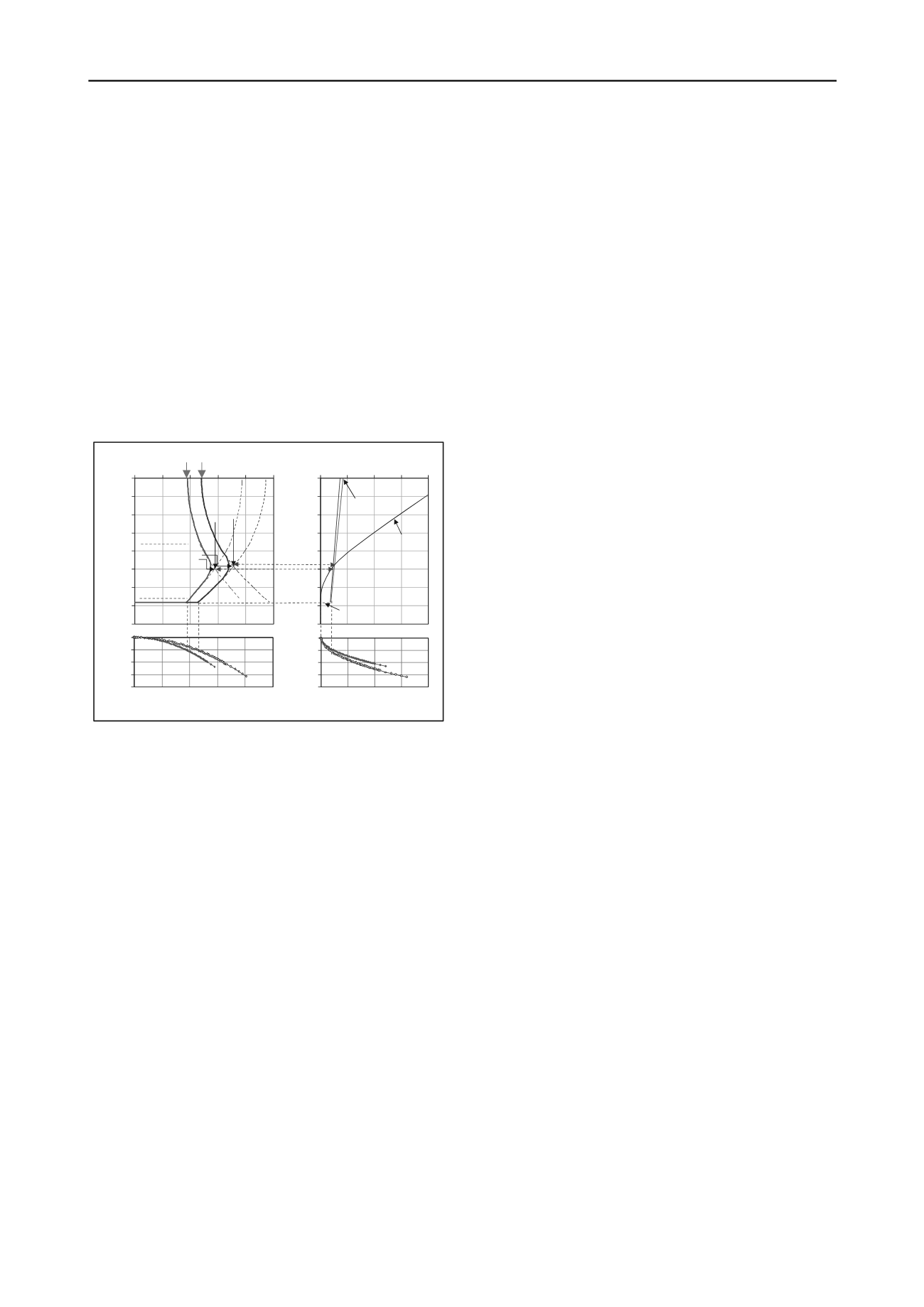

The back-analysis of two tested piles is performed by the

software UniPile (Goudreault and Fellenius 1999) and the

results are presented in Figure 10. Figure 11 shows the long-

term load distribution in the piles TP01 and TP02 starting from

the 3.8 and 4.8 MN sustained load from the structure,

respectively. Assuming that the drag loads accumulated from

negative skin friction are fully mobilized, the maximum loads in

the piles are about 5.8 and 7.2 MN at the neutral planes at 23

through 25 m depth below the ground surface. The maximum

loads are well within the axial structural strength of both piles.

The settlements at the neutral planes and the 'elastic' shortenings

of the piles are about 11 through 13 mm and 9 through 11 mm,

respectively.

The evaluated pile Young’s modulus, E, for the piles TP01

and TP02 correlated to 25 and 22 GPa for the nominal pile cross

section of both piles. The shaft resistances were small and

correlated to an effective stress analysis beta-coefficient of 0.2

and 0.3. The shaft resistances between O-cell and SG1 were

strain-softening. It appears that the shaft resistances for both test

piles were affected by presence of slurry filter cake between the

concrete and the soil.

The measured pile toe stress-movements in percent of

nominal diameters for the piles were essentially linear trend and

have shown no tendency toward an ultimate resistance. The pile

toe response was very soft and not representative for a pile in

high weathered sandstone.

Back-analysis by the Unified Design method shows that the

structure maximum long-term settlements of the piles will be

about 20 mm, which is well below the acceptance value of

40 mm assigned to the project.

6 REFERENCES

0

5

10

15

20

25

30

35

40

0 2 4 6 8 10

DEPTH (m)

Thousands

Silty Sand

TP01

FirmClay

High Weathered Sandstone

Neutral Planes

LOAD (MN)

Max. Load

in Piles

TP02

0

25

50

75

100

0 2 4 6 8 10

Pile Toe Load - Movement

LOAD (MN)

TP02

TP01

0

5

10

15

20

25

30

35

40

0 25 50 75 100

DEPTH (m)

SETTLEMENT (mm)

TP02

Typical Soil

Settlement

Toe

Penetrations

TP01

Neutral Planes

Settlement of

pile heads

0.0

2.5

5.0

7.5

10.0

0 25 50 75 100

MOVEMENT (mm)

Pile Toe Load -

Movement

TP02

TP01

MOVEMENT (mm)

LOAD (MN)

Da Nang University of Technology, 2008. Reports on Bored Pile

Testing for SeaBank Tower, Da Nang, Vietnam, 54p.

Fellenius, B.H., 1984.

Negative skin friction and settlement of piles

.

Proceedings of the Second International Seminar, Pile Foundations,

Nanyang Technological Institute, Singapore, 18 p.

Fellenius, B.H., 1988. Unified design of piles and pile groups.

Transportation Research Board, Washington, TRB Record 1169,

pp. 75-82.

Fellenius, B.H., 1989. Tangent modulus of piles determined from strain

data.

ASCE, Geotechnical Engineering Division

, the 1989

Foundation Congress, F.H. Kulhawy, Editor, Vol. 1, pp. 500-510.

Fellenius, B.H., 2011. Basics of foundation design, a text book.

Revised Electronic Edition,

], 374 p.

Fellenius B.H. and Nguyen H.M., 2013. Large Diameter Long Bored

Piles in the Mekong Delta.

International Journal of

Geoengineering Case Histories,

2(3), 196-207.

Goudreault, P.A. and Fellenius, B.H., 1999. UniPile Version 4.0 for

Windows.

Users

Manual,

UniSoft

Ltd.,

Ottawa,

] 64 p.

Figure 11. Long-term load distribution and settlement profile

for working piles with same diameter and length as the two test

piles.

Nguyen H.M., 2013.

Analysis of Bidirectional Test for Red River

Bridge, Vietnam.

The 3th International Conference on Geotechnical

Engineering, Hammamet, Tunisia, 9p.

As indicated in Figure 1, the soil at depths of the neutral

planes is compressible; this can cause an increase of the pile

penetration into the highly weathered sandstone, i.e., downdrag.

However, this would partially be offset by the increase of the

pile toe force with a subsequent lowering of the neutral plane.

Osterberg, J.O., 1989.

A new device for load testing driven piles and

drilled shafts separates friction and end bearing

. Proc. of Deep

Foundations Institute, Int. Conf. on Piling and Deep Foundations,

London, May 15-18, pp. 421-427.

For pile toe resistance, it is recognized that the pile toe does

not exhibit an ultimate resistance but is a function of the pile toe

stiffness response. Figure 11 also shows the pile toe load-

movement curves established by the O-cell measurements.

When drag loads in the piles TP01 and TP02 reach the

maximum values, the pile toe resistances will increase to about

2.2 and 2.7 MN. The estimated final pile toe movements are

about 10 and 9 mm, respectively.

The acceptable maximum long-term foundation settlement

for the project is about 40 mm, which is larger than the

estimated value. Thus, the testing and the design analysis

indicate that there is no need for having the piles constructed

deeper to bear on or in the bedrock.

5 SUMMARY AND CONCLUSION

The two bidirectional loading tests on Piles TP01 and TP02

established that the pile capacities satisfied the specified values.

The maximum load tests of 3.8 and 4.8 MN achieved

maximum upward movements at the O-cell location of 3.3 mm

and 7.4 mm and maximum downward movements of 28.0 and

49.3 mm, respectively. The maximum upward movements of

the pile heads were 0.2 and 2.5 mm, respectively. The shaft

resistances above 30 m depth were not full mobilized.