2725

Technical Committee 212 /

Comité technique 212

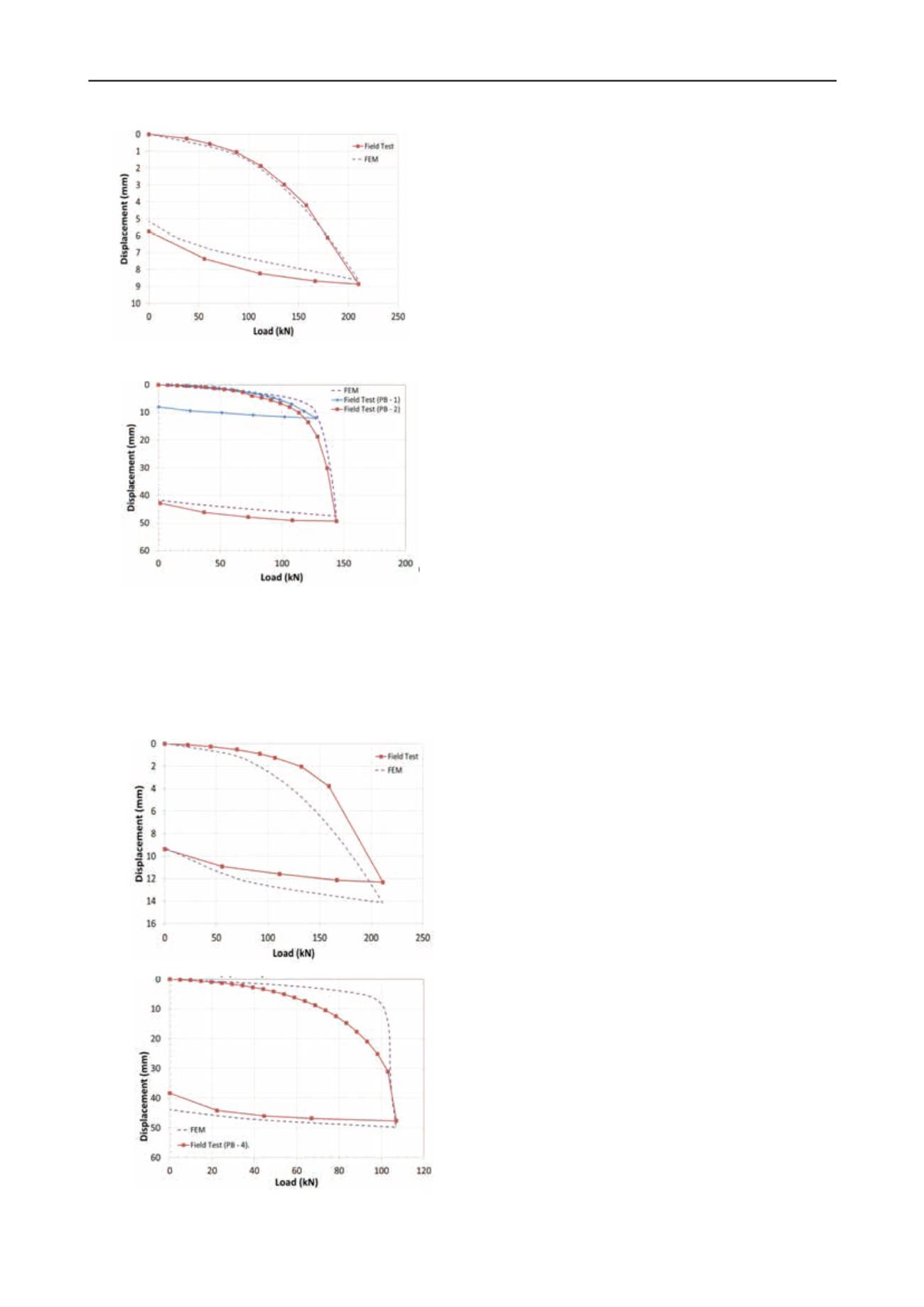

Figure 2. Calibrated numerical model compared to field test of PA-1

Figure 3. Calibrated numerical model of piles PB-1 and PB-2

In order to verify the ability of the calibrated models to

accurately depict the behavior of helical piles under

compressive and lateral loading, the calibrated models were

utilized (considering the same soil properties and boundary and

interface conditions) to analyze the remaining load test data and

the results showed satisfactory agreement with actual test results

of piles PA-3, and PB-4 as shown in Figures 4(a), and 4(b).

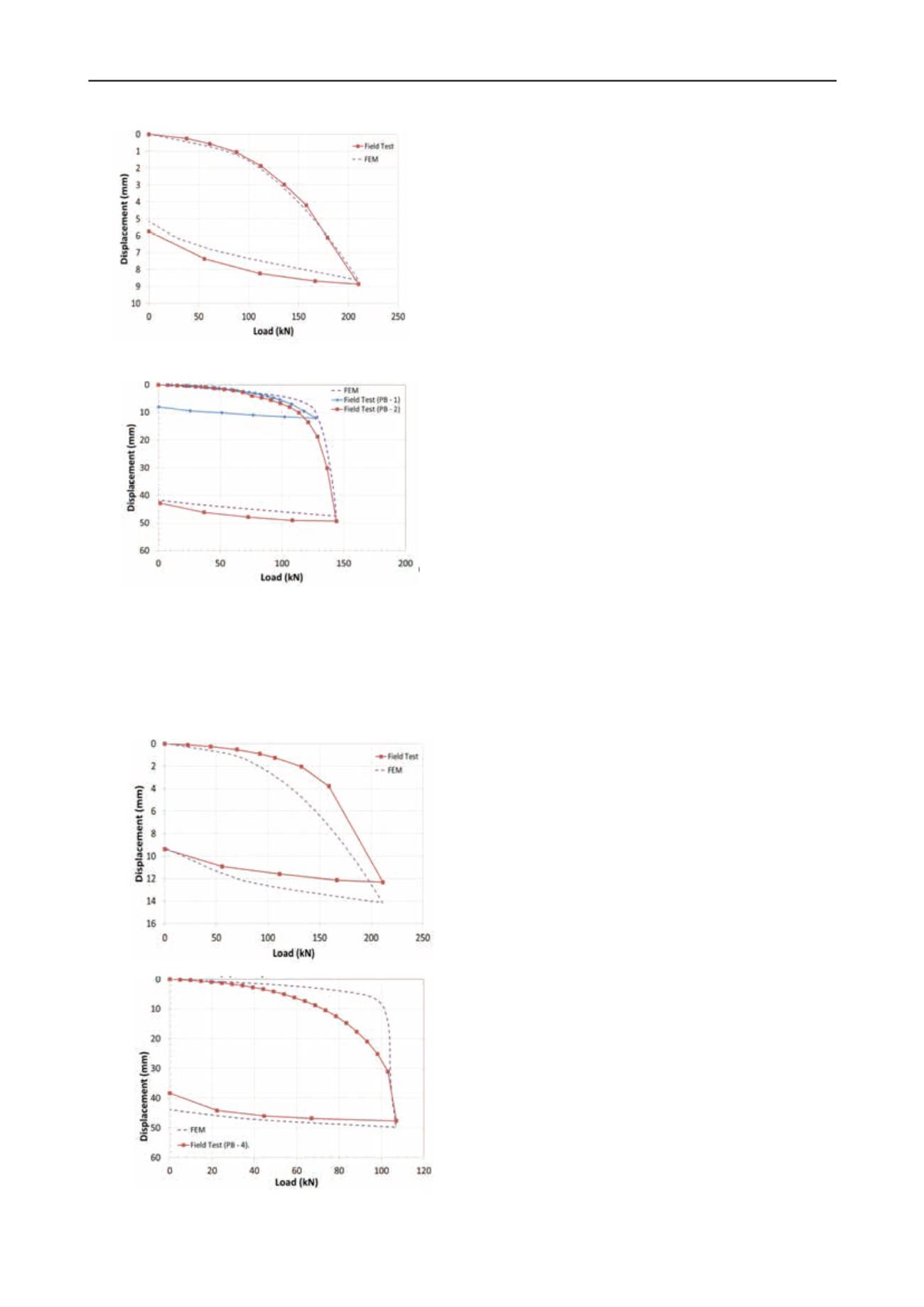

Figure 4. Verified numerical models: a) Pile PA-3; b) Pile PB-4.

Using the same soil properties that are established from the

calibration of model considering pile PA-1 test data, the

calculated response of neighbouring pile PA-3 is softer than the

field test results as shown in Figure 4(a), but the calculated

response of pile PB-4 is stiffer than the load test data. This is

expected due to the natural spatial variability of soil properties.

3.3

Parametric study

Using the previously calibrated and validated models, a

numerical parametric study is conducted considering different

practical pile configurations and common soil types. The piles

considered consist of a 273mm diameter steel pipe that has two

610mm helices attached to it. The inter-helix spacing ratio,

S

r

,

ranges between 1 and 3 helix diameters (i.e. 1

D

, 2

D

, and 3

D

)

with a pile embedment depth of 6 m. The piles are modeled as

single, two, and four piles in a square arrangement with a center

to center spacing,

S

p

, ranging between

2D

to

10D

.

The pile is modeled as elastic steel with

E

= 200GPa and

ν

= 0.3. For piles in sand, the sand is modeled as homogeneous

with

ϕ

r

= 30° and

ψ

= 0° to represent loose to medium dense

sand. The yield cohesion,

c

, is 0 kPa to represent purely

frictional sand. The sand is assumed to have a bulk unit weight

of 20 kN/m

3

and an initial coefficient of lateral earth pressure,

K

o

, equal 0.5. Moreover, the pile-soil interface friction angle, δ,

is assumed to be 0.67

ϕ

r

which yields a friction factor of 0.38.

Finally, the modulus of elasticity of the soil is assumed to be

100MPa and the soil Poisson’s ratio, ν = 0.3.

For piles in clay, it is assumed that the helices are embedded

into a very stiff clay layer with undrained shear strength,

c

u

=

100kPa and

E

= 50MPa, while the soil above top helix (i.e.

along the shaft) is soft clay with

c

u

= 25kPa and

E

= 30MPa.

The clay is modeled assuming the water level is at the ground

surface, and the loading rate is assumed fast enough to invoke

undrained conditions. Therefore, Poisson’s ratio = 0.49 was

considered in the analysis. The adhesion,

c

a

, between the pile

and the soil is estimated from CFEM (2006): for

c

u

= 25 kPa,

c

a

= 25 kPa. A friction factor of 1.0 is used indicating that the

frictional stresses along the shaft are equal to the contact

pressure. However, to account for the adhesion strength, a shear

stress limit along the interface is defined at which slippage

occurs. This shear stress limit along the interface is

c

a

.

a

4 RESULTS AND DISCUSSION

For load-settlement curves with no visually distinctive failure

point, as for the case of piles in sand, the failure loads are

obtained at a practical settlement level equal to

5%D

(i.e.

30mm). The pile settlement is obtained at a service load equal to

the failure load divided by a factor of safety,

FS

, equal to 3.

For a 4-pile group in sand,

R

s

could be as high as 1.3 at

S

p

=

2D

and as low as 1.1 at

S

p

=

5D

.

R

s

is the greatest at

S

p

=

2D

and

decreases gradually with increasing

S

p

as shown in Figure 5. It

is also found that

S

r

has a negligible effect on

R

s

. Moreover,

R

s

at service load considering

FS

= 2 is larger than

R

s

for service

loads given by

FS

= 4, as shown in Figure 6. It is also found that

R

s

for a group of piles is not necessarily an algebraic summation

of the interaction factors,

α

ij

, of the piles in the group. The

existence of other piles in a group (other than the two under

consideration) stiffens the soil. Therefore, the interaction factors

would decrease relative to the case of a 2-pile group. Basile

(1999) made similar observations and concluded that the

interaction factors approach may lead to overestimation of pile

response. Furthermore, Randolph (1994) stated that the

interaction factors should only be applied to the elastic

component of settlement since the plastic component of

settlement is largely due to localized failure close to the pile and

is not transferred to neighboring piles.

b

to axial

ed, first

lements

grees of

n point

r-nodes,

e shell

minimal

extends

the pile

elix is a

rface is

nditions

ttom of

inder is

o move

y plastic

b yield

ratio,

ν

,

d by the

ngle,

ψ

,

d stress,

ngential

soil unit

n initial

are calibrated satisfactorily considering the soil conditions and

load test results of piles PA-1 and, PB-1 and PB-2 as shown in

Figures 2 and 3. The soil properties used in the analysis are

assumed to be the disturbed properties due to pile installation.

Figure 2. Calibrated numerical model compared to field test of PA-1

Figure 3. Calibrated numerical model of piles PB-1 and PB-2

In order to verify the ability of the calibrated models to

accurately depict the behavior of helical piles under

compressive and lateral loading, the calibrated models were

utilized (considering the same soil properties and boundary

and interface conditions) to analyze the remaining load test

data and the results showed satisfactory agreement with

actual test results of piles PA-3, and PB-4 as shown in Figures

4(a), and 4(b).

a)

to axial

ed, first

lements

grees of

n point

r-nodes,

e shell

minimal

extends

the pile

lix is a

rface is

nditions

ttom of

inder is

o

ove

y plastic

b yield

ratio,

ν

,

d the

ngle,

ψ

d stress,

ngential

soil unit

i i

assum d to be the disturbed properties due to pile installation.

Figure 2. Calibrated numerical model compared to field test of PA-1

Figure 3. Calibrated numerical model of piles PB-1 and PB-2

In order to verify the ability f the calibrated models to

a curately depict the behavior of helic l piles und r

compressive and lateral lo d ng, the calibrated models were

utilized (considering the same soil propert es and boundary

and interface condi ions) to analyz the remaining load t st

data and the results showed satisfacto y agreement with

ctual st r sults of piles PA-3, and PB-4 as shown in Figures

4(a), and 4(b).

a)

Figure 4. Verified numerical models: a) Pile PA-3; b) Pile PB-4.

Using the same soil properties that are established from

For piles in clay, it is assumed that the helices are

embedded into a very stiff clay layer with undrained shear

strength,

c

u

= 100kPa a d

E

= 50MPa, while the soil above top

helix (i.e. along the shaft) s s ft clay with

c

u

= 25kPa and

E

=

30MPa. The clay is modeled assuming the water level is at the

ground surface, and the loading rate is assumed fast enough to

invoke undrained conditions. Therefore, Poisson’s ratio = 0.49

was considered in the analysis. The adhesion,

c

a

, between the

pile and the soil is estimated from CFEM (2006): for

c

u

= 25 kPa,

c

a

= 25 kPa. A friction factor of 1.0 is used indicating that the

frictional stresses along the shaft are equal to the contact

pressure. However, to account for the adhesion strength, a

shear stress limit along the interface is defined at which

slippage occurs. This shear stress limit along the interface is

c

a

.

4

RESULTS AND DISCUSSION

For load-settlement curves with no visually distinctive failure

point, as for the case of piles in sand the failure loads a e

obtained at a practical settlement level equal t

5%D

(i. .

30mm). The pile settlement is obtained at a service load equal

to the failure load divided by a factor of safety,

FS

, equal to 3.

For a 4-pile group in sand,

R

s

could be as high as 1.3 at

S

p

=

2D

and as low as 1.1 at

S

p

=

5D

.

R

s

is the greatest at

S

p

=

2D

n

decreases gradually with increasing

S

p

as shown in Figure 5. It is

also found that

S

r

has a negligible effect on

R

s

. Moreover,

R

s

at

service load considering

FS

= 2 is larger than

R

s

for service loads

given by

FS

= 4, as shown in Figure 6. It is also found that

R

s

for

b)

Figure 4. Verified numerical models: a) Pile PA-3; b) Pile PB-4.

Using the same soil properties that are established from

th calibratio of model considering pile A-1 test data, the

calculated response of neighbouring pile PA-3 is softer than the

For piles in clay, it is assumed that the helices are

embedded into very stiff clay layer with undrained shear

strength,

c

u

= 100kP and

E

= 5 MPa, wh le the soil above top

helix (i.e. along the shaft) is soft clay with

c

u

= 25kPa and

E

=

30MPa. The clay is modeled assuming the water level is at the

ground surface, and the loading rate is assumed fast enough to

invoke undrained conditions. Therefore, Poisson’s ratio = 0.49

was considered in the analysis. The adhesion,

c

a

, between the

pile and the soil is estimated from CFEM (2006): for

c

u

= 25 kPa,

c

a

= 25 kPa. A fri tion factor of 1.0 is use indi ating that the

frictional stresses along the shaft are equal to the contact

pressure. However, to account for the adhesion strength, a

shear stress limit along the interface is defined at which

slipp ge occurs. This shear stress limit along the interf ce is

c

a

.

4

RESULTS AND DISCUSSION

For load-settlement curves with no visually di tinctive failure

point, as for the case of piles in sa d, the failure lo ds are

obtained at a practical settlement level equal to

5%D

(i.e.

30mm). The pile settlement is obtained at a service load equal

to the failure load divided by a fact r of safety,

FS

, equal to 3.

F r a 4-pile group in sand,

R

s

could b a high as 1.3 at

S

p

=

2D

and as low as 1.1 at

S

p

=

5D

.

R

s

is the greatest at

S

p

=

2D

and

decreases gradually with increasing

S

p

as shown in Figure 5. It is

also found that

S

r

has a negligible effect on

R

s

. Moreover,

R

s

at

service load considering

FS

= 2 is larger than

R

s

for service loads

given by

FS

= 4, as shown in Figure 6. It is also found that

R

s

for

a group of piles is not necessarily an algebraic summation of

the interaction factors,

α

ij

, of the piles in the group. The

b)

a)

b)