2733

Technical Committee 212 /

Comité technique 212

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

3.2

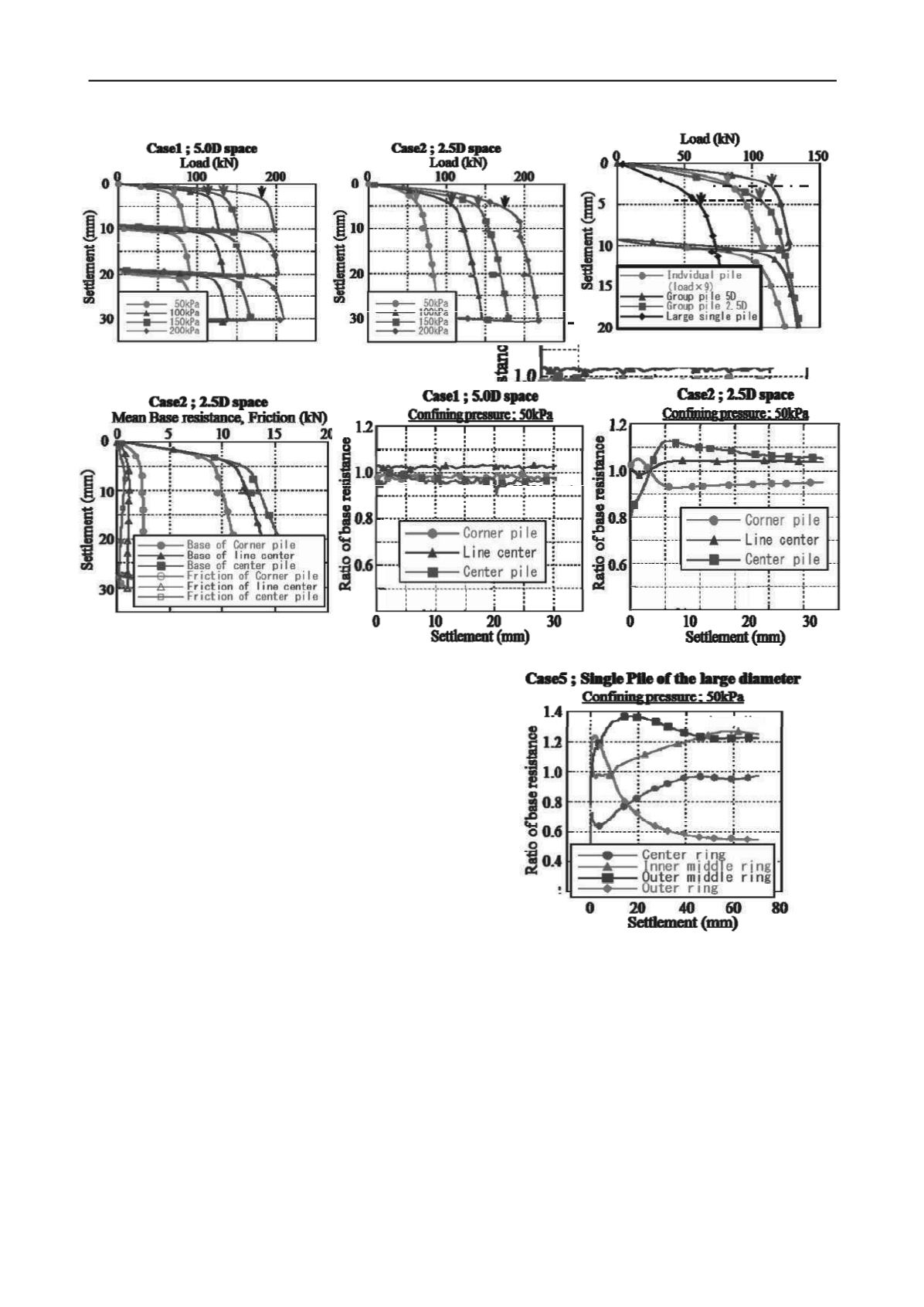

Tip stress distribution by pile location in the group pile

Figure 7 shows the mean pile tip resistance and skin friction

changing with the location of piles

–

at the center (B2 pile in

Fig.1), center of perimeter (A2, B1, B3 and C2), and corner

(A1, A3, C1 and C3) in the group pile 2.5D spacing. The figure

shows that the behavior of each pile in the group pile varies

with the location if the spacing is small.

The skin friction of the corner pile was most significant and

that of the center pile was the least for 2.5D spacing. The soil

immediately below the tip of the central pile was affected by the

other piles and moved down with piles as Fig.12 shows. That is

why the skin friction of the center pile became smaller. In

contrast, the corner piles were in contact with the outer ground

that was less affected by pile displacement. Hence the skin

friction on the corner pile was largest.

The tip resistance of the center pile was the largest and that of

the corner pile was the smallest. This would be because the

ground below the center pile was compacted by other piles.

To discuss the tip resistance more in detail, the resistance ratio

was plotted in Fig. 8. This figure shows the tip resistance

changing with the location of piles, normalized by the total tip

resistance under the confining pressure of 50kPa. With 5.0D

spacing, the ratio of each pile was almost equal to unity

throughout the loading. It suggests that each pile behaved

independently. In contrast, for 2.5D spacing, the ratio changed

with the penetration of the group pile. The load concentration

shifted from the corner piles to the center pile.

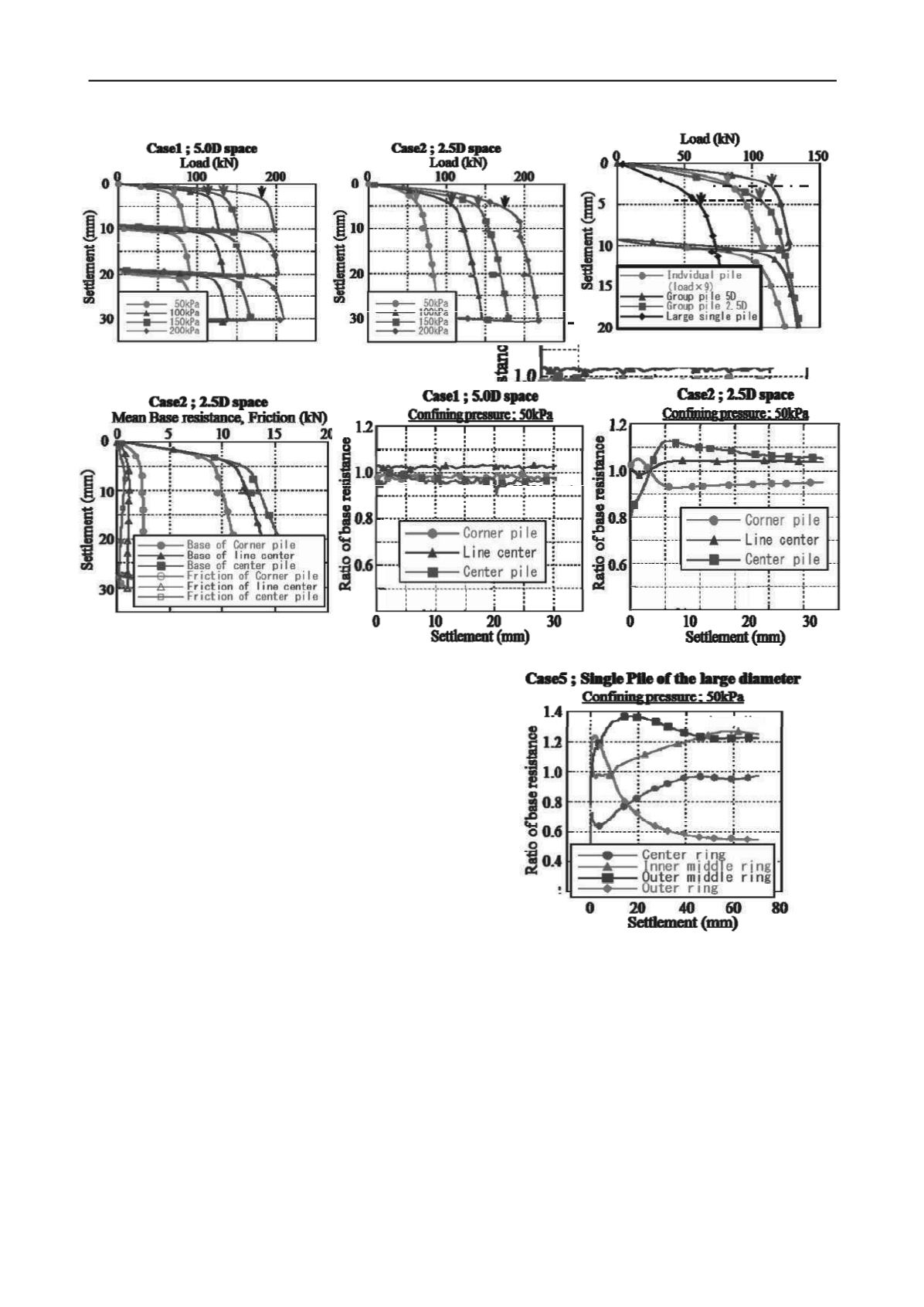

Figure 9 shows the tip resistance changing with the location

within the bottom of the large pile that was measured by annular

load cells as shown Fig.4. The stress concentration also shifted

from the edge to the center of the pile. The tendency of the

stress concentration changing in the bottom of one pile was

similar to that of the 2.5D spacing group pile. This suggests that

the significant interaction occurred in the 2.5D spacing group

pile and all 9 piles behaved as a block.

3.3

Response of tactile sensor

Figure 10 shows the normal pressure distribution at the bottom

of the soil tank, measured by tactile sensors. The lighter color

means higher pressure. The distance between the bottom of

piles and the sensors was 290 mm. In both pile spacings, the

highest pressure occurred below the center pile and the pressure

decreased in an annular manner.

In contrast, the stress distribution near the tip of the piles

varied with the spacing of piles. Fig. 11 shows the stress

distribution when the distance between the pile tip and the

sensor was 110 mm. For 5.0D spacing, the higher pressure

occurred individually below the bottom of each pile. On the

other hand, in case of 2.5D spacing, the pressure distribution

looks like one block and the maximum pressure occurred in the

zone between piles and formed a circular shape. This also

Figure 5. Total Load - settlement curve in the pile

Figure 6. Total Load - settlement curve

in both the single pile and the pile group

Figure 7. Mean base resistance and friction

Figure 8. Ratio of base resistance

Figure 9. Distribution of contact pressure at base

in a single pile with the large diameter