2740

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

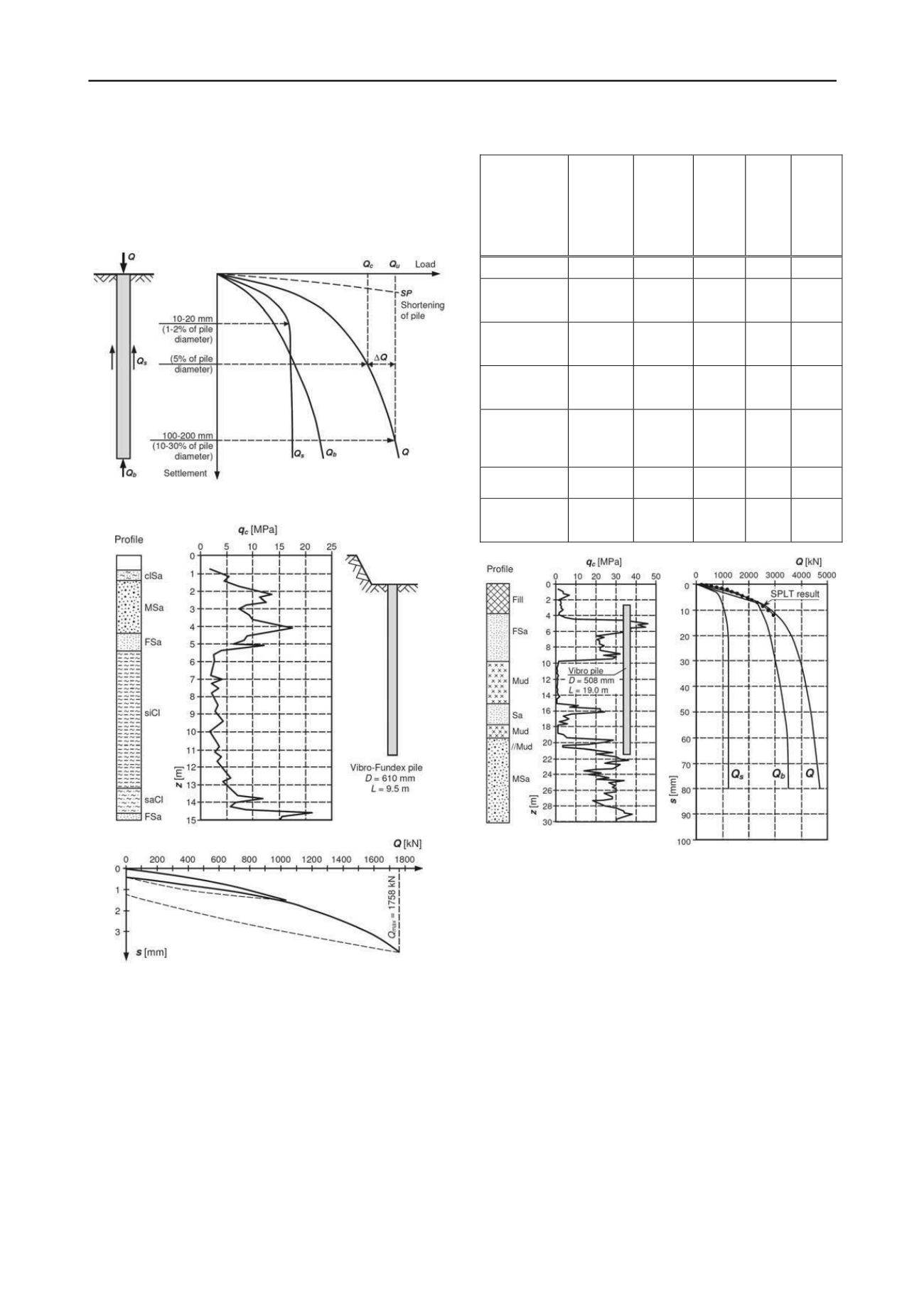

precisely defined (Fig. 1). Possibly, some reserve

∆Q

may be

included in relation to critical load

Q

c

(see Gwizdala 1997).

Comparison of bearing capacities calculated by various

methods reveals significant differences. Exemplary results of

calculations for Vibro pile and for data presented in Fig. 2 are

collated in Table 1.

Figure 1. Generalized load-settlement curves of pile

Figure 2. Data and static load test result of Vibro-Fundex pile, taken

into calculation analysis

Currently big pressure is put on the development of

calculation methods based on direct results of in situ tests, e.g.

CPTU tests and making use of load-transfer

t-z

i

q-z

functions.

Such method has been proposed by Gwizdala and Steczniewski

2007 (see example shown in Fig. 3) and for screw displacement

piles by Krasinski 2012.

The problem becomes much complex for the piles installed

in layered soils with highly diverse strength parameters. In such

cases reliable results can be obtained from static load tests

(SPLT).

Table 1. Static load test and calculation results for Vibro–Fundex pile

Method

Bearing

capacity

based on

characte-

ristic

parameters

[kN]

Corre-

lation

coeffi-

cients

Chara-

cteristic

bearing

capacity

R

c;k

[kN]

Partial

resis-

tance

factor

t

Calcula-

ted

bearing

capacity

R

c;d

[kN]

Design load

Q

r

–

–

–

–

1034.0

PN-83/B-

02482

based on SPLT

1758.0

(

R

c

=

Q

max,SPLT

)

–

–

k

= 0.8

1406.0

EN 1997-1;

2004

based on SPLT

1758.0

(

R

c

=

Q

max,SPLT

)

1

= 1.4

2

= 1.4

1256.0

1.1

1142.0

EN 1992-2;

2007

(DIN 1054)

2378.0

3

= 1.4

4

= 1.4

1699.0

1.1

1545.0

LCPC

Bustamante

& Gianeselli

(1982)

1980.0

3

= 1.4

4

= 1.4

1414.0

1.1

1285.0

– method

API (1984)

1538.0

3

= 1.4

4

= 1.4

1098.0

1.1

998.0

Gwizdala &

Steczniewski

(2007)

2308.0

3

= 1.4

4

= 1.4

1648.0

1.1

1498.0

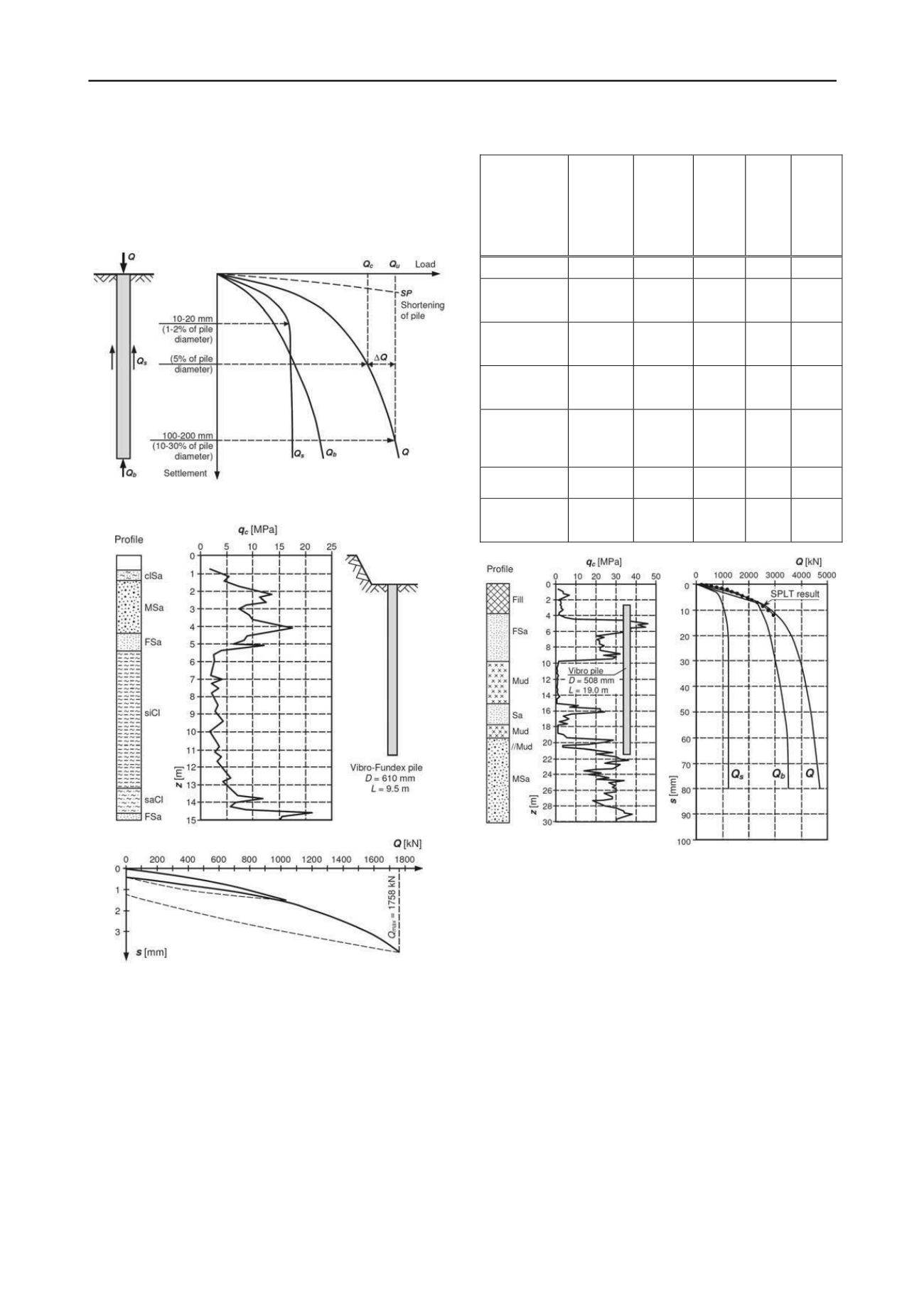

Figure 3. Example of Vibro pile calculation results obtained from load-

transfer functions method (Gwizdala and Steczniewski 2007)

2. EXAMPLES OF IN SITU TESTS ON DRIVEN

DISPLACEMENT PILES

Driven displacement piles are applied for constructions

transmitting large loads and when small settlements are

required, especially plastic settlements for designed load range.

Very good characteristics of subsoil-pile interaction are

obtained for driven cast-in-place displacement piles such as

Virbo, Vibro-Fundex and Franki. (Fig. 3, 4 and 5).

2.1.

Tests on Vibro and Franki piles under bridge object of A1

highway

In the frame of reconnaissance works for foundation of access

flyover roads to large bridge over the Vistula river some tests on

Vibro and Franki piles have been carried out. Vibro piles have

the diameter of 508/560 mm and the length 25.4 m whereas

Franki piles 560 mm and 23.5 m respectively. In Fig. 4

geotechnical conditions in the form of CPTU characteristics and

settlement curves obtained from load tests are presented. Load –