2728

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

have been carried out at End of Initial Drive (EOID) and, after

13 days, at Beggining of Resrtike (BOR) condition is selected to

study the different components contributing to the setup effects.

2 CONSTRUCTION SITE AND TESTS

Fajr II is a 32-hectar utility plant in PetZone of Mahshahr,

located in southwes Iran near Persian Gulf. The site

accommodates a power plant, pre-treatment and treatment water

units and air unit. Different types of precast and prestressed

driven concrete piles at a total of nearly 7000 points have been

constructed within the past three years. About 6000 points

include 450 mm outside diameter prestressed spun piles with a

wall thickness of 80 mm and closed-toe. The spun piles have

been driven with Kobe-35 and Kobe-45 diesel hammers, or

equivalents, down to embedment depths ranging between 14

through 22 m. The dominant soil layering across the

construction site is a very soft to stiff silty clay, average of 15 m

thick (layers I & II), overlain a medium dense to dense sand, 4

to 8 m thick (layer III). The pile tips are mostly embedded

within the sandy layer. Table 1 shows the geotechnical

parameters for construction site layers.

Nearly 5000 spun piles, 450 mm OD were driven to support

12 water tanks. Pile dynamic tests (PDA) and static load tests

were carried out on 30 test piles & 221 construction piles,

including, respectively, 54 & 251 PDA tests and 4 & 32

compressive static load tests. Static and PDA tests procedure

comply with general guidelines and specification of ASTM

D1143 and D4945, respectively. Some of the comparisons

between static and dynamic load tests are presented in

Fakharian et al. (2012). In fact about 5% of the construction

piles were PDA tested and average of 2 piles were static load

tested at each tank. With support of the test program, the factor

of safety was lowered to about 2 to 2.2 and sometimes as low as

1.8, that resulted in considerable savings compared to previous

projects in the region. The construction challenges and cost

savings are presented in more details by Fakharian et al. (2012).

Further information about tank details, test piles and

borehole location, pile arrangement and No. of construction pile

tests can be found in Sarrafzadeh et al. (2012).

The dominant soil layering in the 32-hectar site is highly

variable but classified in three layers, from top to bottom

respectively, layer 1 with 8 m thickness as soft clay, layer 2, 7

m thick as medium stiff to stiff clay, and layer 3, sand down to

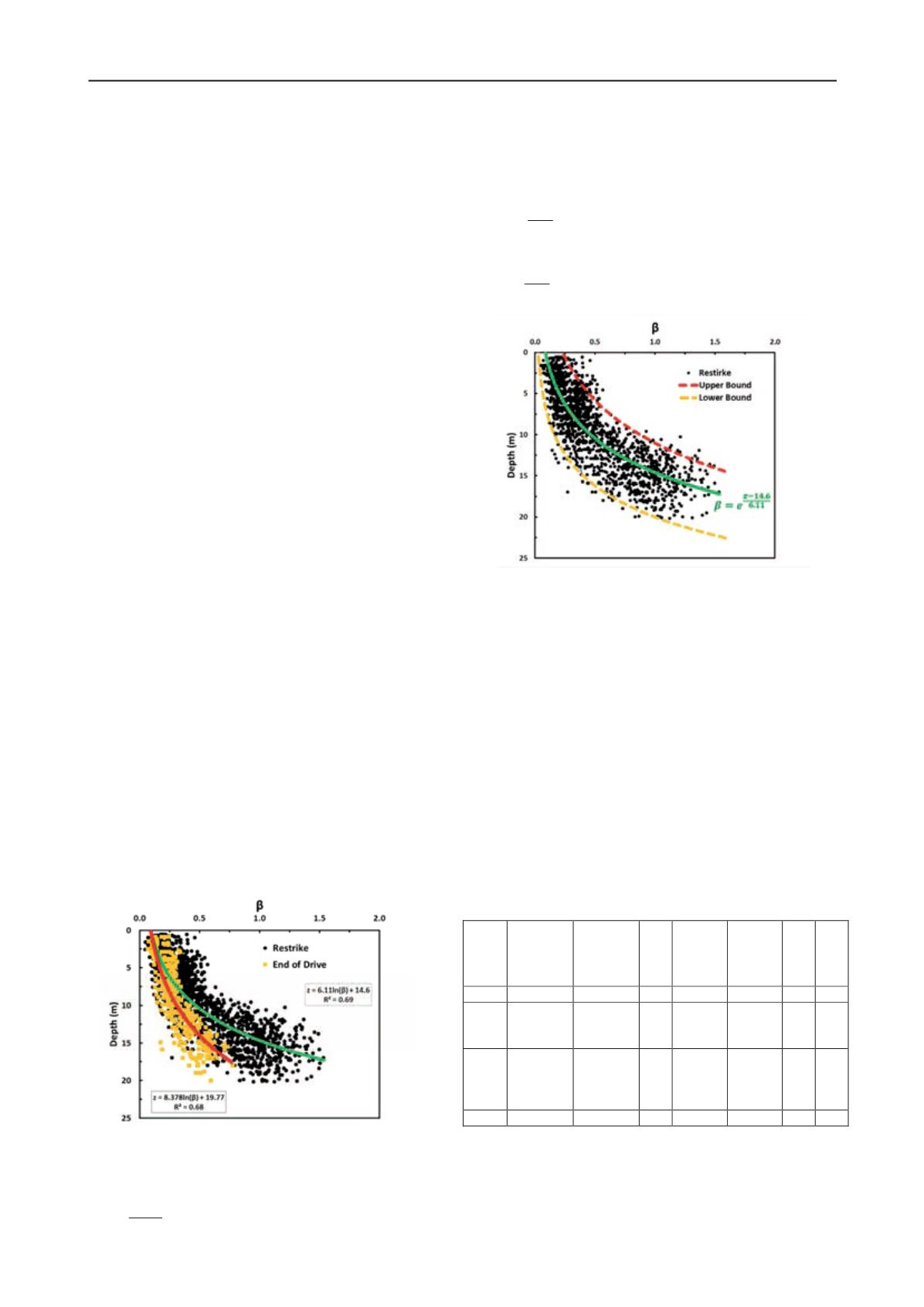

20 m. The incremental and cumulative shaft capacities from

CAPWAP analysis are available, from which,

β

-factor versus

depth is back-calculated. All the data points of five tanks were

put together and the results are presented in Fig. 1.

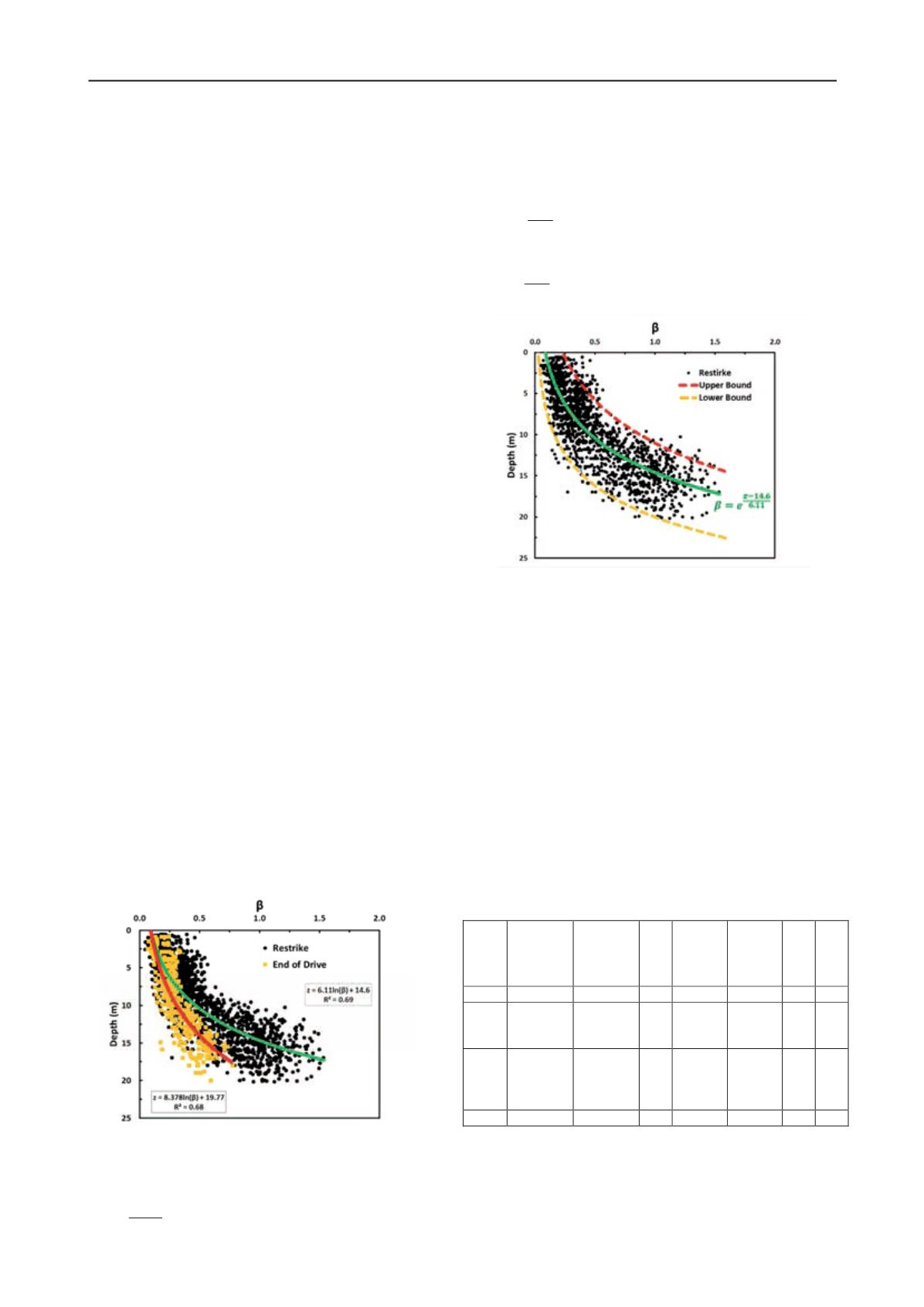

Figure 1.

β

variation with depth at EOD and Restrike for all tanks.

The lower and upper bounds of

β

-values and the average

trend lines are plotted in Fig.2. The average trend line can be

represented by empirical Eq. (1):

e

. .

in which, z (in m) is depth from ground surface.

Similarly, Eqs. (2) and (3) represent the upper bound,

β

, and

lower bound,

β

, respectively. The

β

parameter variation with

depth value is limited to 1.5 in all equations.

e

.

e

.

Figure 2. Mean

β

and lower and upper bounds at restrike.

3 NUMERICAL MODEL AND VALIDATION

Test pile No. 11 with 15.4 m embedment length is selected for

modeling, PDA test was performed at End of Initial Drive

(EOID) and, after 13 days, at Beggining of Resrtike (BOR)

condition. an elastic isotropic cylindrical pile with radius of

225.5 mm and 15.4 m length has been generated using the FEM

numerical package ABAQUS, in 2D axisymmetric condition.

Elasto-perfectly plastic model has been considered for the soil

material. Therefore, the required parameters for the elastic part

include elastic modulus, E, and Poisson’s ratio,

ν

, and Mohr-

coloumb strength parameters for the shear failure. The soil

surrounds the pile shaft with a radius of 5 m and length of 15.4

m. The brick soil elements have been generated 2.5x2.5cm

adjacent to the pile skin with gradual increase in size to reach a

maximum dimension of 2.5x12.5cm at the vertical boundary.

The pile shaft is simulated by 2.5x2.5cm solid elements. Table

1shows the specified parameters for both pile and soil material.

Table 1. Soil and pile parameters in numerical model (for TP 11)

The solid element CAX4RP has been used for which

simultaneous measurements of PWP and stress-strain are

possible. It is assumed that drainage is possible from the ground

surface only. Therefore, the top horizontal boundary was

specified as a zero pressure surface. Interface elements were

φ ̊

C (kPa)

K (m/s)

E (MPa)

γ‘

(kN/m

3

)

Depth

(m)

Soil type

Layer #

0

27

1×10

-9

20

10

0-7.4

Soft clay

I

0

27

1×10

-9

20-50

10

7.4-12.4

Medium

to stiff

clay

II

30

1

1×10

-8

50

10

12.4-15.4

Medium

dense to

dense

sand

III

-

-

-

20,000

14

15.4

Concrete

Pile

β 1.5

(1)

β 1.5

(2)

β 1.5

(3)