2810

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

For the 40 centimeter pile sample, the data of the works

done, obtained during the excavation of 10,00 meter depth piles,

once a load test was made on a pile with those characteristics,

close to boring SPT 1 (Table 2), which results are marked with

grey color in Table 2. Silva (2011) submited all the collected

data to normality tests that evaluate if the frequency distribution

of a data group adheres to the Normal Distribution and verified

that the data adheres to the normal distribution. The central

tendency measures, mean and median, the standard deviation

and the variance are presented in Table 4.

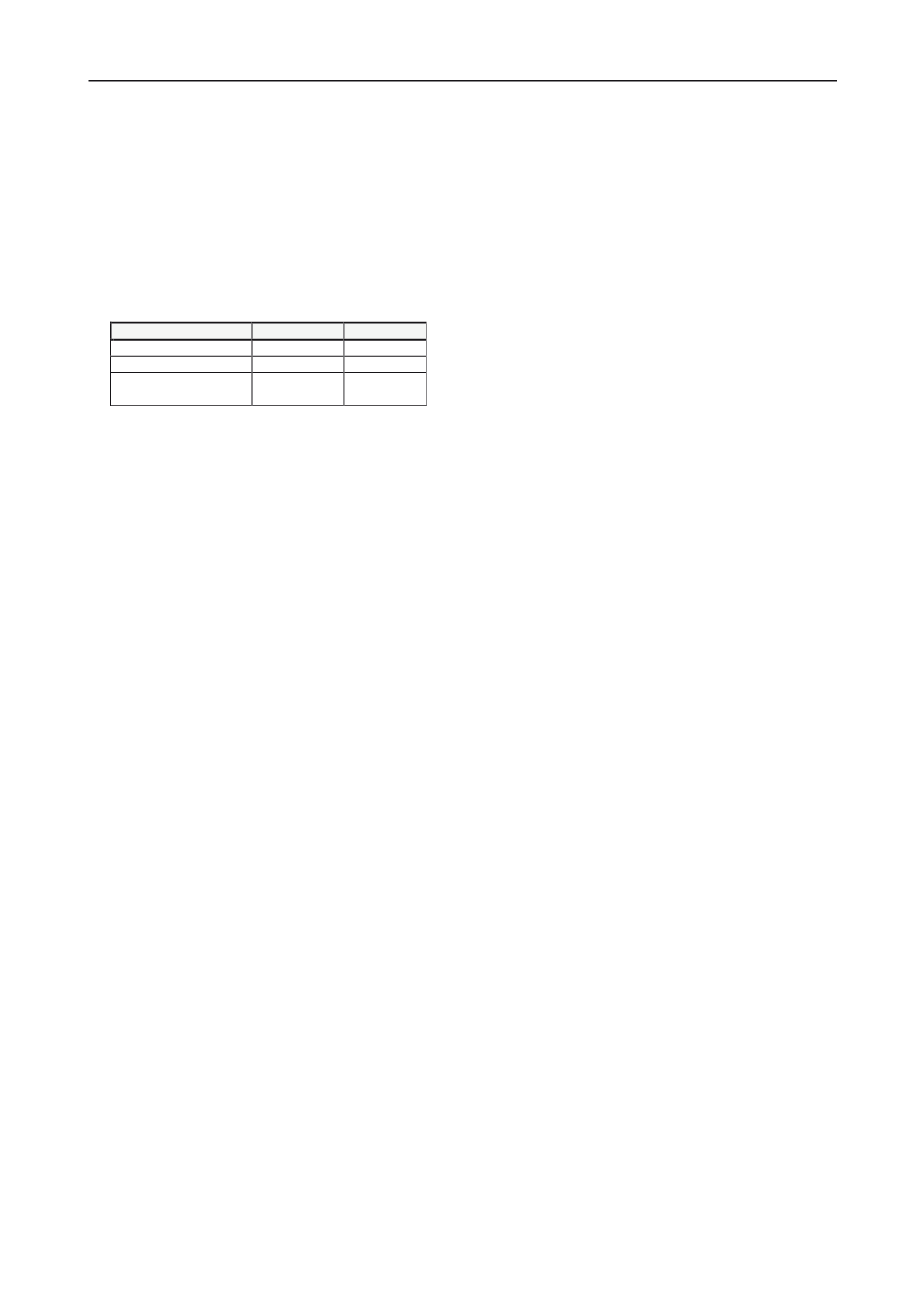

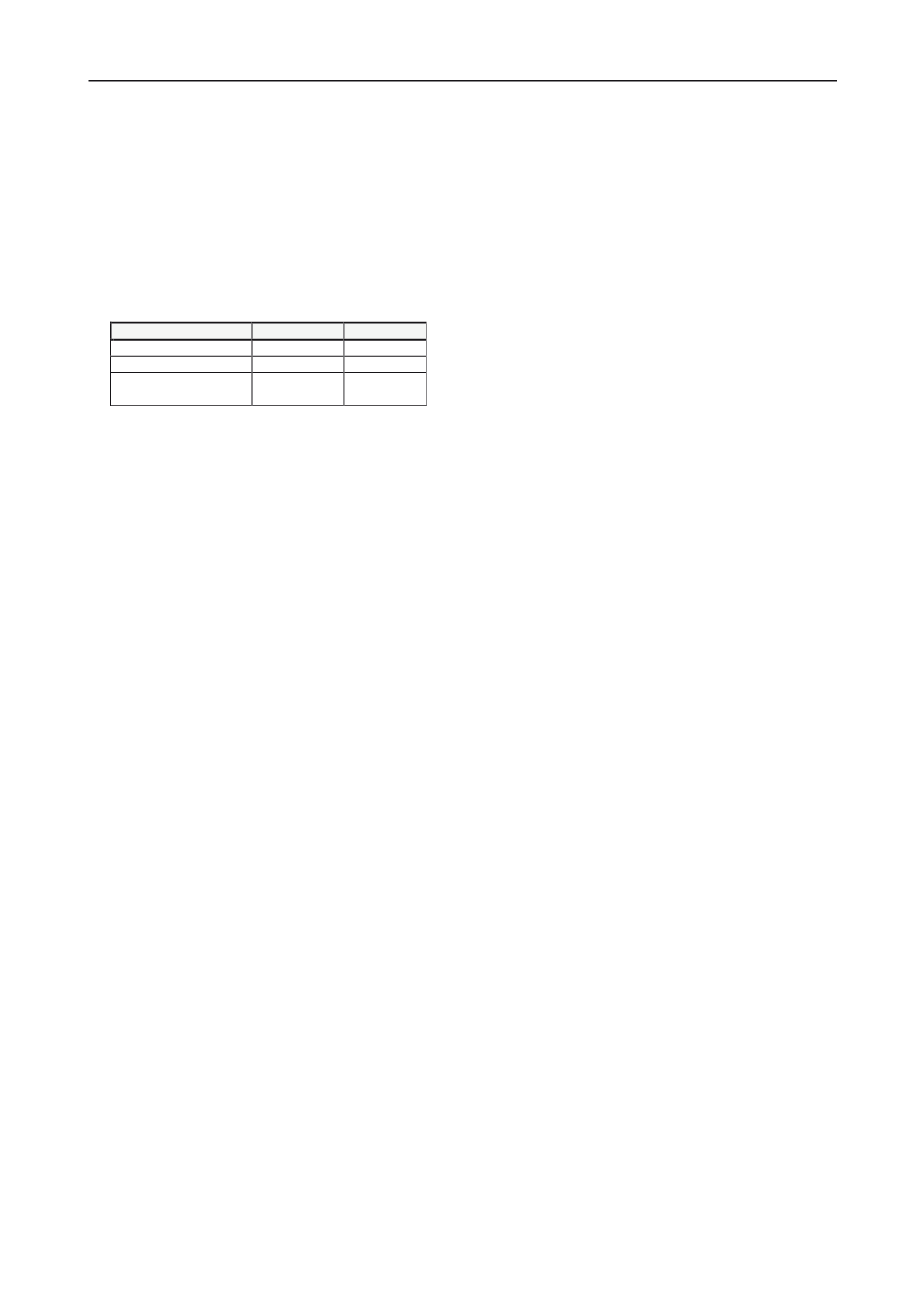

Table 4– Características estatísticas da população e da amostra

Estacas

População

Amostra

Média (MJ)

5,56

3,97

Mediana (MJ)

5,70

3,80

Desvio Padrão (MJ)

1,56

0,84

Variância (%)

29

21

It is observed in this case that the mean and the variance of

the sample was smaller than the population. Such fact was

expected for the mean once it refers to a very folded profile, the

load test was made on the pile with a small depth in favor of

safety. The smaller value of variance is perfectly justified

because in accordance with the methodology, a region with

small variability must be chosen what was assured, in the case,

by the sampling in a restricted area, on the contrary concerning

the piling which was executed taking all the area and

consequently all its variability. Then to assure that the bearing

capacity could be achieved, the SCCAP methodology was

applied during the piling execution, in the case, the first criteria

by considering that the mean is a good representative of the

population, the criterions are:

• It will be accepted the pile which when achieving the

minimum design depth did during excavation a required and

measured work (w) greater than the mean (µ) of the work

measured from the sample (W

≥

µ);

• It will be accepted the pile which when achieving the

minimum design depth did during excavation a required and

measured work (w) greater than the mean (µ) plus the standard

deviation (

σ

) of the work measured from the sample (W

≥

µ+

σ

);

• It will be accepted the pile which when achieving the

minimum design depth did during excavation a required and

measured work (w) greater than the mean (µ) plus two times the

standard deviation (

σ

) of the work measured from the

population sample where they belong (W

≥

µ+2.

σ

).

For the analyses, hypothetical applications were done from

the first and second criterion. Comparing the work done (W) in

each pile during its excavation (Table 3) with the mean (µ) of

the required work to execute the piles of the sample, first

criterion (W

≥

µ), it is observed that it would be necessary to

correct or increase the depth of 4 piles with a diameter of 40 cm

for them to present a cumulative work smaller than the mean

obtained for the sample. By using the second criterion, which is

more conservative, it is noticed that eliminating the piles which

have been excluded from the previous analysis, even though 8

piles with a diameter of 40 cm would be refused.

Once the results presented in Table 3 were set in the

chronological execution sequence of the piling and knowing

that the piling was executed sequentially till the total area of the

construction was covered, it can be verified, for example, in

Table 3, that the piles refused by criterions 1 and 2 are arranged

in group, that is, those piles are neighbors and probably are

founded in regions with NSPT mean value smaller than what

was expected or they were founded on synclinal folds.

It is clear that the adoption of the SCCAP methodology gives

more reliability to the piling in terms of bearing capacity.

4 RELIABILITY

Trying to measure the reliability of CFA pilings, Silva

(2011) from a data file made with energy or wok done records

to execute each pile of the piling, he evaluated the reliability in

bored pilings. He considered the concept that the bearing

capacity of each pile and its deformability are directly related

with the measured energy or the required work to bore it, he

used the proposal of Ang & Tang (1984), which defined the

continuous random variables, in the case, their probability

distributions that define the demanding forces and piling

resistance: X= resistance or resistant capacity of the system; Y=

demanding load acting in the system.

The goal was to assure that the event (X > Y) happens

during the whole life of the foundation. This condition or

warranty can be verified in terms of the which represents the

piling reliability. On the contrary, the probability of failure is

the measurement which corresponds to the completing event.

Once fixed to the shape of the demanding action curves

(loads on foundations) and of resistances (bearing capacity of

piles); and knowing their coefficients of variety and the global

safety factor of the piling, the reliability index can be

determined and the probability of failure of the piling,

interpreted by Cardoso e Fernandes (2001). From that proposal,

Silva (2011) showed that the reliability index (

β)

of the piling

increased a great deal, going from 2,69 to 3,14.

4 CONCLUSIONS

The routines of quality control proposed by the SCCAP

methodology are showing their great importance in

constructions controlled by such technique, assuring quality for

the whole process of excavation. Mainly because it can assure

that all design assumptions in terms of bearing capacity and

deformability are guaranteed through the decrease of the

variability and the increase of reliability. Another important

issue which was observed is that the SCCAP methodology

offers stopping criteria for the boring which has a

complementary and corrective role, contributing to risk

reduction in the construction once it reduces the probability of

failure and increasing the reliability..

5 ACKNOWLEDGEMENTS

The authors would like to thank the foundation company

Empresa Sul Americana de Fundações S/A and Embre

Engenharia for the availability of the data files analyzed in this

study.

6 REFERENCES

CARDOSO, A.S. & FERNANDES, M.M. (2001). Characteristic Values

of Ground Parameters and Probability of Failure in Design

according to Eurocode 7. Geotechnique 51, 6: 519-531.

CLOUGH, R.W. & PENZIEN, J. Dynamics of Structures, 1st Ed., New

York-NW, McGraw-Hill, 634 p., 1975.

SILVA, C.M. Energy and Reliability in Continuous Flight Auger Type

Foundation Works. PhD Thesis, Publication G.TD - 070/11, Civl

and Environmental Department, University of Brasilia, Brasilia,

DF, 303p, 2011. (in portuguese).

SILVA, C.M.; CAVALCANTE, A.L.B.; CAMAPUM DE

CARVALHO, J. On Modelling Continuous Flight Auger Pilings by

means of Energy. International Journal of Science and Engineering

Investigations vol. 1, issue 9, October 2012, ISSN: 2251-8843.