2758

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Research on the Load-Bearing Behaviour of Bored Piles with Different Enlarged Bases

18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

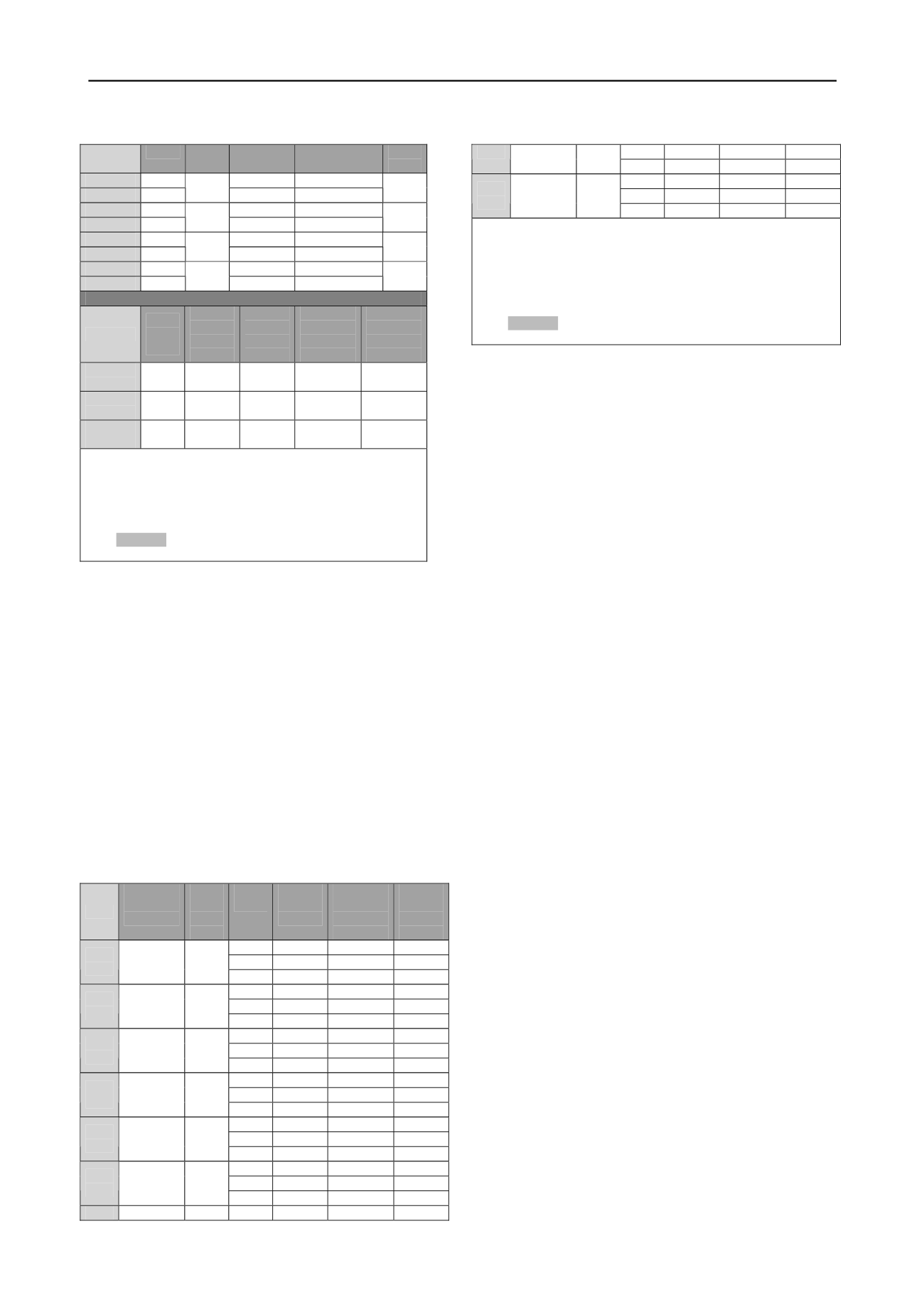

[m]

[%]

1** (b)

1.10

0.95

3.60

2** (b

f

)

1.58 1.44

1.96

3.40

-5.90

3++ (b)

1.50

1.77

4.20

4++ (b

f

)

2.04 1.36

3.27

3.20

-31.30

5## (b)

1.10

0.95

3.80

6## (b

f

)

1.53 1.39

1.84

3.60

-5.60

7*+ (b)

1.50

1.77

3.80

8*+ (b

f

)

2.10 1.40

3.46

4.00

-5.00

Own Tests

Pile

b

resp.b

f

[m]

Ratio

b

f

resp.

b [-]

Pile foot

base

area

[m²]

σb(s

gr

)

(1)

resp.

σb

f

(s

gr

)

(1)

[N/mm2]

σb(s

gr

)

(1)

to

σb

f

(s

gr

)

(1)

[%]

1xD

(b)

3.60

1017.90

1.01

-

2xD

(b

f

)

7.20

2.00

4071.50

0.92

-10.20

3xD

(b

f

)

10.80

3.00

9160.90

0.98

-3.00

(1)

σb(s

gr

) resp. σb

f

(s

gr

)

= R

b

(s

gr

) resp. R

bf

(s

gr

) / ((b resp.bf) · π) / 4)

s

gr

= 0.1 · b resp. b

f

**, ++, ##, *+ Comparable piles comparable lengths, Without base

enlargement (b) /with base enlargement (b

f

)

Note: Pile No. 4 is not comparable because of a shorter pile

length, i.e. not included in the evaluation.

In summarizing, two informative results come from the test

loadings on the scale model test piles. This is on the one hand the

realization that the base enlargement of a drilled pile to three times

it’s shaft diameter would increase the load-bearing resistance

expected due to the effect of D

2

was fair.

On the other hand it turned out that a pile base enlargement

according to DIN 1054 (or EA-Pfähle) using the reducing

coefficient α

enlarged

= 0.75 for calculating the pile base resistance

contains a high safety factor.

Fundamentally, it is to be noted, however, that in the context of

this work the results obtained are based on tests at a small scale

(model tests). Further, are factors (ground-water flows,

inhomogeneous soils) that were left out of consideration, which

could possibly have an influence on the bearing behavior of in situ

piles. This is especially true if, due to pile settlement, a

displacement of the soil in the area of the pile foot base can take

place. Therefore no clear conclusions on the actual bearing behavior

of large drilled pile with base enlargements can be drawn.

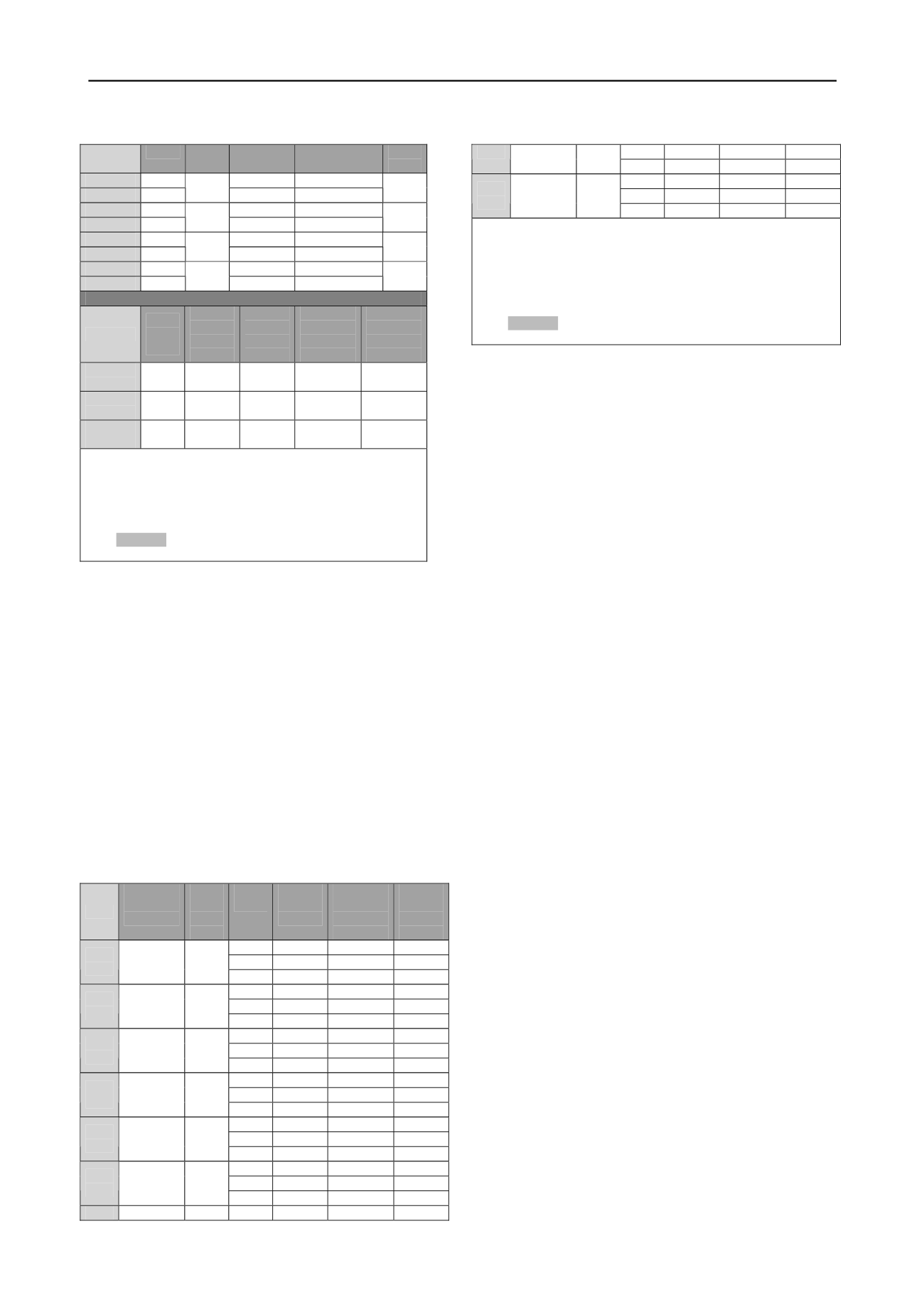

Table 5: Evaluation of In Situ Load Tests by Franke/garbrecht for

various related Settlements, s/D

Pile

Pile base

dia-

meter [m]

Pile

foot

area

[m²]

s/D

(2)

[-]

Settle-

ment

[cm]

σb(s)

(3)

resp.

σb

f

(s)

(3)

[N/mm2]

R

b

(s)

resp.

R

bf

(s)

[MN]

0.02

2.2

1.7

1.6

0.03

3.3

2.0

1.9

1**

(b)

1.10

0.95

0.10

11.0

3.6

3.4

0.02

3.2

1.8

3.5

0.03

4.7

2.1

4.1

2**

(b

f

)

1.58

1.96

0.10

16.0

3.4

6.7

0.02

3.0

1.7

3.0

0.03

4.5

2.3

4.1

3++

(b)

1.50

1.77

0.10

15.0

4.2

7.4

0.02

4.1

1.4

4.6

0.03

6.1

1.7

5.6

4++

(b

f

)

2.04

3.27

0.10

20.4

3.2

10.5

0.02

2.2

1.5

1.4

0.03

3.3

1.8

1.7

5##

(b)

1.10

0.95

0.10

11.0

3.8

3.6

0.02

3.1

1.3

2.4

0.03

4.6

1.8

3.3

6##

(b

f

)

1.53

1.84

0.10

15.3

3.6

6.6

7*+

1.50

1.77

0.02

3.0

1.5

2.7

0.03

4.5

2.0

3.5

(b)

0.10

15.0

3.8

6.7

0.02

4.2

1.9

6.6

0.03

6.3

2.3

8.0

8*+

(b

f

)

2.10

3.46

0.10

21.0

4.0

13,9

(2)

D = b

f

resp.b

(3)

σb(s) resp. σb

f

(s) =

= R

b

(s) resp. R

bf

(s) / ((b resp.bf) · π) / 4)

s = s/D · b resp. b

f

**, ++, ##, *+ Comparable piles comparable lengths, Without base

enlargement (b) /with base enlargement (b

f

)

Note: Pile No. 4 is not comparable because of a shorter pile length, i.e.

not included in the evaluation.

However, since there appears to be a discrepancy between

theory and practice, a continuing analysis would be meaningful and

necessary based on full-scale tests up to the 1:1 scale, since the

reliable data collection on the influence of manufacturing

variabilities can only be investigated in full-scale tests. This

evaluation is valid in particular under the aspect that there are new

techniques and geometries for pile base enlargement – as were

considered in this presentation – to produce new types of pile foot

base enlargements with positive influences on the bearing behavior

or the piles.

Thus, these drilled piles represent a new system for deep

foundation with a special capability regarding the loads and the

deformation limitations. It is of special importance that all of the

new pile cutting equipment for pile foot base enlargement

according to DIN EN 1536 – including the largest – can assuredly

manufacture piles in the soils envisaged for it by specialized

foundation engineering.

If these investigations would lead to a confirmation of available

findings, a safe and economic adjustment of the reducing

coefficient would be possible. Therefore, the work on this topic

should be continued.

6

REFERENCES

DIN EN 1536: Ausführung von Arbeiten im Spezialtiefbau –

Bohrpfähle,Deutsche Fassung EN 1536:2010, Beuth-Verlag Berlin,

2010

DIN 4014:

Bohrpfähle – Herstellung, Bemessung

und

Tragverhalten,Beuth-Verlag Berlin, 1990

Franke/Garbrecht: Lastsetzungslinien von Großbohrpfählen mit und

ohne Fußverbreitung bei 2,5 m Einbindung in Sand und

verschiedenen Pfahllängen (nach Franke/Garbrecht 1976). In:

Smolczyk, U.: Grundbau-Taschenbuch, 4. Auflage, Teil 3, S. 210.

Ernst & Sohn, Berlin, 1992

BAUER: Firma BAUER Spezialtiefbau Schrobenhausener Tage 2006

(unveröffentlicht) / Firmenunterlagen, 2006

Herrmann, Lauber: Vergleichende Untersuchungen zur Kompatibilität

zwischen den nationalen und europäischen Grundbaunormen und

sonstigen Regelwerken – Band 1: Bohrpfähle – Vergleich DIN

4014 mit DIN EN 1536, Beuth-Verlag Berlin, 2000

Herrmann, Lauber: Vergleich DIN 4014 mit DIN EN 1536,

fahlsymposium 2001, TU Braunschweig,

Heft

Nr.

65,

Braunschweig, 2001

Tinteler, Herrmann: Untersuchungen zum Tragverhalten von

Großbohrpfählen mit unterschiedlichen Fußaufweitungen, Institut

für Geotechnik der Universität Siegen, 2012

DIN 1054: Baugrund – Sicherheitsnachweise im Erd- und

Grundbau,Beuth-Verlag Berlin, 2005 / 2010

EA-Pfähle: Empfehlungen des Arbeitskreises “Pfähle” der DGGT, 2007