2809

Technical Committee 212 /

Comité technique 212

control in real time and assure to the execution piling process

conditions for the piles to achieve individually the planed

bearing capacity, assuring quality and the design assumptions. It

is very clear that the final behavior of the pile will also depend,

among other issues, for example, the concrete injection pressure

which depending on the type of soil and its value will have a

great influence on the pile behavior, such fact observed by Silva

(2011).

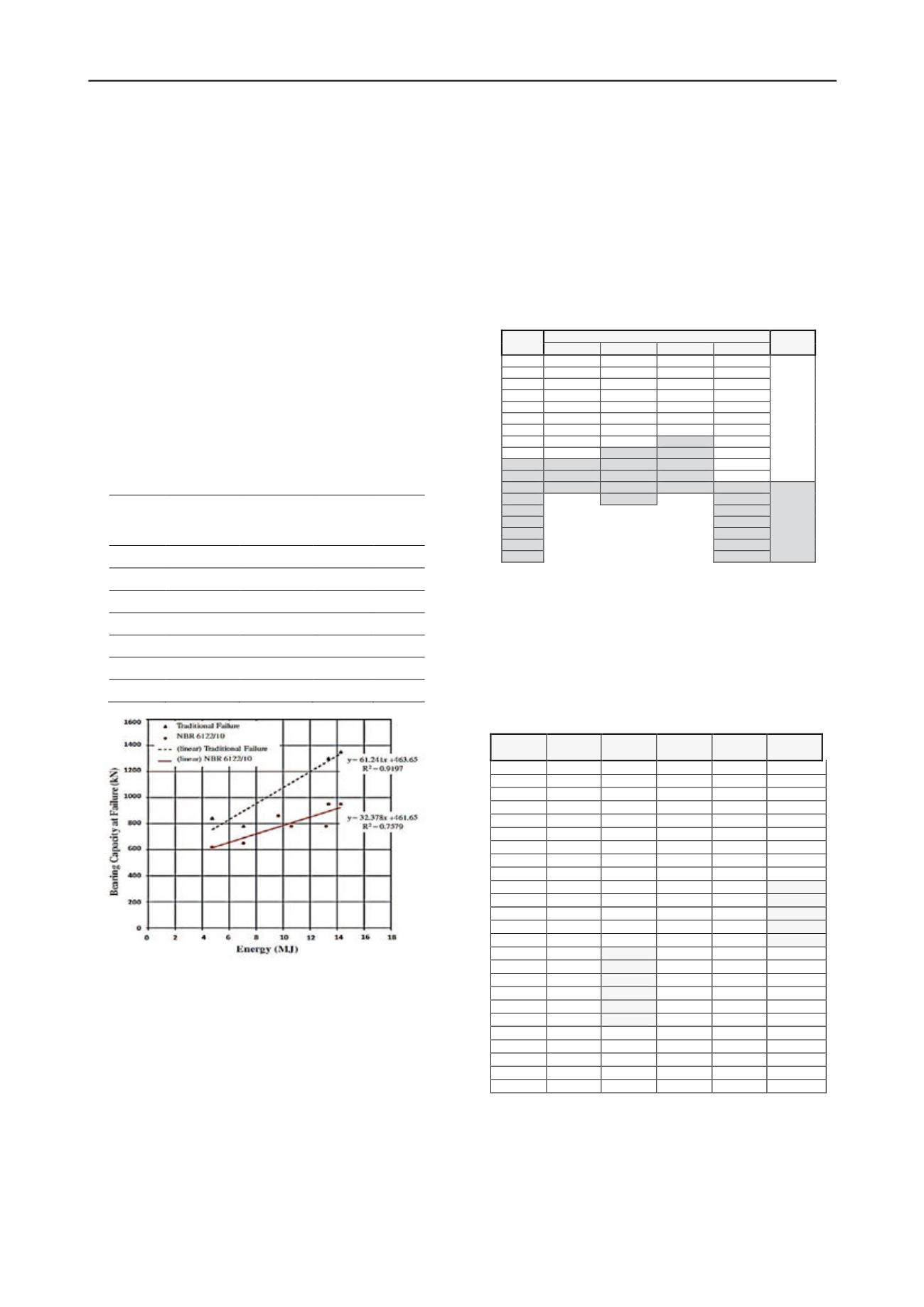

Figure 2 presents the results obtained during the execution

of seven load tests, construction on the Paranoá Lake shore in

Brasília – Brazil and the total required energy to execute each

pile. It can be seen in Figure 2 that the measured energy in each

pile is proportional to its bearing capacity. In Table 1, the most

important geometric and monitored data of the tested piles are

shown. Moreover it’s also observed in Picture 2 that the

ultimate load is rampant with the required energy increase

during the excavation, independently of the failure criteria

adopted, the one from Brazilian norm criterion ( NBR 6122,

ABNT) or the conventional one which corresponds to 10% of

the pile diameter. In this case, all piles were excavated by a

same set machine/operator.

Table 1. geometric features of the piles (modified from silva, 2011).

Pile

Length (m)

Medium

pressure of

concrete

(kPa)

Diameter

(cm)

Total

Energy

(MJ)

E110BA

17,12

100

42

9,64

EPC1BB

15,12

100

42

10,60

TC2BB

12,80

0-75

53

13,18

E55AA

14,24

25-100

37

7,06

EPC1C

10,80

50

42

4,73

GE 24C

20,92

0-50

52

13,36

EE6B

20,08

100

54

14,27

Figure 2. Ultimate bearing capacity versus work done (Silva, 2011).

By the confirmation that the bearing capacity of the pile is

directly proportional to the work done and that the collected

results in the piling (energy) when organized in frequency

distribution conducted to a normal distribution, Silva (2011)

proposed an acceptance for the piles based on Physics concepts

(energy conservation) and on statistics characteristics of

collected energy sample during the execution of the piling.

Preferably they suggested that the population sample would be

collected close to the load test once statistics properties of the

sample could be associated to the real bearing capacity of a pile

in the execution condition adopted in the construction.

According to the authors, if the referred association is not

possible, it is important that the sampling is done in a region

with known geotechnical characteristics, for example, giving

attention to regions where the field tests were executed and have

little variability. Once the region to be sampled was chosen and

its size, the results are put together by class fitting them to a

normalized distribution. By that way, the mean (µ) and the

standard deviation (

σ

), were calculated what made possible to

establish reliability and acceptance criteria to applied in boring.

From the beginning they proposed criteria tht should be chosen

by geotechnical variability basis and the existing quality control

in the construction, for example, it will be accepted the pile

which when achieving the minimum design depth did during

excavation a required and measured work (w) greater than the

mean (µ) of the work measured from the sample (W

≥

µ).

Tabela 2. Caracterização Geotécnica – Ensaio SPT

Deep

(m)

SPT by Layer

Type of

Soil

SPT 01

SPT 02

SPT 03

SPT 04

1

7

6

6

6

Clay

2

4

4

5

5

3

2

4

2

5

4

2

4

4

7

5

4

6

6

10

6

4

6

8

15

7

8

7

4

18

8

7

7

13

13

9

5

11

30

7

10

14

24

30

5

11

32

12

32

9

12

58

31

56

14

Silt

13

52

18

14

21

15

19

16

24

17

27

18

42

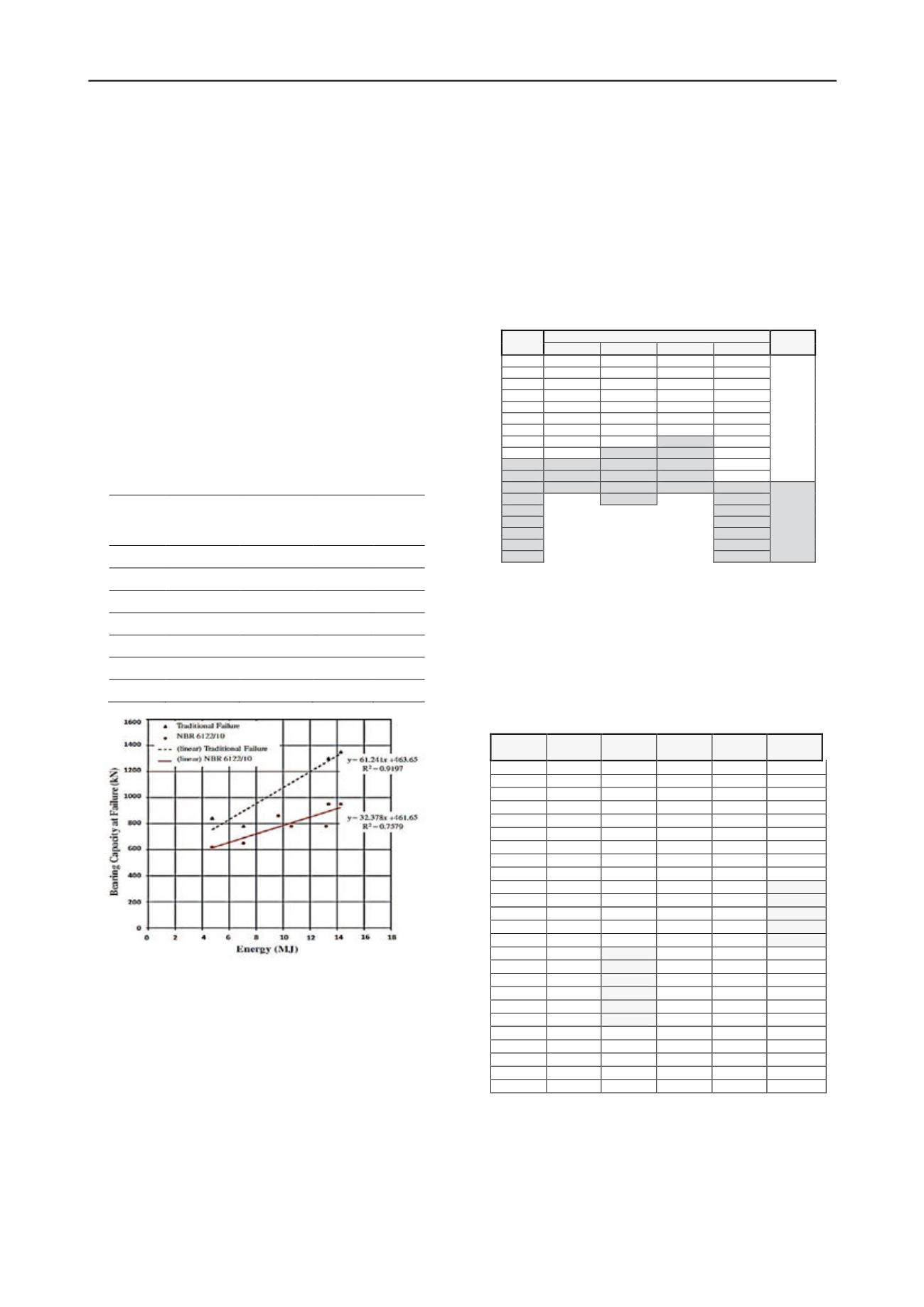

In Table 3 the required energies to excavate each pile are

presented. The tip elevations of the pile bases were defined

based on the geotechnical characterization and its location in the

construction site and three different depths were adopted, 10, 11

and 13 m. It is important to mention that the piles were executed

from elevation -4,00m, which is related to the initial elevation

of the borings because of the existence of an underground level.

Table 3. Energia demandada na escavação das estacas (Silva,2011)

Estaca

Prof. (m)

Energia

(MJ)

Estaca

Prof. (m)

Energia

(MJ)

E42A2C

13,12

6,0

E13A2D

13,12

4,7

E23A2F

13,12

6,4

E18A2A

13,12

4,8

E23A2B

13,12

3,9

E25A2C

13,12

4,9

E23A2D

13,36

6,3

E26A2C

13,12

4,3

E18A2E

13,12

5,8

E13A2C

13,12

6,1

E18A2D

13,12

3,6

E13A2B

13,12

8,2

E23A2E

13,12

4,0

E25A2A

13,12

7,5

E23A2C

13,12

4,9

E26A2A

13,12

6,6

E23A2A

13,12

5,8

E13A2A

13,12

5,1

E18A2F

13,60

5,1

E13GA

10,08

3,1

E18A2C

13,12

2,7

E20GB

10,08

3,6

E18A2B

13,12

3,5

E65DC

10,08

3,8

E25A2B

13,12

6,3

E19GB

10,08

5,1

E26A2B

13,12

6,8

E64DC

10,08

3,8

E10GB

10,08

5,1

E2B1E

11,12

8,5

E17GB

10,08

4,3

E11B1A

11,12

6,9

E23G

10,08

2,9

E17B1D

11,12

6,9

E63DB

10,08

2,8

E5B1A

11,12

7,8

E17GC

10,16

4,3

E2B1C

11,12

6,5

E10GC

10,16

4,9

E17B1B

11,12

6,1

E11B1E

13,04

5,6

E5B1B

11,12

5,4

E17B1E

12,96

8,8

E4B1B

11,12

6,7

E17B1A

13,04

6,6

E17B1C

11,12

6,5

E2B1A

11,12

7,6

E2B1D

11,12

6,6

E4B1A

11,12

7,1

E2B1B

11,12

7,2