2724

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

interaction factor between reference pile 1 and pile

j

and

j

=

2,…,

n.

2 FULL-SCALE TESTING

The field testing program consisted of performing five

compression load tests on four non-instrumented piles of

different sizes at two sites: site (A) is composed primarily of

sand; and site (B) is mainly clayey soil. Two axial compressive

load tests were conducted at Site (A) and three axial

compression load tests were conducted at site (B). The piles

installed at site (A) had single helix, while those installed at site

(B) had double and triple helices. The load tests conformed to

procedure A of ASTM D1143 for axial compression testing.

The subsurface soil condition at site (A) included a top 0.3m

of an organic soil material followed by a thin brown clay layer

that extends 0.5m and consists of silt and sand, and traces of

gravel. Underlying the clay layer is a sand layer that extends to

9m below ground surface. The sand ranged from fine grained at

the top to coarse grained with increasing depth. The Standard

Penetration Test (SPT) blow count number indicated loose to

medium dense sand conditions with depth. The natural moisture

content was averaged at 20% along depth. The groundwater

table was not observed at the time of drilling and the piles were

installed and tested during the month of October.

The subsurface soil profile established from the boreholes at

site (B) comprises a surficial fill layer of sand and gravel mixed

with some organics and extends to 1.5m with an SPT number

ranging between 5 and 6. Underlying the surficial layer is

medium to stiff brown silt and sand that extends to depths

between 2.3m to 4.6m below ground surface with an SPT

number varying between 3 and 12. Further deep is a silty clay

layer that extends to depths 6.1m and 7.6m below ground

surface. The silty clay layer gets softer with increasing depth

and the SPT number ranged from 6 to 0. The ground water table

was encountered 1.0 m below the ground surface.

The tested piles geometrical properties were representative

of typical helical piles geometry in projects that involve light to

medium loading conditions and are summarized in Tables 1 and

2 for site (A) and site (B), respectively.

The test results were used exclusively to calibrate and verify

the numerical models that were then used to perform the

parametric study.

Table 1. Summary of tested piles configurations at site (A)

Test Pile

Depth

(m)

Shaft Diameter

(mm)

Helix Diameter

(mm)

PA-1

5.5

273

610

PA-3

5.6

219

508

Table 2. Summary of tested piles configurations at site (B)

Test Pile

Depth

(m)

Shaft Diameter

(mm)

Helix Diameter

(mm)

PB-1

7.2

178

610x610x610

PB-2

7.2

178

610x610x610

PB-4

3.2

114

406x406

3 NUMERICAL MODELING

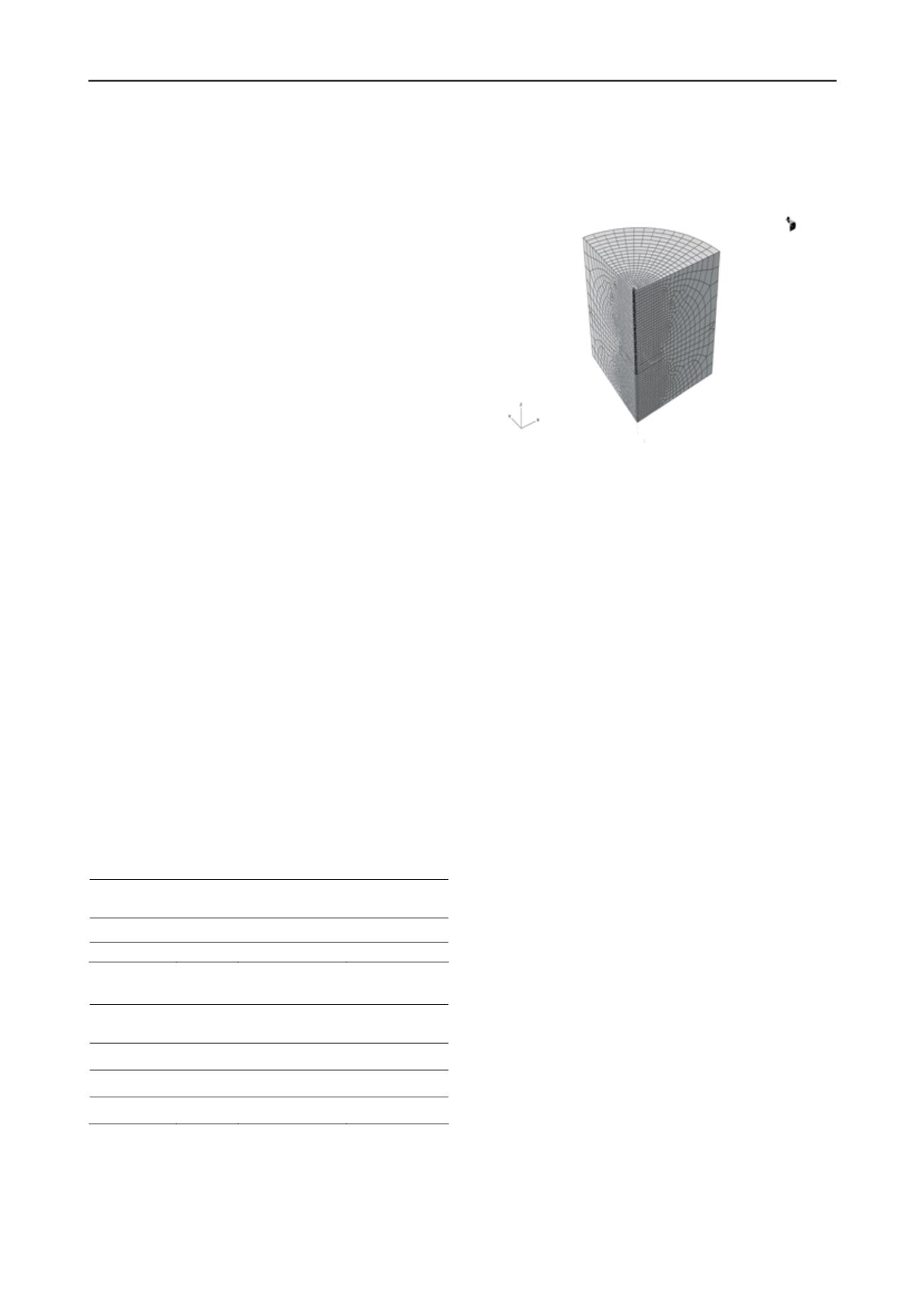

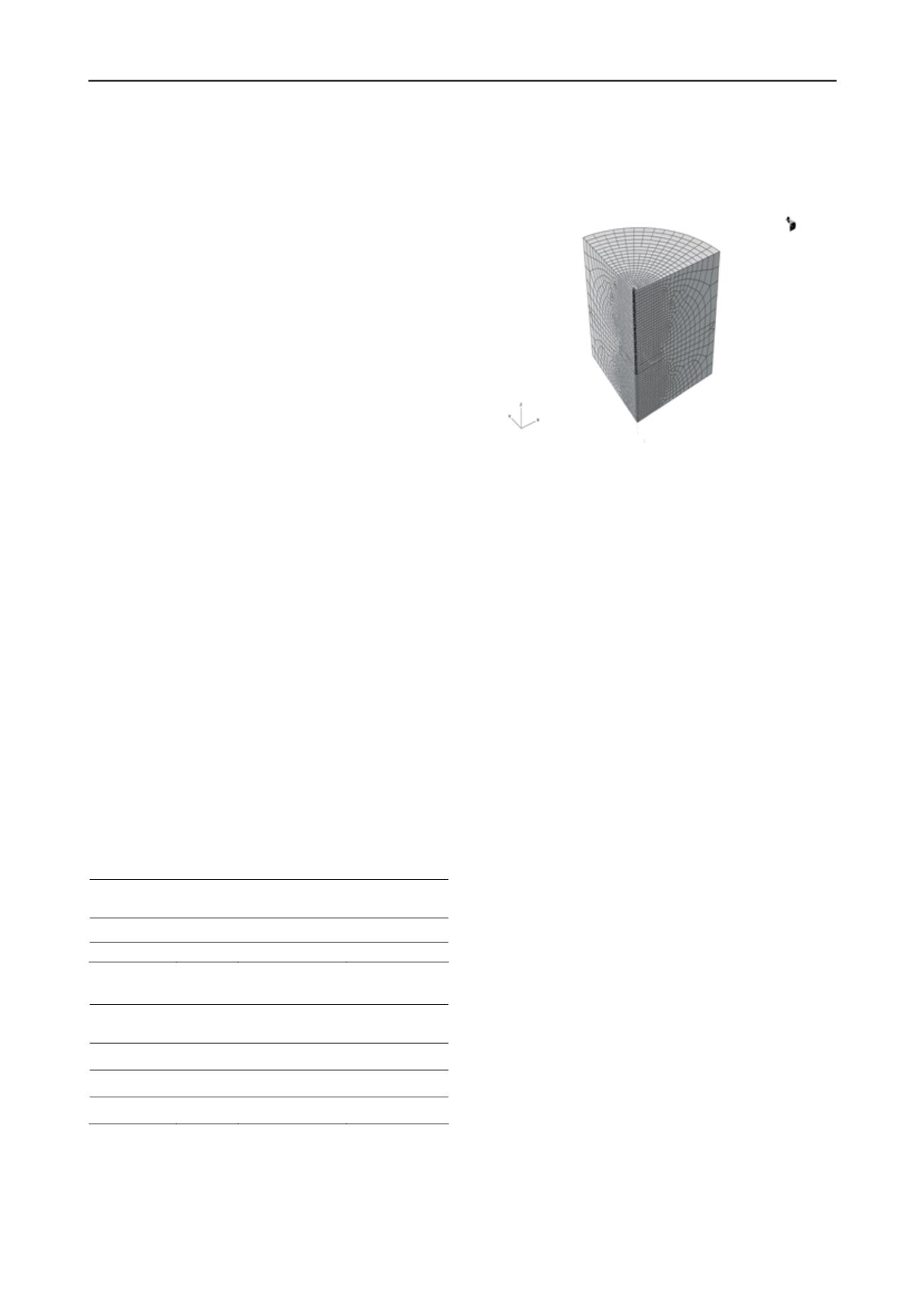

A finite element model is developed using the program

ABAQUS (SIMULIA, 2009) to simulate the experimental

program. The soil continuum is modeled considering a 3D

cylindrical configuration and the pile is placed along the axial z-

direction of the cylinder. The helix is idealized as a planar

cylindrical disk so that modeling of the pile and the surrounding

soil can take advantage of the axisymmetric conditions as

shown in Figure 1.

Figure 1. Numerical model geometry for a single pile subjected to axial

load.

3.1

Model description

The 3-dimensional soil medium is discretized into 8-noded, first

order, and reduced integration continuum solid elements

(C3D8R). The element has three active translational degrees of

freedom at each node and consists of one integration point

located at the centroid. The pile is simulated using four-nodes,

first order, reduced integration, general-purpose shell elements

(S4R).

The boundaries are located such that there is minimal effect

on the results. The radius of the soil column extends

approximately 33 shaft diameters from the center of the pile

shaft. The depth of soil deposits below the lower helix is a

minimum of 6.5 helix diameters. The top soil surface is

considered as stress-free boundary. The boundary conditions

exploited symmetry to reduce the model size. The bottom of the

soil cylinder is pinned. The back of the cylinder is constrained

in the horizontal plane and is free to move vertically.

The soil is modeled as an isotropic elastic-perfectly plastic

continuum with failure described by the Mohr-Coulomb yield

criterion. The elastic behavior was defined by Poisson’s ratio,

ν

,

and Young’s modulus,

E

. The plastic behavior is defined by the

residual angle of internal friction,

ϕ

r

, and the dilation angle,

ψ

,

and material hardening is defined by the cohesion yield stress,

c

,

and absolute plastic strain,

ε

pl

.

The pile-soil interface is modeled using the Tangential

Behavior Penalty-type Coulomb’s frictional model. The soil

unit weight is accounted for in the numerical model as an initial

stress through the geostatic equilibrium step.

3.2

Calibration and verification

Using some of the test results, the above model properties and

configurations, and representative soil properties obtained from

the boreholes and the literature, the numerical models are

calibrated satisfactorily considering the soil conditions and load

test results of piles PA-1 and, PB-1 and PB-2 as shown in

Figures 2 and 3. The soil properties used in the analysis are

assumed to be the disturbed properties due to pile installation.

program. The soil continuum is modeled considering a 3D

cylindrical configuration and the pile is placed along the axial z-

direction of the cylinder. The helix is idealized as a planar

cylindrical disk so that modeling of the pile and the

surrounding soil can take advantage of the axisymmetric

conditions as shown in Figure 1.

Figure 1. Numerical model geometry for a single pile subjected to axial

load.

3.1

Model description

The 3-dimensional soil medium is dis ret zed into 8-nod d, first

order, and reduced integration continuum s lid elements

(C3D8R). The element has three active translational degrees of

freedom at each node and consists of one integration point

located at the centroid. The pile is simulated using four-nodes,

first order, reduced integration, gen al-purpose shell

elements (S4R).

The boundaries are located such that there is minimal

effect on the results. The radius of the soil column extends

approximately 33 shaft diam ters fr m the cent r f the pile

shaft. The depth of soil deposits below the lower helix is a

minimum of 6.5 helix diameters. The top soil surface is

considered as stress-free boundary. The boundary conditions

exploited symmetry to reduce the model size. The bottom of

the soil cylinder is pinned. The back of the cylin er is

constrained in the horizontal plane and is free to move

vertically.

The soil is modeled as an isotropic elastic-perfectly plastic

continuum with failure described by the Mohr-Coulomb yield

criterion. The elastic behavior was defined by Poisson’s ratio,

ν

,

and Young’s modulus,

E

. The plastic behavior is defined by the

residual angle of internal friction,

ϕ

r

, and the dilation angle,

ψ

,

and material hardening is defined by the cohesion yield stress,

c

, and absolute plastic strain,

ε

pl

.

The pile-soil interface is modeled using the Tangential

Behavior Penalty-type Coulomb’s frictional model. The soil unit

weight is accounte fo in the numerical mod l a n initial

stress through the geostatic equilibrium step.

3.2

Cali

Using so

configurat

from the

are calibr

load test

Figures 2

assumed t

Figure 2. C

Figure 3. C

In ord

accurately

compressi

utilized (c

and interf

data and

actual tes

4(a), and

a)