2817

Technical Committee 212 /

Comité technique 212

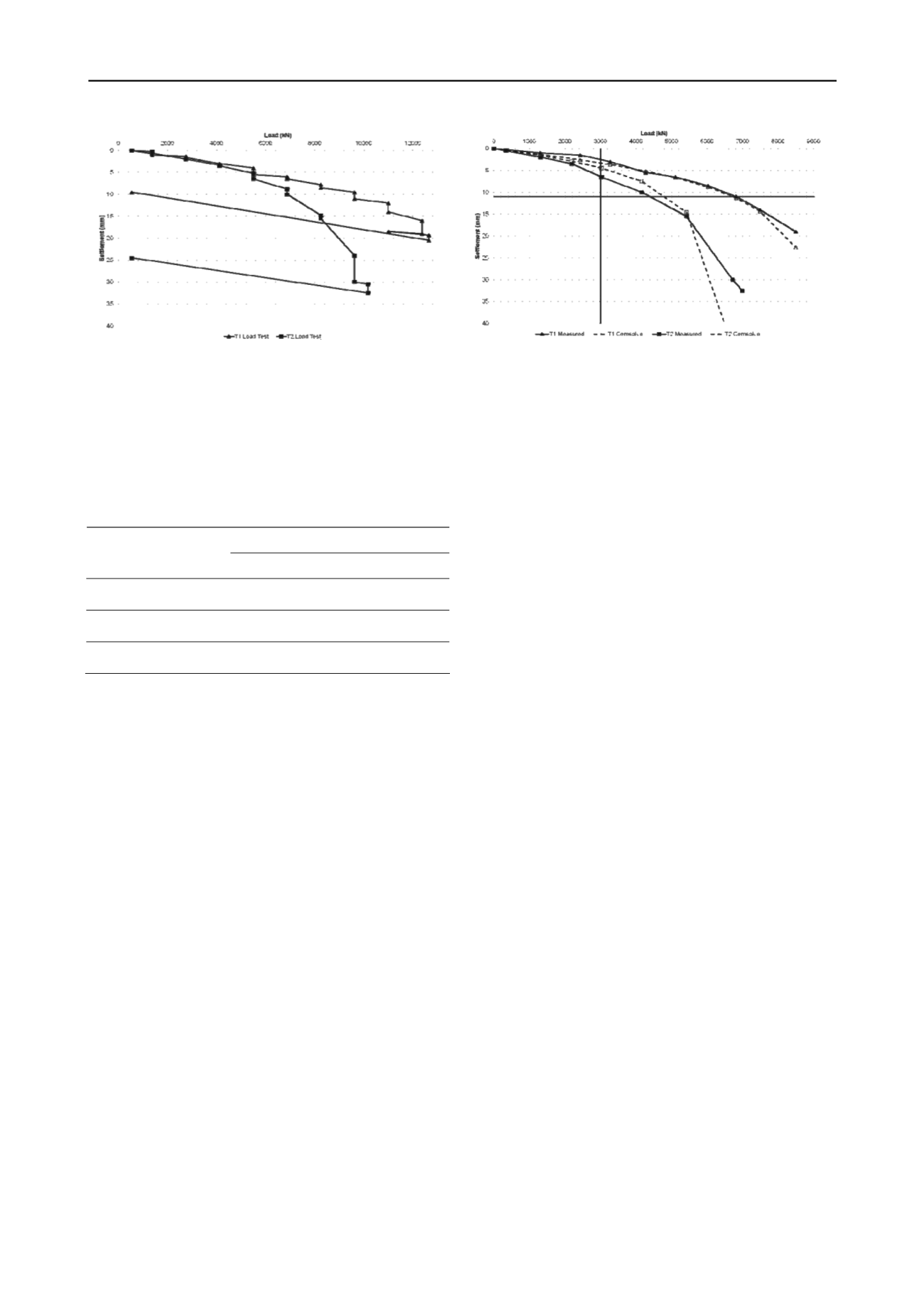

Figure 3. Load-displacement behaviour of piles: measured during

testing.

Strain gauges installed along the length of the piles were

used by Bauer to calculate the skin friction mobilised within

each stratum; this information is summarised in Table 2

alongside the ultimate values originally calculated for tender

design using the site investigation data (see Table 1).

Table 2. Calculated and measured skin friction.

Ultimate Skin Friction (kN/m

2

)

Strata

Calculated

T1

T2

Fine Sand

59

110

50

Loam A: Silty Sand

80

110

45

Loam B: Clayey Silt

50

110

90

4.3

Interpretation of Pile Testing

Several simple calculations were made of the ultimate shaft

capacity using the values of skin friction from the strain gauge

data. From these it was apparent that skin friction had not been

completely excluded over the top 10m of each pile. The first

stage of the interpretation was therefore to remove the

contribution of the top 10m from the results so that they were

comparable to the design values. The load cell installed by

Bauer in the toe of the pile confirmed that very little base

resistance was generated (1.2MN assumed in Cemsolve

analysis).

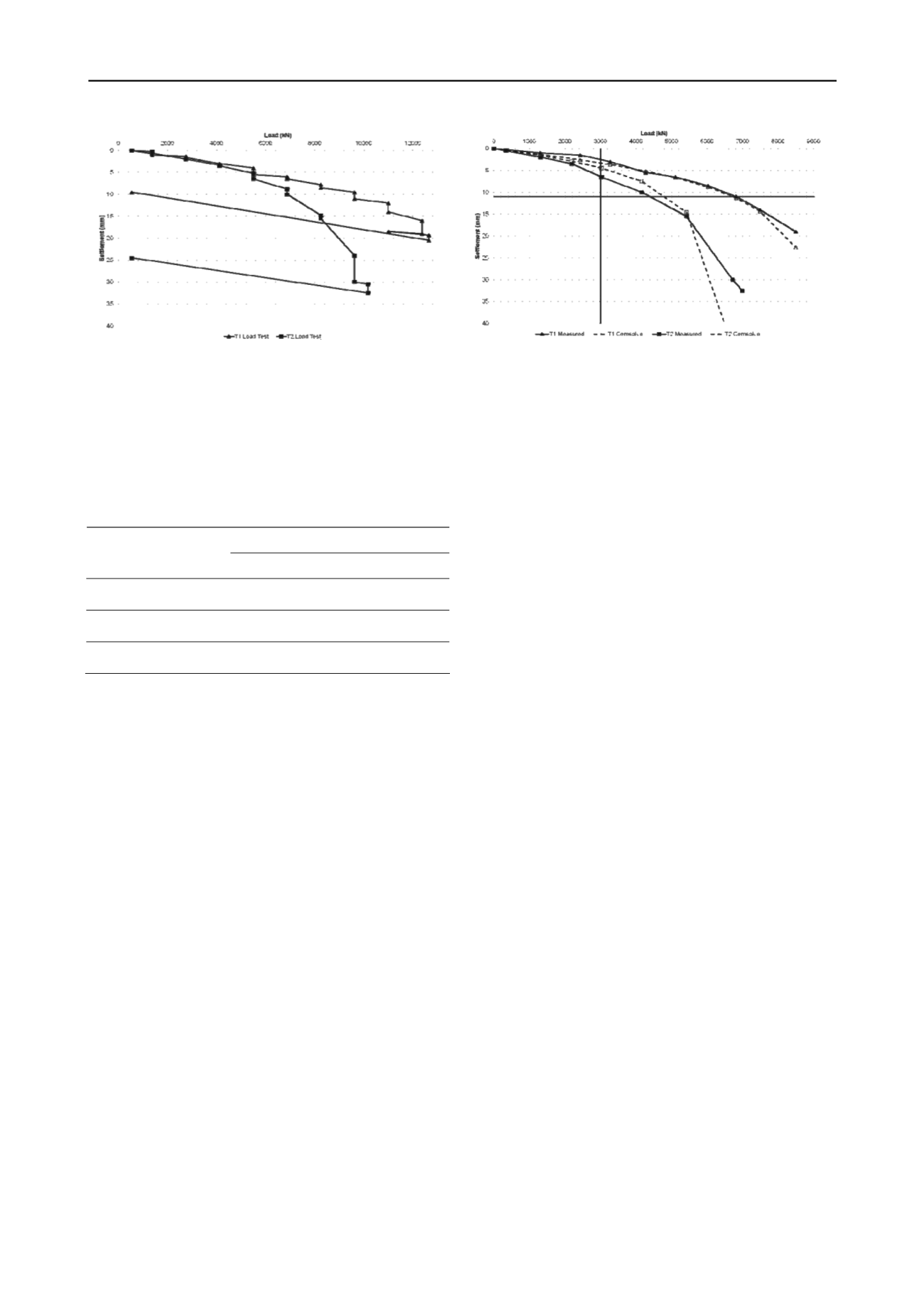

Figure 4 presents the load-displacement behaviour of the two

piles. The values of load applied have been modified at each

stage to remove the contribution of the top 10m of pile. The

measured curve for T1 on Figure 4 has been stopped at the load

stage just prior to the load being reduced and then replaced

(refer also to Figure 3).

The Fugro Loadtest Ltd program Cemsolve was used to

compare the modified test data to Fleming’s load-displacement

relationship, which is commonly used to predict pile behaviour

under loading (Fleming, 1992). Figure 4 also shows the

Cemsolve model of the pile behaviour (back analysed using the

modified data from the load tests). The Cemsolve curve fit

suggests that the ultimate capacity of T1 was 10.0MN (of which

9.5MN was shaft capacity) and of T2 was 7.25MN (of which

6.5MN was shaft capacity); these values were assumed as an

estimate of the failure load i.e. Cemsolve prediction of when

settlement continues to increase with no further load applied.

These values are higher than the loads at which the two pile

tests were terminated, which is considered to be due to practical

difficulties in measuring the response to loading when close to

failure.

Figure 4. Load-displacement behaviour of piles: measured and

Cemsolve predictions (with contribution from top 10m of piles shaft

removed).

5 DISCUSSION

5.1

Comparison of Testing Results with Design Values

The ultimate shaft friction for the untreated pile T2 obtained

from curve fitting (6.5MN) is considered to be in reasonable

agreement with the calculated tender design value 5.47MN.

When considering this in greater detail by comparing the

measured and calculated skin friction values (Table 2) it can be

observed that the Loam A did not provide as much skin friction

as considered within the design and the Loam B provided more.

From this it is proposed that the silt content of the Loam A

reduced its frictional behaviour more than the original design

considered. It is also apparent that the estimate for the

behaviour of the Loam B was too conservative. It is possible

that the high silt and water content of the material resulted in

misleading in-situ testing results.

It is considered that the base resistance was not fully

mobilised for either pile as the test was stopped before the piles

could move a sufficient amount.

5.2

Improvement due to Shaft Grouting

The shaft grouted pile T1 is considered to have performed

considerably better than the untreated pile. Figure 4 shows that

at a working load of 3.0MN, the shaft grouted pile settled

approximately 50% less than the untreated pile. A line has been

plotted on Figure 4 at a settlement of 1% of pile diameter

(11mm) to further illustrate the difference in pile performance.

The untreated pile settled by 11mm at a load of 4.4MN and the

shaft grouted pile settled by 11mm at a load of 6.8MN.

As previously stated it is considered that the ultimate shaft

capacity (calculated from curve fitting) was increased by

approximately 46% from 6.5MN to 9.5MN.

By looking at the strain gauge data in Table 2 it is possible to

infer the relative improvement the shaft grouting made to each

stratum. The data suggests that the skin friction of the Fine

Sand, Loam A and Loam B were respectively improved by

120%, 144% and 22% (i.e. by a factor of 2.2, 2.4 and 1.2).

The Fine Sand and the Loam A were of a relatively similar

grading and so it is perhaps unsurprising that a similar

improvement was achieved in these two strata. Improvement in

the Loam A was not expected due to its higher silt content;

however, the silt content did not impede the improvement and it

is therefore inferred that an enhancement in skin friction is

possible within a material assuming it has a minimum content

of granular material.

The improvement within the Loam B, although

comparatively small, confirms the suggestion that it had