2720

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Shong approach is adapted in the analysis of the results in this

study.

This paper represents a study to investigate the behavior of

soil-pile interaction during soil consolidation. Since full-scale

testing of the influence of the large number of variables

involved is economically unreasonable, a simulated laboratory

experiment has been designated. A special rig was designed

and constructed for this purpose. In order to carry out the

investigations, experimental program was developed.

2 EXPERIMENTAL WORK

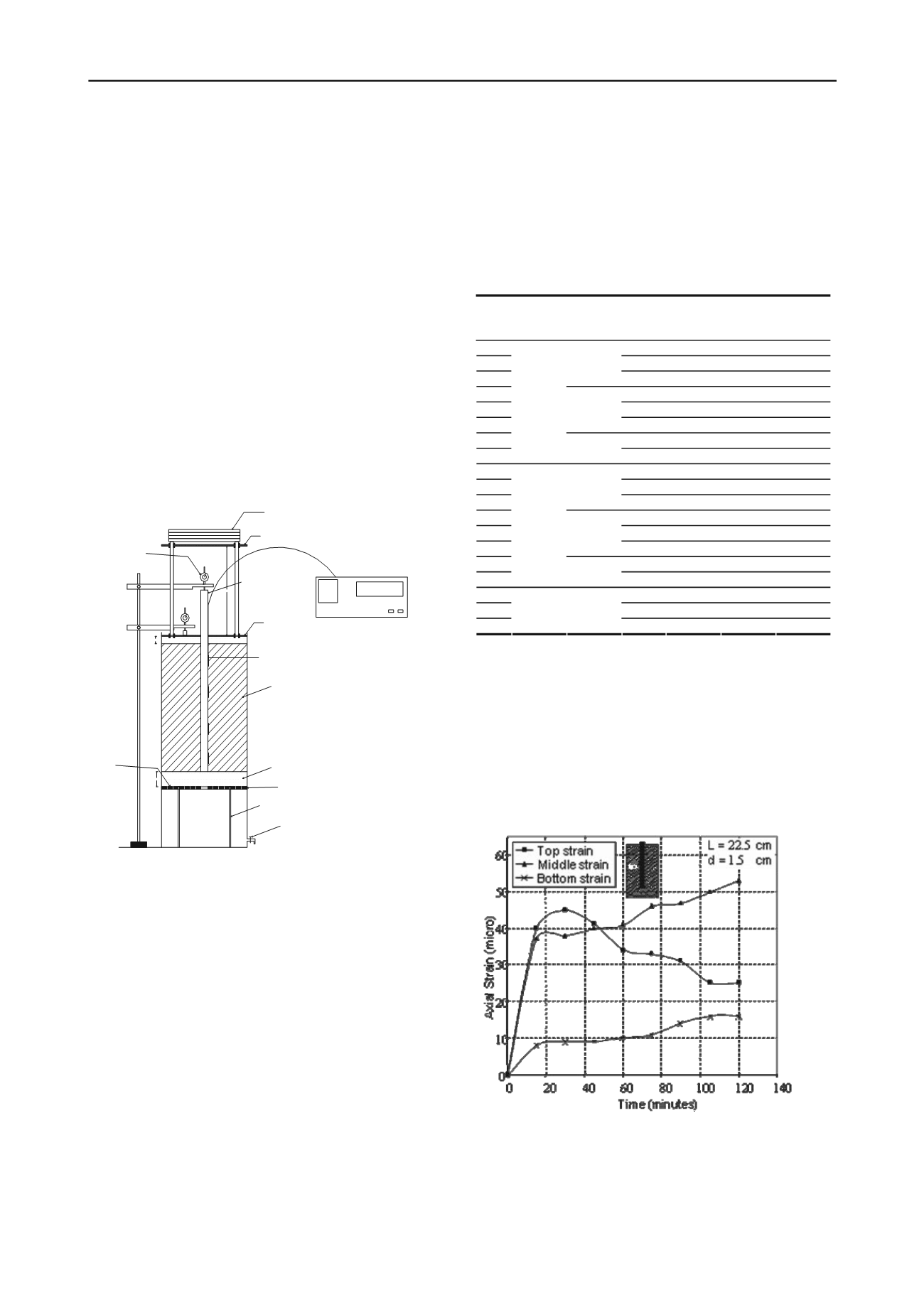

(Nasser 2010) arranged the experimental rig as shown in Figure

1. Three P.V.C circular model piles with different diameters of

1.5, 2 and 2.5 cm were chosen to model the pile in this study.

Compression tests were carried out on a specimen of this P.V.C

pipes to determine its modulus of elasticity. The modulus of

elasticity of the pile material; P.V.C is 1500000 KN/m

2

. The

surface of the pile is smooth.

Fig. 1 The experimental rig

Two layers of sand with depth 5cm for each layer. One of

these layers placed on the surface of soft soil and the second

layer under the soil.

Bentonite soil has been adapted for the experimental

investigation in this study. 85% water content provides a soft

consistency of bentonite. For this condition initial void ratio is

2.38, bulk density is 16 KN/m

3

.

A surcharge has to be applied to the soil layer for

consolidation. Steel and lead plates of 1.2kN total weight were

arranged for the surcharge. These loads simulate a surcharge of

1m fill of unit weight 17kN/m

3

.

The vertical displacement of the model pile and the soil

surface were measured using dial gauges. The displacement of

the model pile is measured at its center. The soil settlement is

measured at a point located at the mid distance between the pile

shaft and the container wall.

Strain gauges are fixed at various depths of the length of the

pile to measure the strains occurred on the pile during soil

consolidation. Number and locations of the strain gauges are

designed depending on the thickness of the clay layer.

Table (1) illustrates the experimental program. Three cases

of boundary conditions were considered in this study. The first

case is the pile ended in the clay layer. This represents clay end

bearing case. The second case is the pile ended in the sand

layer. And the last case represents floating pile. That is, the pile

passes through the lower plate and not resting on any soil. This

case is aimed to investigate the pure shaft resistance without the

interference of the end condition.

Table (1) Different cases with code for each test

No.

Cases

Pile

Diameter

(cm)

L/d Pile

Length

(cm)

Code No. of

Strain

gages

1

10

15 L15EC

3

2

15

22.5

L22.5EC 3

3

1.5

20

30 L30EC

4

4

10

20 L20EC

3

5

15

30 L30EC

4

6

2

20

40 L40EC

4

7

10

25 L25EC

4

8

CASE I (end bearing

clay EC)

2.5

15

37.5

L37.5EC 4

9

10

15

L15ES

3

10

15

22.5

L22.5ES 3

11

1.5

20

30

L30ES

4

12

10

20

L20ES

3

13

15

30

L30ES

4

14

2

20

40

L40ES

4

15

10

25

L25ES

4

16

CASE II (end bearing

sand ES)

2.5

15

37.5

L37.5ES 4

17

10

25

L25F

4

18

15

37.5

L37.5F

4

19

Floating

(F)

2.5

20

50

L50F

4

250mm

50mm

100mm

Soil artificial

soft clay

Steel

Circularplate

P.V.Cpipe

Sand layer

Steel rod

Valve

Perforatedplate

Circular

plate

Theapplied

surcharge

DataLogger

DialGauge

Straingauge

Filterpaper

3 RESULTS AND ANALYSIS

3.1

Time–strain behavior of pile model

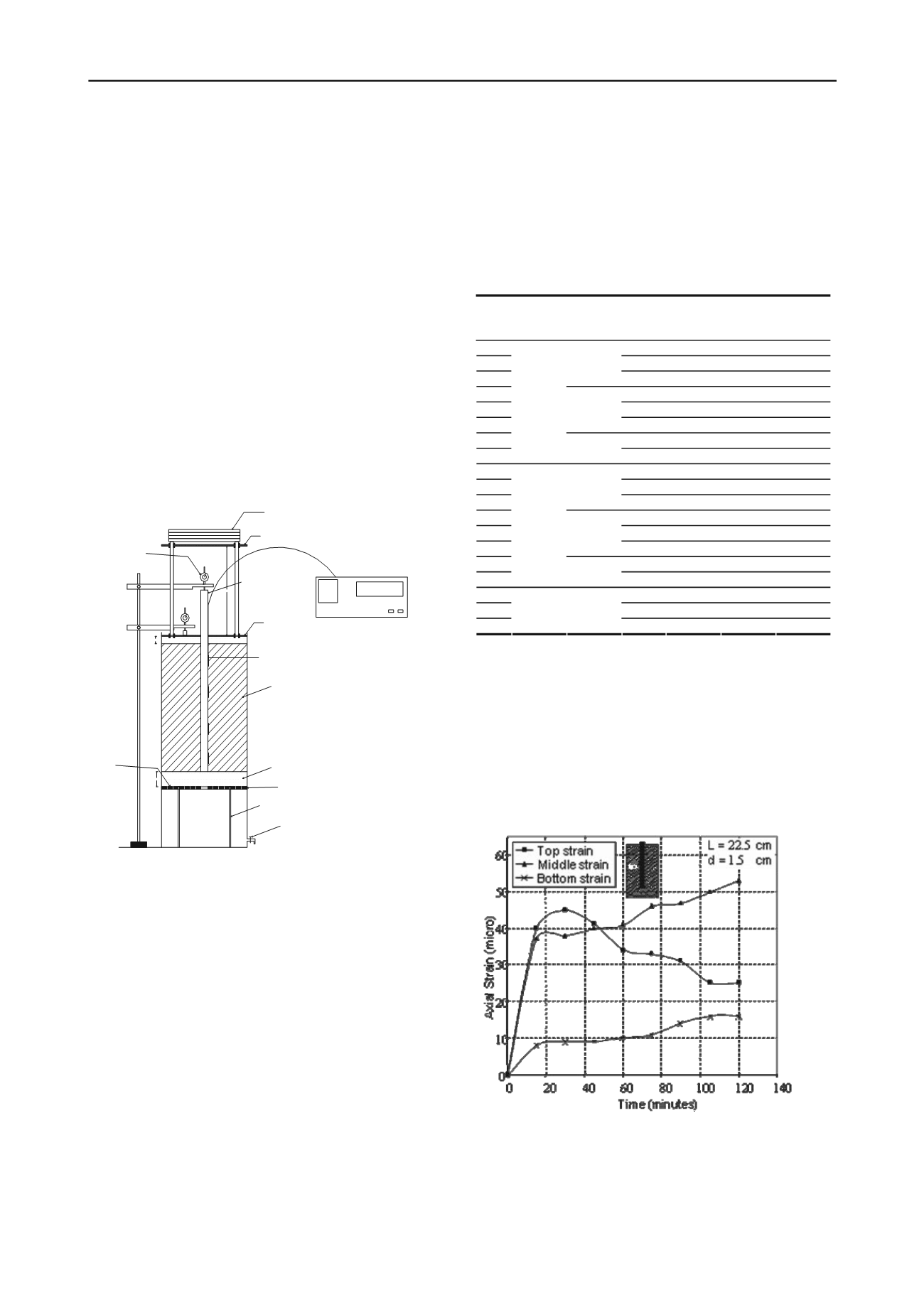

Figures 2 shows the axial strain with time of applying the

surcharge, for pile model (L22.5Ec). From the Figure, it can be

seen that the top strain is higher and occurs earlier than the

middle and the bottom strains. However, it declines just after

reaching the early peak. The other strains continue increasing

until the end of the test.

Fig. 2 Time-Axial strain curves of pile model (L22.5Ec)

It is clear that the top portion of the deposit go through

consolidation due to the nearby surcharge faster than the

remaining deposit. By the time being, the rate of water

dissipation decreases, and, hence, the axial strain decreases.

The middle axial strains continue increasing with lower rate

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2

Shong approach is adapted in the analysis of the results in this

study.

This paper represents a study to investigate the behavior of

soil-pile interaction during soil consolidation. Since full-scale

testing of the influence of the large number of variables

involved is economically unreasonable, a simulated laboratory

experiment has been designated. A special rig was designed

and constructed for this purpose. In order to carry out the

investigations, experimental program was developed.

2 EXPERIMENTAL WORK

(Nasser 2010) arranged the experimental rig as shown in Figure

1. Three P.V.C circular model piles with different diameters of

1.5, 2 and 2.5 cm were chosen to model the pile in this study.

Compression tests were carried out on a specimen of this P.V.C

pipes to determine its modulus of elasticity. The modulus of

elasticity of the pile material; P.V.C is 1500000 KN/m

2

. The

surface of the pile is smooth.

Fig. 1 The exper mental rig

Two layers of sand with depth 5cm for each layer. One of

these layers placed on the surface of soft soil and the second

layer under the soil.

Bentonite soil has been adapted for the experimental

investigation in this study. 85% water content provides a soft

consistency of bentonite. For this condition initial void ratio is

2.38, bulk density is 16 KN/m

3

.

A surcharge has to be applied to the soil layer for

consolidation. Steel and lead plates of 1.2kN total weight were

arranged for the surcharge. These loads simulate a surcharge of

1m fill of unit weight 17kN/m

3

.

The vertical displacement of the model pile and the soil

surface were measured using dial gauges. The displacement of

the model pile is measured at its center. The soil settlement is

measured at a point located at the mid distance between the pile

shaft and the container wall.

Strain gauges are fixed at various depths of the length of the

pile to measure the strains occurred on the pile during soil

consolidation. Number and locations of the strain gauges are

designed depending on the thickness of the clay layer.

Table (1) illustrates the experimental program. Three cases

of boundary conditions were considered in this study. The first

case is the pile ended in the clay layer. This represents clay end

bearing case. The second case is the pile ended in the sand

layer. And the last case represents floating pile. That is, the pile

passes through the lower plate and not resting on any soil. This

case is aimed to investigate the pure shaft resistance without the

interference of the end condition.

Table (1) Different cases with code for each test

No.

Cases

Pile

Diameter

(cm)

L/d Pile

Length

(cm)

Code No. of

Strain

gages

1

10

15 L15EC

3

2

15

22.5

L22.5EC 3

3

1.5

20

30

30

4

4

10

20 L20EC

3

5

15

30 L30

4

6

2

20

40 L40EC

4

7

10

25

25

4

8

CASE I ( nd bearing

clay EC)

2.5

15

37.5

L37.5EC 4

9

10

15

15 S

3

10

15

22.5

22.5 S 3

11

1.5

20

30

30

4

12

10

20

L20ES

3

13

15

30

L30

4

14

2

20

40

40

4

15

10

25

25

4

16

CASE II ( nd bearing

sand ES)

2.5

15

37.5

L37.5ES 4

17

10

25

L25F

4

18

15

37.5

L37.5F

4

19

Floating

(F)

2.5

20

50

50

4

250mm

50mm

100mm

Soil artificial

soft clay

Steel

Circularplate

P.V.Cpipe

Sand layer

Steel rod

Valve

Perforatedplate

Circular

plate

Theapplied

surcharge

DataLogger

DialGauge

Straingauge

Filterpaper

3 RESULTS AND ANALYSIS

3.1

Time–strain behavior of pile model

Figures 2 shows the axial strain with time of applying the

surcharge, for pile model (L22.5Ec). From the Figure, it can be

seen that the top strain is higher and occurs earlier than the

middle and the bottom strains. However, it declines just after

reaching the early peak. The other strains continue increasing

until the end of the test.

Fig. 2 Time-Axial strain curves of pile model (L22.5Ec)

It is clear that the top portion of the deposit go through

consolidation due to the nearby surcharge faster than the

remaining deposit. By the time being, the rate of water

dissipation decreases, and, hence, the axial strain decreases.

The middle axial strains continue increasing with lower rate

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Shong approach is adapted in the analysis of the results in this

study.

This paper represents a study to investigate the behavior of

soil-pile interaction during soil consolidation. Since full-scale

testing of the influence of the large number of variables

involved is economically unreasonable, a simulated laboratory

experiment has been designated. A special rig was designed

and constructed for this purpose. In order to carry out the

investigations, experimental program was developed.

2 EXPERIMENTAL WORK

(Nasser 2010) arranged the experimental rig as shown in Figure

1. Three P.V.C circular model piles with different diameters of

1.5, 2 and 2.5 cm were chosen to model the pile in this study.

Compression tests were carried out on a specimen of this P.V.C

pipes to determine its modulus of elasticity. The modulus of

elasticity of the pile material; P.V.C is 1500000 KN/m

2

. The

surface of the pile is smooth.

Fig. 1 The experimental rig

Two layers of sand with depth 5cm for each layer. One of

Table (1) illustrates the experimental program. Three cases

of boundary conditions were considered in this study. The first

case is the pile ended in the clay layer. This represents clay end

bearing case. The second case is the pile ended in the sand

layer. And the last case represents floating pile. That is, the pile

passes through the lower plate and not resting on any soil. This

case is aimed to investigate the pure shaft resistance without the

interference of the end condition.

Table (1) Different cases with code for each test

No.

Cases

Pile

Diameter

(cm)

L/d Pile

Length

(cm)

Code No. of

Strain

gages

1

10

15 L15EC

3

2

15

22.5

L22.5EC 3

3

1.5

20

30 L30EC

4

4

10

20 L20EC

3

5

15

30 L30EC

4

6

2

20

40 L40EC

4

7

10

25 L25EC

4

8

CASE I (end bearing

clay EC)

2.5

15

37.5

L37.5EC 4

9

10

15

L15ES

3

10

15

22.5

L22.5ES 3

11

1.5

20

30

L30ES

4

12

10

20

L20ES

3

13

15

30

L30ES

4

14

2

20

40

L40ES

4

15

10

25

L25ES

4

16

CASE II (end bearing

sand ES)

2.5

15

37.5

L37.5ES 4

17

10

25

L25F

4

18

15

37.5

L37.5F

4

19

Floating

(F)

2.5

20

50

L50F

4

250mm

50mm

100mm

Soil artificial

soft clay

Steel

Circularplate

P.V.Cpipe

Sand layer

Steel rod

Valve

Perforatedplate

Circular

plate

Theapplied

surcharge

DataLogger

DialGauge

Straingauge

Filterpaper

3 RESULTS AND ANALYSIS

3.1

Time–strain behavior of pile model

Figures 2 shows the axial strain with time of applying the

surcharge, for pile model (L22.5Ec). From the Figure, it can be

seen that the top strain is higher and occurs earlier than the

middle and the bottom strains. However, it declines just after

reaching the early peak. The other strains continue increasing

until the end of the test.