2828

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

methodologies have been carried out. A general description is

indicated in Table 1.

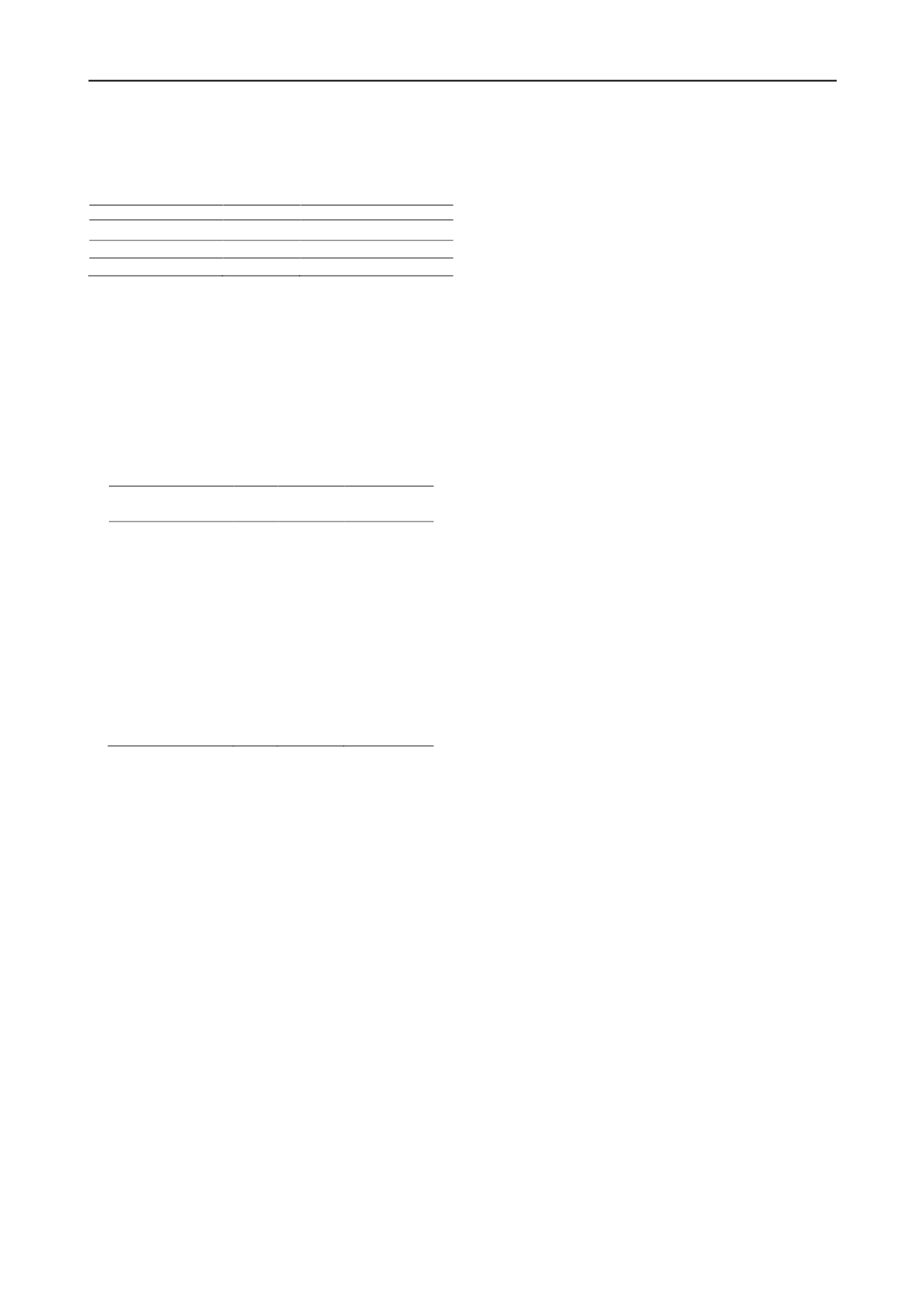

Table 1. Piling Trials.

Trial

Dates

Piles

TOPIC

2001

CFA, Bored, Displacement

RuFUS

2001-2006 CFA, Bored

RaPPER

2007-2009 CFA, Driven

3.2

Pile Installation

A number of different pile types (commercial and

developmental) were installed at the site over 10 years. This

paper focuses only on those types in current use, tested at an age

of up to 5 months, but mostly 2.5-3.5 months, by static

incremental maintained load testing (ML). Other papers

describe piles tested for other purposes (Skinner et al 2003,

Fernie et al 2006, Powell and Brown 2006, Powell and Skinner

2006, Butcher et al 2008, Brown and Powell 2012) Tables 1 and

2 show the piles used in this study.

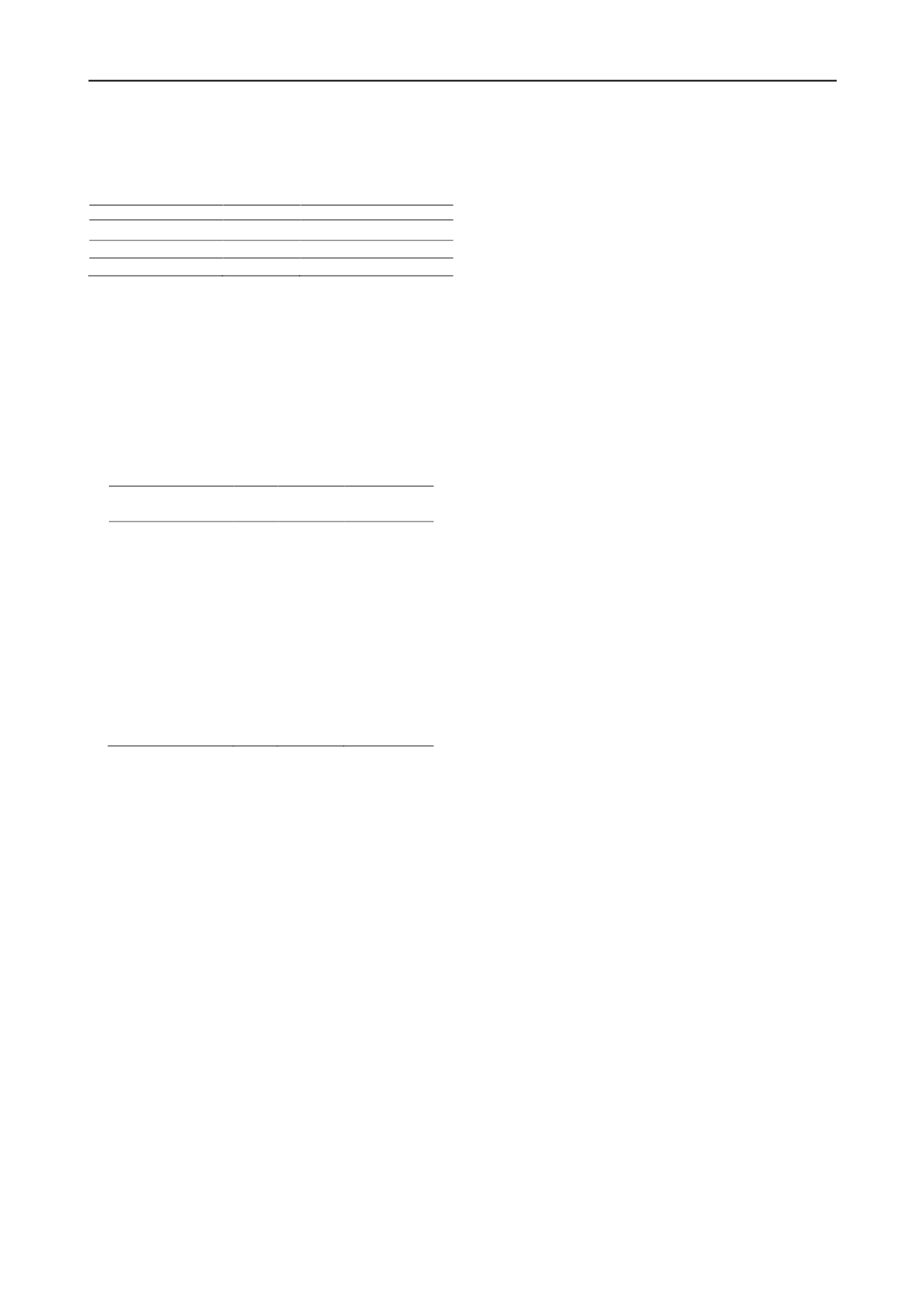

Table 2. The test piles.

Pile

Date Dia.

(mm)

Effective

Length (m)

CFA (T33)

2001 300

10

CFA (T34)

2001 300

10

CFA (T14)

2001 300

10

CFA (T13)

2001 400

7

CFA (T15)

2001 400

7

CFA (MC1)

2007 450

9.5

*

CFA (MC2)

2007 450

9.5

*

Bored (T16)

2001 300

10

Bored (T40)

2001 300

7

Bored (T46)

2001 300

5.8

**

Bored (T47)

2001 300

5.8

**

Screw Dispt (T30)

2001 300/600 7

Displacement (T35)

2001 300

9

Displacement (T36)

2001 300

7

Driven (TP1)

2007 275

10

Driven (TP2)

2007 275

10

* 1.5-11 m, ** 5.2-10.m

3.3

Pile testing

The Topic and RuFUS pile tests were undertaken using a

combination of BRE load frames and a remotely operated

hydraulic loading and control system The loading system

utilised closed loop control of the hydraulic jack, monitoring

displacement transducers and a load cell. Load was applied in

incremental steps; increments of 25kN were each held for a

minimum 1 hour and until the settlement rate reduced to

0.1mm/ hr. Using this procedure it was hoped that the load at

which rupture of the skin friction occurred would be approached

relatively slowly. Tests were terminated once failure was clearly

defined, generally indicted by runaway displacement.

For the RaPPER programme the test equipment was similar

to that described above but operated on site. The test method

used complied with the ICE Specification for Piling and

Embedded Retaining Walls 2nd ed. (ICE 2007); the procedure

was similar to that above but using 125kN increments

throughout firstly up to 500kN, then an unload/reload loop

before continuing until failure was established. The increments

during loading were maintained for a minimum 30mins and

until the rate of settlement reduced to 0.1mm/hr. This criteria

works well until failure is approached.

In the RaPPER project testing was also conducted by

constant rate of penetration, dynamic and rapid load or

statnamic means and is described elsewhere (e.g. Butcher et al,

2008, Brown and Powell 2012).

3.4

Test Results

3.4.1

Definition of shaft failure capacity

The majority of the CFA and bored piles, at 300 to 450mm were

anticipated to be essentially friction piles. These piles had

relatively high length to diameter ratios; additionally no attempt

was made to clean the bases of the bored piles. As failure was

achieved at relatively small displacements, typically less than

5/6mm this would appear to be a reasonable assumption. In

these cases, capacity was taken to be the maximum ‘stable’ load

achieved. Given the tendency in brittle London clay for the pile

to ‘shed’ load down its length as failure is initiated in the upper

part

s then a ‘stable’ load was tak

en to be either the last

increment applied if this was maintained for some time before

significant displacements occurred or the next to last increment

if the pile failed rapidly soon after application. The

interpretation of the failure load increment was more difficult

for larger increments. The screw displacement piles, at 600mm

external diameter, and the driven piles were expected to

demonstrate rather more base capacity. For the driven piles

capacity was taken to be again the maxi

mum ‘stable’ load but

with an allowance for base capacity based on eqn (2). For the

larger ‘displacement’ piles failure was taken as the load at

which significant creep started to occur under load and this was

also checked based on Chin and Fleming constructions.

Based on the failure criteria discussed above, the ultimate

capacity of each pile is shown in Table 3.

4 PILE DESIGN

4.1

Design by calculation

In the UK, it is common to use a total stress method for the

calculation of pile capacity in clay soils. For the purposes of the

present paper the model for pile capacity has been taken

considering undrained behaviour and to be the sum of shaft

(Q

su

) and base (Q

bu

) where:

Q

su

= Σ(q

su

ΔL A

s

)

(1)

Where; q

su

is ultimate unit shaft friction; ΔL the appropriate

section of pile length; A

s

is surface area per unit length of pile

Here :

q

su

= α c

u

where:

α is an empirical factor; c

u

is the average shear strength

over the length ΔL

and base capacity as: Q

bu

= A

b

N

c

c

u base

(2)

where: A

b

is the area of the base of the pile, N

c

is the undrained

bearing capacity factor generally taken as 9, c

u

base is the

undrained shear strength at the base of the pile.

This is used to calculate the pile capacity under BSEN1997-

1 (7.6.2.3), to which model and partial factors are applied to

identify the design pile resistance. Estimates of pile capacity for

the different types of piles have been made for all of the piles

using the α–

c

u

method.

4.1.1

Results

–

alpha values and soil parameters

There is an intimate link between selection of a value of alpha

(α)

and soil strength. One has to ensure that when

α

values are

selected from the literature then the same method of shear

strength derivation has to be used (sampling methods, sample

sizes and testing). Typically a design line for shear strength has

been a

‘mean’ value

and that is what has been adopted here.

All

values for α

(Table 3) were those based on shear strength

profiles from CPTs to the piles correlated to UU triaxial.

Although the main test area described was very uniform, the

area where the RaPPER piles were located was a little distance

away and seems to have undergone desiccation in the upper

layers although the CPTs come together below 5m.