2756

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Research on the Load-Bearing Behaviour of Bored Piles with Different Enlarged Bases

18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2

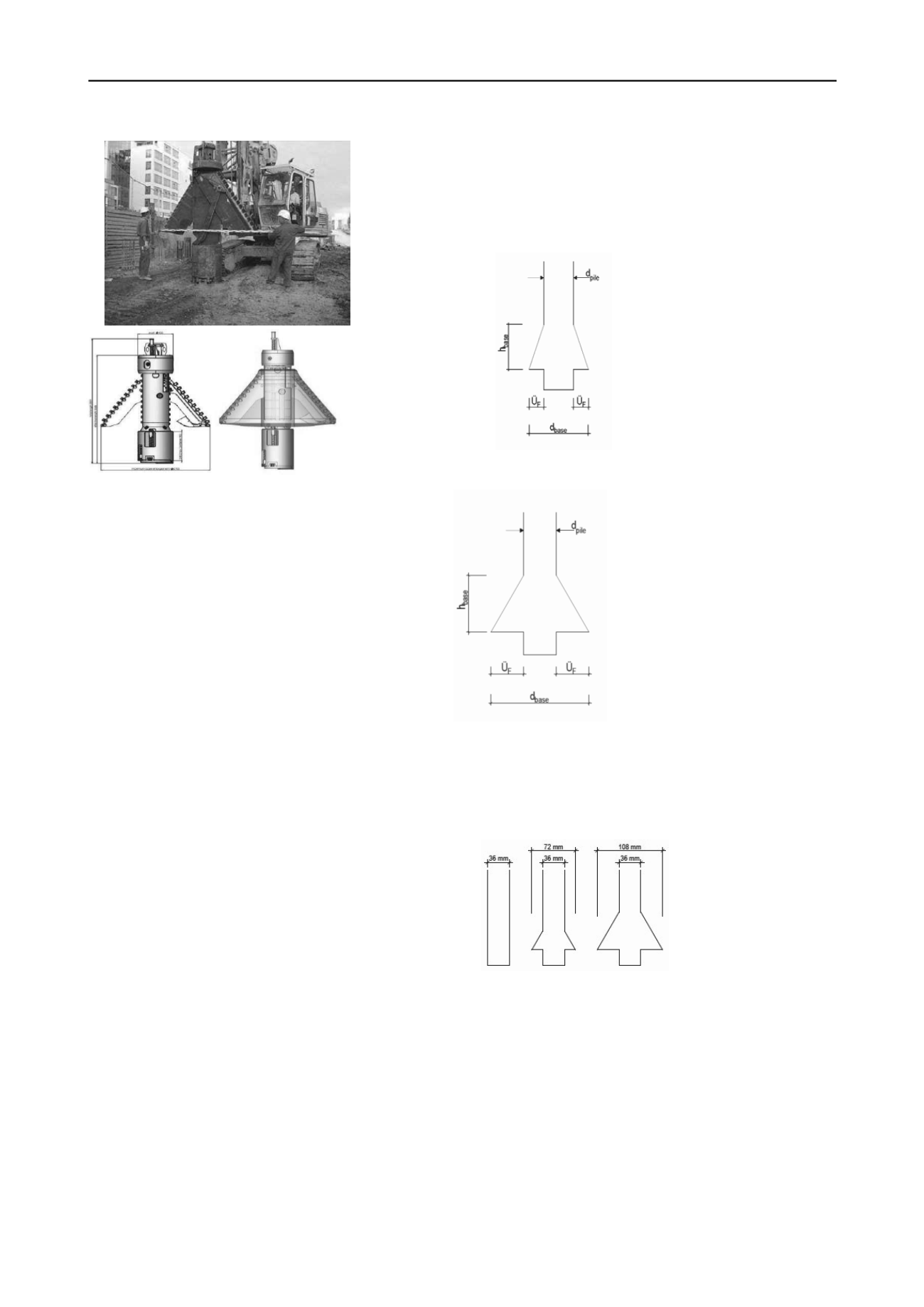

Figure 2. Belling bucket Bauer

This aforesaid drilling tool is denoted as a pile base extension

cutter and generally consists of two cutting arms and a cutting

body that functions as a borehole reamer to produce a pile (an

under-pile) beneath the pile base enlargement.

2.2

Advantages of the Pile Base Enlargement

• Higher load-carrying capacity of the single pile or

settlement reduction

• Fewer piles under concentrated loads

• Simple pile head construction (none or smaller pile head

slabs)

• Reduced pile shaft diameter with shallower drilling

depths

• Smaller drilling equipment (more favorable BE/BR,

lower costs)

• Savings on pile concrete (more favorable relationship

load/m

3

concrete)

2.3

Pile geometry

2.3.1

Pile Shaft

The drilled pile shaft exhibits a constant cross section, which is

selected according to the static requirements for the internal bearing

capacity from the top of the pile down to the beginning of the

enlargement. Usually the pile is manufactured using a C30/35

concrete. Unreinforced or partially reinforced piles are permissible

in principle, while at the same time the load distribution according

to EC 2 must be considered. With wide base enlargements and high

pile loadings, high-strength concrete can be used, permitted in

accordance with DIN EN 1536, or steel fiber reinforcing would be

useful.

2.3.2

Pile base

It must be noted foremost, that the widening of the foot of the

pile is dependent on the basic geometry of the drilled pile, meaning

the diameter of the shaft and the overboring equipment used. This is

due to the different opening mechanisms of the cutting arms.

Modern cutters, like those presented in the current paper, are able to

produce flat bottoms within the area of the widening, which was not

the case with older models. Also with these types of devices,

depending on the manufacturer, an under-pile beneath the

enlargement with the same diameter as the shaft is created. This has

a positive influence on the friction of the base of the overboring to

provide additional support and provides a stopper effect which

mechanically increases the bottom of the pile. Investigations by

BAUER showed that with these new type cutting devices, even the

largest, all pile foot enlargements according to DIN EN 1536 can be

manufactured in the soils envisioned for special foundation

construction safer and with a higher quality.

According to DIN EN 1536 the area of the foot enlargement is

reduced as follows depending of the soil in the base area:

with cohesionless soils (See Figure 3):

a)Foot height / Foot Overboring = h

Base

/ Ü

F

≥ 3 (similar to DIN

4014)

b)

max. permissible pile foot diameter = 2 x pile shaft

diameter, d

Base

Figure 3. Pile foot base enlargement in

cohesionless soils

In cohesive soils (See Figure 4):

a)Foot height / Foot Enlargement = h

Base

/ Ü

F

≥ 1.5

b)max. allowable pile foot diameter = 3

x pile shaft diameter, d

Base

(1.5 fold

value from DIN 4014)

c)max. allowable pile foot area = 10 m²

max. allowable pile foot diameter =

3.57 m

Figure 4. Pile foot base enlargement in

cohesive soils

2.4

Pile tests

2.4.1

Pile tests Description

The investigation of the differences in the bearing capacities of the

piles depending on the different pile foot base enlargements (see

Tinteler, Herrmann) was carried out with load tests on scale models.

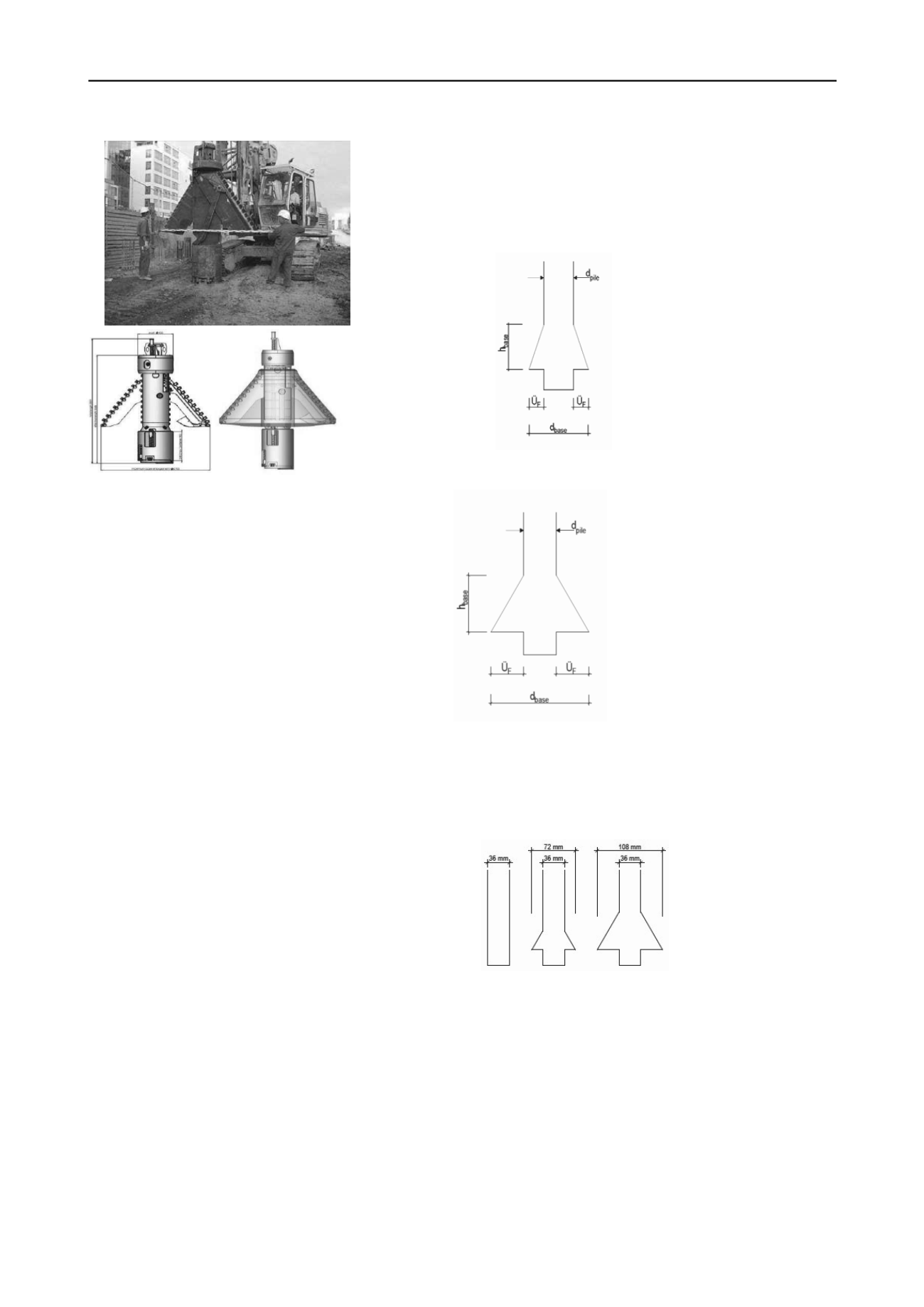

(see figure 5).

Figure 5. Cross section of the pile models (M = 1:25)

In each case two tests conditions were investigated: using a

casing in order to eliminate skin friction and to measure point

resistance R

b

only, and without a casing to determine the entire pile

resistance R

b+s

. The experimental soil was a sand with a uniformity

coefficient, U, of 2.5 – 2.8. It can further be said that this soil was

prepared by an in-place compaction, I

D

, of approximately 0.74,

which corresponds to a dense condition.

For statistical reasons and to acquire meaningful strong results,

for each case three identical loads (in each case three per cross

section with and without casing – altogether 18 trials) were applied

with the different models (See Figures 1 & 5).