2748

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

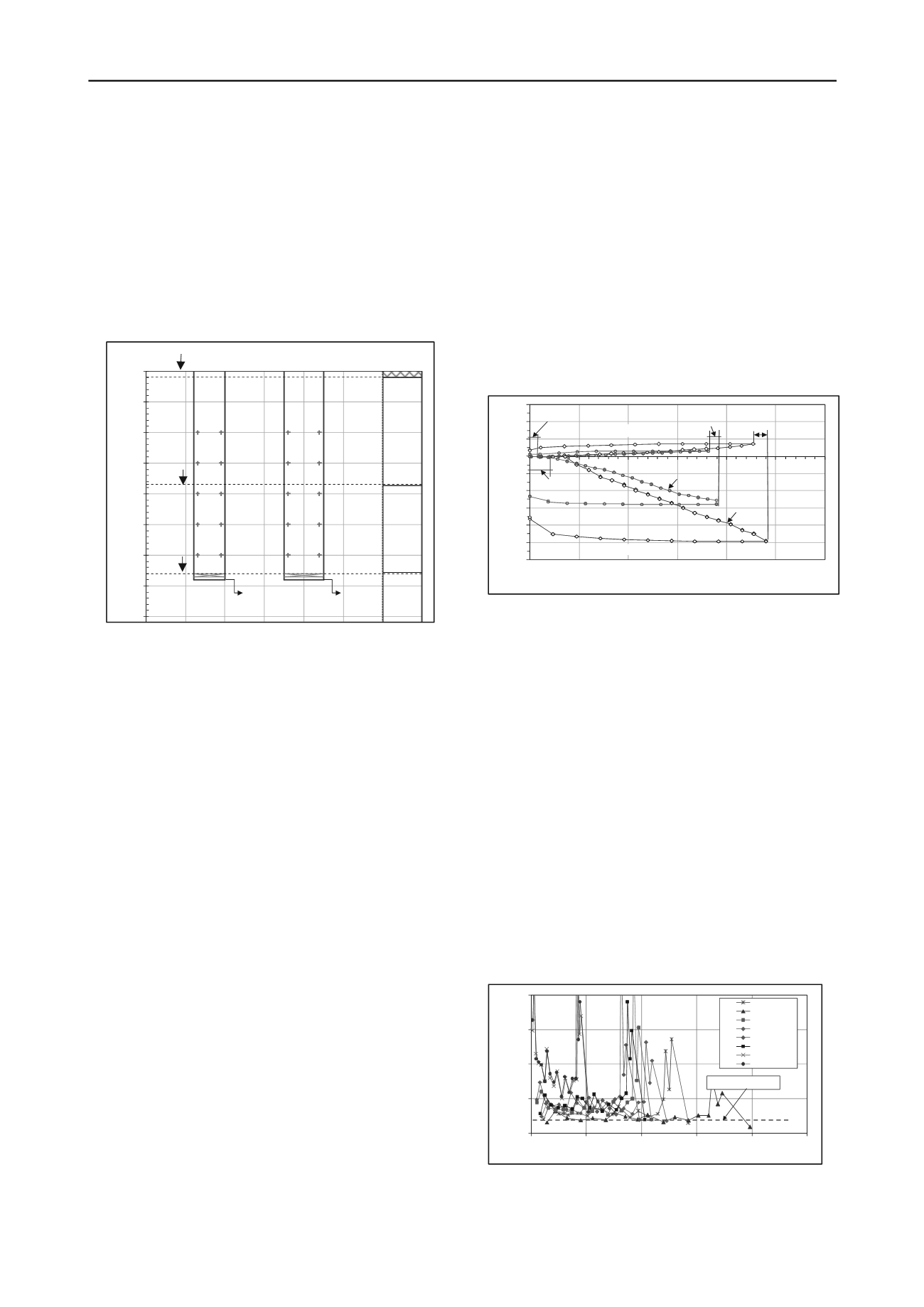

3 PILE CONSTRUCTION AND TEST PROGRAMME

The two test piles, Piles TP01 and TP02 of 800 and 1,000 mm

diameter, were constructed using bucket drill technique with

bentonite slurry on 24 and 26 August 2012, to 34 m depth,

respectively. The production piles were designed with the

reinforcing cages of sixteen 20 and 22 mm bars to 11 m depth

and eight 20 and 22 mm bars below this depth. The O-cells

attached at 0.5 and 0.8 m above the pile toes, as shown in

Figure 2. However, to avoid damage to the instrumentation

during the lowering the reinforcing cages into piles the

reinforcing cages of the test piles were supplied with sixteen

bars.

Figure 2. Details of instrumented test piles

The test piles were instrumented with a pair of diametrically

opposed vibrating wire strain-gages at four levels and two pairs

of diametrically opposed vibrating wire strain-gages at levels

SG1 and SG4, respectively.

The test piles were constructed by first inserting 820 mm and

1,020 mm outer diameter temporary casings, respectively,

to 7.6 m depth. Thereafter, the test piles were drilled to 34 m

depth using a bucket drill with bentonite slurry. Before

concreting each shaft, the shafts were cleaned and a reinforcing

cage with the O-Cell assembly was lowered into the shafts. The

O-cell assemblies consisted of three O-cells; 200 mm diameter

in Pile TP01 and 220 mm in TP02.

On completion of the drilling, on August 24 and 26, 2012,

a 219 mm diameter tremie pipe was inserted to the bottom of

each shaft and tremie placing of the concrete was commenced,

displacing the bentonite slurry.

The concrete cube strength was determined 28 days after

casting to 40 MPa and 44 MPa for the concrete used in Piles

TP01 and TP02, respectively.

The bottom 0.5 and 0.8 m length of Piles TP01 and TP02,

respectively, was equipped with a 114 mm diameter coring tube

attached to the reinforcing cage. The coring was performed after

the concrete had cured and showed that an about 20 mm thick

layer of debris and slurry existed below the toe of Pile TP01.

Pile TP02 could not be cored because the coring tube was

obstructed by steel reinforcement bars..

The static loading tests were performed on September 16 and

17, 2012, 23 and 22 days after concreting.

4 TEST RESULTS AND ANALYSIS

1.1

Load – movement measurements

The internal bond of the O-cells was broken at loads of at 190

and 480 KN load for Piles TP01 and TP02, respectively.

Theoretically, the O-Cell does not impose an additional upward

load until its expansion force exceeds the bond breaking load,

the buoyant weight of the pile above the O-Cell and the residual

load, if any, acting at the O-cell level. For both test piles TP01

and TP02, the initial upward movement records were taken at

570 and 960 KN; that is, these recorded loads included bond

breaking load, the buoyant weight and residual load. The pile

buoyant weights above the O-Cell for Piles TP01 and TP02

were 163 KN and 255 KN, respectively. Therefore, the residual

loads determined at O-cell locations of Piles TP01 and TP02 are

217 and 225 KN, respectively.

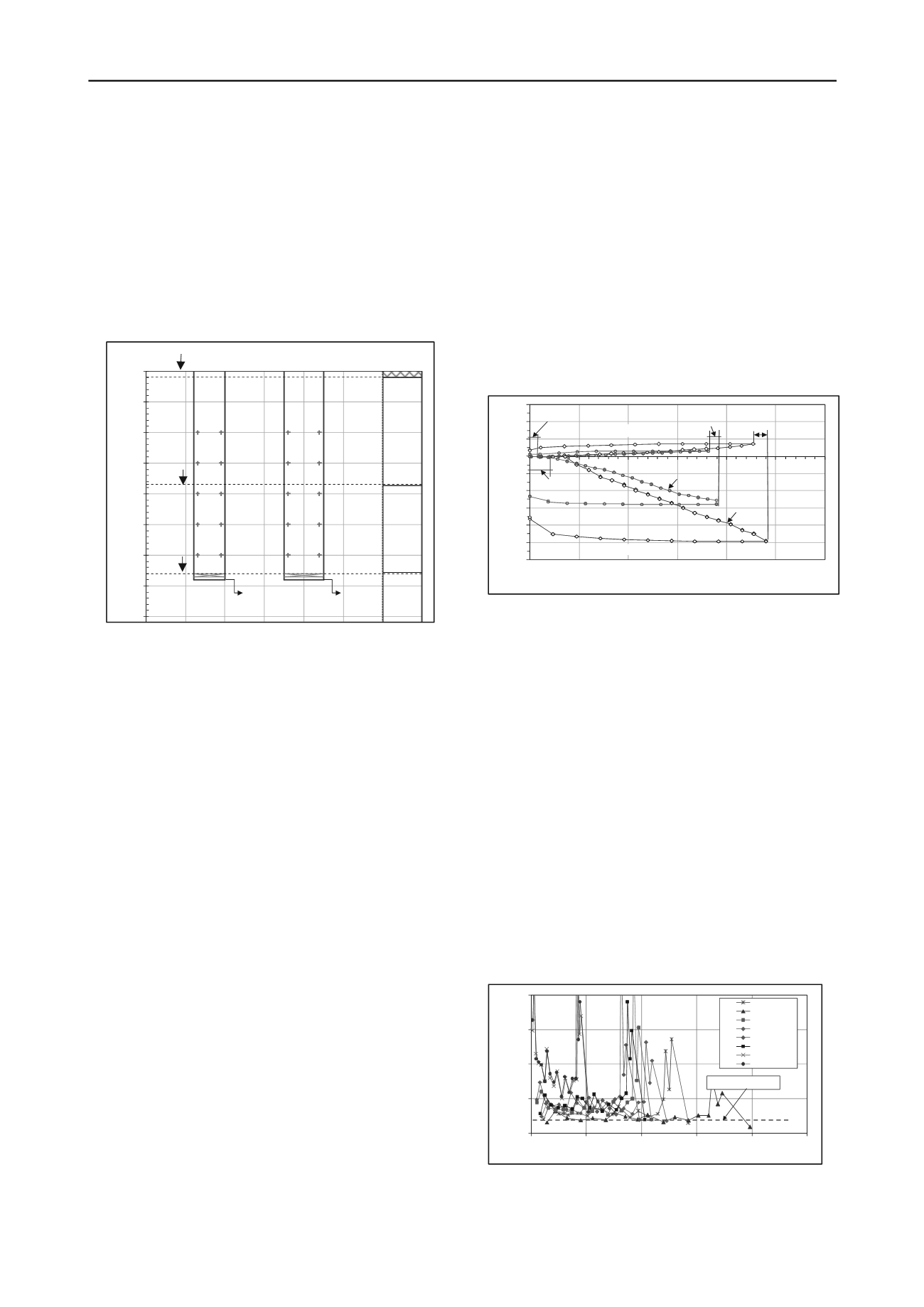

Figure 3 shows the load-movement records of the two O-cell

tests. After subtracting the buoyant weight of the piles TP01 and

TP02 above the O-Cell, the maximum upward resistances were

3,636 and 4,544 KN, respectively. The maximum O-cell upward

movements were 3.3 mm and 7.4 mm, the maximum O-cell

downward movements were 28.0 and 49.3 mm, and the

maximum pile head movements (upward) were 0.2 and 2.5 mm,

respectively.

0

5

10

15

20

25

30

35

40

O-Cell

Pile TP01

D800

18.5 m

33 m

0.0 m

DEPTH (m)

Ground Surface

15 m

20 m

25 m

30 m

10 m

33.2 m

SILTY

SAND

FIRM

CLAY

SAND

STONE

SG1

SG2

SG3

SG4

SG5

SG1

SG2

SG3

SG4

SG5

Pile TP02

D1000

15 m

20 m

25 m

30 m

10 m

33.5 m

O-Cell

34 m

34 m

-60

-50

-40

-30

-20

-10

0

10

20

30

0

1000 2000 3000 4000 5000 6000

MOVEMENT (mm)

LOAD (KN)

Buoyant Weight

255 KN

UPWARD

DOWNWARD

Buoyant Weight

163 KN

TP02

TP01

Breaking Bond

TP01-190 KN

Breaking Bond

TP02-480 KN

Figure 3. Load-movement curves of the piles

1.2

Strain measurements and determining Axial Modulus

To determine the secant modulus of the pile material, the best

way is to use "tangent modulus" or "incremental stiffness" plot

which is the applied increment of load over the induced

increment of strain plotted versus the measured strain. The

tangent modulus is then converted to the secant modulus

(Fellenius 1989; 2011). The incremental stiffness plots for the

two tests are shown in Figures 4 and 5. The incremental

stiffness method assumes that for load increments applied after

the shaft resistance at the studied gage level has been fully

mobilized, the continued incremental stiffness values will plot

along a slightly sloping line, representing the tangent modulus

relation for the pile cross section. Because of the combined

effect of the strain-softening and the scatter of values, the

incremental stiffness method did not provide sufficiently precise

values for the tangent and secant stiffnesses. Therefore, for this

case, the authors have preferred to rely on the linear portions of

load-strain relations and convert the measured strains using

constant stiffnesses, AE, of 12.5 GN and 17.0 GN for Piles

TP01 and TP02, respectively. Correlated to the nominal cross

sectional areas, the values indicate that the E-modulus of Piles

TP01 and TP02 is about 25 and 22 GPa, respectively.

0

20

40

60

80

0

100

200

300

400

500

SG - 1A

SG - 1B

SG - 1C

SG - 1D

SG - 2A

SG - 2B

SG - 3A

SG - 3B

INCREMENTAL STIFFNESS AE

(GN)

STRAIN (μS)

AE = 12.5 (GN)

Figure 5. Increment stiffness plot of records from Levels 1 to 3,

Pile TP01