2822

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The arrangement of the load test is shown in picture 4. The

basic idea of the arrangement was similar to the load test in

Turku. The loading was again achieved with hydraulic jack

against steel beam and counterweights. Applied load was

measured with load sensor and the movement was measured as

relative to normal ground surface.

4 MONITORING OF SETTLEMENT

There have been monitoring of settlements in some test projects

in Finland. Unfortunately there is not any settlement history

before the installation of polymer pillars, because these houses

are privately owned. Also the monitoring period after the

projects is still quite short. The longest monitoring period is

only less than two years.

The relative settlement of the houses show the settlement

slows significantly with cohesion polymer pillars. In these test

projects the polymer pillars have usually been installed under

only part of the building.

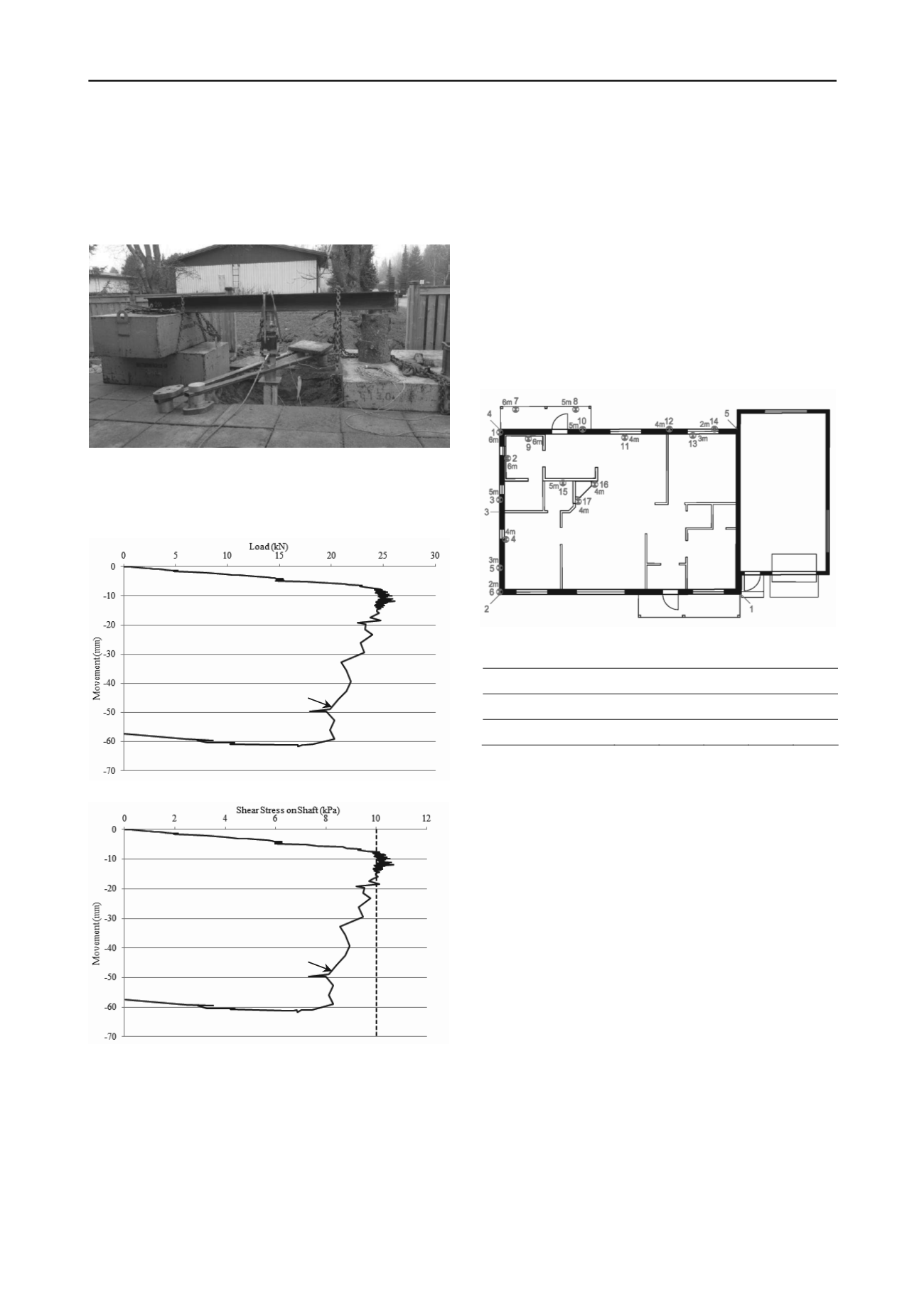

Pillars and settlement monitoring points of one test project

are shown in picture 5. The relative settlement of the monitoring

points is presented in Table 5. The first monitoring was made

before the installation and the second after the installation.

Picture 4. Arrangement of the load test in Salo 2012.

The load-movement curve was drawn from the results as

shown in Figure 4. As a comparison to the test pillars in Turku,

the shear stress-movement curve was also drawn. The shear

stress-movement curve is shown on Figure 5.

S1

Picture 5. Pillars and settlement monitoring points of a test project.

Table 5. Relative settlement of the test project in millimeters.

1

2

3

4

5

25.05.2010

± 0

- 20

-

- 105

- 32

23.01.2012

± 0

- 6

- 46

- 98

- 28

5 CONCLUSION

Figure 4. Load-movement curve of the load test in Salo 2012.

The polymer pillar is a relatively new product. There have been

some load tests and material tests as presented in this paper.

Nevertheless there are still a lot of tests to be done to determine

the bearing capacity and the suitability of the polymer pillar in

different types of soil conditions. Beside these tests, there are

projects done all the time and there is a lot of data to be

collected from these projects.

S1

6 ACKNOWLEDGEMENTS

The load tests presented were sponsored by TEKES – the

Finnish Funding Agency for Technology and Innovation.

7 REFERENCES

Figure 5. Shear stress-movement curve of the load test in Salo 2012.

The measured C

u

value of the clay is shown with dashed line.

Lehtonen J. 2011. Underpinning project; owners’ views on technology,

economy and project management. Helsinki.

The load steps in Salo were estimated a bit too high.

Therefore there were only 3 steps before the failure of the pillar.

Sauerwald M. 1994. Hygiene-Institut of the Ruhr Area. Evaluation of

effect on water quality. Gelsenkirchen.

The ratio between shear stress and undrained shear stress of

the clay was not as big in Salo as it was in Turku. Reason for

this is probably the size of the load steps.

Kwarteng W. and Füchtjohann L. 2011. HuK Umweltlabor GmbH.

Umweltunbedenklichkeitsuntersuchungen. Wenden-Hünsborn.

van der Wal A. 2010. Chemical resistance of Uretek Resins. Foxhol.