2749

Technical Committee 212 /

Comité technique 212

Figure 5. Increment stiffness plot of records from Levels 1 to 3,

Pile TP02

1.3

Load distribution along the pile shafts

The evaluated stiffness (EA) values were used to convert the

strain measurements to load. Figure 6 shows the so-evaluated

load distributions. The shaft resistances shown along the upper

about 30 m for both piles were not fully mobilized.

Figure 6. Load Distributions with Approximate Head-down

Curve of Piles TP01 and TP02

As shown in Figure 1, the soil at the depth of SG1 to SG3

was a firm clay layer. It is a reasonable expectation that the

load distributions would have shown a gentle shape with a

decreasing slope toward depth, reflecting increasing shaft

resistance as SPT N-indices increase with depth. That this is

not the case is considered due to varying effect of the slurry

filter cake and, possibly varying pile cross section.

Assuming that the shaft resistance would show a uniform

proportionality to effective overburden stress, Figure 6 shows

the actual and approximate equivalent head-down load-

distribution curves. The latter are obtained by an effective stress

calculation for ß-coefficient of 0.2 to 18.5 m depth and 0.3

below this depth to the pile toes. The effective stress analysis

indicates the toe resistance and total shaft resistance of Pile

TP01 are 3,723 and 4,088 KN, and of Pile TP02 are 4,495 KN

and 4,932 KN, respectively.

1.4

Unit stress versus movement for shaft resistances and pile

toes

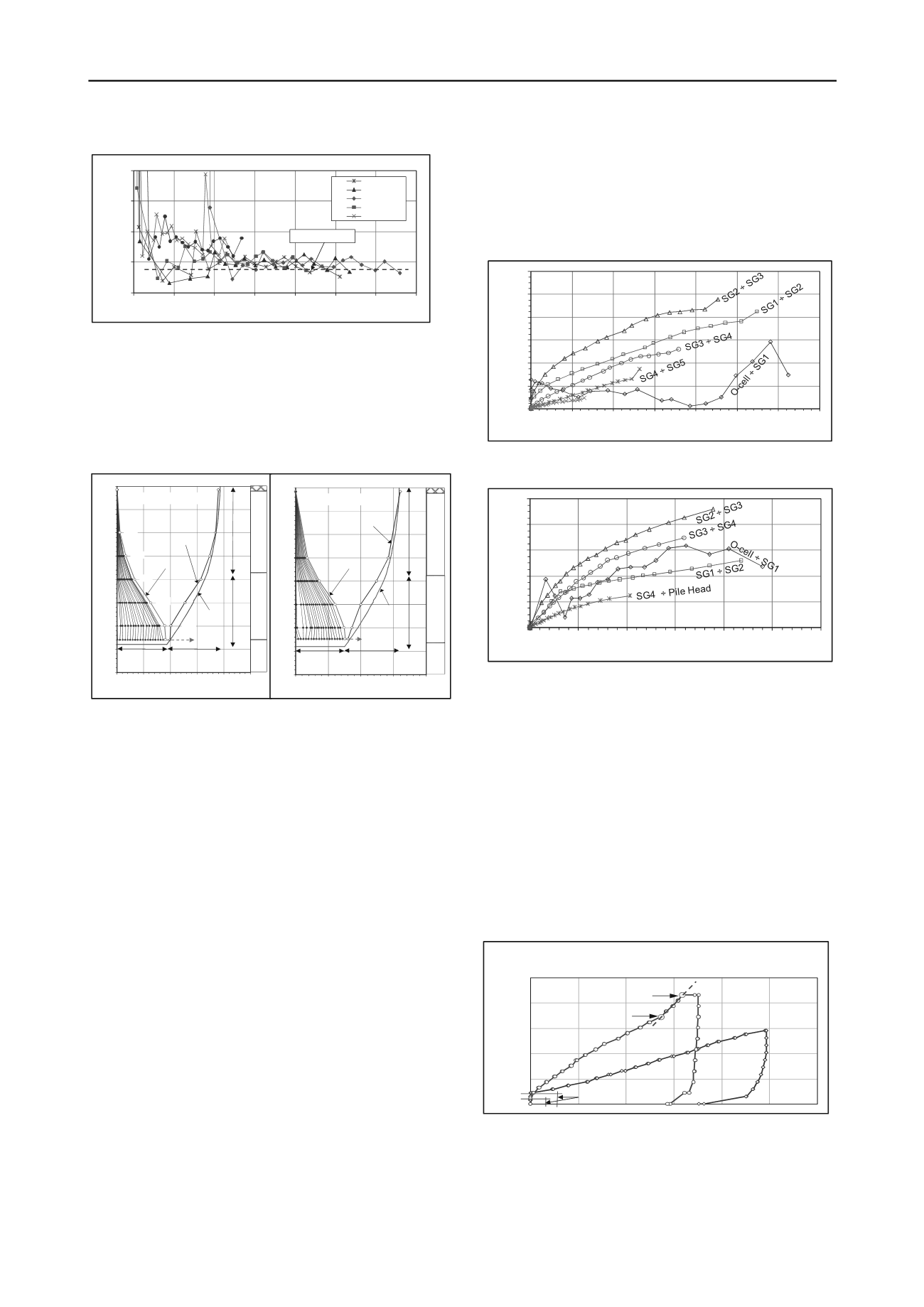

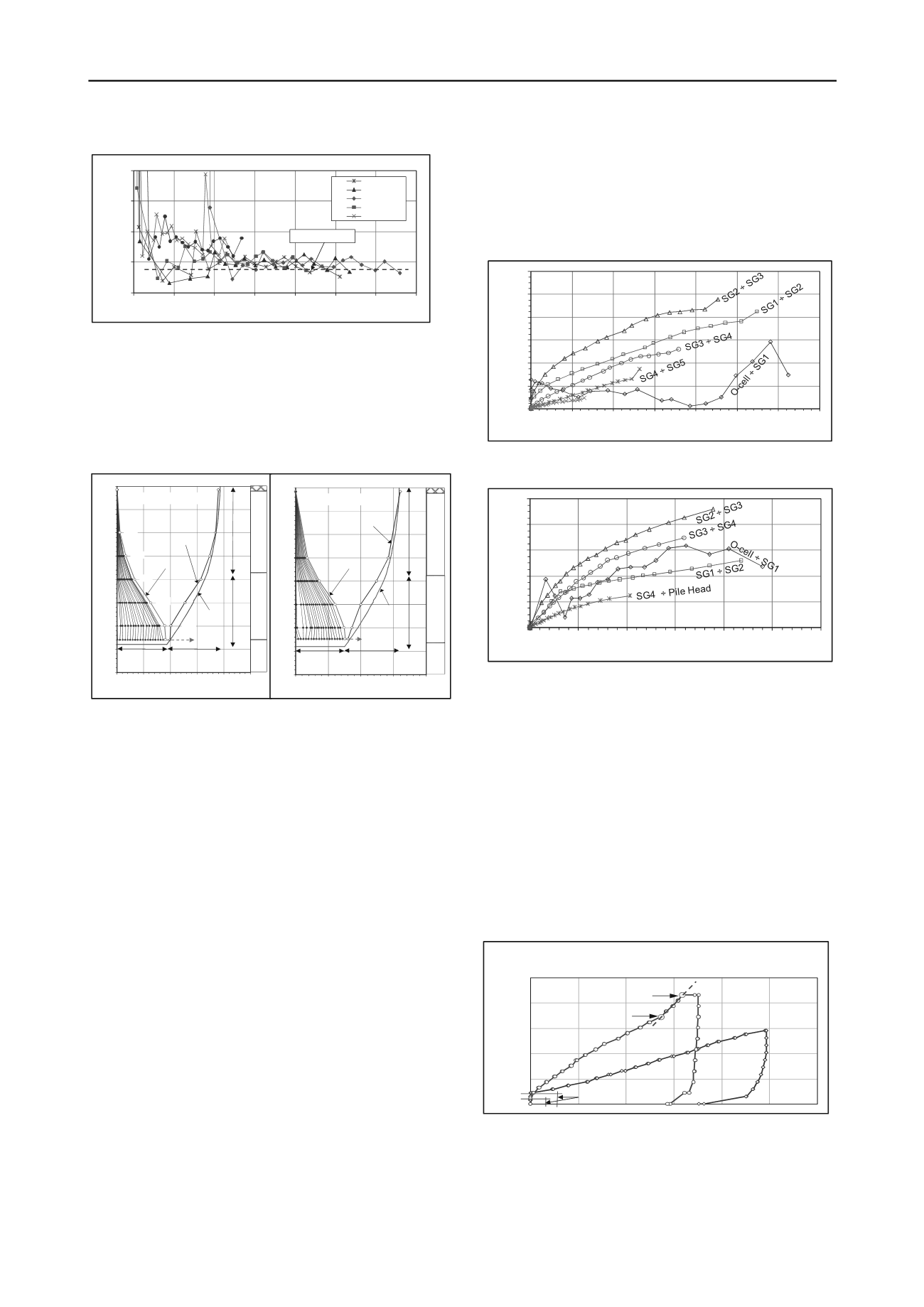

The average unit shaft shear resistance between the gage levels

can be determined as the difference in evaluated strain-gage

load divided by the surface area between the gage levels.

Figures 8 and 9 show those values plotted against movements

for the particular gage levels. The maximum values of the unit

shaft resistance evaluated between the O-cell and SG1 for both

test piles showed the average unit shaft resistances of about

60 kPa. Because of strain-softening, the shear resistances were

smaller than expected. Moreover, the resistances from SG1

through SG3 are smaller than between SG2 and SG3 for both

piles.. It is probable that the construction process left a filter

cake between the concrete and the soil and, therefore, the shear

movement occurred in the filter cake. The curves also show

that, for both piles, ultimate shaft resistance along the length

above the O-cell level has not occurred excepting for the curves

from O-cell to SG1. The uppermost gage level movements and

loads were too small to produce meaningful curves in pile. The

records of unit shear resistance between SG4 and SG5 in Pile

TP02 were unreliable and are therefore omitted.

0

20

40

60

80

0

50

100

150

200

250

300

350

SG - 1A

SG - 1B

SG - 2A

SG - 2B

SG - 3A

INCREMENTAL STIFFNESS AE (GN)

STRAIN(μS)

AE = 17 (GN)

Figure 8. Average shear resistance between gage levels of Pile

TP01

0

20

40

60

80

100

120

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

MOVEMENT (mm)

AVERAGE SHEAR (KPa)

SG5 ÷ Pile Head

0

5

10

15

20

25

30

35

40

0 2,000 4,000 6,000 8,000 10,000

LOAD(KN)

DEPTH (m)

Measured

Distributio

n

Figure 9. Average shear resistance between gage levels of Pile

TP02

Figure 10 shows stresses applied to the pile toe versus the

pile toe movements divided by the pile diameter in percent. The

stresses are determined by dividing the measured load at O-cells

with the nominal shaft areas below O-cell. The maximum toe

movements were about 3 and 5 mm, respectively. The

increasing stiffness measured for Pile TP01 is considered due to

the debris at the pile toe having become compressed.

For both piles, the pile toe stress-movement response was

essentially linear and showed no tendency toward an ultimate

resistance. It is obvious that the pile toe response is not

representative for pile toes placed in weathered sandstone or in

sand. Similar observation for large diameter bored piles is

reported by (Fellenius and Nguyen 2013).

Figure 10. Stress-% downward movement curve of Piles TP01

and TP02

1.5

Back-analysis to response long-term settlements of piles

The back-analysis of two tested piles was performed by “The

Unified Pile Design” method (Fellenius 1984; 1988; 2011).

O-cell

#4

#3

#2

#1

#5

SILTY

SAND

FIRM

CLAY

SAND

STONE

ExistingGroundSurface

Rt= 3,723KN Rs= 4,088KN

TP01 (D800)

Equivalent

Head-down

Distribution

Approximate

Head-down

Distribution

0

5

10

15

20

25

30

35

40

0

3,000 6,000 9,000 12,000

LOAD(KN)

DEPTH (m)

0

20

40

60

80

100

0.0

1.5

3.0

4.5

6.0

7.5

9.0

MOVEMENT (mm)

AVERAGE SHEAR (KPa)

O-cell

ExistingGroundSurface

SILTY

SAND

#4

#3

#2

#1

FIRM

CLAY

SAND

STONE

#5

Measured

Distribution

TP02 (D1000)

Equivalent

Head-down

Distribution

Rt= 4,495KN

Approximate

Head-down

Distribution

Rs= 4,932KN

0.0

0.5

1.0

1.5

2.0

2.5

0

1

2

3

4

5

6

MOVEMENT/DIAMETER (%)

TP01-D800

TP02-D1000

NORMALIZED TOE STRESS (MPa)

Breaking Bonds