2824

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The results of three of the axial tests are summarized by

Abdelrazaq et al (2011). However, the as-built records for one

of the nominal 2.5 m diameter test piles, TP-03, indicated a

variation in verticality, concrete quality and pile shape. The as-

built records for TP-03 were reviewed ahead of the pile test, and

assessment was made of the the likely performance of the as-

built pile under the proposed pile test load sequence. The as-

built assessment was based on construction records for

excavation and concreting and the results of non-destructive

testing (Koden and sonic logging). These records facilitated an

assessment of the pile shape, verticality and concrete quality.

These characteristics were then used to assess the way in which

load is shed along the test pile.

Excavation of the pile hole to a depth of 34 m (within the

weathered soil) was carried out by reverse circulation drilling

(RCD) between 10 and 11 May 2010. Further advance of the

pile hole to the final depth of 47 m was carried out by RCD

after a 3 day interval between 15 and 18 May 2010.

2.2 Koden Survey and Pile Verticality

A Koden survey of the pile profile was carried out one day

after excavation of the pile hole had been completed by RCD.

The Koden results showed the following:

pile casing installed vertically with casing shoe located at a

depth of approximately 33 m (i.e. 14 m above the pile toe).

pile diameter variation in the range of 2.5 m to 3.2 m within

the weathered soil, weathered rock and soft rock.

pile profile inflection at an average depth of 37 m from near

vertical to 1(H):10(V).

socket profile over-break with short and long wavelength

variation of 0.4 m over approximately 4 m lengths and

superimposed shorter wavelength variation of 0.1 m to 0.2

m over 1 m lengths, respectively.

2.3 Pile Concreting Summary

Pile concreting was carried out on 22 May 2010 over a

period of approximately 12 hours (4 days after pile hole

excavation had been completed). A total of 282 m

3

of concrete

was used to fill the pile hole to a depth of 4 m from the surface.

The theoretical concrete volume for a pile of 2.35 m net

diameter and 47 m in length is 204 m

3

. It was therefore

assessed that an additional approximately 38% concrete volume

was used for pile TP-03. The pile temporary casing was lowered

to the pile toe and then raised in 7 stages of 5 m and 6 m lengths

depending on casing section length, with measurements of the

concrete level taken prior to and after extraction of each section

of casing. Small changes in concrete level were noted during

extraction of the first two lengths of casing, indicating a

difference between theoretical and measured concrete volume

of approximately 3 to 6 m

3

. This reflected a deficit of about 10-

20% as compared with the Koden over-break measurements and

it was considered that water entrapment may have occurred as

the casing was lowered to the base of the pile at the start of

concreting; therefore the pile socket bond could have been

affected.

A large drop in concrete level (approximately 6.5 m) was

measured as a result of extracting the third length of casing.

This represented a significant over-break within the depth range

31.5 m to 36.5 m. The summary chart of concreting works

indicated that the tip of the tremie tube was located 2 m below

the “fallen” concrete level. Further drops in concrete level in the

range of 1.5 m to 3 m were measured for the extraction of the

remaining four sections of casing.

The measured differences in concrete level for each casing

extracted are summarized in Table 1. These measurements

indicated a variation in the diameter of the pile with depth.

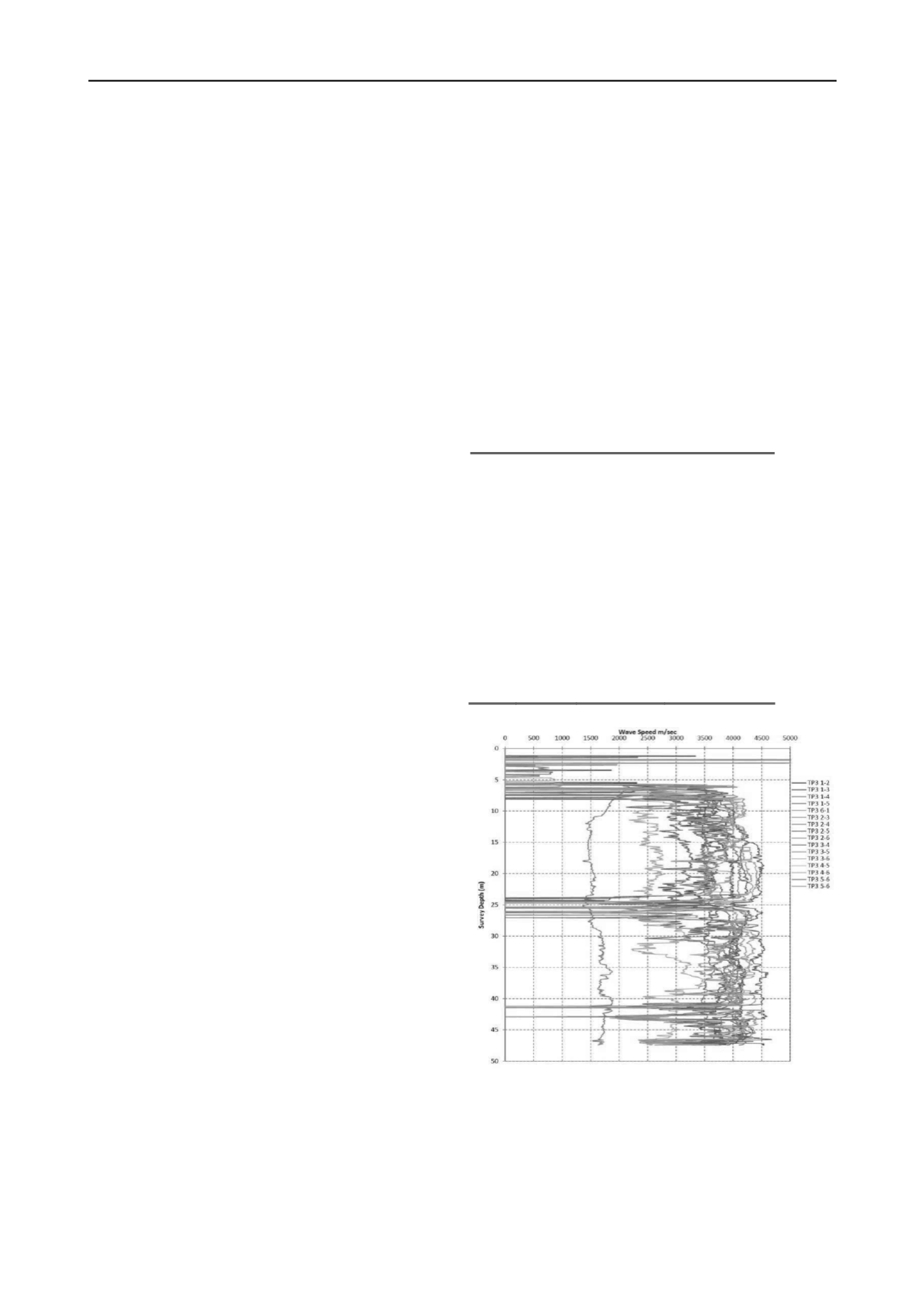

2.4 Sonic Logging Survey

A sonic logging survey was carried out for TP-03 on 28 May

2010, 6 days after concreting of the pile was completed. An

assessment of the survey results could not be carried out using

the standard sonic report sheets as poor correlation was

observed with apparent changes in wave velocity (“artefacts”)

associated with subsequent observations of irregular pipe

spacing, poor pipe verticality and possible de-bonding. The

summary wave trace files were therefore obtained from the

testing sub-contractor and are summarized in Figure 2, which

indicates the large range in wave speed measured and variation

thereof over short and long depth intervals.

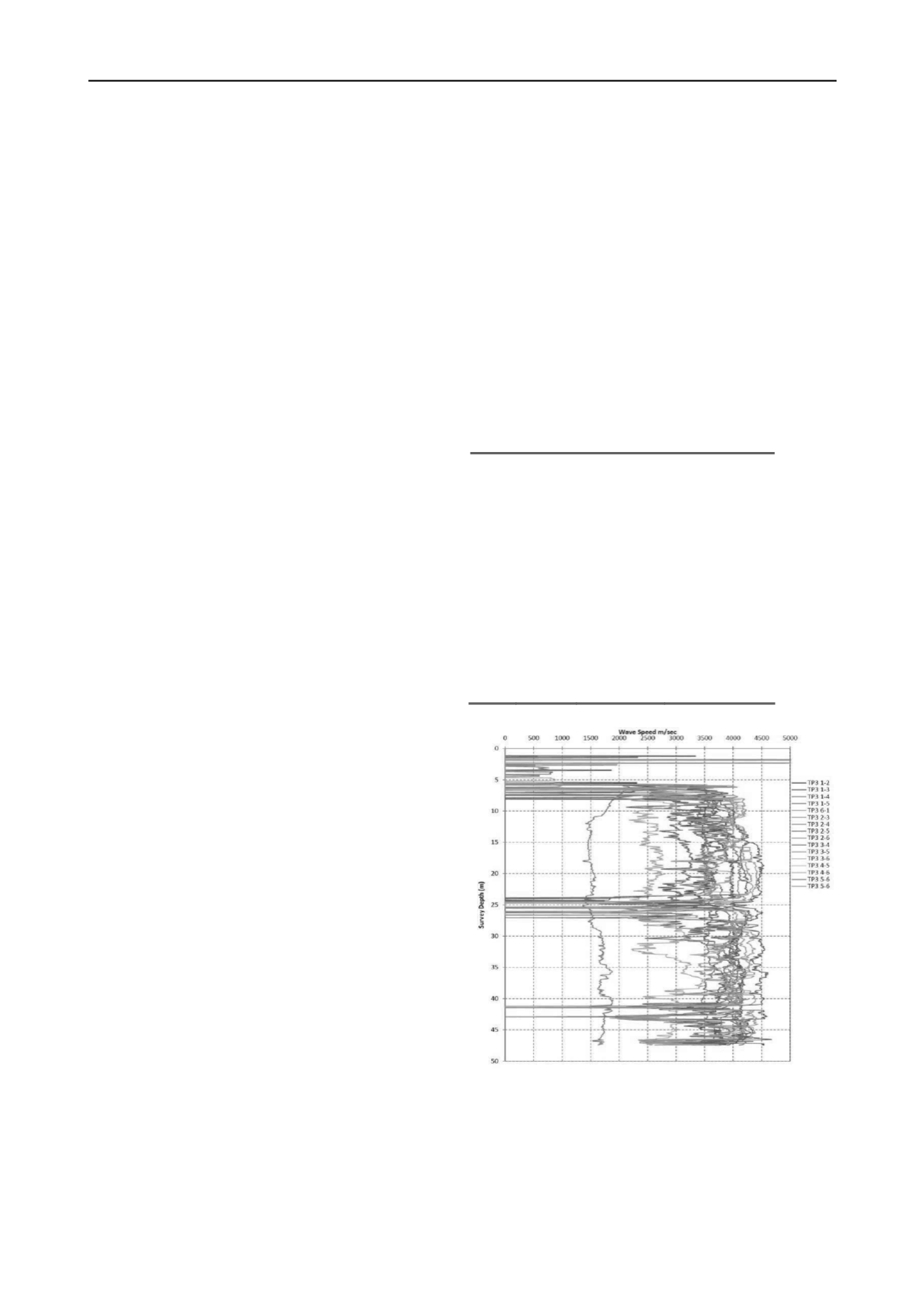

An iterative process was adopted to exclude the artefact

effects mentioned above from the measured wave velocities,

and the results were resolved to provide sonic tomography

representations of the concrete quality along the piles length in

two sections at right angles to one another. The adjusted sonic

tomography plots showing variation along the pile length are

shown in Figure 3.

Table 1. Summary of as-built concreting records

Casing Depth

Range (m)

Casing

Length (m)

Concrete Level

Drop (m)

9

14

5

2.0

14

19

5

3.0

19

24

5

2.0

24

29

5

2.0

29

35

6

6.5

35

41

6

1.0

41

47

6

0.5

Figure 2 Measured wave speed versus depth along pile

Figure 3 indicates that poor concrete quality (shown as the

darker zones) is restricted to discrete levels with abrupt and

pervasive boundaries. The concrete quality was also found to

vary across the pile cross section. The information so derived

was processed to estimate the percentage of good quality

concrete within various depth ranges, as summarized in Table 2

below.