2736

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

With introduction of a new section bearing a heavier load,

600 mm piles were also adopted, with load tests indicating a

permissible load of 1,800 kN. At this point, 1,569 stakes had

been planned for completion of the entire project. However, as a

result of the tests, and subsequent project design optimization

taking into account the increased loads, this number fell, in a

second step, to 1,275 (an 18% decrease in the number of

remaining piles). This decrease resulted in a direct cost

reduction of 1.62 million reais, not taking into account the

number of blocks needed, and also the indirect costs.

Considering the costs involved in performing the load tests, the

actual cost reduction amounted to 1.08 million reais.

The final total of all piles placed, both before and after the

revision, came to 3,838. A total of 38 (thirty-eight) static load

tests were programmed throughout the project, 27 (twenty

seven) for 500 mm piles, 9 (nine) for the 600 piles, and 2 (two)

for 400 mm piles. However, two of the load tests, specifically

the 33rd and 34th, indicated problems in the pile caps, and had

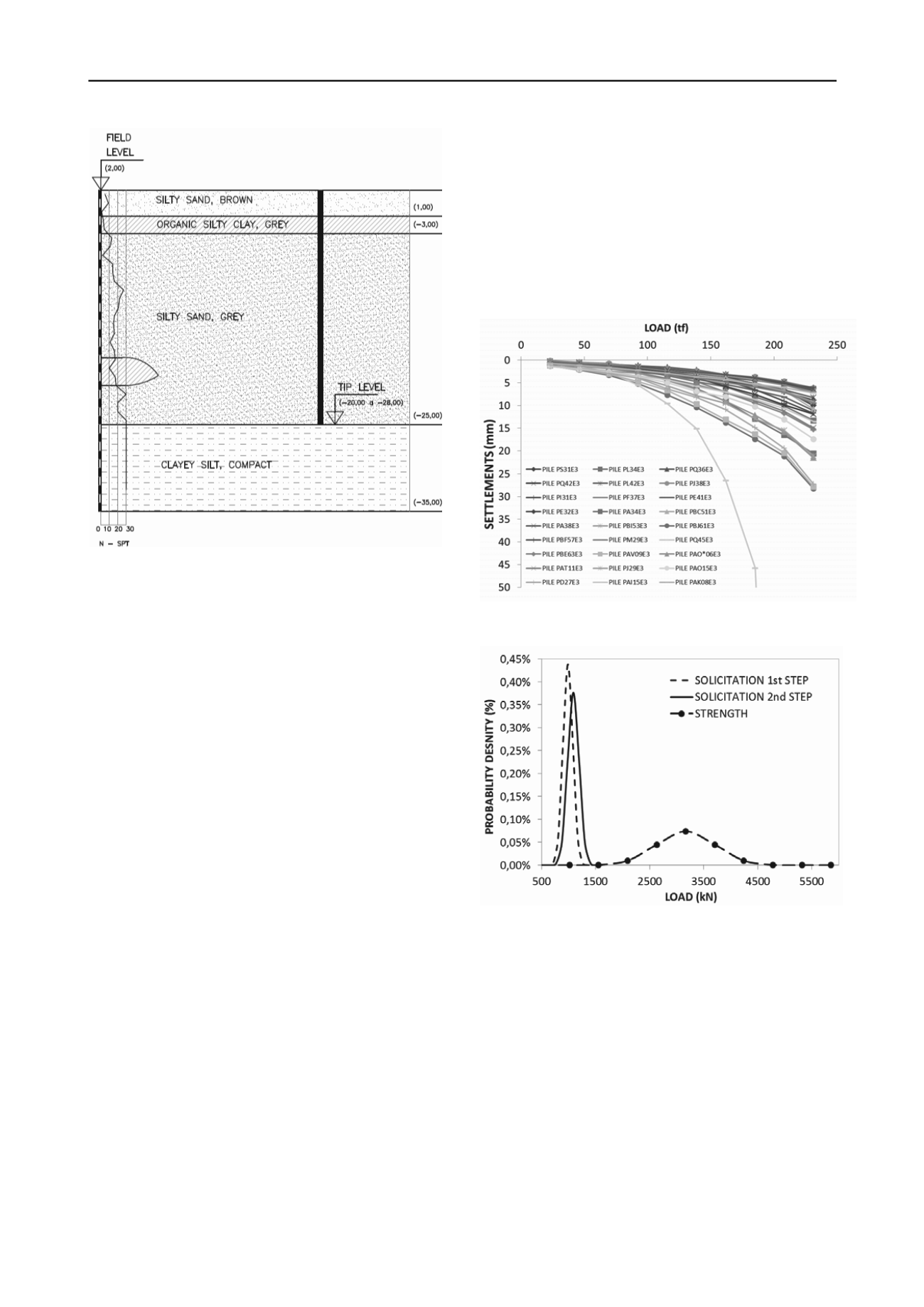

to be redone. Figure 2a shows the diagram regarding Load x

Settling for the piles analyzed in the study. The Van der Veen

equation was used as a criterion for extrapolating the rupture

load for the load tests.

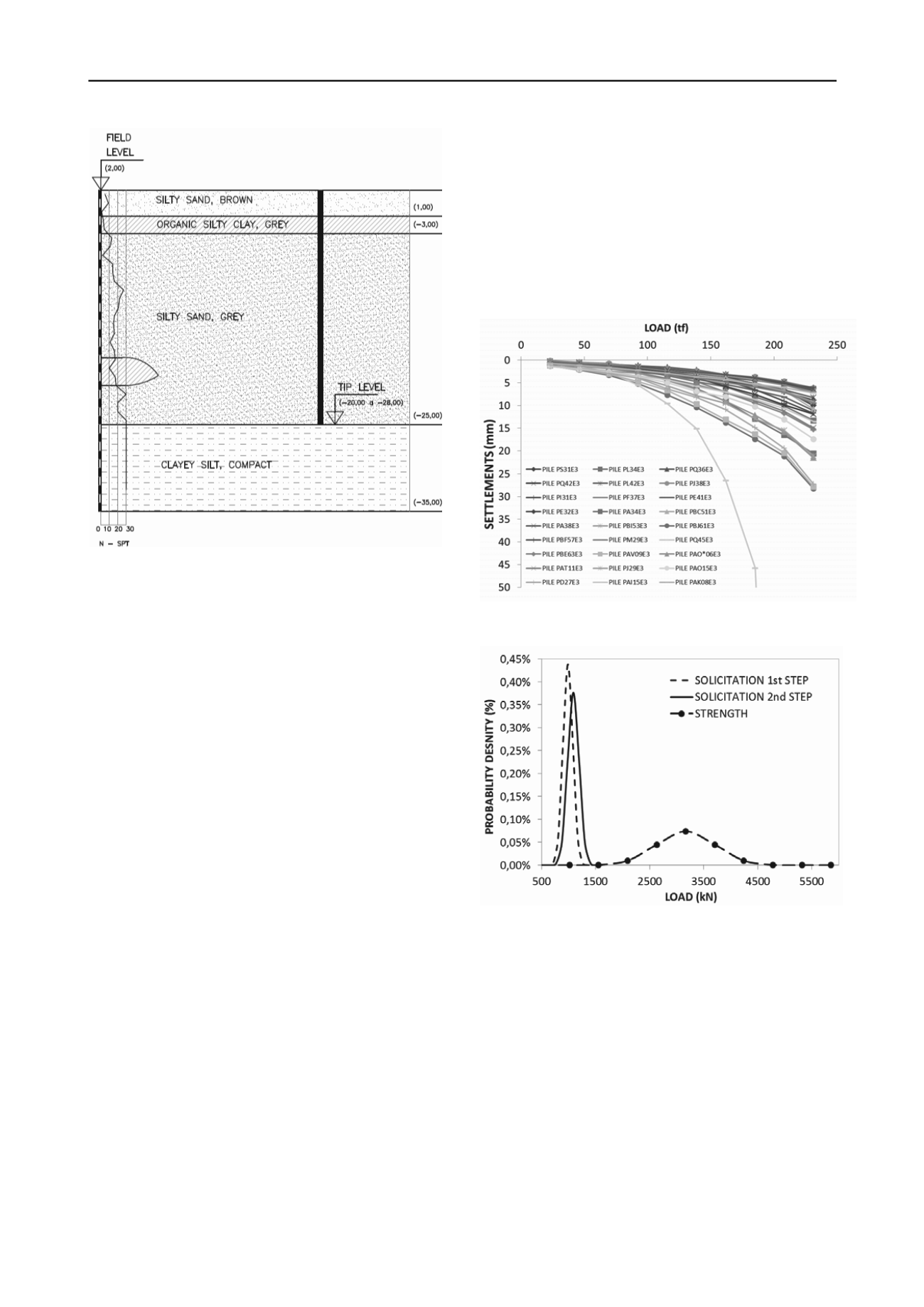

Figure 1. Subsoil profile

The final total of all piles placed, both before and after the

revision, came to 3,838. A total of 38 static load tests were

programmed throughout the project, 27 for 500 mm piles, 09 for

the 600 piles, and 02 for 400 mm piles. However, two of the

load tests, specifically the 33rd and 34th, indicated problems in

the pile caps, and had to be redone. Figure 2a shows the

diagram regarding load versus settlement for the piles analyzed

in the study. The Van der Veen equation was used as a criterion

for extrapolating the geotechnical rupture load for the load tests.

3 STATISTICAL ANALYSIS

A mean value (µR) can be imagined in a representative area

where the resistances are distributed, and a standard deviation

(σR) can measure the distance this data is from this mean

average. Analogically, in designing the details of a project with

deep foundations, normally the piles are not designed with

expectations to have to withstand maximum admissible loads.

Generally, verifiable loads are less than, but close to admissible,

presenting an average (µS), and standard deviation (σS)..Since

not all locations in the subsoil present the same resistance, it is

possible that in a certain location, the resistance is found to be

less than that which is required to withstand the load indicated.

The likelihood that this phenomenon occurs is called the

probability of failure.

Sample variation can be measured by the ratio between the

standard deviation and the mean, this ratio is called the

coefficient of variation. Reliability is a concept opposed to

variability. The reliability index (β) is defined as the inverse of

the coefficient of variation. The reliability index increases as the

normal distribution is concentrated to a greater degree around

the mean. The concept of a Safety Margin, which is defined as

the difference between the requirements demanded, and the

actual resistance, also is distributed normally, and through it can

be obtained the parameters for analysis of potential for failure.

For the case of the project under study, we studied the

probability of failure values before and after revision of the

foundation design project for the piles with 500 mm diameters,

since the number of samples was greater. This review only

changes the curve for requirements, considering that the mean

load (μR) per pile was reviewed. For the first step, which

preceded the review, mean and standard deviation values were

verified for operating loads of 985 and 91.5 kN, respectively.

For the second step, values of 1,086 and 106.0 kN, respectively,

were determined. Regarding load resistance, values of 536 and

3,167 kN were verified. A standard curve can only be set up

using its mean value, and its standard deviation.

From the data obtained, standard curves were plotted for

both steps, similarly for the requirements, and the resistances.

They are presented in Figure 2b. For the first step, the

Reliability Index (β) measured 3.99, and the Probability of

Failure (pf) was 1/30,893. For the second stage, β measured

3.79, and the pf measured 1/13,373.

(a)

(a)

(b)

Figure 2. (a) Results of load tests for the 500mm piles; (b) Standard

curves for the first and second phase compared to the normal curve of

resistance.

The load tests carried out for the project were not conducted

all at once, thus, during the course of testing, the standard

resistance curves could be adjusted to include the last test

performed. As each new test is considered, a different pair of

mean and standard deviation values is obtained. In such a

manner, it is possible to trace standard curves that consider

different steps for implementing quality controls for the

foundation, or for different quantities of static load test

performed, varying the size of the sample until the completion

of predictive control for the work.

As the sample increases, dispersion analysis is

incorporated. This dispersion arises from the variability of the

subsoil profile, the variability of the materials used, and from

the uncertainties regarding measurements of the loads and

settlement.

With introduction of a new section bearing a heavier load,

600 mm piles were also adopted, with load tests indicating a

permissible load of 1,800 kN. At this point, 1,569 stakes had

been planned for completion of the entire project. However, as a

result of the tests, and subsequent project design optimization

taking into account the increased loads, this number fell, in a

second step, to 1,275 (an 18% decrease in the number of

remaining piles). This decrease resulted in a direct cost

reduction of 1.62 million reais, not taking into account the

number of blocks needed, and also the indirect costs.

Considering the costs involved in performing the load tests, the

actual cost reduction amounted to 1.08 million reais.

The final total of all piles placed, both before and after the

revision, came to 3,838. A total of 38 (thirty-eight) static load

tests were programmed throughout the project, 27 (twenty

seven) for 500 mm piles, 9 (nine) for the 600 piles, and 2 (two)

for 400 mm piles. However, two of the load tests, specifically

the 33rd and 34th, indicated problems in the pile caps, and had

to be redone. Figure 2a shows the diagram regarding Load x

Settling for the piles analyzed in the study. The Van der Veen

equation was used as a criterion for extrapolating the rupture

load for the load tests.

Figure 1. Subsoil profile

The final total of all piles placed, both before and after the

revision, came to 3,838. A total of 38 static load tests were

programmed throughout the project, 27 for 500 mm piles, 09 for

the 600 piles, and 02 for 400 mm piles. However, two of the

load tests, specifically the 33rd and 34th, indicated problems in

the pile caps, and had to be redone. Figure 2a shows the

diagram regarding load versus settlement for the piles analyzed

in the study. The Van der Veen equation was used as a criterion

for extrapolating the geotechnical rupture load for the load tests.

3 STATISTICAL ANALYSIS

A mean value (µR) can be imagined in a representative area

where the resistances are distributed, and a standard deviation

(σR) can measure the distance this data is from this mean

average. Analogically, in designing the details of a project with

deep foundations, normally the piles are not designed with

expectations to have to withstand maximum admissible loads.

Generally, verifiable loads are less than, but close to admissible,

presenting an average (µS), and standard deviation (σS)..Since

not all locations in the subsoil present the same resistance, it is

possible that in a certain location, the resistance is found to be

less than that which is required to withstand the load indicated.

The likelihood that this phenomenon occurs is called the

probability of failure.

Sample variation can be measured by the ratio between the

standard deviation and the mean, this ratio is called the

coefficient of variation. Reliability is a concept opposed to

variability. The reliability index (β) is defined as the inverse of

the coefficient of variation. The reliability index increases as the

normal distribution is concentrated to a greater degree around

the mean. The concept of a Safety Margin, which is defined as

the difference between the requirements demanded, and the

actual resistance, also is distributed normally, and through it can

be obtained the parameters for analysis of potential for failure.

For the case of the project under study, we studied the

probability of failure values before and after revision of the

foundation design project for the piles with 500 mm diameters,

since the number of samples was greater. This review only

changes the curve for requirements, considering that the mean

load (μR) per pile was reviewed. For the first step, which

preceded the review, mean and standard deviation values were

verified for operating loads of 985 and 91.5 kN, respectively.

For the second step, values of 1,086 and 106.0 kN, respectively,

were determined. Regarding load resistance, values of 536 and

3,167 kN were verified. A standard curve can only be set up

using its mean value, and its standard deviation.

From the data obtained, standard curves were plotted for

both steps, similarly for the requirements, and the resistances.

They are presented in Figure 2b. For the first step, the

Reliability Index (β) measured 3.99, and the Probability of

Failure (pf) was 1/30,893. For the second stage, β measured

3.79, and the pf measured 1/13,373.

(a)

(a)

(b)

Figure 2. (a) Results of load tests for the 500mm piles; (b) Standard

curves for the first and second phase compared to the normal curve of

resistance.

The load tests carried out for the project were not conducted

all at once, thus, during the course of testing, the standard

resistance curves could be adjusted to include the last test

performed. As each new test is considered, a different pair of

mean and standard deviation values is obtained. In such a

manner, it is possible to trace standard curves that consider

different steps for implementing quality controls for the

foundation, or for different quantities of static load test

performed, varying the size of the sample until the completion

of predictive control for the work.

As the sample increases, dispersion analysis is

incorporated. This dispersion arises from the variability of the

subsoil profile, the variability of the materials used, and from

the uncertainties regarding measurements of the loads and

settlement.