2820

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

During the installation the element is filled with expanding

geopolymer. The geopolymer fills the geotextile tube and the

diameter of polymer pillar increases. After the installation the

diameter of the polymer pillar is approx. 330 millimeters. The

final diameter depends on the counter pressure of the soil and

the amount of geopolymer injected.

1.3

Installation

The polymer pillars are installed directly under the old

foundation. First there will be a hole drilled through the

foundation. The diameter needed for the hole is only 65

millimeters.

After the hole has been drilled, the casing is installed

through the hole to the ground. The casing is only temporary aid

and it will be removed after the installation of pillar element.

The casing can be made either from plastic or steel, depending

on the soil conditions. The steel casing is normally used on very

soft clayey soils.

The injection of pillar is made through the injection tube

inside the element. The injection tube is pulled up

simultaneously with the injection. Therefore the element is

filled continuously from bottom to top. The amount of injected

geopolymer per linear meter can be adjusted by chancing the

pulling speed of injection tube.

The injection is continued until it reaches the bottom of the

old foundation. The level of the old structure is monitored

during the injection. Usually injection will be stopped when

there is approx. 1 to 2 millimeters of raise in the structure.

1.4

Materials used

The polymer pillar is a composition of geotextile and

geopolymer. The geotextile at the outside surface of the pillar

keeps the geopolymer in specified space. This ensures certain

diameter for polymer pillar. With specific diameter and specific

amount of geopolymer injected per linear meter, the structural

capacity of polymer pillar is designable.

The geotextile has very high tensile strength. It is designed

particularly to be used in polymer pillars. The geotextile also

allows small amount of geopolymer to pass through. This

feature actually helps gaining good grip with surrounding soil.

The geopolymer consists of several components. There are

also several different geopolymers to be used. Choose of the

geopolymer depends on the properties of the surrounding soil.

The materials are environmentally safe. There have been a

lot of tests for the materials. These tests show that the ground

water has no effect on the materials. On the other hand the

materials have no effect on the ground water (Sauerwald 1994,

Kwarteng and Füchtjohann 2011). The materials have also good

or excellent resistance against several chemicals i.e. gasoline,

mineral oil, sodium hydroxide and ammonium hydroxide (van

der Wal 2010).

2 STRUCTURAL BEHAVIOR

The structural behavior of polymer pillars has been tested with

three samples. The samples were cut from polymer pillars that

were dig from ground. The original polymer pillars were used to

test the geotechnical capacity of polymer pillars in Turku as

described in chapter 3.

The measures of the samples are shown in Table 1. The

length of samples varies, because it was not possible to get

original pillars from ground as whole. The grip between ground

and pillars were so strong that the pillars got broken into two or

more pieces.

Table 1. Measures of the samples.

2

4

5

Lenght

L

(mm)

850

589

499

Diameter

D

1

(mm)

321

358

357

Diameter

D

2

(mm)

320

263

264

Cross Section

A

(mm

2

)

80676

73948

74022

Sample 2 is from original pillar T7 and samples 4 and 5 are

from original pillar T3.

The samples were slightly ellipse. Therefore the smallest and

biggest diameter was measured and the cross section was

calculated with equation 1.

(1)

2.1

Stress-strain behavior

The elastic behavior of polymer pillars was tested in laboratory

of Turku University of Applied Sciences. The maximum

compression capacity of test facility was 450 kN. With that

compression force the samples did not break.

At the test the compression force was increased at the rate of

5 kN/minute. The test arrangement is shown in picture 2.

Picture 2. Test arrangement for Stress-strain behavior.

4

5

2

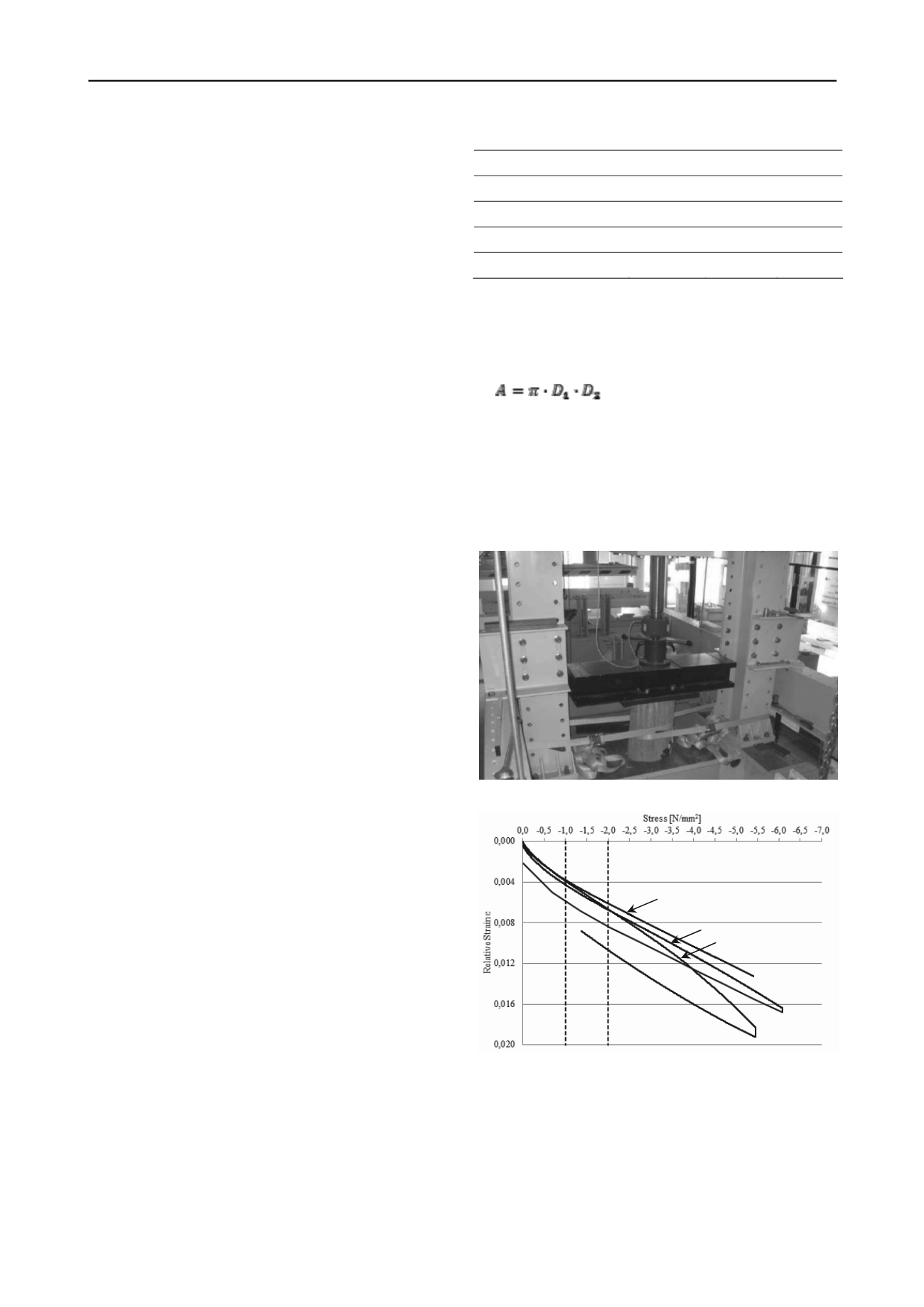

Figure 1. Stress-strain behavior of the samples.

As shown in Figure 1, the elastic modulus of the material is

not constant. It varies little depending on the stress level. The

elastic modulus was determined at the stress range from 1.0

N/mm² to 2.0 N/mm². This stress range represents the average

stress level of the polymer pillars in serviceability state.

The curve of sample 4 ends sooner than other curves. That is

because of a malfunction in a computer operating the hydraulic

jack. It suddenly just stopped the test and lifted the jack up.

Therefore there is no data from release.