2825

Technical Committee 212 /

Comité technique 212

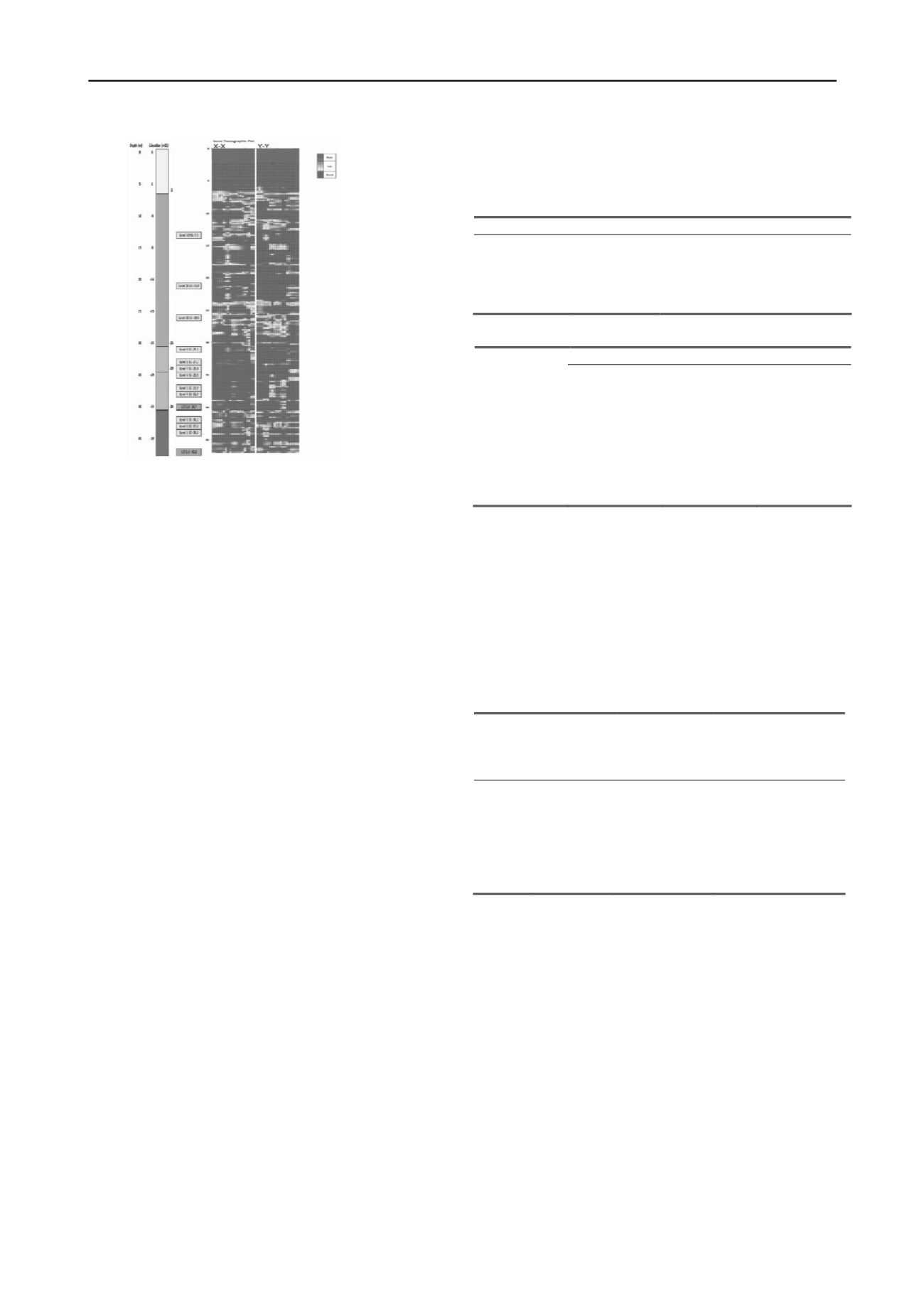

Figure 3 Tomographic image of pile

3. ANTICIPATED EFFECTS OF NON HOMOGENEITY

The effect that variation in the pile profile (i.e. over-break

and necking) and concrete quality could have on strain

measurements obtained during the pile load testing was

estimated based on the measurements during construction

described above. The effect of the pile shape and concrete

quality was assessed using the finite element analysis program

PLAXIS.

3.1 Pile Shape Effect on Strain Measurements

The strain measurements recorded during the pile load test

were resolved to assess stress at levels within the pile based on

the cross sectional area of the pile and the concrete modulus. A

uniform cylindrical pile shape was assumed but it was

recognised that, where large over-breaks occurred, the stress

within the pile at these locations could be underestimated, as the

pile stiffness is proportional to the square of the pile radius.

The measurements taken during the pile concreting were

limited to measurements every 5 m or 6 m and therefore did not

enable the pile profile to be accurately assessed. Table 3 gives

an indication of the effect of pile over-break on pile stiffness,

for various length intervals, based on some of the diameters that

may be possible on the basis of the concreting records. If the

pile diameter is not considered when the pile load results are

analysed, capacities will be underestimated at over-break levels

and overestimated where necking occurs. This phenomenon

may then appear as an apparent stress reversal within the pile.

3.2 Concrete Quality Effect on Strain Measurements

In interpreting pile load test data, the pile concrete quality is

generally assumed to be homogeneous throughout the pile and

results are resolved from a single modulus value for the pile.

The sonic logging results for TP-03 derived from the sonic

tomography showed that marked variation in the pile concrete

quality occurs at specific locations across the full cross section

of the pile, and also occurs non-uniformly along the pile.

Variable strains are therefore likely to develop within the pile

during testing, with measured differences in excess of 50%

anticipated. The sonic logging tomography assessment

facilitates reconciliation of the measured results with the

concrete quality and allows attribution of apparent “bending” to

concrete quality variation, rather than to changes in pile

verticality or shape. In general, the stress at a particular level is

assessed based on an average of 2 or 4 strain gauge

measurements and results will need to be reviewed individually

to avoid the pile stress being miscalculated.

Table 2. Summary of Assessed Concrete Quality

Depth Range m

Assessed % good quality concrete

4.5

7.5

10

11.5

13.5

70

23.5

27.0

0 to 30

27.0

29.0

30 to 70

41.0

47.0

60

Table 3. Pile stiffness variation due to pile overbreak

% change in pile stiffness due to overbreak

Interval length of pile section considered m

Depth range m

1

2

3

9-14

300

150

122

14-19

400

275

133

19-24

300

150

122

24-29

300

150

122

29-35

750

263

172

35-41

200

125

111

41-47

150

113

105

3.3 Finite Element Analysis: Pile Shape and Load Distribution

Finite element analyses were carried out for TP-03, using the

computer program PLAXIS, to assess the impact of over-break

on the load distribution along the length of the pile.

An axi-symmetric model using 15-node elements was

developed to model a uniform cylindrical pile, as well as

models representing piles with varying overbreak diameters

over varying sections of the pile. A summary of the cases

analysed is presented in Table 4. Ground elevation was at

+6.0mEL.

Table 4. Summary of Finite Element Analysis Cases

Case

Pile

Diameter

(m)

Overbreak

Diameter

(m)

Elevation of

Overbreak Section

(m EL)

1

2.4

N/A

N/A

2

2.4

6.6

-30.2 to -31.2

3

2.4

4.3

-28.2 to -31.2

4

2.4

3.5

-25.2 to -31.2

The geotechnical parameters used in the analysis are

summarised in Table 5. The pile load test was simulated by the

application of a traction load of 7500kPa at depths of EL-34.4 m

and EL-34.8 m, which are similar to the elevation of the upper

O-cell and below the modelled pile over-break zones. The pile

was modelled using linear elastic elements with appropriate

concrete stiffness parameters ascribed. A plate element with

negligible axial stiffness was also modelled within the concrete

to allow assessment of the normal force developed within the

pile due to the applied loading.

The results of the PLAXIS analysis are summarised in

Figures 4 and 5. Figure 4 shows the assessed load distribution

along the pile length resulting from the applied load. Figure 5

shows the calculated difference in pile stress at locations along

the pile as compared to the expected distribution for a pile of

uniform cross-section. It can be seen from Figure 5 that the

presence of irregularities in the pile cross section results in

unusually high stresses being calculated within the pile section

immediately below the pile over-break zones.