2829

Technical Committee 212 /

Comité technique 212

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

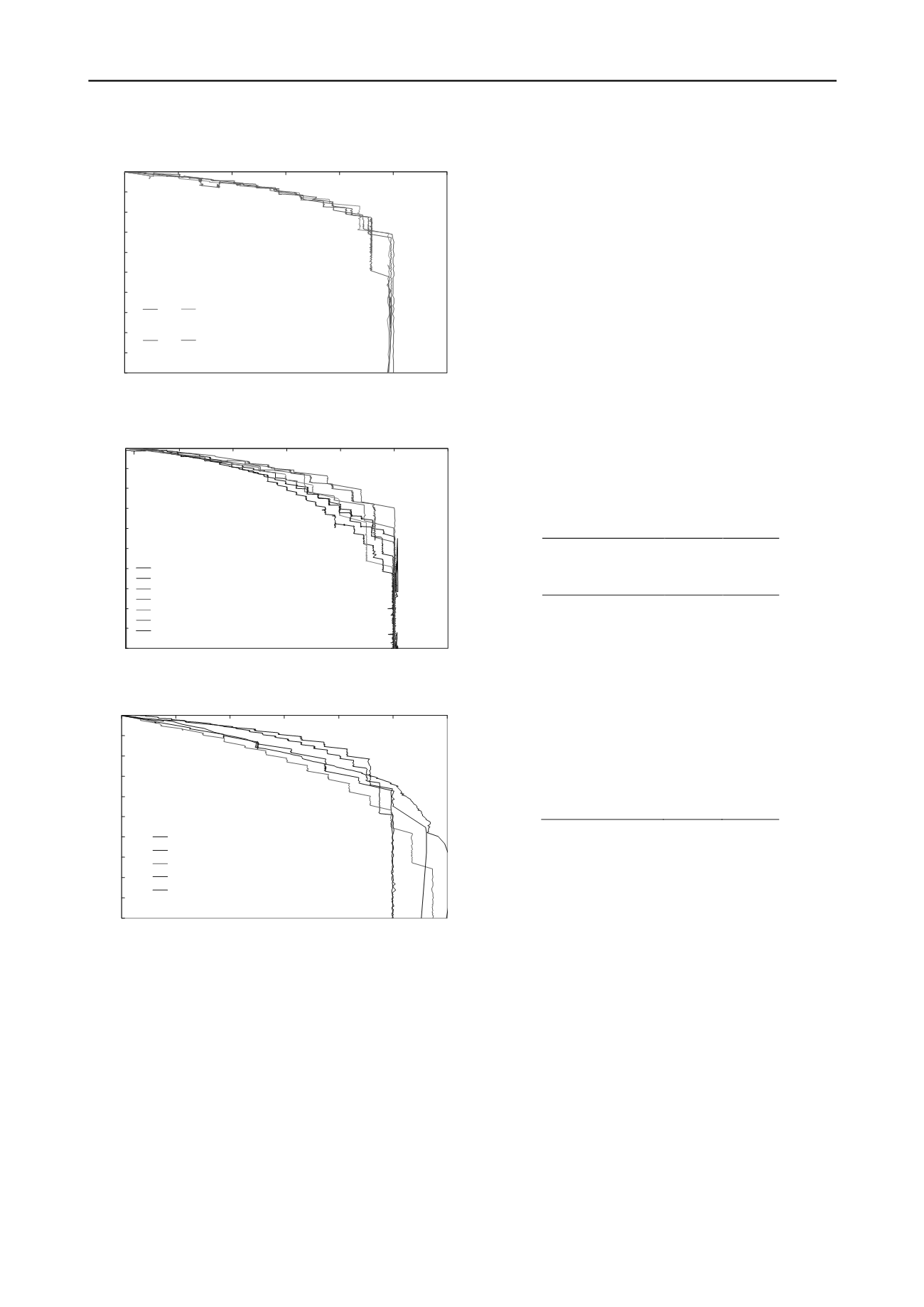

Figure 2. Normalised bored pile test results.

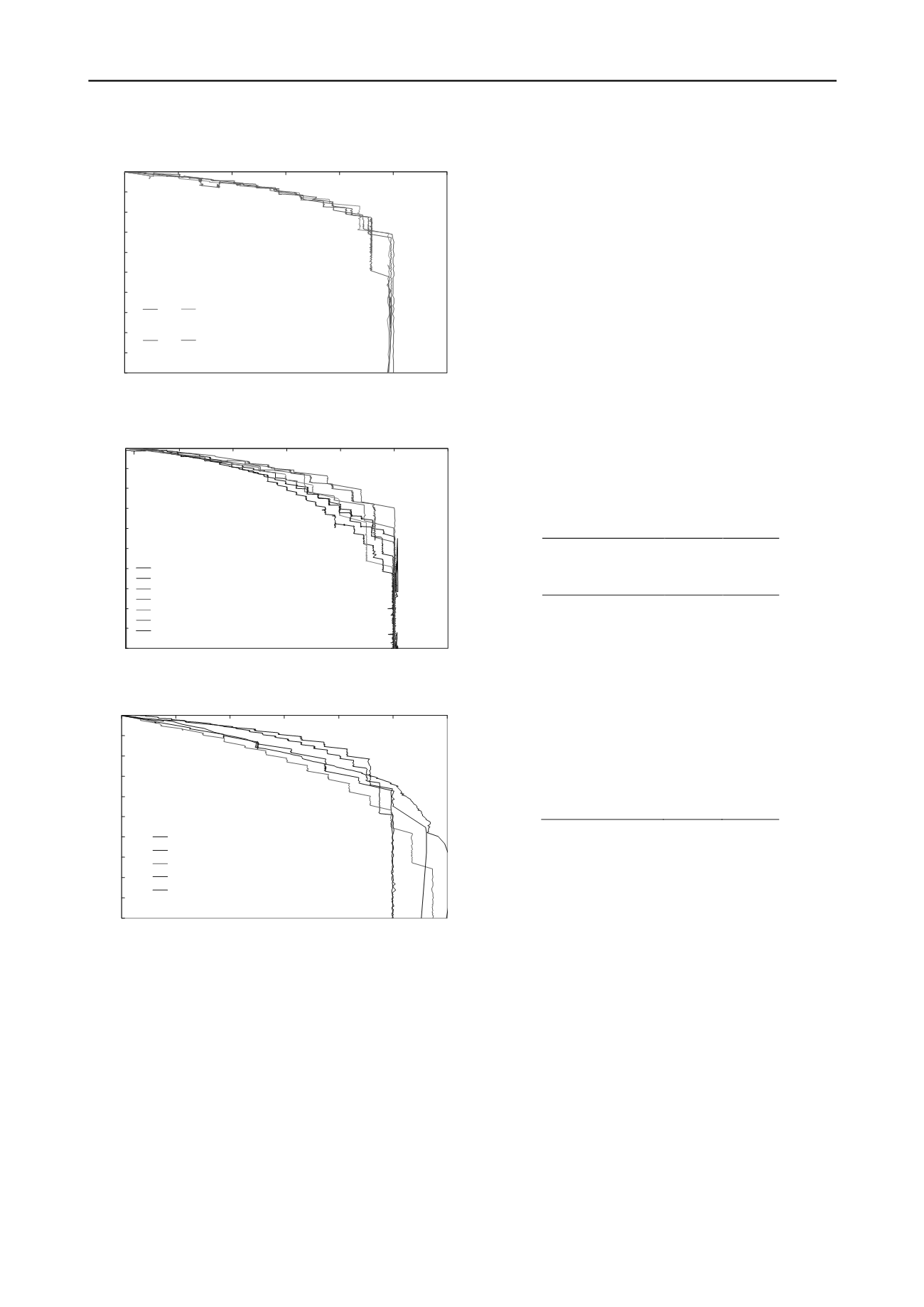

Figure 3. Normalised CFA pile test results.

Figure 4. Normalised displacement pile test results.

4.1.2

Results

–

bored piles

The results from the 4 bored piles gave remarkably consistent

values for

α

in the range 0.5 to 0.55. They all gave a very

similar behaviour, failing at a pile head movement of about

3mm as shown in normalized plot in Figure 2.

4.1.3

Results

–

CFA piles

The 7 CFA piles showed a significant variation in capacity with

control of installation. The ‘normal’ drilling installation

parameters for a clay of this type is around 100mm penetration

per revolution. A lower penetration per revolution increases the

potential for greater smearing of the bore, whilst the converse is

true where higher penetration rates are used.

In the study, rates of 150mm or 120mm, 100mm and 50mm

penetration/revolution were used for the different 300mm and

400mm diameter augers with a common pitch of 350mm

(Skinner et al 2003). These rates were label

led ‘tight’, ‘normal’

and ‘loose’. The capacities found

showed that there was an

increase in

α

for a higher penetration per revolution (Table 3).

The value found could be related to installation (Figure 5). The

worst value obtained (TP13) gave an

α

value close to that of the

‘bored’ piles! The change of α

for CFA piles has potential

benefits for challenging sites, but carries a warning that

preliminary test piles need to be installed with the same

parameters same as working piles, to ensure the design

parameters selected are appropriate. The 3

‘normal’ CFA piles

gave

α

values in the range 0.72-0.75 which are somewhat higher

than the typically used value of 0.6. This may reflect the fact

that low values have been encountered previously and this may

have been a result simply of poor construction control.

They all showed basically similar behaviour, failing at a pile

head movement of between 3 and 5mm, those going to 5mm

showing a slightly more curved response as shown in Figure 3

normalized plots. For the 300mm diameter CFA piles, the

longer piles show the more curved behaviour but these were

also loaded in smaller increments and as a result took longer

times to failure - which may have allowed more shedding of

load down the pile as local failure occurred at shallow depths.

The 450mm diameter piles (MC1 and MC2) showed the stiffest

behaviour but were loaded in larger increments and so shorter

times.

Table 3. Derived Alpha values

Pile type

Static

failure

load

(kN)

Alpha

CFA (T33)

700

.84

CFA (T34)

600

.72

CFA (T14)

625

.75

CFA (T13)

325

.52

CFA (T15)

500

.82

CFA (MC1)

1000

.72

CFA (MC2)

1050

.75

Bored (T16)

450

.54

Bored (T40)

225

.51

Bored (T46)

300

.52

Bored (T47)

310

.54

Screw Dispt (T30)

650*

.72

Displacement (T35)

525

.73

Displacement (T36)

300

.65

Driven (TP1)

1000

1.0

Driven (TP2)

950

.95

*interpreted shaft only

4.1.4

Results

–

displacement piles- auger

Auger displacement piles have the advantage of minimal spoil

generation without the noise disadvantage of driven piles.

Within the auger displacement pile category two pile types

were tested, straight forward parallel sided piles with all soil

displaced laterally and ‘screw’ displacement piles where a

screw thread is cut out from the central shaft thereby giving a

larger overall diameter to the pile, still with no soil removal and

using less concrete than a CFA or bored pile of the same

diameter. The normalised results are shown in Figure 4.

The displacement piles (T35 and T36) gave

α

values of 0.65-

0.72 while the screw displacement pile gave an

α

of 0.72 (based

on the external diameter of the screw thread). The screw pile

had a slightly softer response to loading but with the much

larger potential base area and the different potential shaft failure

modes this is not surprising. In the literature the diameter used

to back calculate skin friction values is sometimes taken as a

mean value between the central core and maximum thread

diameter and care should be taken when comparing values as to

the diameter used. The screw pile type tested (Atlas) showed

capacity equivalent to a 600mm diameter CFA pile, with

significantly lower concrete consumption.

0

1

2

3

4

5

6

7

8

9

10

0

0.2

0.4

0.6

0.8

1

1.2

Displacement (mm)

Load / assessed shaft capacity

T16 T40

T47 T46

0

1

2

3

4

5

6

7

8

9

10

0

0.2

0.4

0.6

0.8

1

1.2

Displacement (mm)

Load / assessed shaft capacity

T34

T33

MC2

MC1

T15

T13

T14

0

1

2

3

4

5

6

7

8

9

10

0

0.2

0.4

0.6

0.8

1

1.2

Displacement (mm)

Load / assessed shaft capacity

T35

T36

T30

TP1

TP2