2821

Technical Committee 212 /

Comité technique 212

Table 2. Elastic modulus at compressive stress range from 1.0 N/mm

2

to

2.0 N/mm

2

.

2

4

5

E (N/mm

2

)

254

304

274

3 GEOTECHNICAL CAPACITY

So far there have only been two load tests for the cohesive

polymer pillar. Both of the load tests have taken place in

Southwest of Finland. The first load test was in June 2010 in

city of Turku. The second load test was in November 2012 in

city of Salo.

Both of the load tests were made in co-operation with

Tampere University of Technology. The pillars were tested until

they could not hold the load any more.

The test pillars are named with a letter T or S depending on

the city and a number.

3.1

Load test in Turku, 2010

The load test was accomplished at the front yard of a test

project. The polymer pillars for the load test were installed into

a soft clay layer. Undrained shear strength of the clay was

measured with vane test and the result was 15 kPa.

Total of five polymer pillars were tested. The top of each

pillar was excavated to sight and they were cut to achieve

smooth surface for loading. Therefore the lengths of pillars are

not equal. The lengths of pillars and amounts of injected

geopolymer are shown in Table 3.

Table 3. Tested polymer pillars in Turku 2010.

T2

T3

T4

T6

T7

Original length (m)

4.0

4.0

4.0

4.0

8.0

Tested length (m)

3.65

3.53

3.54

3.00

6.21

Total injection (kg) 210.5 165.8 196.0 142.5 300.8

Injection (kg/m)

52.6

41.4

49.0

35.6

37.6

The arrangement of the load test is shown in Picture 3. The

loading was achieved with hydraulic jack against steel beam

and counterweights. Applied load was measured with load

sensor and the movement was measured as relative to normal

ground surface.

Picture 3. Arrangement of the load test in Turku 2010.

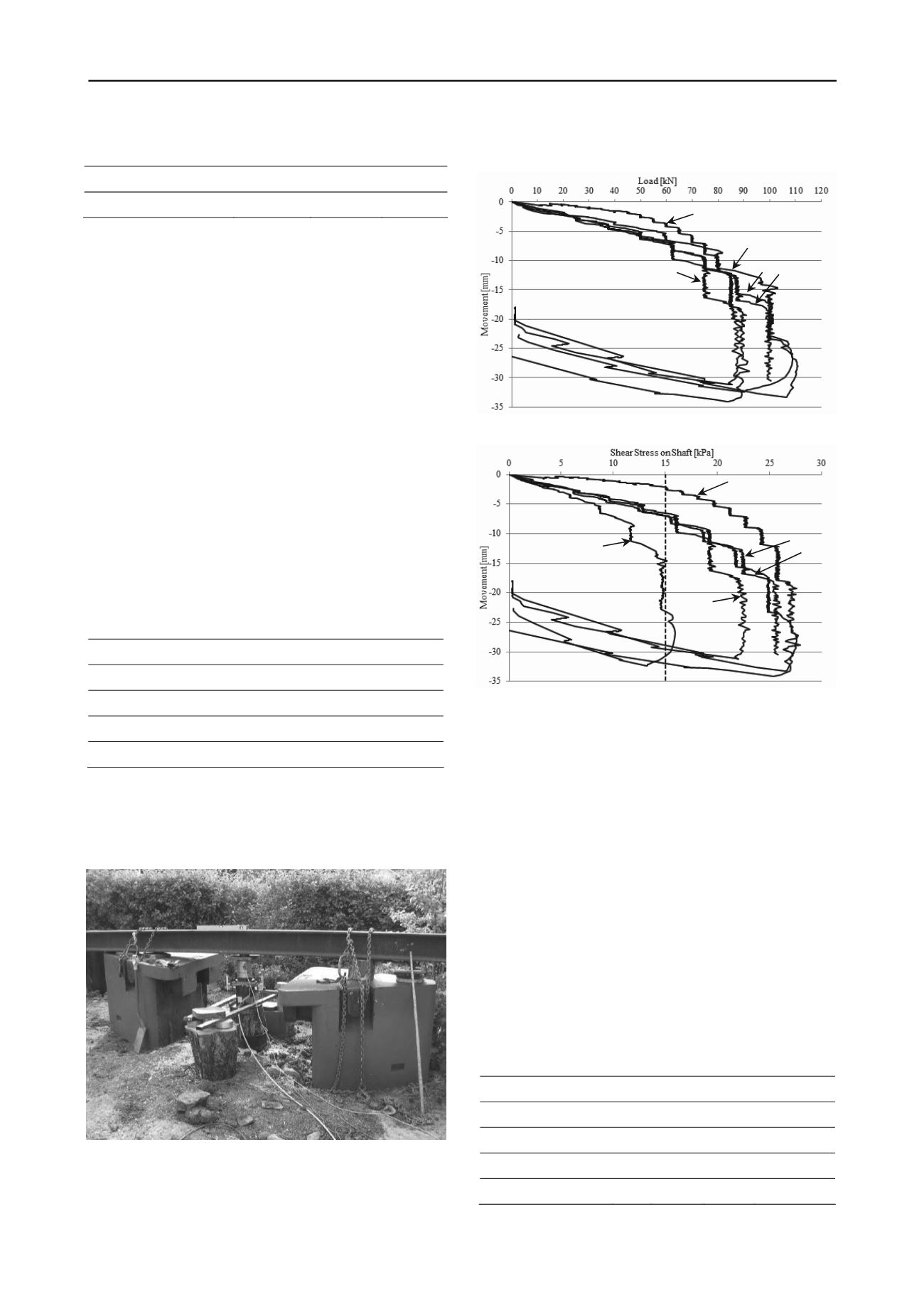

The load-movement curve was drawn from the results as

shown in Figure 2. Because of different lengths of pillars, the

load-movement curve does not give the information needed.

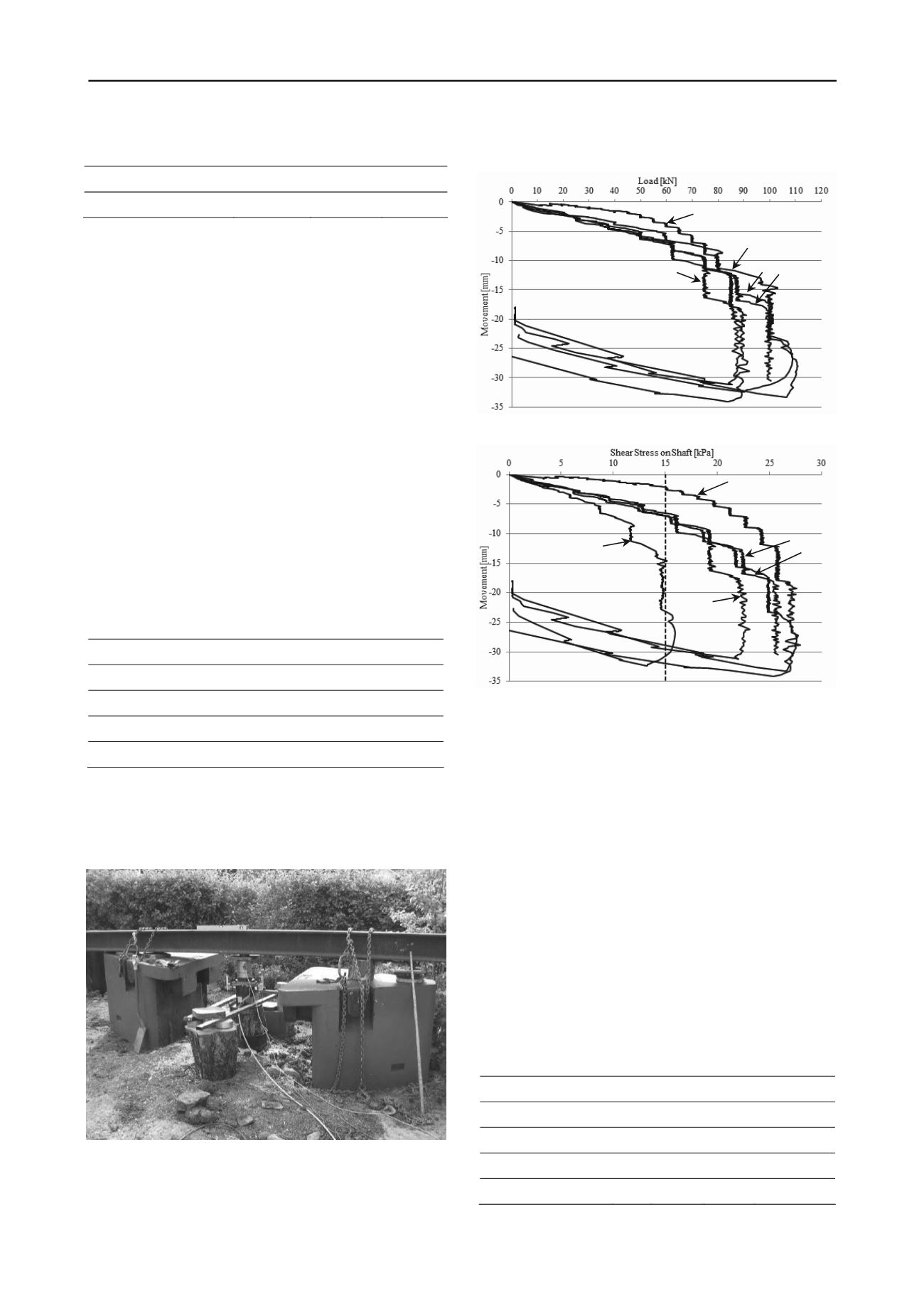

Therefore was needed to calculate the shear stress between shaft

of pillar and clay. The shear stress-movement curve is shown on

Figure 3.

T6

T7

T2

T3

T4

Figure 2. Load-movement curves of the load test in Turku 2010.

T6

T4

T7

T2

T3

Figure 3. Shear stress-movement curve of the load test in Turku 2010.

The measured C

u

value of the clay is shown with dashed line.

The installation on test pillar T7 was not succeeded. There

had been some problems with the injection pump during the

injection. Nevertheless it was decided to be tested. The result is

significantly worse than the result of the shorter pillars.

With other pillars the test succeeded. The test shows the

cohesive grip between pillar and clay is good. The shear stress

between the shaft of the pillar and the clay is bigger than the

undrained shear strength of the clay. Partly this can be

explained with the speed of the load test. Each load step was 30

minutes and the entire loading took about 4 hours per pillar.

3.2

Load test in Salo, 2012

This load test was also accomplished at the front yard of a test

project. The polymer pillar for the load test was installed into a

soft clay layer. Undrained shear strength of the clay was

measured with vane test and the result was 10 kPa.

Only one pillar was tested at this site. The preparing

procedure for pillar was similar to the test pillars in Turku. The

length of pillar and the amount of injected geopolymer is shown

in Table 4.

Table 4. Tested polymer pillar in Salo 2012.

S1

Original length (m)

3.0

Tested length (m)

2.36

Total injection (kg)

90.0

Injection (kg/m)

30.0